Abstract

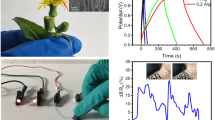

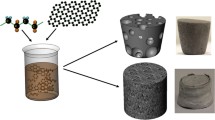

Graphene aerogel (GA), with low density, high conductivity, and good mechanical properties, has important application potentials in the field of flexible electronics. Here, a balanced approach was developed in this work: Graphene oxide (GO) nanosheets were induced to assemble into a homogeneous porous hydrogel under alkali induction, and then, the oxygen-containing functional groups of GO were removed by reductant of formamidine sulfonic acid (FAS). Besides, the hydrogel of GA precursor can be quickly dried at a high temperature (150 °C) within 30 min to obtain pure GA of FGA. After further calcination, the obtained aerogel of AFGA with ordered structure has ultralow density (3.88 mg/cm3), high conductivity (7.4 S/m), supercompression recovery performance (99%), high sensitivity (S = 0.83 kPa−1), large reversible compression cycle performance (200 cycles under 90% strain), and high fatigue resistance (10,000 cycles under 70% strain), which presents excellent piezoresistive properties and can find wide applications in piezoresistive sensors as the high-performance sensing material.

Graphical Abstract

Similar content being viewed by others

References

Souri H, Banerjee H, Jusufi A, Radacsi N, Stokes AA, Park I, Sitti M, Amjadi M (2020) Wearable and stretchable strain sensors: materials, sensing mechanisms, and applications. Adv Intell Syst 2:2000039. https://doi.org/10.1002/aisy.202000039

Gao S, Zhao X, Fu Q, Zhang T, Zhu J, Hou F, Ni J, Zhu C et al (2022) Highly transmitted silver nanowires-SWCNTs conductive flexible film by nested density structure and aluminum-doped zinc oxide capping layer for flexible amorphous silicon solar cells. J Mater Sci Technol 126:152–160. https://doi.org/10.1016/j.jmst.2022.03.012

Ji X, Zhong Y, Li C, Chu J, Wang H, Xing Z, Niu T, Zhang Z et al (2021) Nanoporous carbon aerogels for laser-printed wearable sensors. ACS Appl Nano Mater 4:6796–6804. https://doi.org/10.1021/acsanm.1c00858

He Y, Zhou M, Mahmoud MHH, Lu X, He G, Zhang L, Huang M, Elnaggar AY et al (2022) Multifunctional wearable strain/pressure sensor based on conductive carbon nanotubes/silk nonwoven fabric with high durability and low detection limit. Adv Compos Hybrid Mater 5:1939–1950. https://doi.org/10.1007/s42114-022-00525-z

Das HS, Roymahapatra G, Nabdu PK, Das R (2021) Study the effect of ZnO/Cu/ZnO multilayer structure by RF magnetron sputtering for flexible display applications. ES Energy Environ 13:50–56. https://doi.org/10.30919/esee8c441

Kong D, El-Bahy ZM, Algadi H, Li T, El-Bahy SM, Nassan MA, Li J, Faheim AA et al (2022) Highly sensitive strain sensors with wide operation range from strong MXene-composited polyvinyl alcohol/sodium carboxymethylcellulose double network hydrogel. Adv Compos Hybrid Mater 5:1976–1987. https://doi.org/10.1007/s42114-022-00531-1

Hui Y, Xie W & Gu H (2021) Reduced Graphene Oxide/nanocellulose/amino-multiwalled carbon nanotubes nanocomposite aerogel for excellent oil adsorption. ES Food Agroforestry 5:38–44. https://doi.org/10.30919/esfaf531

Xiong S, Yang Y, Zhang S, Xiao Y, Ji H, Yang Z, Ding F (2021) Nanoporous polybenzoxazine aerogels for thermally insulating and self-extinguishing materials in aerospace applications. ACS Appl Nano Mater 4:7280–7288. https://doi.org/10.1021/acsanm.1c01253

Pan D, Yang G, Abo-Dief HM, Dong J, Su F, Liu C, Li Y, Xu BB et al (2022) Vertically aligned silicon carbide nanowires/boron nitride cellulose aerogel networks enhanced thermal conductivity and electromagnetic absorbing of epoxy composites. Nano-Micro Lett 14:118. https://doi.org/10.1007/s40820-022-00863-z

Wei D, Weng M, Mahmoud MHH, Elnaggar AY, Azab IHE, Sheng X, Huang M, El-Bahy ZM et al (2022) Development of novel biomass hybrid aerogel supported composite phase change materials with improved light-thermal conversion and thermal energy storage capacity. Adv Compos Hybrid Mater 5:1910–1921. https://doi.org/10.1007/s42114-022-00519-x

Dang C, Mu Q, Xie X, Sun X, Yang X, Zhang Y, Maganti S, Huang M et al (2022) Recent progress in cathode catalyst for nonaqueous lithium oxygen batteries: a review. Adv Compos Hybrid Mater 5:606–626. https://doi.org/10.1007/s42114-022-00500-8

Wu X, Hou K, Huang J, Wang J, Yang S (2018) Graphene-based cellular materials with extremely low density and high pressure sensitivity based on self-assembled graphene oxide liquid crystals. J Mater Chem C 6:8717–8725. https://doi.org/10.1039/C8TC01853G

Guo F, Jiang Y, Xu Z, Xiao Y, Fang B, Liu Y, Gao W, Zhao P et al (2018) Highly stretchable carbon aerogels. Nat Commun 9:881. https://doi.org/10.1038/s41467-018-03268-y

Pang K, Song X, Xu Z, Liu X, Liu Y, Zhong L, Peng Y, Wang J et al (2020) Hydroplastic foaming of graphene aerogels and artificially intelligent tactile sensors. Sci Adv 6, eabd4045. https://doi.org/10.1126/sciadv.abd4045

Lv Z, Liu J, Yang X, Fan D, Cao J, Luo Y, Zhang X (2020) Naturally derived wearable strain sensors with enhanced mechanical properties and high sensitivity. ACS Appl Mater Interfaces 12:22163–22169. https://doi.org/10.1021/acsami.0c04341

Wu X, Han Y, Zhang X, Zhou Z, Lu C (2016) Large-area compliant, low-cost, and versatile pressure-sensing platform based on microcrack-designed carbon black@polyurethane sponge for human-machine interfacing. Adv Funct Mater 26:6246–6256. https://doi.org/10.1002/adfm.201601995

Zu G, Kanamori K, Nakanishi K, Lu X, Yu K, Huang J, Sugimura H (2019) Superelastic multifunctional aminosilane-crosslinked graphene aerogels for high thermal insulation, three-component separation, and strain/pressure-sensing arrays. ACS Appl Mater Interfaces 11:43533–43542. https://doi.org/10.1021/acsami.9b16746

Xie W, Yao F, Gu H, Du A, Lei Q, Naik N, Guo Z (2022) Magnetoresistive and piezoresistive polyaniline nanoarrays in-situ polymerized surrounding magnetic graphene aerogel. Adv Compos Hybrid Mater 5:1003–1016. https://doi.org/10.1007/s42114-021-00413-y

Lv L, Zhang P, Xu T, Qu L (2017) Ultrasensitive pressure sensor based on an ultralight sparkling graphene block. ACS Appl Mater Interfaces 9:22885–22892. https://doi.org/10.1021/acsami.7b07153

Lv W, Zhang C, Li Z, Yang Q-H (2015) Self-assembled 3D graphene monolith from solution. J Phys Chem Lett 6:658–668. https://doi.org/10.1021/jz502655m

Bai H, Chen Y, Delattre B, Tomsia Antoni P & Ritchie Robert O (Bioinspired large-scale aligned porous materials assembled with dual temperature gradients. Sci Adv 1: e1500849. https://doi.org/10.1126/sciadv.1500849

Hu H, Zhao Z, Wan W, Gogotsi Y, Qiu J (2013) Ultralight and highly compressible graphene aerogels. Adv Mater 25:2219–2223. https://doi.org/10.1002/adma.201204530

Wang L, Zhang M, Yang B, Tan J, Ding X (2020) Highly compressible, thermally stable, light-weight, and robust aramid nanofibers/Ti3AlC2 MXene composite aerogel for sensitive pressure sensor. ACS Nano 14:10633–10647. https://doi.org/10.1021/acsnano.0c04888

Goldstein AP, Mickelson W, Machness A, Lee G, Worsley MA, Woo L, Zettl A (2014) Simultaneous sheet cross-linking and deoxygenation in the graphene oxide sol-gel transition. J Phys Chem C 118:28855–28860. https://doi.org/10.1021/jp5092027

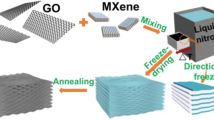

Chen T, Wang J, Wu X, Li Z & Yang S (2021) Ethanediamine induced self-assembly of long-range ordered GO/MXene composite aerogel and its piezoresistive sensing performances. Appl Surf Sci 566:150719. https://doi.org/10.1016/j.apsusc.2021.150719

Xu X, Zhang Q, Yu Y, Chen W, Hu H, Li H (2016) Naturally dried graphene aerogels with superelasticity and tunable Poisson’s ratio. Adv Mater 28:9223–9230. https://doi.org/10.1002/adma.201603079

Zhang X, Zhang T, Wang Z, Ren Z, Yan S, Duan Y, Zhang J (2019) Ultralight, superelastic, and fatigue-resistant graphene aerogel templated by graphene oxide liquid crystal stabilized air bubbles. ACS Appl Mater Interfaces 11:1303–1310. https://doi.org/10.1021/acsami.8b18606

Zhang J, Yang H, Shen G, Cheng P, Zhang J, Guo S (2010) Reduction of graphene oxide vial-ascorbic acid. Chem Commun 46:1112–1114. https://doi.org/10.1039/B917705A

Chua CK, Pumera M (2014) Chemical reduction of graphene oxide: a synthetic chemistry viewpoint. Chem Soc Rev 43:291–312. https://doi.org/10.1039/C3CS60303B

Chen W, Yan L (2011) In situ self-assembly of mild chemical reduction graphene for three-dimensional architectures. Nanoscale 3:3132–3137. https://doi.org/10.1039/C1NR10355E

Yao B, Chen J, Huang L, Zhou Q, Shi G (2016) Base-induced liquid crystals of graphene oxide for preparing elastic graphene foams with long-range ordered microstructures. Adv Mater 28:1623–1629. https://doi.org/10.1002/adma.201504594

Yang G, Yang Y, Chen T, Wang J, Ma L, Yang S (2022) Graphene/MXene composite aerogels reinforced by polyimide for pressure sensing. ACS Appl Nano Mater 5:1068–1077. https://doi.org/10.1021/acsanm.1c03722

Moon IK, Lee J, Ruoff RS, Lee H (2010) Reduced graphene oxide by chemical graphitization. Nat Commun 1:73. https://doi.org/10.1038/ncomms1067

Yu H, Wang B, Zhou S, Zhu M, Chen W, Chen H, Li X, Liang S et al (2021) Polyvinylpyrrolidone functionalization induces deformable structure of graphene oxide nanosheets for lung-targeting delivery. Nano Today 38: 101151. https://doi.org/10.1016/j.nantod.2021.101151

Yang H, Zhang T, Jiang M, Duan Y, Zhang J (2015) Ambient pressure dried graphene aerogels with superelasticity and multifunctionality. J Mater Chem A 3:19268–19272. https://doi.org/10.1039/C5TA06452J

Wicklein B, Kocjan A, Salazar-Alvarez G, Carosio F, Camino G, Antonietti M, Bergström L (2015) Thermally insulating and fire-retardant lightweight anisotropic foams based on nanocellulose and graphene oxide. Nat Nanotechnol 10:277–283. https://doi.org/10.1038/nnano.2014.248

Phan C M (2021) The surface tension and interfacial composition of water/ethanol mixture. J Mol Liq 342: 117505. https://doi.org/10.1016/j.molliq.2021.117505

Wang C, He X, Shang Y, Peng Q, Qin Y, Shi E, Yang Y, Wu S et al (2014) Multifunctional graphene sheet–nanoribbon hybrid aerogels. J Mater Chem A 2:14994–15000. https://doi.org/10.1039/C4TA02591A

Yang W, Peng D, Kimura H, Zhang X, Sun X, Pashameah RA, Alzahrani E, Wang B et al (2022) Honeycomb-like nitrogen-doped porous carbon decorated with Co3O4 nanoparticles for superior electrochemical performance pseudo-capacitive lithium storage and supercapacitors. Adv Compos Hybrid Mater. https://doi.org/10.1007/s42114-022-00556-6

Meyer JC, Geim AK, Katsnelson MI, Novoselov KS, Booth TJ, Roth S (2007) The structure of suspended graphene sheets. Nature 446:60–63. https://doi.org/10.1038/nature05545

Bai S, Shen X, Zhu G, Yuan A, Zhang J, Ji Z, Qiu D (2013) The influence of wrinkling in reduced graphene oxide on their adsorption and catalytic properties. Carbon 60:157–168. https://doi.org/10.1016/j.carbon.2013.04.009

Chen P-Y, Sodhi J, Qiu Y, Valentin TM, Steinberg RS, Wang Z, Hurt RH, Wong IY (2016) Multiscale graphene topographies programmed by sequential mechanical deformation. Adv Mater 28:3564–3571. https://doi.org/10.1002/adma.201506194

Hu K-M, Liu Y-Q, Zhou L-W, Xue Z-Y, Peng B, Yan H, Di Z-F, Jiang X-S et al (2020) Delamination-free functional graphene surface by multiscale, conformal wrinkling. Adv Funct Mater 30:2003273. https://doi.org/10.1002/adfm.202003273

Fan Z-J, Kai W, Yan J, Wei T, Zhi L-J, Feng J, Ren Y-M, Song L-P et al (2011) Facile synthesis of graphene nanosheets via Fe reduction of exfoliated graphite oxide. ACS Nano 5:191–198. https://doi.org/10.1021/nn102339t

Kuila T, Bose S, Khanra P, Mishra AK, Kim NH, Lee JH (2012) A green approach for the reduction of graphene oxide by wild carrot root. Carbon 50:914–921. https://doi.org/10.1016/j.carbon.2011.09.053

Ma Q, Song J, Jin C, Li Z, Liu J, Meng S, Zhao J, Guo Y (2013) A rapid and easy approach for the reduction of graphene oxide by formamidinesulfinic acid. Carbon 54:36–41. https://doi.org/10.1016/j.carbon.2012.10.067

Chua CK, Ambrosi A, Pumera M (2012) Graphene oxide reduction by standard industrial reducing agent: thiourea dioxide. J Mater Chem 22:11054–11061. https://doi.org/10.1039/C2JM16054D

Liu H, Chen X, Zheng Y, Zhang D, Zhao Y, Wang C, Pan C, Liu C et al (2021) Lightweight, superelastic, and hydrophobic polyimide nanofiber /MXene composite aerogel for wearable piezoresistive sensor and oil/water separation applications. Adv Funct Mater 31:2008006. https://doi.org/10.1002/adfm.202008006

Ma Y, Yue Y, Zhang H, Cheng F, Zhao W, Rao J, Luo S, Wang J et al (2018) 3D synergistical MXene/reduced graphene oxide aerogel for a piezoresistive sensor. ACS Nano 12:3209–3216. https://doi.org/10.1021/acsnano.7b06909

Acknowledgements

This work was funded by the National Natural Science Foundation of China (No. 51975562) and the National Basic Research Program of China (JCKY2019130C105).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Handling Editor: Mark Bissett.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file2 (AVI 16196 KB)

Supplementary file3 (AVI 36375 KB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, G., Qin, X., Chen, T. et al. Ultralight, superelastic pure graphene aerogel for piezoresistive sensing application. J Mater Sci 58, 850–863 (2023). https://doi.org/10.1007/s10853-022-08113-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-08113-8