Abstract

Carbon fibers (CFs) demonstrate a range of excellent properties including (but not limited to) microscale diameter, high hardness, high strength, light weight, high chemical resistance, and high temperature resistance. Therefore, it is necessary to summarize the application market of CFs. CFs with good physical and chemical properties stand out among many materials. It is believed that highly fibrotic CFs will play a crucial role. This review first introduces the precursors of CFs, such as polyacrylonitrile, bitumen, and lignin. Then this review introduces CFs used in BESs, such as electrode materials and modification strategies of MFC, MEC, MDC, and other cells in a large space. Then, CFs in biosensors including enzyme sensor, DNA sensor, immune sensor and implantable sensor are summarized. Finally, we discuss briefly the challenges and research directions of CFs application in BESs, biosensors and more fields.

Highlights

-

CF is a new-generation reinforced fiber with high hardness and strength.

-

Summary precursors from different sources of CFs and their preparation processes.

-

Introduction of the application and modification methods of CFs in BESs and biosensor.

-

Suggest the challenges in the application of CFs in the field of bio-electrochemistry.

-

Propose the prospective research directions for CFs.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The technological era has increased the demand for new materials that can overcome the limitations of traditional materials [1, 2]. In virtue of their outstanding physical and chemical properties, carbon fibers (CFs) have become widely used in defense, aerospace, healthcare, construction, and other industries [3,4,5]. CF has a long history of development (Fig. 1a). Domestic CF industry started late, still lagged behind the world’s advanced level, and failed to seize the market first (Fig. 1b). It can be seen from the national policy that the country promotes and applies CF as a new material, continuously guides the development of domestic CF, and thus attracts the attention of many researchers. Typical CFs are long filamentous materials with diameters in the micron range and carbon contents exceeding 95% [6]. From the perspective of the crystal structure of CFs, the crystal faces are almost parallel to the axis of the fiber. It is this parallel arrangement that makes CFs stronger than other fibers [7,8,9]. The original CFs are divided into two types: one is CF, which is prepared in the temperature range of 1000–1500 °C; the other is called graphite fiber, which is prepared above 2000 °C. In the process of development, the differences between them have been removed, and both are considered to be CFs. The CFs prepared at low temperature are high-strength CFs, and the CFs prepared at high temperature are high modulus CFs. CFs are stronger than steel but lighter than aluminum. CFs are used in the treatment of fibrosis (a lung disease resulting from damage and scarring of lung tissue), as they process both the inherent characteristics of carbon and the softness and processability of textile fibers. Besides being more lightweight, harder, and stronger than existing materials, CFs have high chemical and temperature resistance. CFs pyrolyzed from suitable precursor fibers [10] at low and high temperature are known as “high-strength CFs” and “high-modulus CFs”, respectively. The first CFs were constructed from cellulose fibers by Thomas Edison in the 1870s [4]. Compared with other fibers, CF has more regular fiber structure, coupled with its high fibrous structure in various fields of application occupy a leading position [6]. In the 1960s, CFs were used as lightweight reinforcement materials in composites, as their structural properties are superior to those of synthetic rayon precursor [10]. The global annual growth of CFs was approximately 58,000 tons in 2015 [11], and the volume of CF-polymer composite materials is projected to reach 197,000 tons by 2023 [12].

CFs have been widely used in bio-electro-chemistry applications, such as bio-electrochemical systems (BESs), biosensors, biological supercapacitors, and biological electrochemical reactors. The present reviews focus on the applications of CFs in BESs and biosensors. The electrode materials are the highest proportion of CF used in BESs. To meet various functional design and application requirements, CF is used as a matrix to be synthesized into different forms for electrode materials. Although conventional CF materials, such as CF cloth, carbon felt, CF paper, and CF nanomaterials, are relatively stable and have good electrical conductivity [13], their uses in BESs and biosensors are limited by various disadvantages (small surface area, large aperture and corrosion vulnerability). Moreover, as CF materials are inherently hydrophobic, they exhibit poor biological adhesion and low electron transfer capacity. These problems are further exacerbated by secretions from microorganisms [14, 15]. The poor application efficiency, requiring CF modification. Surface treatment of fiber materials can improve the adhesion between the fiber surface and polymeric resins [7]. Recently, the surface modification of CFs has become an interesting research area.

This paper discusses three sources of CFs from different raw materials: polyacrylonitrile (PAN), bitumen, and lignocellulose. As illustrations of recent CF applications in bio-electro-chemistry, we discuss the developments in the gas phases of these three sources, BESs, and biosensors. After presenting the research progress of conventional CFs and the advantages of modified CFs, we list some modification methods. Finally, we highlight the challenges faced by CF applications and future research direction in this field. The production of CF is the first and crucial step in the application of CF, and the first step of production is to select the appropriate precursor. The precursor determines the performance and application of CF, that is, a good precursor lays the foundation for the opening of the application market of CF.

CFs with Different Precursors and Their Advantages

CFs are produced by heat-treating precursor fibers through at least two stages of stabilization and carbonization [7]. In theory, almost any fiber containing carbon atoms can be converted into CF via heat treatment. The earliest CFs made from human-made precursor fibers delivered insufficient tensile strength and strength. PAN, bitumen, and lignocellulose precursors were significantly improved. Table 1 clearly shows the performance comparison of PAN, bitumen, and lignin precursors.

PAN-Based CF

PAN is widely used in textiles, for air filtration, as protective clothing, and for water purification. CFs made from PAN silk are the most valuable additives [16]. Acrylic fiber with an acrylonitrile content of > 85% is an ideal precursor material for CF production. PAN-based CFs are mainly used as a reinforcement of composite materials (Fig. 2a). PAN endows the CFs with high melting point and high carbon yield 50–60% [17]. Based on their mechanical properties, PAN-based CFs are divided into high-strength CFs, high-modulus CFs, and high-strength high-modulus CFs. By virtue of their low density, high chemical stability, and excellent mechanical properties, PAN-based CFs are widely used in aerospace, bio-electrochemistry, and other fields [18]. Today, PAN-based CFs comprise over 90% of the commercial CFs [19]. PAN molecules are composed of hydrocarbon main chains and repeated nitrile chains [20] with a simple structure and stereotactic properties (Fig. 2b). The stereotactic polymers formed by PAN usually have different mechanical and chemical properties [20].

a Preparation process of polyacrylonitrile-based CFs; b schematic of the molecular structure of polyacrylonitrile (PAN); reproduced with permission from Ref. [21], Copyright 2021, Elsevier

As PAN precursor dominates the CF market, understanding the formation of PAN precursors is necessary for producing high-performance CFs. The literature mentions wet [22], dry, and dry–wet jet-spinning techniques for manufacturing acrylic fibers. In the wet technique, a polymer is dissolved in a solvent and then poured into a solidified liquid containing a non-solvent liquid to form the primary fiber. The solvent is separated from the polymer coating in a coagulation bath and the non-solvent portion diffuses through the polymer. The excess solvent is then washed, rinsed, stretched, and dried in a bath and hot roller [22]. PAN-based CFs are manufactured by a three-stage process of polymer-precursor synthesis, fiber spinning, and heat treatment. The heat treatment stage includes two main steps: (1) thermal stabilization in an air environment and (2) carbonization at high temperatures in a nitrogen/argon environment [23, 24]. The thermal stabilization step is a slow and energy-intensive process, consuming 65% of the total energy of converting PAN to CFs. This high energy consumption significantly increases the cost of PNA-based CFs [25,26,27,28]. Wet–dry jet-spinning is beneficial for stretching and improving the molecular orientation of the filaments. It also avoids the high diffusivity caused by the temperature difference between the spinning stock and filaments in a coagulation bath [29]. PAN-based CFs and their composites are promising structural materials with excellent properties and low weight but the high cost of PAN limits their application potential. Thus, the development of lower-cost precursor materials is essential.

As for the cost of CF, because PNA-based CF has excellent quality and fine mechanical properties, which account for the highest proportion in CF. Consequently, we take PAN-based CF as an example to analyze the production cost of CF. The production and preparation costs of PAN-based CF mainly include PAN proto-filament, peroxidation, low temperature, and high temperature carbonization, and then sizing and winding cists. Among them, PAN proto-filament accounts for 51%, which is the main factor affecting CF production. The second is peroxidation and carbonization, accounting for 16% and 23% respectively. Proto-filament preparation is the core link of production, and peroxidation and carbonization are the central links of production. Both are the keys to CF production and preparation processes, and the processes are shown in Fig. 3.

Bituminous-Based CF

To expand the CF market, the production costs must be reduced as mentioned above [30]. The costs of PAN and spinnable bitumen precursors are almost 50% of the total production cost [31]. One lower-cost alternative is bitumen material, a solid-tar-like substance with high viscosity at room temperature and a very high carbon content. Bitumen is sourced from natural products, such as petroleum distillates and hydrated coal, or from synthetic materials, such as pyrolyzed poly-aromatic compounds and polymers [32]. Bitumen has a low molecular weight and comprises hundreds of different substances (mainly polycyclic aromatic hydrocarbons) that increase the CF quality [32]. With a carbon yield of up to 85%, bitumen was one of the early candidates for CF precursors. The preparation process is shown in Fig. 4a.

a Preparation process of pitch-based carbon fiber; SEM micrographs of carbon fibers obtained from b atmospheric distillation bituminous coal (A-HPC-THFS-AD), c pressurized distillation bituminous coal (A-HPC-THFS-PD), d atmospheric distillation sub-bituminous coal (B-HPC-THFS-AD), and e pressurized distillation sub-bituminous coal (B-HPC-THFS-PD)-derived spinnable pitches; f tensile strength of obtained carbon fibers; reproduced with permission from Ref. [30], Copyright 2016, Elsevier

Yang et al. [30] prepared CFs using emulable bitumen developed from the tetrahydrofuran-soluble portion (THFS) of hyper coal (HPC). The CFs were stabilized at 270 °C for 1 h and carbonized at 800 °C for 5 mins. Scanning electron microscopy (SEM) (Fig. 4b–e) revealed a smooth and uniform fiber surface with no evidence of melting. The cross section of the CFs was randomly structured, indicating an isotopic THFS fraction of the HPC-derived spacing. As HPC has a very low ash content and excellent thermoplasticity [33], it impregnates bitumen and facilitates CF production from imitated bitumen raw materials. HPC-derived bitumen usually reduces the CF production cost, and the tensile strength of the resulting CFs exceeds 800 MPa (Fig. 4f). HPC has been proven as an effective bitumen-based precursor of low-cost CFs. The excellent properties of bitumen as a precursor material are conferred by the large size of the graphite micro-crystallites and the ability to produce ultra-high-modulus CFs.

Lignocellulosic-Based CF

As an abundant renewable biopolymer resource, cellulose is low-cost, easily obtained, nontoxic, renewable, and ecofriendly. For these reasons, the production of cellulose-based materials has attracted significant research attention [34]. Lignin, a byproduct of cellulose production, is produced in large amounts annually. With its unique biodegradability, high thermal stability, and antioxidant properties [35], lignin is a renewable resource with a high potential for CF production. The basic structural unit of lignin is shown in Fig. 5a. Chitin vies with lignin as the second-most abundant organic macromolecule in nature [36]. Lignin is contained in all vascular plants [37] and when used as a precursor, it reduces the CF production cost by ≥ 35%, demonstrating the excellent use of renewable byproducts on a large scale [38]. Lignin precursor delivers high productivity, low energy consumption per kilogram of fiber, and high carbon yield while being less toxic than other precursors. Furthermore, lignin precursors are independent of fossil energy sources [38]. Lignin-based CFs are promising and have attracted interest from some researchers in the field.

At present, lignin-based CFs are best prepared by extracting and preparing a suitable lignin, which is then melted and spun into fibers in an inert atmosphere. The resulting lignin fiber is oxidized, stabilized, and carbonized to produce CFs. This process is complex (Fig. 5b) and requires careful control of the spinning conditions and treatment temperatures to obtain high-strength CFs. Lignin is cheaper and more renewable than other precursors and can be oxidized and thermally stabilized at a faster rate [31]. Kadla et al. [39] investigated CF production from three types of lignin: hardwood lignin, cork sulfate lignin, and hardwood sulfate lignin. They showed that hardwood lignin is easier to melt into a fiber than the other lignin, whereas cork lignin has lower thermal stability. Some researchers have fabricated CFs using lignin from the wood-strengthening process. Unlike the traditional sulfate-pulping processes, this process first recovers highly purified lignin from the lignin-rich portion. The pure lignin is burned in a boiler to recover the pulp mill chemicals and provide energy. The lignin is precipitated for pulping, then washed, and recycled with dilute acid. The lignin obtained using this method is more carbohydrate- and salt-free than traditional sulfate lignin [40].

In general, the increasing demand for CF has resulted in the increasing demand for precursors, which are manufactured on a commercial scale using PAN, bitumen and lignin. The quality of precursor determines the performance of CF and plays a crucial role in the production of CF. Under the condition of sufficient preparation, CF has many outstanding properties that other materials cannot surpass. It has formed an important new material system and been applied in many fields.

CF Material for BESs

BES is a sustainable power generation technology that has been rapidly developed for wastewater treatment in the past decade [41]. BESs can cleanly produce high-value chemicals and fuels [42] via reduction and oxidation reactions at the cathode and anode, respectively. The resulting potential difference drives the spontaneous flow of electrons from a low to a high potential [43]. The microbial fuel cell (MFC) in BESs generates electricity by degrading organic matter in an anode chamber. MFC uses microorganisms to produce a low redox potential for organic oxidation at the anode and a high redox potential for oxygen reduction reactions (ORRs) at the cathode [44]. Microbial electrolysis cell (MEC) drives chemical production when a certain external voltage is applied to the cathode potential [45]. Microbial electrosynthesis (MES) reduces CO2 or organic molecules to higher-value organic molecules at the cathode [46]. Microbial desalination cell (MDC) is used in water desalination [47]. All BESs require two electrodes for biofilm formation and redox reactions, which occur in two-stage chambers [48]. The electrode material of BESs is typically a conventional CFs, such as CF cloth, carbon felt, or CF paper. Although conventional CFs often exhibit relatively stable and conductive properties, their hydrophobic characteristics inhibit microbial adhesion and lower the electron transfer ability and output power. Therefore, some researchers have developed electrode modification methods to improve the output power.

CF Materials in MFC

Anode and Modifications

MFC is a bio-electro-chemical method that harnesses the energy produced by bacteria degrading organic matter and converts it to electricity [44]. MFC contains two chambers, each containing an electrode, a cathode and an anode, separated by a cation exchange membrane [49] (Fig. 6a). As the performance of MFC partly depends on the electrode material, the electrode is the most important component of MFC. Meanwhile, the anode is crucial for energy generation and pollutant removal. It makes direct contact with the bacteria and is responsible for the electron transfer rate from the electroactive bacteria to the anode surface. The material and cost of the anode pose challenges in MFC research. Several potential natural materials and modification strategies for battery construction are known (Fig. 6b). The anode is made from conventional fiber materials, such as carbon paper, carbon cloth, CFs, and carbon brushes [50]. Among these materials, CFs are most commonly used owing to their slightly larger surface area than other carbon materials, large space gap, and relatively high porosity [49]. It is more flexible and conductive than ordinary carbon paper, but is costly and its chemical instability reduces the long-term stability of the electrode [51]. Conversely, carbon paper is used as an electrode when high cost is not a priority. Carbon brushes are also disadvantaged by chemical instability and high cost but their high surface area and area-to-volume ratio are advantageous. Most of the recent research on carbon brushes focuses on cost reduction. As anodes, carbon veils are cost-effective, conductive, porous, and efficient energy generators. A single-layer carbon veil is brittle and can be folded to form a three-dimensional (3D) anode [52]. Carbon felt with high porosity, good electrical conductivity, and high mechanical stability is also commonly used as a low-cost anode [53]. However, the power outputs of all the above materials are reduced by defects. Modifying the anode to improve its output power and optimizing the battery performance are urgent tasks. As the anode is the attachment point of the bacteria and receives the electrons generated by substrate metabolism, a poorly performing anode is a major obstacle in practical applications. A successfully modified anode can effectively improve the power generation efficiency of MFC (Table 2). In addition, the surface properties of a material can enhance the bacterial properties and improve the contact between the anode and bacterial species [49].

a Structure and working principle of MFC, b anode material and anode electrode synthesis route; reproduced with permission from Ref. [49], Copyright 2020, Elsevier

MFCs can be modified with carbon nanotubes (CNTs), to increase their power output [54, 55]. Some conventional CNTs, despite their high surface area, are insufficiently biocompatible, and require modification for bacterial formation and adhesion. Ci et al. [56] prepared bamboo nanostructured nitrogen-doped carbon nanotubes (Bamboo-NCNTs) by catalytic pyrolysis of ethylenediamine as modified materials for MFC carbon cloth anode. They prepared three MFCs, Bamboo-NCNTs-MFC, CNTs-MFC, and CC-MFC. Figure 7a shows that Bamboo-NCNTs-MFC significantly improved the maximum power density of MFC. By observing the effects of anode modification on individual potential, it was found that the cathodic potentials of the three MFCs are similar. But there were significant differences in the anode potential (Fig. 7b, c), including that the modification and application of CNTs had a great influence on the anode potential, especially Bamboo-NCNTs. Above results indicated that the anodic potential of Bamboo-NCNTs was lower and more electricity could be generated after modification, that is, Bamboo-NCNTs could significantly improve the anodic performance. Figure 7d and inset of Fig. 7d show that Bamboo-NCNTs has superior acetate oxidation performance. And the negative pole of Bamboo-NCNTs has the largest double-layer capacitor of 0.31F compared with the negative pole of CNTs (0.031F) and CC anode (0.0088F). The results show that Bamboo-NCNTs negative electrode has a larger surface area which could be used for electron transfer. In conclusion, the anode in MFC was modified by nitrogen-doped CNTs of bamboo structure, which significantly improved the performance of MFC. Yang et al. [57] synthesized doped and undoped carbon nanoparticles by chemical vapor deposition. To modify the carbon cloth anode, ultrasonic treatment was uniformly added into the carbon cloth electrode, which increased the anodic absorption of flavin secreted by Shivaella and promoted the shuttle-mediated transfer of extracellular electrons. Consequently, the performance of the MFC anode improved and its maximum power density was 3.5 times greater than that of an unmodified carbon cloth anode [57].

a Polarization curves and power density curves of Bamboo-NCNTs-MFC, CNTs-MFC, and CC-MFC; variation of cathode potentials (b) and anode potentials c of the three MFCs; d Nyquist curves of three MFC EIS tests; reproduced with permission from Ref. [56], Copyright 2012, Elsevier; e graphene was electrodeposited onto the surface of the carbon brush as MFC biological anode for wastewater treatment; reproduced with permission from Ref. [62], Copyright 2021, Elsevier

The MFC electrode is often modified with graphene (Gr). The unique properties and structure of Gr favor the energy excitation transfer (EET) between the anode material and anode microorganisms. Guo et al. [58] prepared Gr-modified carbon paper anodes using a layer-by-layer method that exploits the electrostatic adsorption reaction of negatively charged Gr and positively charged polyethylene imine (PEI). The functionalized carbon paper electrode was alternately immersed in positively charged PEI aqueous solution and negatively charged Gr suspension for washing and hot air drying. PEI/Gr layered structures were formed, and the cycle was repeated to form multilayer films. To highlight the role of Gr in MFCs performance, blank carbon paper electrodes were used as reference blanks. The results showed that electrostatic adsorption reaction considerably increased the number of microorganisms on the anode of graphene-modified carbon paper. The Gr-modified MFC delivered a maximum power density of 368 mW·m−2, more than twice that of the unmodified MFC. Gr is usually modified on a substrate material [59] such as carbon paper or carbon cloth. Gr-modified electrodes avoid clogging caused by microbial attachment, thereby improving the biocompatibility and EET efficiency [60]. The macro-porous structure of a Gr-modified material increases the active surface area, enhances the interaction between multiple biofilms and electrodes. Meanwhile, it enhances the electrical conductivity, reduces the polarization phenomenon, and improves the energy exchange efficiency [61]. Sayed et al. [62] prepared Gr oxide (GO) using an improved Hummer method. Applying electrophoretic techniques, they then bound a thin GO layer to a carbon brush, forming a biological anode for the MFC treatment of actual wastewater (Fig. 7e). Electrophoretic deposition of GO on the carbon brush surface improved the MFC performance and power density by more than 10 times. Electrochemical impedance the spectroscopy measurements showed that Gr improved anodic electrode performance by improving the electron transfer from microorganisms to the anodic surface.

Metal and metal oxide nanocomposites can reduce and improve the ohmic loss after bacterial cell adhesion [63, 64]. Oxides of Sn, Ti, Mn, Fe, and other metals have been incorporated into carbon-containing nanocomposites and used as anode modifiers [13]. Tang et al. [65] improved the MFC performance with TiO2. The performance was further improved after modifying a 3D anode with a nanostructured capacitance layer, in which TiO2 bonded with egg white protein is integrated into loofah sponge carbon to boost the capacitance of the 3D electrode. The output power density was obviously improved from that of the unmodified anode, thereby enhancing the electrochemical capacitance and synergistic effect between TiO2. The authors attributed these improvements to the unique properties of TiO2, namely high biocompatibility, high surface area, and surface functionalization for interfacial microbial electron transfer [65]. Fu et al. [66] prepared Gr/Fe2O3 composites using a simple one-step hydrothermal reduction method and incorporated them into a modified anode for MFCs. CF and Gr/Fe2O3 composites, which removed metal impurities and organic matter, were transferred to the autoclaves for reflow, cooled to room temperature. And the prepared Gr/Fe2O3-CFs were washed and dried with deionized water, and used as modified anode of MFC. The high output power density (2.59 times that of the unmodified anode) was attributed to good biocompatibility of Gr/Fe2O3 composites. The biocompatibility was likely improved by the high conductivities of Gr and Fe2O3, which facilitate the transfer of electrons outside the cell. Therefore, Gr/Fe2O3 can effectively improve the MFC performance [66].

Cathodes and Modification

Although biodegradation occurs in the anode chamber of MFC, the output power largely depends on the ORR in the cathode chamber. ORR biological cathode is a reversible bacterial electrode. Due to the large amount of biomass preferentially developed in the cathode phase, its periodic arrangement can make the cathode phase acidified and the anode phase alkalized, which can improve the electro-catalytic efficiency [94]. ORR comprises three stages: (1) gas—oxygen-electron acceptor, (2) liquid—electrolyte-reaction medium, and (3) solid electrode—electron donor.Thus, it is complex [95]. Electrocatalysis of ORR is a combination of several different pathways, and electrode materials are one of the factors affecting the activation or inhibition of this pathway. Simultaneously, the maximum performance of the oxygen microbial cathode has not yet reached the optimal level. With the increase of biofilm thickness, the utilization of dissolved oxygen is declining, which also becomes one of the factors limiting the performance of MFC [96]. In addition, because MFC comprises proton and electron acceptors and its structural characteristics affect the substrate oxidation efficiency, its performance and economic feasibility are affected by the cathode material [97]. Therefore, the cathode process is challenging. In the past few years, numerous CF materials have been used as electrode materials for cathodes, because they are outstanding in cost, activity and durability, and high-performance electrode materials have been explored. MFC anode materials, such as CF fabrics, CF felt, CFs, carbon brushes, and paper fibers, are also employed as cathode materials, implying that insufficient MFC output power is due to limitations of conventional CFs. That is, the cathode must also be modified to enhance the MFC performance and increase the output power density (Table 3).

To improve the performance of MFC cathodes, Aryal et al. [69] modified a 3D CF brush cathode with three nanomaterials, Ni nanoparticles (NPs), multiwalled CNTs (MWCNTs), and MWCNT/Ni. The authors observed the roles of the modified cathodes in MFC electricity generation and wastewater treatment efficiency. The results indicated that the three electrodes can improve the electricity generation capacity of MFC in different degrees, regardless of the deposition of 1.5 mg/cm2 or 3.0 mg/cm2 nanomaterial. The MWCNT increases the current by increasing the surface area of the electrode, so as to improve the power generation. It also increases the ohm resistance of the MFC, because MFC has a higher resistivity compared to CFs. In contrast, Ni reduces the ohmic resistance of MFC because Ni has a lower resistivity than CFs. By increasing the current and conductivity of the electrode, MWCNT/Ni optimizes the power density while reducing the internal resistance. MWCNT has the greatest effect on the performance of MFC in the aspect of increasing power production. MWCNT/Ni showed the best performance in reducing internal resistance and cathode charge transfer resistance. MWCNTs were deemed the most practical cathode-modification materials in terms of price, performance, and stability [69]. Liu et al. [98] modified MFC carbon cloth cathodes with CNTs and Gr through in situ polymerization using polyaniline (PANI) as a binder [99]. Next, they treated cresol wastewater with an anaerobic fluidized bed MFC (AFB-MFC) based on the modified cathodes. The cathodes modified with PANI + Pt/C + Gr and PANI + Pt/C + CNTs delivered good electron transfer ability and electro-catalytic activity. The AFB-MFC with PANI + Pt/C + Gr maximized the power generation effect, generating a maximum power density was of 910.40 mW/m2, 616.46% higher than that of AFB-MFC with PANI + Pt/C, because of the large specific surface area and excellent electrical conductivity of Gr (Fig. 8a, b). From the degradation effect of cresol wastewater, AFB-MFC with PANI + Pt/C + Gr as the electrode had the highest degradation rate, reaching 91.76%, and the degradation efficiency of AFB-MFC with PANI + Pt/C + CNTs electrode was 91.72%. This is because the addition of CNTs and Gr increased the specific surface area of the carbon cloth cathode, increased the contact space between microorganisms and organic matter, and increased the degradation reaction rate of organic matter [98]. Among the plate modification materials used by researchers, CNTs, and Gr most significantly improve the MFC performance.

Voltage output (a), power density, and polarization curves (b) of different modified cathodes; reprinted with permission from Ref. [98], Copyright 2020, American Chemical Society

CF Materials in MECs

MECs are associated with environmental biotechnology and can be used for wastewater treatment while producing renewable energy in the form of electricity, hydrogen or valuable chemicals [121, 122]. Catalyzed by metals or electrically active biofilms attached to a cathode [46], MECs convert the chemical energy of low-grade biomass into hydrogen and simultaneously restore the pollutants [123]. MECs can also electro-synthesize various carbon natural power fuels or extract industrially usable chemicals from waste CO [124, 125]. In this way, they capture, recover, and use CO2, thus reducing the greenhouse effect [126]. Unlike the spontaneous reactions in MFCs, the reactions in MECs must be driven by an external power supply. The power can be sourced from common voltage regulators or renewable sources, such as solar, wind, geothermal, and tidal power [127]. MEC systems have great potential as green and sustainable energy producers. A typical MEC comprises a core component, an anode, and a cathode, separated by an ion-exchange membrane. The electrode performance affects the microbial attachment, internal resistance, electron transfer, and reaction kinetics on the electrode [127].

Anode and Its Modifications

The anode is an indispensable core component of MECs (Fig. 9a). Improving the electrolytic cell performance is particularly critical because electron transfer to the electrode occurs when an external electronic group attaches to the anode surface [128]. CFs are the earliest electrode type in MECs and are still used today owing to their low cost, easy manufacturability, good electrical conductivity, and high chemical stability. In laboratory-scale MEC studies, the common CF-based anode materials are carbon cloth, CF paper, carbon felt, and carbon brushes. The anodes can be identical to those used in MFCs. However, every conventional anode material demonstrates different advantages and disadvantages. Carbon cloth is soft and porous, providing a high surface area for microbial growth [129], but its relatively high cost limits its large-scale use [130]. Carbon paper is very thin and easily connected to wires, but it has low strength and poor durability [131]. Graphite felt is a very thick fiber fabric with good electrical conductivity [132], high strength, and numerous fiber interconnections. However, low mass transfer rate and high inner-surface resistance hinder the use of graphite felt as an electrode material [127]. Carbon brushes are known as a new type of electrode formed by cutting CF to a set length and winding it around a conductive but noncorrosive titanium wire. Carbon brush electrodes exhibit high specific surface area and high conductivity, and are relatively inexpensive and easy to manufacture [127]. A carbon brush electrode can be modified, to improve and stabilize the reactor efficiency [133, 134]. Overall, low power density of the biological anode has severely hampered hydrogen production by MECs. To improve the performance of MECs [135], researchers have explored their limiting factors, such as anode materials [136, 137] and proton exchange membranes [138,139,140]. Improving the electron transfer efficiency of biological anodes is considered crucial for improving the MEC performance [141].

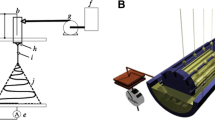

a Schematic diagram of the structure principle of MEC; b continuous flow, graphite brush anode MEC designs. Graphics and photographs for the MEC with graphite brushes of (A, D) 1.5 cm diameter, (B, E) 4.5 cm diameter, and (C, F) 5.5 cm diameter. Arrows indicate the general direction of electrolyte flow; reproduced with permission from Ref. [142], Copyright 2021, Elsevier; c the compound 2-mercaptobenzothizaole (MBT) degradation product; d mechanistic routes proposed for the transformation of MBT under the reaction conditions; reproduced with permission from Ref. [143], Copyright 2020, Elsevier

Fonseca et al. [142] compared the performances of two MEC systems (Fig. 9b): one with a single large or small fibrous brush anode, the other with multiple brushes. The brush fibers of the single-brush MEC were compressed, until they partly or completely filled a 1.3-cm-high anode chamber. After unintruppted monitoring and assessment of the anode potential, they concluded that the MEC with the single-brush anode MEC outperformed the MEC with the multi-brush anode and generated a more stable current. These results show that MEC performance can be enhanced by compressing the brushes into a smaller space, and that the anodic potential can approach the thermodynamic minimum [142]. Isabelsan-Martin et al. [143] studied the degradation pathway of 2-mercaptobenzothizaole (MBT) and the related microbial community at a MEC anode (Fig. 9c, d). Commonly detected in wastewater and surface water, MBT is a potential threat to human health. Analyzing a series of indicators, the authors showed that Gr-modified anodes provided more favorable conditions for the enrichment of specific microbial communities than bare anodes. In addition, hydroxyl substituents were continuously added to the MBT benzene ring in a reactor equipped with Gr-treated electrodes. This phenomenon was attributed to significant biotoxicity reduction in the MEC with the Gr-modified anode [143].

Cathode and Its Modifications

CFs used for anodic electrodes are also suitable for cathodic electrodes. When used alone, CF-based cathodes typically require a higher cathode overpotential to drive electrolytic hydrogenation [144] or electro-methanogenesis [125, 145]. Researchers are also constantly exploring new cathode-modification techniques. Some studies have proposed coating a thin layer or metal complex catalyst with a noble metal catalyst, such as Pt [146], Pd [147], or Au [148]. The coating improves the electrochemical efficiency of CFs by reducing the activation energy threshold [127]. At present, Pt-catalyzed carbon cloth is the most commonly used catalyst in cathode-modification techniques [149]. However, Pt-catalyzed carbon cloth is limited to the laboratory level due to its high cost, scarcity [144], and risk of chemical poisoning [150]. In addition, its short life cannot meet the requirements of practical engineering [151]. For these reasons, new electrode materials and low cost multifunctional catalysts are in demand. Power et al. [152] prepared a novel MnO2-coated carbon felt cathode (Mn/CF) electrode for MECs via potentiostat electrodeposition. They employed MnO2 as the cathode catalyst to promote electron transfer and significantly reduce the cost of MECs. The maximum stable current density obtained by the MnO2-coated Mn/CF-MEC was more than twice that obtained by an uncoated carbon felt cathode. In addition, the acetic acid yield of the Mn/CF-MEC with two compartments significantly exceeded that of the uncoated CF-MEC. This study confirmed that the interaction between MnO2 and microbial cells enhanced the extracellular electron transfer and might thus play a role in biofuel production. The MnO2-coated CF also delivered higher electrode area and electron transfer efficiency than the uncoated CF-MEC [152].

Hu et al. [153] synthesized noble metal-free cathodes via electrodeposition of NiMo and NiW on a CF woven fabric. The NiMo cathode outperformed the NiW cathode. Under an applied voltage of 0.6 V, the current density of hydrogen production by the MEC with the NiMo cathode was 270 A/m3 (2.0 m3/day/m3), 33% higher than that of the NiW cathode and second only to a Pt catalyst. These data indicate the high potential of carbon cloth with a nickel alloy catalyst as the MEC cathode material [153].

CF Materials in MDC

As MDCs can treat wastewater and generate electricity while desalting seawater, they are promising agents for sustainable water desalination. The power output of MDCs exceeds that of MFCs, which include an additional desalination chamber to reduce the electrolyte resistance [154]. Technically, MDC is an extended form of BES that generates electrical energy through direct oxidation of organic matter. The oxidation products are extracellularly released and transferred via aerobic bacteria at the anode, thus realizing self-powered operation [155]. MDCs are multichambered and maintained charge-neutral by brine extraction through an ion-exchange membrane. More specifically, MDC has two membranes between the anode and cathode, forming an intermediate chamber for seawater desalination, an anion exchange membrane near the anode device, and a cation exchange membrane near the cathode device. The bacteria on the anode generate a current due to the potential difference between the electrodes. The ionic material in the intermediate chamber is transferred to both electrode chambers, eventually desalinating the water in the intermediate chamber [156] (Fig. 10a). Some experimental studies have demonstrated complete salt removal by MDCs [156]. Unlike other traditional pressure/heat-driven desalination processes, such as reverse osmosis and heat/membrane distillation, the MDC process consumes no external energy. Thus, it considered as an ecofriendly and sustainable seawater desalination process.

a Schematic diagram of the structure principle of MDC; schematic set-up of the biocathode microbial desalination cell (b) and measuring circuit (c); Reproduced with permission from Ref. [157], Copyright 2012, Elsevier; d schematic diagram of degradation of methylene blue by polypyrrole-modified cathode in bio-electro-Fenton coupled microbial desalination cell; reproduced with permission from Ref. [158], Copyright 2018, Elsevier

The electrode material system affects the MDC functionality, to some extent. The selected material should be inexpensive and physically proper to form a biofilm and an electron delivery layer [131]. Biological cathode materials should possess outstanding electrical conductivity and surface roughness. Carbon-based electrodes, such as carbon cloth, carbon felt, and carbon brushes, are important standard biological cathodes with high specific surface areas and strong power outputs [129]. Wen et al. [157] tested an aerobic biological electrode composed of carbon felt and bacterial catalyst, as the cathode material of MDC. The biological cathode produced higher power density and desalination rate than other MDC cathodes [157] (Fig. 10b, c). Huang et al. [158] established a combined treatment system for dye wastewater and high-salinity seawater desalination. They tested the performance of a poly-pyrrole-modified PAN-based CF cathode hydrogen peroxide electrolysis using the bioelectric Fenton process. They also evaluated the desalting, power generation, and fuel removal efficiency of the system (Fig. 10d). The H2O2 yield of the recycled MDC with the polypyrrole-modified cathode reached 24.07 g H2O2 m−3 day−1, versus 6.95 g H2O2 m−3 day−1 in the unmodified MDC. In addition, the maximum power density of the modified MDC reached 566 mW m−3, whereas the unmodified MDC reached only 267 mW m−3. The desalination efficiency of the MDC with the polypyrrole-modified PAN-based CF brush biocathode was 64.98% [158].

CF Materials in MES

MES is a novel bioenergy strategy exploiting the ability of chemoautotrophic bacteria to absorb electrons directly or indirectly. Using electricity as an energy source, chemoautotrophs reduce the CO2 from the cathode of electrochemical cells to multi-carbon organic molecules, which can be used as transport fuels or other organic commodities [159, 160] (Fig. 11a). The conversion of electrical energy into extracellular multi-carbon products is an attractive option for energy storage [161]. As a form of artificial photosynthesis, MES can convert solar energy to electrical energy [162]. MES commonly employs conventional CFs (such as carbon cloth and carbon felt) as the electrode materials. The commercialization of MES needs to be optimized and scaled up, particularly by enhancing the electron exchange on the cathode surface while optimizing cost.

Copyright 2020 American Chemical Society. c Schematic of conversion of CO2 to formate using a g-C3N4-NiCoWo4 photoanode supported by activated carbon fibers in a microbial electrosynthesis system; reproduced with permission from Ref. [165], Copyright 2022, Elsevier; d schematic diagram of enhanced microbial electrosynthesis of 3D graphene functionalized cathodes prepared by solvothermal synthesis; reproduced with permission from Ref. [166], Copyright 2016, Elsevier

a Schematic diagram of the structure principle of MES; design of the artificial electron mediator-modified cathodes in the MES systems, schematic showing the design for the CF self-assembly with PBNCs and the biofilm growth on the modified cathode (b); reprinted with permission from Ref. [164].

Zhang et al. [163] coated the cathode carbon cloth material of MES with different materials (chitosan, melamine, 3-aminopropyl tri-ethoxy-silane, and PANI). The modified carbon cloth enhanced the electrosynthesis of positively charged microorganisms. Relative to the unmodified carbon cloth, the acetate yield of the functionalized chitosan and melamine increased by 6–7 times, and that of 3-aminopropyl tri-ethoxy-silane increased by three times. The electrosynthesis of the PANI cathode was also three times higher than in MES with the unmodified carbon cloth. However, not all methods providing a positively charged surface have been successful: for instance, treating CF cloth with melamine or ammonia does not stimulate the electrical synthesis of acetate [163]. Tian et al. [164] designed a Prussian blue nano-cube-modified carbon felt as an artificial electron dielectric modified cathode for producing organic molecules from CO2 sources. Regulating the microbial community composition to improve the biocatalytic activity is a new direction in MES electrode modification, indicating that cathodes based on artificial electronic media should improve the MES efficiency [164] (Fig. 11b). Gupta et al. [165] first demonstrated the efficient formation from CO2 in a photo-assisted MES system. They employed an activated CF-supported g-C3N4-NiCoWo4 optical node and a g-C3N4 biocathode (Fig. 11c). Combining the photoanode and biocathode in an MES cell, they efficiently harvested solar energy to achieve a sustainable high rate of biochemical formation [165]. Aryal et al. [166] synthesized a 3D Gr-functionalized carbon blanket composite cathode that rapidly transfers electrons to a microbial catalyst (Fig. 11d). The modified 3D Gr grids increased the CO2 electrosynthesis rate of acetic acid by 6.8 times while significantly increasing the biofilm density and current consumption. The specific surface area of the composite 3D Gr/carbon felt cathode was doubled, forming a more substantial biofilm than the unmodified control. In addition, cyclic voltammetry (CV) analysis showed a higher current response of the 3D Gr/carbon felt [166].

CF Materials in Proton Exchange Membrane Fuel Cells (PEMFCs)

PEMFC is a promising energy conversion device, for a wide range of commercial, industrial, and transportation applications. It is a clean, efficient power source, that directly converts the chemical energy stored in hydrogen and oxygen to electrical energy [167] (Fig. 12a). PEMFCs have received considerable attention for their high power density, high energy efficiency, and environmental protection properties [168, 169]. However, their availability as viable power sources for large-scale use is limited by the high manufacturing cost of many key battery components, such as the bipolar plate (BP) [170, 171], solid polymer electrolyte membranes [172, 173], and catalyst layers [174, 175]. Researchers favor CFs, which not only deliver high performance at low cost but can also be used in other parts of PEMFCs, such as the gas diffusion layer (GDL) and electrode catalyst carrier.

a Schematic presentation of a PEMFC with reactions at respective electrodes; Reproduced with permission from Ref. [188], Copyright 2019, Elsevier; HR-TEM images of b CNF-Pt, c high-magnification image of CNF-Pt, d FCNF-Pt. Inset of Fig. 1b is the diffraction pattern of CNF-Pt; e polarization curves obtained with a rotating disk electrode for the ORR on b CNF-Pt, c FCNT-Pt, and d FCNF-Pt in O2-saturated 0.5 M H2SO4. Sweep rate: 10 mV/s; reprinted with permission from Ref. [189], Copyright 2009, American Chemical Society

The BP is a critical multifunctional component in PEMFCs. Specifically, the BP is a flow channel that delivers hydrogen and oxygen to the anode and cathode, respectively, and removes water and unreacted gasses. By reducing the BP cost, the total manufacturing cost of a PEMFC can be reduced. To this end, many researchers developed lightweight and cost-effective BPs [176, 177]. The BP should also provide high electrical conductivity, high mechanical strength, good corrosion resistance, low permeability, low interfacial contact resistance, and other basic properties [178, 179]. The BP is most commonly constructed from graphite, which possesses excellent electrical conductivity and chemical stability [179]. However, graphite processing is difficult and incurs a high manufacturing cost. Graphite is also brittle and graphite BPs are usually made thick to increase the volume and quality of the stack [180]. Pure graphite as the BP material can be substituted with polymer composite, which has excellent corrosion resistance and low manufacturing cost. To develop composite BPs with good electrical conductivity and mechanical properties, some researchers are optimizing the composition and manufacturing parameters of the BP material. When added to BP composites, CFs contribute their high strength and modulus to realize BP composites with improved bending strength, hardness, and stiffness. A popular choice is PAN-based CFs, which have a high aspect ratio and > 90% carbon content. A high CF content increases the hydrogen permeability, which is detrimental to PEMFCs. Ghosh et al. [181] studied the influence of CF length on compound BPs and identified the optimal length as 1 mm [181].

The GDL plays a vital role in the transfer of energy, electrons and matter through PEMFCs. The GDL is composed of a microporous basement (MPS) and a microporous layer. The MPS comprises horizontally and anisotropically stacked brittle CFs with diameters of 7–9 μm. The CFs are bonded into a mesh matrix by a polymer binder. The highly porous microstructure of MPS provides a pathway for mass and low degree heat transfer, whereas its solid region provides an efficient pathway for electrons and heat transfer [182]. Many studies have focused on optimizing the transmission characteristics of MPSs, which are largely determined by their engineering parameters, such as their material and design specifications. As its name suggests, carbon-based MPS is a moisture-resistant porous material made from carbon, which is typified by high permeability, high electronic conductivity, and a controlled pore structure [182]. For example, woven carbon cloth has a uniform microstructure, whereas carbon blankets are composed of randomly bent CFs. Because carbon cloths and carbon blankets are heat-treated at relatively low temperature, their corrosion resistances are poor [182].

Arbitrarily stacked ultrafine CFs, are treated with hydrophobic agents, in order to form a carbon paper, with a desired microstructure (MPSs), providing an efficient mass transfer function [183]. However, studies show that carbon paper work better under low humidity conditions because its convoluted and complex structure facilitates water retention and minimizes the ohmic resistance. In contrast, carbon cloth is a better choice under high humidity conditions because its structure is less zigzagged and provides more direct routes for water removal. The rough surface of carbon cloth also promotes water removal, thereby improving the battery performance under high humidity conditions. Other researchers have modified the existing microstructure of carbon cloth and paper to control the movement of water in cells. Kimball et al. [184] set up single large holes (approximately 400 μm in diameter), at opposite positions of different channels of cathode flow. They conducted performance tests in the “cathode up” and “cathode down” positions, and correlated the distribution profile with the movement of liquid water. They found that liquid water could be forced out of a specific location through a single large hole under the influence of gravity and surface tension [184]. Carbon paper has also been customized using perforation technology to improve its mass transfer characteristics under two-phase flow conditions [185].

Carbon nanofibers (CNFs) are also used as electrocatalyst carriers in PEMFCs. The graphite-shaped structure of CNFs confers high thermal and electrical conductivities. Fuel cell carries formed from CNFs achieve sufficient oxidation resistance [186]. In 2013, Li et al. [187] compared the unique properties of CNFs and those of other carbon nanostructures in PEMFCs. They demonstrated higher thermal stability, decomposition, and electrochemical degradation in PEMFCs with CNFs than in PEMFCs with other carbon nanostructures [187]. Moreover, the cathode side of PEMFCs has been supported by functionalized CNFs, yielding an electrocatalyst with greater Pt dispersion and higher Pt load than electrocatalysts with non-functionalized CNFs. Before functionalization, the Pt NPs settled on the inner walls of CNFs due to the pyrolytic carbon layer on the outer surface (Fig. 12b). From the high-magnification image in Fig. 12c, the approximate size of the Pt NPs was determined as 6–7 nm. After CNF functionalization, the Pt NPs were less agglomerated and settled on both the inner and outer walls of CNFs. As shown in Fig. 12d, the size of the Pt NPs deposited on the inner and outer CNF walls was reduced to 3 nm. Meanwhile, the CV curve (Fig. 12e) shows a twofold higher electroactive area of the functionalized sample than of the non-functionalized sample.

CF Materials for Biosensors

CFs not only shine in BESs, but also play an indispensable role in various biosensors. Using conversion elements and signal amplification devices, a biosensor transforms the sensitive responses of the molecular recognition elements in certain substances into observable signals. Biosensor comprises three parts: (1) molecular recognition element, which adsorbs enzymes, antigens, or antibodies on the sensor surface and reacts with the substances to be measured. (2) A signal converter that converts biological signals into electrical signals; here, the biological molecules on the electrodes interact with the detected substances to produce electrochemical reactions. And (3) a signal amplification device, which converts the electrical or optical signals generated by the reaction into an electrical signal for the output. In terms of molecular recognition elements, biosensors can be divided into enzyme, immune, DNA, cell, and tissue biosensors. In terms of sensor type, they can be divided into electrochemical, optical, and gravity biosensors. Optical biosensor instruments are too expensive for practical applications, whereas gravity biosensors are prone to interferences. Electrochemical biosensors are thus favored in applications and have since been research value. Biosensors were first used in glucose, detection and have since been applied to medicine, environmental monitoring, food, and other fields [190]. To reduce the cost and improve the poor relative selectivity of biosensors, and low sensitivity, researchers have investigated new materials and methods. CFs have high mechanical strength, strong toughness, large relative surface area, and good electrical conductivity, which are favorable for constructing microelectrodes. Their surfaces contain oxygen-containing functional groups, which can be chemically modified using various methods. CFs are considered as ideal electrode materials for biosensors [191].

Enzyme Biosensors

Enzyme biosensor combines an enzyme recognition element with an electrochemical signal through an enzyme-specific reaction. When fabricating enzyme biosensor, the enzymes must be fixed to the electrode surface. This process requires care to avoid enzyme deformation; therefore, most metals are excluded from the list of candidate electrode materials. Carbon-based materials are widely used as electrode materials for enzyme biosensors because they provide good electronic conductivity and a relatively large adsorption surface area. However, when analyzing complex samples, carbon-based electrodes often become contaminated and their sensitivity must be improved by accelerating the electron transfer rate, which requires in-depth and modification of the electrode. The surfaces of carbon nanomaterials are usually hydrophobic but biosensors must work in a hydrophilic environment. To improve the biosensor sensitivity, Kim et al. [192] modified an activated CF electrode with urea. They found that more glucose enzymes adsorbed after the modification process (Fig. 13a), affirming the improved sensitivity of the enzyme biosensor [192].

a The GOx can be stored in the slit pores of the carbon. Some residual GOx in the carbon slit pores can also be modified by the nitrogen and oxygen group effects, such as the grabbing effects due to semi-ionic interactions, to yield high-efficiency enzyme storage; Reproduced with permission from Ref. [192], Copyright 2014, Elsevier; b schematic illustration of the three-dimensional highway-like graphite/carbon fiber (G/CF) hybrid electrode adopting a three-electrode configuration; reproduced with permission from Ref. [194], Copyright 2022, Elsevier; c schematic illustration of the formation of GQDs assembly and AuPd–ANPs decorated GQDs assembly. Step i: electrodeposition of GQDs on ACF using OTF as the electrolyte to form a close-pack GQDs assembly; Step ii: electrodeposition of AuPd–ANPs on ACF on GQDs; Reproduced with permission from Ref. [195], Copyright 2018, Elsevier

Tao et al. [193] designed a three-layer composite design that resolves sensor damping and the low-quality factor of CF-based acoustic biosensors. These problems are caused by the rough CF surface and difficulty in coating the voltage layer. The CFs were coated first with a polyimide (PI) layer, and then with a ZnO film. On the PI/CF structure, biosensor comprising the composite electrode could be effectively used for glucose monitoring [193]. To accelerate the slow electron transfer process after the enzyme–substrate reaction, Yi et al. [194] improved the sensing performance of carbon-based materials and then fabricated CF frames from carbon paper. Finally, they embedded a graphite sheet in a CF frame, forming a hybrid electrode for monitoring glucose electrodes (Fig. 13b). The hybrid electrode delivered good electrochemical performance without requiring a chemical pretreatment to remove adhesives or nanomaterials that increase the cost of carbon electrodes. The CF matrix improved the sensitivity and detection limit of the graphite electrode and a wide linear response range [194]. Hydrogen peroxide has been detected by sensors based on precious metals and alloy NPs, which avoid the complex and expensive fixation procedures required for natural enzyme biosensors. Xu et al. [195] coated CFs with Gr quantum dot components modified with gold platinum alloy NPs, forming double nano-enzyme-modified microelectrodes (Fig. 13c). Flexible microelectrodes based on CFs achieve high temporal and spatial resolution, fast electronic and mass transfer, and excellent mechanical strength and flexibility in real-time and in situ monitoring of biological signals [195].

DNA Biosensors

DNA biosensor recognizes molecular DNA and converts reactions with substances to a detectable process. DNA biosensors are applied in food, medicine, and environmental monitoring. The key step of DNA biosensors is fixing the DNA probe on the electrode to capture the substance to be measured and to convert the signal. The reaction between the biological receptor and the target is carried out on the surface of the electrode. The biological reaction between the biological receptor and the target can produce or consume ions or electrons, and change the current, potential and other properties of the solution. Biological signal generated by the change is converted by the transducer into a detectable signal proportional to the concentration of the target and displayed on the computer [196]. Its basic principle is shown in Fig. 14a. Mechanism of DNA biosensor is based on the affinity between DNA nanostructure and target analyte, which has the advantages of fast response, high sensitivity, low cost and easy to use. Therefore, when researching and developing DNA biosensors, researchers seek high-efficiency, and high-activity DNA fixation methods. CFs are popular electrode materials for DNA biosensors owing to their high mechanical stability, excellent conductivity, and large relative surface area. They can not only accelerate the electron transfer rate at the interface, but also connect the biomolecules to the conductor of the electrode [197]. CF can be used as signal molecular carrier because of its unique physical, chemical and electrochemical properties. Dogru et al. [198] constructed a CF electrode DNA biosensor with methylene blue (MB) as an indicator. The preparation process of the DNA biosensor is shown in Fig. 14b. First, a preliminary study was conducted to determine the optional MB accumulation time, ssDNA concentration and hybridization time. The MB voltammetry of CF microelectrode (CFME), ssDNA-modified CFME and dsDNA-modified CFME was monitored under optimal conditions. The results show that the biosensor has a good ability to detect specific DNA sequences [198].

Immune Biosensors

Immune biosensor recognizes the response of an antigen to an antibody. An immobilized antibody or antigen combines with substances in the detection environment to form an immune complex. The quantitative conversion and the amplification of information from the process reaction directly give the concentration of the detected substance. Immune-response sensors can detect viruses, bacteria, proteins and parasites. Immune biosensors have become powerful tools in clinical diagnosis, environmental monitoring and food safety applications because of their high specificity [200]. Transducers for these sensors include antibodies that are immobilized through covalent interactions by introducing functional groups, such as carboxyl, amino, aldehyde or sulfhydryl groups [201]. The working principle is based on detecting, processing and displaying signals caused by the formation of antibody–antigen complexes [200]. Figure 15a depicts some possible immunoassay combination configurations. Owing to the huge surface area of CFs, multiple antibody–antigen proteins can be immobilized and are suitable for immune biosensors. Zahrawi et al. [202] successfully functionalized a CF-modified electrode to fix spike proteins and coated the biosensor with cotton. A biosensor developed for the Middle East respiratory syndrome coronavirus (MERS-CoV) achieves high sensitivity, accuracy, reproduction, and selectivity, and is an effective tool for MERS-CoV detection [202]. CF is mainly composed of carbon atoms with a diameter of about 5–10 μm, which has overwhelming advantages. Therefore, the CF microelectrode prepared by CF has small volume, high sensitivity and good electrochemical performance. It is simple to make and can be used to construct the substrate of electrochemical sensor. A novel electrochemical immune biosensor platform was designed by Chen et al. for the detection of LCN2 in human body fluids on CF microelectrodes functionalized with anti-LCN2 antibodies [203]. They performed in sandwich mode using thionine-coordinated BCN nano-sheets and horseradish peroxidase-labeled LCN2 detection antibodies (Fig. 15b). Thionine, as an electronic medium, and horseradish peroxidase, as a biological active enzyme with high catalytic rate, were fixed on the CF microelectrode, and they showed high voltammetry under the synergistic effect. Meanwhile, it was found that the immune sensing system based on BCN showed good electrochemical response to the target LCN2 in the range of 0.001–10 ng/mL.

a Possible immunoassay binding configurations: (I) sandwich structure formation, (II) competitive style immunoassays, (III) extended sandwich structure formation, (IV) sandwich structure formation on a (micro-nanoparticle) surface [204]; b schematic illustration of boron carbon nitride (BCN) nanosheet-based electrochemical immunoassay toward lipocalin-2 (LCN2) on monoclonal mouse anti-human (5G5) lipocalin-2 antibody-modified carbon-fiber microelectrode using peroxidase/thionine/biotinylated antibody-conjugated BCN nano-sheets as the detection antibody; reproduced with permission from Ref. [203], Copyright 2018, Elsevier

Implantable Biosensors

CFs are widely used as microelectrodes in implanted biosensors for medical applications owing to their extremely small size, good performance, stable structure, low cost, and high biocompatibility. For these reasons, they have attracted considerable attention in biology and life sciences. Other fiber materials can easily cause inflammation in the body. The good biocompatibility, simple manufacturing process, and low cost of CFs are desirable properties for manufacturing implantable devices and developing practical applications. CF-based biosensors are widely used to monitor human physiological indices and cellular active components [205]. Charles et al. [206] proposed that to avoid tissue damage after inserting traditional enzyme biosensors with a platinum electrode into the brain, the large platinum electrode could be replaced with platinum-plated CF microelectrodes. During tests, the CF-based biosensor monitored hydrogen peroxide and enzymes in brain fluid with higher sensitivity than the traditional sensor [206]. Yan et al. [207] modified a highly ordered nitrogen-doped CNT array by developing a flexible nanohybrid microelectrode based on CFs modified with Au NPs (Fig. 16a). The flexible hybrid microelectrode delivered excellent performance and could effectively monitor the hydrogen peroxide secreted by cancer cells [207]. CF electrodes also avoid the high cost and large size of enzyme biosensors using an oxidase micro-platinum-based electrode for hydrogen peroxide measurements. To improve the monitoring sensitivity of CF-based biosensors for hydrogen peroxide, Wang et al. [208] electro-metallized CFME through Pt NP electrodeposition and deposited permeable layers of polyaniline and Nafion. The CF-based biosensor showed higher sensitivity to hydrogen peroxide and higher resolution in physiological-related detection [208].

a Schematic illustration of the fabrication procedure of CF@NCNTAs-GNPs nanocomposite. Step i: growth of ZnO-NRAs on CF via hydrothermal process; Step ii coating PDA layer on ZnO-NRAs via polymerization of DA; Step iii: decorating GNPs on PDA layer via chemical reduction of KAuCl4 precursor by catechol groups of PDA. Step iv: carbonizing and removing ZnO-NRAs template; reproduced with permission from Ref. [207], Copyright 2018, Elsevier. b (I) carbon fiber microelectrode, and (II) the process of electrode modification; reproduced with permission from Ref. [209], Copyright 2005, Elsevier

Tian et al. [209] electrodeposited gold nanoparticles modified with cysteine onto an implantable CFME (Fig. 16b(I)), and then fixed superoxide dismutase (SOD) onto the electrode (Fig. 16b(II)). The direct electrochemical action of SOD fixed on the CFME-based electrode was achieved by electron transfer promoter (the limit deposit of cysteine molecules on the CFME). The study found that the CFME-based biosensor has an amazing ability to analyze and measure O2·− properties. Meanwhile, the synthetic CFME-based biosensor has excellent performance, such as optional operating potential, high selectivity, high sensitivity and good stability. Anmad et al. [210] fixed glucose oxidase onto chemically modified CF to create a novel implantable electro-catalytic glucose monitoring that is capable of measuring directly glucose concentration during glucose infusion. It allows for more refined glucose control in patients with diabetes because the implantable biosensor is not subject to biocompatibility glitches.

Perspectives and Outlook

BES must generate or realize a reduction reaction with a certain potential through electron transfer between an electron acceptor and donor. Most researchers focus on the selection and optimization of electrode materials, which are paramount for the electron transfer process. CFs are the most used commonly electrode materials in BESs. Because CFs form different morphologies and structures, they usually exhibit physiological activities facilitating their interaction with microorganisms. When used as the anode material, CFs can significantly promote the colonization of microorganisms at the interface and accelerate the formation of extracellular biofilm. CFs provide a conducive environment for extracellular electron transport and ultimately improve the electrical power density. When used as the cathode material, CFs can catalyze ORRs with high activity and efficiency. The pioneering CF electrodes have greatly progressed in this field. Nevertheless, some problems cannot be avoided. First, CFs in applications shoe low bacterial adhesion activity, low amounts of biofilm formation, and low output power. Current research focuses on modifying and optimizing of the electrode materials to improve the electron transport pathway and enhance the stability of bacteria on an electrode surface. Second, when modifying CF-based electrodes, an efficient and significant modification method that can be widely used and that maximizes the power output is required. Third, single CFs cannot meet the current needs and require combination with other metal- or non-metal-based materials to compensate the limitations of CFs. Owing to their lightweight and simple preparation, the porosity, surface area, chemical structure and surface function of CFs can be customized for specific uses, targeted optimization, and performance improvement. Structural change is a feasible alternative to material modification. For example, changing a 2D structure to 3D structure can increase the contact area with air and provide favorable conditions for combining oxygen and electrons [211].

Conclusion

With their high strength-to-weight ratio, CFs are more attractive energy saving materials than traditional strength-bearing materials such as steel. Lightweight, corrosion-resistant CFs are widely used in many fields, and constitute the highest proportion of BES applications. They are especially popular as electrode materials in various biofuel cells or as significant components in biosensors. However, as pure CF cannot meet the needs of laboratory applications, it is modified by a variety of effective modification methods. CFs modified with different nano-functional materials overcome the drawbacks of unmodified CFs and exploit the advantages of CFs while saving costs and improving the battery performance. In addition, CFs can be customized to a required structure, morphology, or porosity. Such a modified CF can achieve more targeted bacterial binding, reduce the incubation time, and shorten the experimental cycle. Numerous methods of surface functionalized CFs are exploited in bioelectrochemistry. The application of CF electrodes in bioelectrochemistry establishes the connection among CFs, electrochemical analysis technology, and cellular-level biomolecular detection. At present, applications of CF electrodes have also been explored in clinical medicine. In future work, researchers could explore other bioelectrochemistry applications of CFs along with techniques to improve their efficiencies. Such applications might also be combined with other fields to solve practical problems.

References

Li D, Long X, Wu Y, Hou H, Wang X, Ren J, Zhang L, Yang D, Xia Y. Hierarchically porous and defective carbon fiber cathode for efficient Zn-air batteries and microbial fuel cells. Adv Fiber Mater. 2022;4(4):795.

Chen M, Wang Z, Li K, Wang X, Wei L. Elastic and stretchable functional fibers: a review of materials, fabrication methods, and applications. Adv Fiber Mater. 2021;3(1):1.

Lim TH, Kim MS, Yeo SY, Jeong E. Preparation and evaluation of isotropic and mesophase pitch-based carbon fibers using the pelletizing and continuous spinning process. J Ind Text. 2019;48(7):1242.

Aldosari SM, Khan M, Rahatekar S. Manufacturing carbon fibres from pitch and polyethylene blend precursors: a review. J Mater Res Technol. 2020;9(4):7786.

Zhang F, Chen J, Yang J. Fiber materials for electrocatalysis applications. Adv Fiber Mater. 2022;4(4):720.

Das TK, Ghosh P, Das NC. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: a review. Adv Compos Hybrid Mater. 2019;2(2):214.

Shirvanimoghaddam K, Hamim SU, Karbalaei Akbari M, Fakhrhoseini SM, Khayyam H, Pakseresht AH, Ghasali E, Zabet M, Munir KS, Jia S, Davim JP, Naebe M. Carbon fiber reinforced metal matrix composites: fabrication processes and properties. Compos Part A. 2017;92:70.

Oroumei A, Naebe M. Mechanical property optimization of wet-spun lignin/polyacrylonitrile carbon fiber precursor by response surface methodology. Fibers Polym. 2017;18(11):2079.

Dong C, Davies IJ. Effect of stacking sequence on the flexural properties of carbon and glass fibre-reinforced hybrid composites. Adv Compos Hybrid Mater. 2018;1(3):530.

Liu Y, Kumar S. Recent progress in fabrication, structure, and properties of carbon fibers. Polym Rev. 2012;52(3–4):234.

Fang W, Yang S, Wang X-L, Yuan T-Q, Sun R-C. Manufacture and application of lignin-based carbon fibers (LCFs) and lignin-based carbon nanofibers (LCNFs). Green Chem. 2017;19(8):1794.

Poursorkhabi V, Abdelwahab MA, Misra M, Khalil H, Gharabaghi B, Mohanty AK. Processing, carbonization, and characterization of lignin based electrospun carbon fibers: a review. Front Energy Res. 2020;8:208.

Hindatu Y, Annuar MSM, Gumel AM. Mini-review: anode modification for improved performance of microbial fuel cell. Renew Sustain Energy Rev. 2017;73:236.

Zhu Y, Ji J, Ren J, Yao C. Ge L Conductive multilayered polyelectrolyte films improved performance in microbial fuel cells (MFCs). Colloids Surf A. 2014;455:92.

Chou H-T, Lee H-J, Lee C-Y, Tai N-H, Chang H-Y. Highly durable anodes of microbial fuel cells using a reduced graphene oxide/carbon nanotube-coated scaffold. Bioresour Technol. 2014;169:532.

Khayyam H, Jazar RN, Nunna S, Golkarnarenji G, Badii K, Fakhrhoseini SM, Kumar S, Naebe M. PAN precursor fabrication, applications and thermal stabilization process in carbon fiber production: experimental and mathematical modelling. Prog Mater Sci. 2020;107: 100575.

Der A, Dilger N, Kaluza A, Creighton C, Kara S, Varley R, Herrmann C, Thiede S. Modelling and analysis of the energy intensity in polyacrylonitrile (PAN) precursor and carbon fibre manufacturing. J Clean Prod. 2021;303: 127105.

Ye C, Wu H, Huang D, Li B, Shen K, Yang J, Liu J, Li X. The microstructures and mechanical properties of ultra-high-strength PAN-based carbon fibers during graphitization under a constant stretching. Carbon Lett. 2019;29(5):497.

Golkarnarenji G, Naebe M, Badii K, Milani AS, Jazar RN, Khayyam H. Support vector regression modelling and optimization of energy consumption in carbon fiber production line. Comput Chem Eng. 2018;109:276.

Kausar A. Polyacrylonitrile-based nanocomposite fibers: a review of current developments. J Plast Film Sheet. 2019;35(3):295.

Ahn H, Yeo SY, Lee B-S. Designing materials and processes for strong polyacrylonitrile precursor fibers. Polymers. 2021;13(17):2863.

Fakhrhoseini SM, Khayyam H, Naebe M. Chemically enhanced wet-spinning process to accelerate thermal stabilization of polyacrylonitrile fibers. Macromol Mater Eng. 2018;303(8):1700557.

Nunna S, Naebe M, Hameed N, Fox BL, Creighton C. Evolution of radial heterogeneity in polyacrylonitrile fibres during thermal stabilization: an overview. Polym Degrad Stab. 2017;136:20.

Khayyam H, Fakhrhoseini SM, Church JS, Milani AS, Bab-Hadiashar A, Jazar RN, Naebe M. Predictive modelling and optimization of carbon fiber mechanical properties through high temperature furnace. Appl Therm Eng. 2017;125:1539.

Youn YS, Kim S. Real-time atomic force microscopy imaging of collagen fibril under ultraviolet irradiation. J Ind Eng Chem. 2016;42:15.

Khayyam H, Naebe M, Bab-Hadiashar A, Jamshidi F, Li QX, Atkiss S, Buckmaster D, Fox B. Stochastic optimization models for energy management in carbonization process of carbon fiber production. Appl Energy. 2015;158:643.

Zhang XY, Xu JJ, Wu JY, Shan F, Ma XD, Chen YZ, Zhang T. Seeds triggered massive synthesis and multi-step room temperature post-processing of silver nanoink-application for paper electronics. RSC Adv. 2017;7(1):8.

Nunna S, Creighton C, Hameed N, Naebe M, Henderson LC, Setty M, Fox BL. Radial structure and property relationship in the thermal stabilization of PAN precursor fibres. Polym Test. 2017;59:203.

Frank E, Ingildeev D, Buchmeiser MR. 2—high-performance PAN-based carbon fibers and their performance requirements. In: Bhat G, editor. Structure and properties of high-performance fibers. Oxford: Woodhead Publishing; 2017. p. 7–30.

Yang J, Nakabayashi K, Miyawaki J, Yoon S-H. Preparation of isotropic pitch-based carbon fiber using hyper coal through co-carbonation with ethylene bottom oil. J Ind Eng Chem. 2016;34:397.

Baker DA, Rials TG. Recent advances in low-cost carbon fiber manufacture from lignin. J Appl Polym Sci. 2013;130(2):713.

Frank E, Steudle LM, Ingildeev D, Spoerl JM, Buchmeiser MR. Carbon fibers: precursor systems, processing, structure, and properties. Angewandte Chemie-International Edition. 2014;53(21):5262.

Takanohashi T, Shishido T, Kawashima H, Saito I. Characterisation of hyperCoals from coals of various ranks. Fuel. 2008;87(4):592.

Wang S, Lu A, Zhang L. Recent advances in regenerated cellulose materials. Prog Polym Sci. 2016;53:169.

Okolie JA, Nanda S, Dalai AK, Kozinski JA. Chemistry and specialty industrial applications of lignocellulosic biomass. Waste Biomass Valoriz. 2021;12(5):2145.

Chen X, Yan N. Novel catalytic systems to convert chitin and lignin into valuable chemicals. Catal Surv Asia. 2014;18(4):164.

Chatterjee S, Saito T, Bhattacharya P. 11-lignin-derived carbon fibers, in lignin in polymer composites. In: Faruk O, Sain M, editors. 2016, William Andrew Publishing. pp. 207–216.

Souto F, Calado V, Pereira N Jr. Lignin-based carbon fiber: a current overview. Mater Res Express. 2018;5(7): 072001.

Kadla JF, Kubo S, Venditti RA, Gilbert RD, Compere AL, Griffith W. Lignin-based carbon fibers for composite fiber applications. Carbon. 2002;40(15):2913.

Tomani P. The lignoboost process. Cellul Chem Technol. 2010;44(1–3):53.

Mohan SV, Mohanakrishna G, Velvizhi G, Babu VL, Sarma PN. Bio-catalyzed electrochemical treatment of real field dairy wastewater with simultaneous power generation. Biochem Eng J. 2010;51(1–2):32.

ElMekawy A, Srikanth S, Bajracharya S, Hegab HM, Nigam PS, Singh A, Mohan SV, Pant D. Food and agricultural wastes as substrates for bioelectrochemical system (BES): the synchronized recovery of sustainable energy and waste treatment. Food Res Int. 2015;73:213.

Patil SA, Gildemyn S, Pant D, Zengler K, Logan BE, Rabaey K. A logical data representation framework for electricity-driven bioproduction processes. Biotechnol Adv. 2015;33(6):736.

Bajracharya S, Sharma M, Mohanakrishna G, Benneton XD, Strik DPBTB, Sarma PM, Pant D. An overview on emerging bioelectrochemical systems (BESs): technology for sustainable electricity, waste remediation, resource recovery, chemical production and beyond. Renew Energy. 2016;98:153.