Abstract

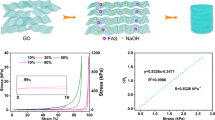

Graphene-aerogel-based flexible sensors have heat tolerances and electric-resistance sensitivities superior to those of polymer-based sensors. However, graphene sheets are prone to slips under repeated compression due to inadequate chemical connections. In addition, the heat-transfer performance of existing compression strain sensors under stress is unclear and lacks research, making it difficult to perform real-temperature detections. To address these issues, a hyperelastic polyimide fiber/graphene aerogel (PINF/GA) with a three-dimensional interconnected structure was fabricated by simple one-pot compounding and in-situ welding methods. The welding of fiber lap joints promotes in-suit formation of three-dimensional crosslinked networks of polyimide fibers, which can effectively avoid slidings between fibers to form reinforced ribs, preventing graphene from damage during compression. In particular, the inner core of the fiber maintains its macromolecular chain structure and toughness during welding. Thus, PINF/GA has good structural stabilities under a large strain compression (99%). Moreover, the thermal and electrical conductivities of PINF/GA could not only change with various stresses and strains but also keep the change steady at specific stresses and strains, with its thermal-conductivity change ratio reaching up to 9.8. Hyperelastic PINF/GA, with dynamically stable thermal and electrical conductivity, as well as high heat tolerance, shows broad application prospects as sensors in detecting the shapes and temperatures of unknown objects in extreme environments.

Graphical Abstract

Polyimide fibers in graphene aerogel are in-suit welded to fabricate a composite with excellent hyperelasticity and adjustable thermal conductivity for artificial intelligence sensing over a wide temperature range.

Similar content being viewed by others

Data availability

All relevant data are within the manuscript and its Supporting Information files.

References

Pang C, Koo JH, Nguyen A, Caves JM, Kim MG, Chortos A, Kim K, Wang PJ, Tok JB, Bao Z. Highly skin-conformal microhairy sensor for pulse signal amplification. Adv Mater. 2015;27:634.

Wang Y, Zhu Z, Fattner P, Yan H, Jin L, Chen S, Francisco M-L, Franziska L, Liu J, Rabiah IN, Chen Z, Chung JW, Linder C, Toney FM, Murmann B, Bao Z. A highly stretchable, transparent, and conductive polymer. Sci Adv. 2017;3: e1602076.

Wang X, Gu Y, Xiong Z, Cui Z, Zhang T. Silk-molded flexible, ultrasensitive, and highly stable electronic skin for monitoring human physiological signals. Adv Mater. 2014;26:1336.

Yu Y, Zheng G, Dai K, Zhai W, Zhou K, Jia Y, Zheng G, Zhang Z, Liu C, Shen C. Hollow-porous fibers for intrinsically thermally insulating textiles and wearable electronics with ultrahigh working sensitivity. Mater Horiz. 2021;8:1037.

Yu Y, Zhai Y, Yun Z, Zhai W, Wang X, Zheng G, Yan C, Dai K, Liu C, Shen C. Ultra-stretchable porous fiber-shaped strain sensor with exponential response in full sensing range and excellent anti-interference ability toward buckling, torsion, temperature, and humidity. Adv Electron Mater. 2019;5:1900538.

Zhang Z, Wang L, Yu H, Zhang F, Tang L, Feng Y, Feng W. Highly Transparent, self-healable, and adhesive organogels for bio-inspired intelligent ionic skins. ACS Appl Mater Interfaces. 2020;12:15657.

Wang M, Anoshkin IV, Nasibulin AG, Korhonen JT, Seitsonen J, Pere J, Kauppinen EI, Ras RH, Ikkala O. Modifying native nanocellulose aerogels with carbon nanotubes for mechanoresponsive conductivity and pressure sensing. Adv Mater. 2013;25:2428.

Zhang H, Liu N, Shi Y, Liu W, Yue Y, Wang S, Ma Y, Wen L, Li L, Long F, Zou Z, Gao Y. Piezoresistive sensor with high elasticity based on 3D hybrid network of sponge@CNTs@Ag NPs. ACS Appl Mater Interfaces. 2016;8:22374.

Yang M, Zhao N, Cui Y, Gao W, Zhao Q, Gao C, Bai H, Xie T. Biomimetic architectured graphene aerogel with exceptional strength and resilience. ACS Nano. 2017;11:6817.

Ding Y, Xu T, Onyilagha O, Fong H, Zhu Z. Recent advances in flexible and wearable pressure sensors based on piezoresistive 3D monolithic conductive sponges. ACS Appl Mater Interfaces. 2019;11:6685.

Gao HL, Wang ZY, Cui C, Bao JZ, Zhu YB, Xia J, Wen SM, Wu HA, Yu SH. A highly compressible and stretchable carbon spring for smart vibration and magnetism sensors. Adv Mater. 2021;33: e2102724.

Tian Y, Han J, Yang J, Wu H, Bai H. A highly sensitive graphene aerogel pressure sensor inspired by fluffy spider leg. Adv Mater Interfaces. 2021;8:2100511.

Wang P, Yao L, Pan Z, Shi S, Yu J, Zhou Y, Liu Y, Liu J, Chi Q, Zhai J, Wang Q. Ultrahigh energy storage performance of layered polymer nanocomposites over a broad temperature range. Adv Mater. 2021;33: e2103338.

Wang T, Long M-C, Zhao H-B, An W-L, Xu S, Deng C, Wang Y-Z. Temperature-responsive intumescent chemistry toward fire resistance and super thermal insulation under extremely harsh conditions. Chem Mater. 2021;33:6018.

Yuan R, Zhou Y, Fan X, Lu Q. Negative-poisson-ratio polyimide aerogel fabricated by tridirectional freezing for high- and low-temperature and impact-resistant applications. Chem Eng J. 2022;433: 134404.

Pan Y, Xie X, Huang Q, Gao C, Wang Y, Wang L, Yang B, Su H, Huang L, Huang W. Inherently Eu2+/Eu3+ codoped Sc2O3 nanoparticles as high-performance nanothermometers. Adv Mater. 2018;30: e1705256.

Yu H, Chen C, Sun J, Zhang H, Feng Y, Qin M, Feng W. Highly thermally conductive polymer/graphene composites with rapid room-temperature self-healing capacity. Nanomicro Lett. 2022;14:135.

Yao W, Mao R, Gao W, Chen W, Xu Z, Gao C. Piezoresistive effect of superelastic graphene aerogel spheres. Carbon. 2020;158:418.

Guo F, Jiang Y, Xu Z, Xiao Y, Fang B, Liu Y, Gao W, Zhao P, Wang H, Gao C. Highly stretchable carbon aerogels Nat Commun. 2018;9:881.

Gao W, Zhao N, Yao W, Xu Z, Bai H, Gao C. Effect of flake size on the mechanical properties of graphene aerogels prepared by freeze casting. Rsc Adv. 2017;7:33600.

Jiang Y, Xu Z, Huang T, Liu Y, Guo F, Xi J, Gao W, Gao C. Direct 3D printing of ultralight graphene oxide aerogel microlattices. Adv Funct Mater. 2018;28:1707024.

Chen H, Guo F, Liu Y, Huang T, Zheng B, Ananth N, Xu Z, Gao W, Gao C. A defect-free principle for advanced graphene cathode of aluminum-ion battery. Adv Mater. 2017;29:1605958.

Ying J, Tan X, Lv L, Wang X, Gao J, Yan Q, Ma H, Nishimura K, Li H, Yu J, Liu TH, Xiang R, Sun R, Jiang N, Wong C, Maruyama S, Lin CT, Dai W. Tailoring highly ordered graphene framework in epoxy for high-performance polymer-based heat dissipation plates. ACS Nano. 2021;15:12922.

Yan Q, Alam FE, Gao J, Dai W, Tan X, Lv L, Wang J, Zhang H, Chen D, Nishimura K, Wang L, Yu J, Lu J, Sun R, Xiang R, Maruyama S, Zhang H, Wu S, Jiang N, Lin CT. Soft and self-adhesive thermal interface materials based on vertically aligned, covalently bonded graphene nanowalls for efficient microelectronic cooling. Adv Funct Mater. 2021;31:2104062.

Gao J, Yan Q, Lv L, Tan X, Ying J, Yang K, Yu J, Du S, Wei Q, Xiang R, Yao Y, Zeng X, Sun R, Wong C-P, Jiang N, Lin C-T, Dai W. Lightweight thermal interface materials based on hierarchically structured graphene paper with superior through-plane thermal conductivity. Chem Eng J. 2021;419: 129609.

Qiang L, Miao Z, Liang H, Yingru L, Ji C, Chun L, Gaoquan S. High-quality graphene ribbons prepared from graphene oxide hydrogels and their application for strain sensors. ACS Nano. 2015;9:12320.

Pang Y, Zhang K, Yang Z, Jiang S, Ju Z, Li Y, Wang X, Wang D, Jian M, Zhang Y, Liang R, Tian H, Yang Y, Ren TL. Epidermis microstructure inspired graphene pressure sensor with random distributed spinosum for high sensitivity and large linearity. ACS Nano. 2018;12:2346.

Yang Z, Pang Y, Han XL, Yang Y, Ling J, Jian M, Zhang Y, Yang Y, Ren TL. Graphene textile strain sensor with negative resistance variation for human motion detection. ACS Nano. 2018;12:9134.

Huang J, Wang H, Li Z, Wu X, Wang J, Yang S. Improvement of piezoresistive sensing behavior of graphene sponge by polyaniline nanoarrays. J Mater Chem C. 2019;7:7386.

Zhang Z-H, Chen Z-Y, Tang Y-H, Li Y-T, Ma D, Zhang G-D, Boukherroub R, Cao C-F, Gong L-X, Song P, Cao K, Tang L-C. Silicone/graphene oxide co-cross-linked aerogels with wide-temperature mechanical flexibility, super-hydrophobicity and flame resistance for exceptional thermal insulation and oil/water separation. J Mater Sci Technol. 2022;114:131.

Zhang Q, Xu X, Li H, Xiong G, Hu H, Fisher TS. Mechanically robust honeycomb graphene aerogel multifunctional polymer composites. Carbon. 2015;93:659.

Yang G, Yang Y, Chen T, Wang J, Ma L, Yang S. Graphene/MXene composite aerogels reinforced by polyimide for pressure sensing. ACS Appl Nano Mater. 2022;5:1068.

Pu L, Liu Y, Li L, Zhang C, Ma P, Dong W, Huang Y, Liu T. Polyimide nanofiber-reinforced Ti3C2Tx aerogel with “lamella-pillar” microporosity for high-performance piezoresistive strain sensing and electromagnetic wave absorption. ACS Appl Mater Interfaces. 2021;13:47134.

Ma W, Li W, Li M, Mao Q, Pan Z, Zhu M, Zhang Y. Scalable microgel spinning of a three-dimensional porous graphene fiber for high-performance flexible supercapacitors. J Mater Chem A. 2020;8:25355.

Lv P, Tan X-W, Yu K-H, Zheng R-L, Zheng J-J, Wei W. Super-elastic graphene/carbon nanotube aerogel: A novel thermal interface material with highly thermal transport properties. Carbon. 2016;99:222.

Zhao X, Yao W, Gao W, Chen H, Gao C. Wet-spun superelastic graphene aerogel millispheres with group effect. Adv Mater. 2017;29:1701482.

Pang K, Song X, Xu Z, Liu X, Liu Y, Zhong L, Peng Y, Wang J, Zhou J, Meng F, Wang J, Gao C. Hydroplastic foaming of graphene aerogels and artificially intelligent tactile sensors. Sci Adv. 2020; 6: eabd4045.

Qiu L, Liu JZ, Chang SL, Wu Y, Li D. Biomimetic superelastic graphene-based cellular monoliths. Nat Commun. 2012;3:1241.

Chen X, Lai D, Yuan B, Fu M-L. Tuning oxygen clusters on graphene oxide to synthesize graphene aerogels with crumpled nanosheets for effective removal of organic pollutants. Carbon. 2019;143:897.

Du T, Xiong Z, Delgado L, Liao W, Peoples J, Kantharaj R, Chowdhury PR, Marconnet A, Ruan X. Wide range continuously tunable and fast thermal switching based on compressible graphene composite foams. Nat Commun. 2021;12:4915.

Xu Q, Chang X, Zhu Z, Xu L, Chen X, Luo L, Liu X, Qin J. Flexible pressure sensors with high pressure sensitivity and low detection limit using a unique honeycomb-designed polyimide/reduced graphene oxide composite aerogel. RSC Adv. 2021;11:11760.

Ren R-P, Wang Z, Ren J, Lv Y-K. Highly compressible polyimide/graphene aerogel for efficient oil/water separation. J Mater Sci. 2018;54:5918.

Qin Y, Peng Q, Ding Y, Lin Z, Wang C, Li Y, Xu F, Li J, Yuan Y, He X, Li Y. Lightweight, superelastic, and mechanically flexible graphene/polyimide nanocomposite foam for strain sensor application. ACS Nano. 2015;9:8933.

Cao X, Zhang J, Chen S, Varley RJ, Pan K. 1D/2D nanomaterials synergistic, compressible, and response rapidly 3D graphene aerogel for piezoresistive sensor. Adv Funct Mater. 2020;30:2003618.

Liao D, Guan Y, He Y, Li S, Wang Y, Liu H, Zhou L, Wei C, Yu C, Chen Y. Pickering emulsion strategy for high compressive carbon aerogel as lightweight electromagnetic interference shielding material and flexible pressure sensor. Ceram Int. 2021;47:23433.

Qin M, Xu Y, Cao R, Feng W, Chen L. Efficiently controlling the 3D thermal conductivity of a polymer nanocomposite via a hyperelastic double-continuous network of graphene and sponge. Adv Funct Mater. 2018;28:1805053.

Zhang F, Feng Y, Qin M, Gao L, Li Z, Zhao F, Zhang Z, Lv F, Feng W. Stress controllability in thermal and electrical conductivity of 3D elastic graphene-crosslinked carbon nanotube sponge/polyimide nanocomposite. Adv Funct Mater. 2019;29:1901383.

Zhang F, Feng Y, Qin M, Ji T, Lv F, Li Z, Gao L, Long P, Zhao F, Feng W. Stress-sensitive thermally conductive elastic nanocomposite based on interconnected graphite-welded carbon nanotube sponges. Carbon. 2019;145:378.

Yu H, Feng Y, Gao L, Chen C, Zhang Z, Feng W. Self-healing high strength and thermal conductivity of 3D graphene/PDMS composites by the optimization of multiple molecular interactions. Macromolecules. 2020;53:7161.

Wu X, Shi S, Tang B, Chen J, Shan L, Gao Y, Wang Y, Jiang T, Sun K, Yang K, Yu J. Achieving highly thermal conductivity of polymer composites by adding hybrid silver–carbon fiber fillers. Compos Commun. 2022;31: 101129.

Zhang Z, Liao M, Li M, Li L, Wei X, Kong X, Xiong S, Xia J, Fu L, Cai T, Pan Z, Li H, Han F, Lin C-T, Nishimura K, Jiang N, Yu J. Enhanced thermal conductivity for polydimethylsiloxane composites with core-shell CFs@SiC filler. Compos Commun. 2022;33: 101209.

Yu H, Guo P, Qin M, Han G, Chen L, Feng Y, Feng W. Highly thermally conductive polymer composite enhanced by two-level adjustable boron nitride network with leaf venation structure. Compos Sci Technol. 2022;222: 109406.

Cai Y, Yu H, Chen C, Feng Y, Qin M, Feng W. Improved thermal conductivities of vertically aligned carbon nanotube arrays using three-dimensional carbon nanotube networks. Carbon. 2022;196:902.

Zhao Y, Jiang T, Wang Y, Wu X, Jiang P, Shi S, Sun K, Tang B, Li W, Yu J. Study on preparation and properties of ultrahigh molecular weight polyethylene composites filled with different carbon materials. ACS Omega. 2022;7:5547.

Yu H, Feng Y, Chen C, Zhang Z, Cai Y, Qin M, Feng W. Thermally conductive, self-healing, and elastic Polyimide@Vertically aligned carbon nanotubes composite as smart thermal interface material. Carbon. 2021;179:348.

Yu H, Zhang B, Bulin C, Li R, Xing R. High-efficient synthesis of graphene oxide based on improved hummers method. Sci Rep. 2016;6:36143.

Park S-J, Lee E-J, Kwon S-H. Influence of surface treatment of polyimide film on adhesion enhancement between polyimide and metal films. B Korean Chem Soc. 2007;28:188.

Sazanov YN. Thermoanalytical investigation of high-temperature transformations of polymides. J Therm Anal Calorim. 1988;34:1117.

Acknowledgements

This work was financially supported by National Key R&D Program of China (No. 2022YFB3805702), National Natural Science Foundation of China (Grant Nos. 52173078, 52130303, 51973158, 51803151, and 51973152), the Science Foundation for Distinguished Young Scholars in Tianjin (No. 19JCJQJC61700).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflicts of interest

The authors declare that there is no financial and non-financial competing interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yin, W., Qin, M., Yu, H. et al. Hyperelastic Graphene Aerogels Reinforced by In-suit Welding Polyimide Nano Fiber with Leaf Skeleton Structure and Adjustable Thermal Conductivity for Morphology and Temperature Sensing. Adv. Fiber Mater. 5, 1037–1049 (2023). https://doi.org/10.1007/s42765-023-00268-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42765-023-00268-6