Abstract

In this paper, the up-to-date state of polyepichlorohydrin-based electrolytes is reviewed. Research works are persistently ongoing to develop free-standing solid polymer electrolytes with exceptional performances and stabilities that can suit the needs of present and next-generation technologies. Polyepichlorohydrin (PECH), for example, is one of the polymer hosts under consideration due to its ether electron donor groups that deliver coordinating spots for cation transport as well as alkyl chloride groups for changing its surface character. Because of this structure, PECH has certain incredible characteristics including small glass transition temperature (Tg), tremendous flexibility, as well as the power to form complexation with diverse salts. Furthermore, the alkyl chloride groups serve as a location for surface modification of the polymer via nucleophilic substitution reactions, resulting in surface changes or bulk properties. As a result, the PECH in chemically modified or pristine form is an emerging option that has been researched and is being considered for use in energy storage devices. This paper reviews the latest studies on the improvements of PECH-based electrolytes for lithium-based battery storage systems. The synthesis methods of PECH polymer, types of lithium batteries, and opportunities and challenges of lithium batteries have been presented briefly. Findings on PECH-based electrolytes have been presented and discussed thoroughly. Lastly, the paper presents, battery performance needs, and cation transportation mechanisms as well as future prospects for the advancement of PECH electrolytes in the field of storage systems.

Article Highlights

-

The alkyl chloride groups of polyepichlorohydrin polymer play a significant role in modifying the characteristics of the polymer through chemical reactions.

-

The inherent characteristics of PECH-based polymers including their amorphousity, glass transition temperature, functionality, and others can be altered via chemical and physical means.

-

The impressive electrochemical characteristics of PECH-based electrolytes make them a viable option for energy storage/conversion devices applications as electrolytes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The need for clean and renewable energy is increasing worldwide as a result of an increase in global temperature due to CO2 emissions, which will be met by developing efficient energy storage and conversion devices. These devices store the harnessed energy in chemical form and convert it back to electrical energy when needed. Rechargeable batteries such as Lithium Ion Batteries (LIBs) are examples of such efficient energy storage devices. LIB has been progressively developed and expanded as energy storage and conversion hotspots for modern society due to their ubiquitous use in consumer markets such as PCs, cameras, cell phones, and other devices [1,2,3,4,5,6,7,8,9,10]. Moreover, LIB has sparked large interest since its commercialization in 1991(11) due to its higher energy content compared to other alkali metal batteries [12, 13], see Fig. 1. However, the currently available LIBs have limitations ensuring the safety of their operations and high costs, hence attempts to address these problems led to the emergence of LIBs with polymer electrolytes [14,15,16,17,18]. In addition to solving the flammability, volatility, toxicity, and other issues of the existing LIBs, polymer electrolytes (PEs), for example polyepichlorohydrin (PECH) based electrolytes, enable the application of high-energy electrode materials such as Li–S systems [19]. PECH is a linear polymer composed of epichlorohydrin monomers, an appealing alternative for PEs synthesis due to its ether groups which promote ionic transport. The presence of lone pair of electrons \({(-{\mathrm{CH}}_{2}{-\mathrm{ CH}(\mathrm{CH}}_{2}\mathrm{Cl})-\ddot{\mathrm{O}}-)}_{n}\) in the polymer backbone gives PECH its solvation power, allowing it to easily form complexes with salts and offering direct channels for cation passage. Furthermore, the halogen groups (i.e. chlorine atoms) of PECH serve as a site for the surface modification of the polymer [20]. Hence, PECH is one of the researched polymer hosts due to its flexible backbone and capacity to solvate ions.

Energy density diagram of different batteries [21]

Though PEs including PECH-based electrolytes emerged as a viable solution to the weaknesses of the existing LIBs, they strongly suffered from poor ionic conductivity and high interfacial resistance when compared to their liquid counterparts. These limitations of PEs severely limit their practical applications, necessitating ground-breaking research, particularly to address the poor ionic conductivity of PEs at room temperature. Many research groups have attempted to meet the practically minimal conductivity requirements (i.e. 10–3 S/cm), but none have been successful. The majority of research has focused on improving the amorphousness, glass transition temperature, and functional groups of polymeric hosts and/or their electrolytic systems, which are critical for improving polymeric host segmental mobility as well as the amounts of salts to be dissociated. However, some of the approaches used to improve the conductivity of PEs were found to harm the system's dimensional (i.e. mechanical) stability, raising safety concerns. As a result, critical trade-off research between conductivity and mechanical stability should be carried out. Furthermore, the effect of physical entanglement of polymeric chains on the translational and rotational motions of PEs, and thus on the conductivity of PEs, has never been studied and should be taken into account. This review focuses on PECH-based energy storage/conversion devices and reviews the different approaches employed to enhance the conductivity of PECH-based electrolytes. Furthermore, the polymerization of epichlorohydrin monomers, and lithium battery types as well as the future perspectives of these batteries are discussed. The latest outcomes of PECH-based electrolytes as an essential part of batteries are the focus area of this review paper. Technical challenges of PEs and perspectives for future research are presented. Section 2 discusses the energy density of various energy storage and conversion systems (Ragone plot) as well as the various types of lithium batteries. Section 3 describes the synthesis of polyepichlorohydrin polymers as well as the methods for modifying polyepichlorohydrin polymers. Section 4 discusses the electrochemical properties of Polyepichlorohydrin-based electrolytes in their pristine, blended, copolymerized/cross-linked, composite, plasticized, and gel forms. Sections 5, 6, 7, respectively, deal with the ion transport mechanisms and performance requirements of PECH electrolytes, the opportunities and challenges of lithium batteries, and the conclusion and outlooks of PECH electrolytes.

2 Lithium battery as a promising energy storage device

2.1 Energy and power density of energy storage devices/Ragone plot

The various types of Energy Storage Systems (ESSs) such as batteries, capacitors, supercapacitors, flywheels, pressure storage devices, and others are compared using specific energy density and power density via the Ragone plot [22, 23]. The Ragone plot is a graph drawn by plotting the power density of ESSs (in W/kg) against the specific energy density of the devices (in Wh/kg) so that ESSs are placed in a characteristic region of the plot (Fig. 2). In such a graph, the energy density and power density axes are presented in a log–log plot so that the performances of various ESSs could be compared. In general, energy density refers to the amount of available energy, whereas, power density depicts how fast that energy can be delivered [24]. The ratio of energy to power is a straight line and is referred to as the characteristic time of an application. For batteries, for example, the discharge time is for a long time, whereas, capacitors are used for a short time. In the Ragone plot, a specific point refers to the period during which the available energy can be delivered at the power [25]. Ragone plots are very interesting to depict the upper and lower boundary of the existing power and energy of an ESS and also the optimal working region of the devices where both energy and power are reasonably high. As a result, the power density required for the application plays a big role in deciding which ESS to use.

Ragone plot for various energy storage systems [26]

2.2 Lithium battery types

The PECH-based electrolytes could be efficiently employed in different types of rechargeable lithium batteries like lithium Metal Batteries (LMBs), Li-ion Batteries (LIBs)/Li-ion polymer batteries (LIPBs), lithium-sulfur Batteries (LSBs), and Lithium-Oxygen (air) Batteries (LABs) [25] with different energy density due to the difference in electrode materials. Metallic lithium with the topmost theoretical capacity of 3860 mAh g–1 and lowermost electrochemical potential (–3.04 V versus the standard hydrogen electrode) is supposed to be used as the anode in LMBs, LSBs, and LABs with ultrahigh theoretical energy densities [27]. LMB is constructed with a metallic lithium anode and a lithium intercalation oxide and the battery could be assembled with PEs either in a charged or discharged state. Regardless of the cathode material, LMBs possess a theoretical energy density of 400 ~ 1000 Wh kg−1 [28]. But the poor ionic conductivity of PEs at low temperature, a delicate balance between conflicting demands of mechanical strength, ionic conductivity, and wide operational potential window for high-voltage applications should be secured and solved for viable practical applications as these issues potentially affect the electrochemical performance of the battery, becoming technical challenges for developing practical LMBs. For improving the performance of LMBs, more research activities focusing on these challenging issues should be carried out. LIPBs are composed of graphite or hard carbon anodes and lithium intercalation metal oxide cathodes, built for addressing the safety problems of LMBs. However, the energy density of these batteries is lower than that of LMB, lower than 300 Wh/kg [29]. The presence of a polymer matrix in these batteries makes them more stable and less prone to problems associated with electrolyte leakage and volatility, overcharging, or abuse. However, the effective surface area of the electrodes and thus the power capacity are limited. LIPBs, with a voltage of 3.7 V, are widely used in portable devices. The research areas of LIPBs include improving energy density, conductivity, interfacial resistance, and other issues of batteries. LAB is a lithium battery in which the anode is made of metallic lithium and hence lithium is oxidized at the anode, while the cathode is made of mesoporous carbon with a metal catalyst acting as an oxygen host material where oxygen from the air is reduced. LABs may be constructed using solid electrolytes and the electrochemical details of the system are determined by the types of electrolytes used in these batteries. LABs are appealing for electric vehicle applications owing to the energy density they possess. The larger voltage hysteresis between charging and discharging, and oxygen (air) handling are some of the problematic issues of LABs. LSBs, composed of a sulfur cathode and a metallic lithium anode, attract the attention of battery developers and researchers because of their higher energy density, the abundance of sulfur elements, and eco-friendly [30]. In comparison with LIB, LSB possesses a theoretical gravimetric energy density of 2,510 Wh/kg, which is 8 times greater than that of the traditional LIBs [29, 31], and also sulfur provides a theoretical capacity of around 1,675 mAh/g, which is larger than the capacity of cathode materials in Li-ion batteries [29, 31, 32]. As sulfur is an electron insulator, a carbon matrix is used to form the cathode, yielding a cell voltage of about 2 V. LSBs could be constructed with PEs. Due to the potential limitations of LSBs including relatively low practical energy density against the expected value, rapid decline in capacity during cycling, and high self-discharge rate (8–15% per month), they are not still commercialized [33]. Moreover, lithium anode is corrosive, and the poor electronic conductivity of sulfur and significant volume change (80%) during cycling are some of the additional limitations of LSBs that hamper their commercialization [29, 32] and hence looking for more appropriate electrolytes for LSBs are critical. All in all, the application of PECH-based electrolytes in LMB, LAB, and LSB has not been investigated, and hence needs consideration.

3 Synthesis of polyepichlorohydrin polymer (PECH)

PECH is a synthetic polymer with a reactive functional alkyl chloride group that was first created in the 1950s by catalytic ring opening polymerization of epichlorohydrin monomer (ECH, \(-{\mathrm{CH}}_{2}{-\mathrm{ CH}(\mathrm{CH}}_{2}\mathrm{Cl})-\ddot{\mathrm{O}}-\)) (Fig. 3a) [34, 35]. PECH, which could be applied in different fields due to its unique characteristics such as oil, heat, fuel, and ozone resistance, as well as its low-temperature flexibility, can be classified as isotactic or atactic depending on how the alkyl chloride groups are arranged. Isotactic PECH, which is a semi-crystalline polymer, was initially prepared in 1954 by Pruitt and Baggett while atactic PECH, an amorphous polymer, was later synthesized in 1957 by EJ Vandenberg ECH polymerization via Anionic Ring-Opening Polymerization (AROP) is difficult due to its alkyl chloride functional group, which renders ECH incompatible with the reaction and thus unpolymerizable via AROP. As ECH possesses two functional groups, epoxide, and alkyl chloride, it undergoes different chemical transformations when combined with different reactive components (Fig. 3b) either along the epoxides or along the alkyl chloride pendant groups. The pendant groups (i.e., alkyl chloride groups) play a significant role in minimizing the crystallinity of PECH membranes [36], demonstrating that -CH2Cl has a strong influence on the flexibility of the polymer chains.

a Synthesis of PECH, b synthesis of functional epoxides from ECH, c PECH post modification reactions, d copolymers based on ECH, e and f ROP mechanisms of ECH [34]

The polymerization conditions, particularly the type of initiators used, determine the microstructure and molecular weight of PECH (i.e., amorphous or semi-crystalline). PECH homopolymer is mostly synthesized using cationic or organometallic initiators [37], and in the cationic catalytic process, Lewis acids or tertiary oxonium salts serving as cation initiators are complexed with water, alcohol, or ether to produce atactic low molecular weight PECH having –OH end groups. On the other hand, telechelic PECH with higher molecular weight (\(\le\) 15 × 103 g/mol) could be prepared using 1, 4-butanediylditriflate as the initiator. However, the majority of modern PECH is synthesized via the Vandenberg process [35] with organometallic initiators, yielding high molecular weight PECH with a fraction of atactic and isotactic parts.

Polymers synthesized with ECH monomer could be modified after the polymerization reactions, primarily along the alkyl chloride groups, using a variety of nucleophilic substitution reactions, as shown in Fig. 3c. ECH monomer could also be used as a monomer to synthesize other polymers such as polyethers, polyesters, poly (thio) carbonates, and others, as shown in Fig. 3d. Mostly, the copolymerization reactions of ECH monomers are difficult and incompatible for AROP owing to the reactiveness of -CH2Cl groups. However, since the 1950s, the Vandenberg process has been widely used to produce copolymers containing ECH monomers. Cationic Ring Opening Polymerization (CROP) reactions are used to polymerize ECH monomers. The CROP of ECH is carried out via two mechanisms, namely the Activated Chain End mechanism (ACE) and the Activated Monomer (AM) mechanism (see Fig. 3e and f) [34, 38]. The ACE mechanism generates oligomeric linear and cyclic PECH polymers as a result of ECH side reactions with water, protonic acids, organic salts, and Lewis acids, which result in chain transfer, backbiting, and termination reactions. In this method, the propagating center is formed by the oxonium ion at the chain end and the propagation reaction is initiated by a combination of protogenic species like water and protonic acids, organic salts, and Lewis acid. In ACE, cyclic polymers are formed due to the intramolecular chain transfer reaction, which decreases the molecular weight of the end product and the yield of the reaction but increases the polydispersity of the polymer, hence producing undesirable products through cyclization reactions [46]. AM techniques, on the other hand, are used to polymerize epoxides in the presence of alcohol. In this method, the ECH monomer forms an ionic complex with a protonic species like alcohol and the polymer chain end is neutral, which reduces backbiting, leading to the formation of high molecular weight and linear polymer. In contrast to ACE, the concentration of ECH monomer should be low during polymerization reaction and this can be accomplished by slow addition of ECH to the reaction. The properties of PECH including its Molecular Weight (MW), polydispersity (PD), fraction of cyclic formation and others depend on polymerization conditions such as reaction temperature, type of initiators, rate of monomer addition, and others. Guanaes et al.[38], for instance, investigated the impact of polymerization conditions on the MW and PD of PECH using alcohol as the solvent. They discovered that the MW of the polymer was affected by the reaction temperature and monomer addition rate, whereas, the PD was strongly affected by the monomer addition rate and decreased as the monomer addition rate was reduced, indicating homogenous polymer fabrication. At a lower precursor addition rate and a higher reaction temperature, higher molecular weight PECH was produced.

4 PECH based electrolytes

4.1 Pristine PECH-based electrolytes

Polymers, in contrast to their insulating qualities, have been identified as ionic conducting qualities since 1973 [39], resulting in a larger emphasis on polymer electrolyte-based investigations. However, their low ionic conductivity and crystalline property at ambient temperature make them unsuitable for practical applications. To address these issues, different approaches including modifying the structure of polymers either through physical means or chemical means have been proposed and the proposed approaches are desired to improve the performances of PEs including their strength but still becoming ideal issues [31]. It is well recognized that cation transport mainly occurs along the amorphous regions of the system, while the crystalline region supports the stability of the system. Hence, compromising the ionic mobility with the stability of the system becomes a technical problem in polymer electrolytes. The conductivity of pristine PECH electrolytes was investigated in 1992 and was found to have an ionic conductivity of 2 × 10–9 S/cm at 30 C [36] which is far away from the desired conductivity for practical applications. This is attributed to the structural stiffness of the host which restricts its segmental motion. Hence, for enhancing its conductivity at low temperatures, different approaches, as discussed in Sect. 4.2, have been proposed and confirmed to yield appreciable enhancements.

4.2 PECH combination with other polymers

4.2.1 PECH blended with other polymers

Polymer blending is one of the proposed methods investigated for improving the performances and stabilities of PECH-based electrolytes [40]. Polymer blending, as the name implies, is the physical mixing of two or more polymers/copolymers in a common solvent for synthesizing membranes with improved properties for the required applications[41]. The properties of blends strongly depend on the processing conditions, composition, and miscibility of parental polymers, as well as the interaction forces between polymers. To synthesize promising electrolytes, polymers with complementary properties should be blended. Blends of polymers could be classified as miscible forming homogeneous structures and immiscible forming heterogeneous structures. Immiscible blends exhibit multiple amorphous phases with more than one Tg value, whereas, miscible blends have a homogenous morphology with a single Tg. In electrolytic application, polymers are blended for a variety of purposes: (1) to increase the number of functional motif groups, (2) to lower the crystallinity of the hosts, (3) to lower the glass transition temperature, (4) to ensure the mechanical integrity of the system, and (5) to enhance the stability of the system and others, which will promote the performances of the system. Hence, the research on the polymer blending is ongoing for fabricating suitable blend electrolytes. PECH could be blended with variety of polymers such as PAN, PEO, PMMA, poly (ethylene oxide-co-allyl glycidyl ether), PVA, and others to improve its electrochemical performances and thermal properties. In synthesizing efficient polymer blend membranes, the parental polymers should be interacted through strong physical forces for reducing the Tg values and crystallinity of the system. However, it is familiar to see immiscible polymers have been blended and the amorphousity of the system appears to be increased through segregation of molecules. Off course, such immiscible polymers could be interacted by incorporating additional polymer/ oligomer that can be interacted with the immiscible components simultaneously though the effect of such additional component on the electrochemical performance of PEs has not been investigated. The thermal properties and conductivities of some of the PECH based blend membrane electrolytes are shown in Table 1.

The effect of parental polymer composition, electrolyte immersion time, and temperature on the stability and performances of polymer blend electrolytes (i.e. PVA-PECH blend) was investigated [40] and the pristine form of PVA exhibited a distinct XRD (2θ) peak at 20° due to its semi-crystalline nature. However, when PVA was blended with PECH, the intensity of its peaks was dramatically reduced (Fig. 4) due to a drop in PVA crystallinity and the peaks became broader and broader as the PECH concentration increased. The blended membranes, on the other hand, were found to be miscible at lower concentrations of PECH, as confirmed by SEM analysis, demonstrating that polymer miscibility is compositional dependent. With a rise in PECH concentration, the blended membranes were altered from a uniform and homogenous surface morphology to a heterogeneous morphology, yielding specific bigger polymer aggregates at a 1:0.5 ratio, and the composite membrane eventually revealed phase-separated morphology at a 1:1 ratio (PVA: PECH), resulting in poor ionic conductivity as internal resistance increased. Because of the uniform and homogeneous structure of the system, the conductivity of blended electrolytes was found to be higher at lower concentrations of PECH in the system, which correlates with SEM analyses. Furthermore, the electrolyte conductivity increased with immersion time and temperature, as predicted by the Arrhenius equation. The maximum and minimum ionic conductivity of 2.19 × 10–2 S/cm and 1.2 × 10–3 S/cm were achieved at 1:0.2 and 1:1 ratios of PVA/PECH, respectively. The system has a 2 V window potential, making it a good choice for ESSs. As the concentration of PECH grew, the mechanical characteristics of the electrolytes dropped. Ju et al. [43] synthesized polymer blend electrolytes using poly(ECO)/NBR blend hosts complexed with LiClO4/PC through solution casting methods. The dynamic mechanical analysis revealed that the ECO/NBR polymer blends are immiscible while the impedance spectroscopy analysis depicted the dependence of conductivity on LiClO4, ECO, and PC ingredients of the electrolytes. It was found that conductivity increased with the increase in ECO and LiClO4 contents due to the formation of more continuous ion-conducting pathways and an increase in the number of carriers, respectively. Fonseca et al. [42] fabricated polymer blend electrolytes using poly(dimethylsiloxane-co-ethylene oxide) (P(DMS-co-EO)) and poly(epichlorhydrin-co-ethylene oxide) (P(EPI-co-EO)) as polymer blend host and LiClO4 as salt via solution casting techniques and they studied the effect of salt content on the conductivity of PEs. Scanning electron microscopy analysis depicted that the morphology of the polymer blend membrane has been influenced by the incorporation of salts, and the amorphous phase content increased with the increase in salt concentration. The crystalline phase of the host membrane varnished with the increase in salt content due to ion complexation that acts as cross-linking nodes to decrease the degree of crystallinity, whereas, the glass transition temperature (Tg) progressively increased. The tensile strength and elongation at break of the electrolyte decreased as the salt concentration increased, which indicate an incompatible system. The maximum ionic conductivity of 1.2 × 10–4 S cm−1 was achieved in the presence of 6 Wt. % LiClO4.

The XRD spectra of PVA/PECH/KI blend solid PEs (a) pristine PVA (b) PVA/ PECH with 1:0.2 ratio, c PVA/PECH with 1:0.5 ratio, and d PVA/PECH with 1:1 ratio [40]

4.2.2 PECH copolymerized/cross-linked with other polymers

Copolymerization is a chemical reaction that involves the simultaneous polymerization of two different monomers intending to incorporate their structures into a single polymeric chain, the terms terpolymerization and multicomponent polymerization could be used to refer to polymerization of three or more monomer types, respectively. The copolymerization reaction increases the range and diversity of properties available to copolymer molecules, as well as allowing for the integration of desirable properties from various monomer units, which can be useful in a variety of applications. Copolymers do not necessarily have the same composition as the ingredient monomers they are made of, and not all comonomer combinations can polymerize. Monomers having a poor tendency for self-polymerization (i.e. homopolymerization) are more likely to form copolymers when combined with compatible comonomers. It is critical to distinguish between copolymers and polymer blends; in copolymers, the monomers are joined together by a covalent bond, and the monomers are found in a single polymer chain (produced by a chemical reaction), whereas, polymers are physically mixed and interacted through a secondary force in polymer blends. Copolymers are synthesized either by chain growth or step growth copolymerization reactions. Copolymerization is another method being extensively considered for synthesizing PEs with desired properties such as improved amorphousness, enhanced thermal and mechanical stability, a large number of polar motifs with their suitable configurations, improved electrochemical performances, and others. In copolymerization reactions, monomers could be combined in a variety of ways such as in block, random, alternative, graft, or cross-linked fashions, and hence could have diverse properties due to the diversity in microstructures. Block copolymers and graft copolymers are most frequently investigated for synthesizing PEs. In a block copolymer, one block is responsible for ionic conductivity while the other enhances the mechanical integrity of the system. On the other hand, in graft copolymer, the backbone improves the mechanical strength of the system while the grafted (branched) part improves the ionic conductivity. Hence, reasonable mechanical strength with impressive ionic conductivity could be attained in copolymerized PEs at a lower temperature. Copolymers exhibit superior properties such as disrupted structure, and dimensional stability when compared to monomers or homopolymers alone. As a result, the copolymer membranes upgrade the performances of PEs including their mechanical characteristics and electrochemical performances [44,45,46,47,48,49]. PECH polymer or its monomer could be chemically joined with other polymers or monomers via copolymerization or surface modification reactions to improve its properties, including flexibility and functional motifs. The thermal and electrochemical performances of some of the PECH based copolymer and crosslinked membrane electrolytes are depicted in Table 2.

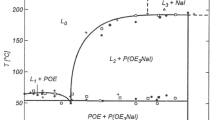

Rodrigues et al. [53] synthesized an epichlorohydrin monomer-based terpolymer electrolytes using poly(ECH-co-EO-co-allyl glycidyl ether) polymer host complexed with LiClO4 or LiTFSI salts via solution casting methods and studied their performances for PEs. DSC analysis revealed that the synthesized PEs are completely amorphous and the Tg of the electrolytes has a positive relation with salt concentration. The pristine polymer blend film was found to have Tg of -48 °C, and the Tg of an electrolyte increased with salt concentration, from low salt to salt-rich systems. This behavior could be related to the increase in interactions within polymer chains and salt cations with oxygen atoms in the polymer chains, which restricts the local motion of polymer chains. The impendence spectroscopy analysis revealed the conductivity of the copolymer electrolytes is larger when doped with LiClO4 salt than that of LiTFSI salts due to the difference in lattice energy, indicating that the nature of salts influences the ionic conductivity of PEs. The conductivity of PEs arose with the increase in salt content until it reached the optimal concentration due to the enhancement in charge carrier numbers. However, increasing salt concentration above its optimal level reduced the conductivity of the PEs due to ion aggregation and the formation of transient ionic cross-links, which reduced chain mobility. LiClO4-based PEs achieved the highest conductivity of 4.2 × 10−5 S/cm at 55 \(^\circ{\rm C}\) and the electrolyte demonstrated a broad wide potential window (around 5 V versus Li/Li+), indicating that PEs could be a viable candidate in ESSs. Kohjiya et al. [54] prepared epichlorohydrin monomer-based copolymer electrolytes using P(ECH/EO) as host and LiClO4 as salt through the solution casting method and they investigated the performances of the synthesized PEs. DSC analysis exhibited that the Tg of the copolymer was linearly shifted to lower temperature with increasing EO content due to the lowering of Tg in PEO than in PECH. Tg of the PEs, on the other hand, increased progressively with salt content due to ion aggregations. The PEs conductivity was improved with the increase in EO and LiClO4 concentration. Nithya et al. [52] fabricated PEs using LiClO4 and P(ECH-EO). DSC analysis depicted the increase in Tg of electrolytes with salt content due to ion–dipole interactions, which stiffens chains. A free-standing and amorphous electrolyte with broad peaks was produced, as revealed via XRD analysis, and the electrolytes grew more amorphous with increasing salt concentration due to salt-polymer interaction. The maximum conductivity (1.3 × 10–5 S/cm) was achieved with 15 wt% of salt at RT. Lee et al. [51] investigated the ionic conductivity of PECH-based grafted copolymer electrolytes consisting of poly (ECH-g-poly((oxyethylene) methacrylate)) copolymers complexed with potassium iodide (KI) salts through a solution casting process. FT-IR analysis revealed that new absorption bands at 1,724 and 1,034 cm−1 were formed in the graft copolymer as a result of carbonyl (C = O) and ether (–O–) stretching of POEM, respectively. Additionally, the strong band at 744 cm−1 belonging to C–Cl stretching mode in PECH declined noticeably in the graft copolymer, showing the efficacy of POEM side chains graft copolymerization on PECH backbone. The stretching band at 1,724 cm−1 was not significantly altered by salt complexation, whereas, stretching bands at 1,095 and 1,034 cm−1 were displaced to 1,091 and 1,027 cm−1, respectively. The shift in the stretching band is a possible result of the interaction between K+ and ether oxygen atoms, depicting that K+ does not interact with carbonyl oxygen atoms but with the ether oxygens. DSC analysis revealed that uncomplexed PECH-g-POEM comb copolymer has Tg of − 48 °C with no melting temperature, found its rubbery amorphous state. Tg of PEs increased with salt content till it reaches 15 wt% due to the interaction of cations with ether oxygens, causing the polymeric chain mobility to be restricted. Ionic conductivities in the graft copolymer electrolyte enhanced with salt content up to 5 wt% due to the rise in the charge carriers numbers, and then gradually decreased with salt content. The highest conductivity of 3.7 × 10−5 S/cm at 5 wt% of salt concentration was achieved. Choudhury et al. [55] synthesized epichlorohydrin monomer-based cross-linked terpolymer electrolyte using poly(ECH-EO-ally ether) polymer host and Ethylene Thiourea (ETU) and magnesium oxide cross-linkers and they investigated the influence of cross-linking on PEs conductivity and mechanical properties. The crosslinking reaction occurred at chlorine atoms of ECH via nucleophilic substitution reactions and its efficiency depends on the concentration of ETU. As shown in Fig. 5 the tensile strength and modulus of the PEs improved with increasing ETU concentration, and stronger cross-linking is required to prevent crystallization of polymer hosts. It is demonstrated that (Fig. 5b), increasing the immersion period of polymer membranes into electrolyte solution until the membranes reached saturation increased electrolyte uptake, whereas, increasing ETU decreased electrolyte uptake. The storage modulus (E') values of PEs were affected by the degree of cross-linking. With lower cross-linking density materials, the decrement effect is stronger due to the plasticizing effect of electrolyte solution, separating polymeric chains. The tan \(\delta\) plot revealed that the degree of crosslinking did not affect the Tg of the polymer hosts, but that electrolyte loading does. Tg of the electrolytes shifted with the oxygen atom of the polymer, restricting chain mobility. The conductivity of PEs declined with the increase in ETU due to the increased structural stiffness of the system, as seen in Fig. 5g. PEs prepared with the optimal concentration of both ETU and electrolyte uptake exhibited the highest conductivity in the order of 10–4 S/cm. Gazotti et al. [50] prepared epichlorohydrin-based copolymer electrolytes using poly(epichlorohydrin-co-ethylene oxide) copolymer hosts complexed with LiClO4 salts and they studied the effect of temperature, relative humidity, and salt content on the conductivity and stability of the PEs. DSC analysis revealed that as the ECH monomer content in the copolymer hosts increased, so did the Tg of the copolymer host. Moreover, Tg of PEs increased with salt concentration due to the ion–dipole interactions, cations of salt, and oxygen atoms of the polymer. The impedance spectroscopy analysis revealed that the ionic conductivity of PEs improved with the increase in EO content in the copolymer matrix because of the strong interaction between EO and Li+ when compared to ECH monomers, indicating that the molar ratio of comonomers in the copolymer hosts influenced the conductivity of PEs. Moreover, the conductivity of PEs increased exponentially with relative humidity due to the presence of moisture which facilitates ionic transport. The dry and moisturized (84%) PEs exhibited the highest conductivity of 4.1 × 10–5 S/cm and 2.6 × 10–4 S/cm, respectively, and the window potential of the electrolytes was found to be 4.0 V.

Illustration a Stress–Strain graphs for cross-linked PEs with a variation of ETU content, b electrolyte loading with respect to time at different ETU levels. The storage modulus of polymer matrix as a function of temperature at different ETU levels (c) before immersion into the electrolyte solution (d) after immersion. Tan δ as a function of temperature for the system at different ETU levels, e before dipping and (f) after dipping. g Variation of conductivity (S/cm) as a function of the amount of ETU (phr) [55]

4.3 PECH combination with fillers and plasticizers

It is worthy to distinguish between composite, plasticized, and gel PEs. Composite PEs are formed by combining PEs (i.e. PEs = polymer + salt) with ceramic fillers while plasticized PEs are the combinations of PEs and aprotic solvents or ionic liquids and the final mixture appears in solid (thin film) form. In composite and plasticized PEs, the conductivity of ionic species dominantly takes place along the polymeric membranes. On the other hand, gel PEs are the combinations of PEs and a large content of aprotic solvents or ionic liquids, and the final mixture appears in gelly or semi-liquid form. In gel PEs, the ionic conductivity of the system predominantly takes place along the liquid components and the polymer membrane mainly provides mechanical integrity to the system. Hence, the incorporation of ceramic fillers into PEs is another method that has been extensively investigated to enhance the performance of electrolytes at an ambient temperature either by lowering the crystallinity of polymeric chains or by providing an alternative way for the ionic species pathway. The ceramic fillers reduce the crystallinity tendency of polymeric chains either by segregating between chains or by interacting with polymeric chains through physical forces. In addition to improving the electrochemical performances of PEs, ceramic fillers play a significant role in reducing the reactivity of the electrodes and electrolytes, and also dendrite formation. Moreover, nanofillers improve the dimensional and thermal stability of Pes [56, 57]. However, the effect of fillers on the characteristics of PEs depends on the size, nature, concentration, dispersion, and morphologies of the incorporated fillers. For example, the amorphousness and ionic conductivity of PEs is increased at ambient temperature when filler particles are completely dispersed in the polymer membranes. Besides, in contrast to particles and random nanowires, aligned nanowires paired with polymers can create continuous ionic species transport routes as shown in Fig. 6 [58].

Illustration of ionic transport pathway in (a) pure PEs, b composite PEs with nanoparticles, c random nanowires, and (d) aligned nanowires [58]

Besides to fillers, the combination of PEs with liquid components declines the cohesive forces between polymeric chains, improving the physical properties such as flexibility, viscosity, microstructure, and so on of polymeric hosts, and the effect sounds more in gel PEs than in plasticized PEs. The decline in cohesive forces between chains brings the amorphous region to increase, and the Tg of polymers to go down. The incorporated liquid components significantly improve the flexibility, processability, and segmental motion of polymeric chains, as well as the conductivity of PEs. Incorporating liquid components into PECH-based electrolytes is the other technique used for improving the conductivity of PECH electrolytes, enhancing conductivity in the order of 10–3 S cm−1 at ambient temperature [59]. Plasticizers, besides improving polymer chain segmental mobility, dissolve more salts and increase the mobile medium for ions, thereby enhancing the charge transfer mechanism of cations in the polymer matrix. However, these achievements are accomplished at the expense of mechanical and thermal stabilities of PECH electrolytes [60], rising the flammability, volatility, dendrite formation, and other serious issues, especially in gel PEs. Furthermore, polar liquid components could react with the electrodes, causing active materials to be lost. The positive and negative effects of the incorporated liquid components on PEs and electrodes are influenced by their nature and concentration, including their viscosity, dielectric constant, donor number, polymer–plasticizer interaction, and ion–plasticizer interaction [61, 62]. The thermal characteristics and electrochemical performances of some of the PECH based plasticized electrolytes shown in Table 3.

Nithya et al. [64] synthesized plasticized ECH copolymer-based electrolytes using poly(epichlorohydrin-ethylene oxide), \(\gamma\)-butyrolactone (\(\gamma\)-BL) and LiClO4 as polymer host, plasticizers and salt, respectively, through solution casting methods. XRD analysis depicted that the addition LiClO4 to the polymer host diminished the diffraction intensity of the host and peaks associated with the salt have been eliminated. Similarly, the incorporated plasticizer (γ-BL) declined the diffraction intensity of the polymer host. This suggests that incorporating LiClO4 and the plasticizer to the host enhanced the amorphousity of PEs. Additionally, the disappearance of peaks corresponding to pure LiClO4 in PEs signifies the full complexation of salts with the polymer hosts, totally dissolved in the system. The impendence spectroscopy characterization depicted the enhancement in conductivity with the rise in plasticizer concentration because of the drop in activation energy of polymeric chains, boosting the local motion of chains, and free volume of the system. The maximum ionic conductivity of 1.3 × 10–4 S/cm for poly(ECH-EO):y-BL:LiClO4 (70:15:15) was achieved at room temperature. The conductivity of plasticized PEs arose nonlinearly with temperature, indicating that the complexes obey the Vogel-Tammann-Fulcher (VTF) equation. When temperature rises, polymeric chains acquire faster internal modes in which bond rotations bring local motion of chains, promoting inter-chain hopping and intrachain ion movement, resulting in a high conductivity of the PEs. Nithya et al. [65] synthesized plasticized PECH copolymer-based electrolytes using P(ECH-co-EO), LiClO4, and PC and dimethylformamide (DMF) as polymer host, salt, and plasticizers, respectively, and they researched the influence of plasticizer chemistry on PEs conductivity. XRD analysis depicted that the diffraction peaks of the electrolytes shifted, broadened and declined in intensity when plasticized with PC due to increment in amorphousity of PEs. The diffraction peaks of PEs at 21.33° displaced to 22.46°, 23.11° and 21.49° when plasticized with 5, 10 and 15 mol % of PC, respectively. The disappearance of LiClO4 peaks in the plasticized PEs shows us that LiClO4 is fully dissolved in the system. Similar phenomena were observed when plasticized with DMF but at a stronger tone, demonstrating the performance and characteristics of PEs relying on the chemistry of plasticizers, and better conductivity when PEs plasticized with plasticizers having lower viscosity as shown in Fig. 7. Similarly, the mechanical and thermal stability of PEs declined dramatically when plasticized using low viscous plasticizers. The maximum ionic conductivity of 5.8 × 10−4 S/cm at 303 K was achieved at 15 mol% of plasticizers. A similar observation was conducted using the same copolymers with γ-BL and PC plasticizers [63].

Influence of plasticizers chemistry and concentration on the conductivity of PECH electrolytes (PC and DMF plasticizers) [65]

4.4 PECH combination with ionic liquids

In addition to aprotic solvent based plasticizers, the incorporation of organic plasticizers (ionic liquids) into PEs is considered as a potentional option to improve the conductivity and stability of the electrolytes as ionic liquids have wider electrochemical potential, good conductivity, chemical and thermal stability; they participate both in plasticizing the electrolyte system and transporting the ionic species between the electrodes[66, 67]. For example, Chen et al. [66] synthesized PECH based monolithic ionogel electrolytes composed of quaternary ammonium poly (epichlorohydrin), 1-ethyl-3-methylimidazolium bis-(fluorosulfonyl)-imide (EMImFSI) and lithium bis-(fluorosulfonyl) imide (LiFSI) as polymer host, ionic liquid and salt respectively through solution casting techniques, and they investigated the electrochemical performances and mechanical strength of the electrolytes. The created ionogel electrolytes demonstrated excellent thermal stability up to 250 C, a high ionic conductivity of 1.21 mS/ cm at 20 C, a broad electrochemical potential window of about 5 V, and a yield stress of over 2 MPa. Additionally, as shown in Fig. 8, Li/ionogel electrolyte/LiFePO4 assemblies produced high capacity with good cycling stability and an excellent C-rate response. It is apparent from the charge/discharge curves at 0.2C (Fig. 8a) that the electrolytes are all flat and essentially unaffected by additional cycling, and even at the 60th cycle, the polarization voltage is less than 110 mV, indicating rapid cation transport and electrochemical reaction kinetics. The improved electrode/electrolyte interface also increases discharge capacity during the first few cycles (Fig. 8b). The cell had a discharge capacity of 150.0 mAh/g after 10 cycles and 148 mAh/g after 60 cycles. After several cycles, the cell's Coulombic efficiency approaches 100% (Fig. 8c). Additionally, the discharge capacity decreases with increasing current rate (Fig. 8d and e). As shown in Fig. 8d, the polarization voltage remains below 110 mV at a high current density of 1C, demonstrating fast electrochemical reaction kinetics. After ten consecutive cycles, it achieves stable capacities of 142.2 mAh/g and 125.8 mAh/g at 0.5C and 1C, respectively. The capacity is restored to 150.0 mAh/g when the current rate returns to 0.2C (Fig. 8e), indicating excellent and stable lithium storage performance.

Electrochemical performance of Li/ionogel electrolyte/LiFePO4 cells at 20 C: a first, tenth and sixty cycles, b discharge capacity and (c) Coulombic efficiency during cycling at 0.2C. d charge/discharge voltage profiles at current densities between 0.2C and 1C, and e capacity and Coulombic efficiency during cycling at current densities between 0.2C and 1C [66]

5 Ion transport and performance needs in polymer electrolytes

5.1 Performance requirements of PECH-based electrolytes

PECH-based electrolytes perform two functions: separating the electrodes and mediating the ionic species between the electrodes. Hence, PECH electrolytes perform a noteworthy role in deciding the performance and stability of batteries. For practical applications, PECH-based electrolytes need to meet the following characteristics[68, 69]:

-

(a)

Ionic conductivity: For practical uses, PECH electrolytes should have larger conductivity at ambient temperature (\(\ge {10}^{-4} \mathrm{S}/\mathrm{cm})\). It has been found that the conductivity of PECH electrolytes is poor [51], and electronically insulator, leading to negligible self-discharge. Its conductivities could be improved using various approaches, such as graft copolymerization along the alkyl chloride groups, which could be used to enhance the physicochemical and electrochemical properties of PECH polymers. Even though PECH has several fascinating properties that can be exploited and manipulated, PECH-based electrolytes have received less attention when compared to other polymers.

-

(b)

Cation transference number: PECH electrolytes are expected to possess a cation transference number near unity (\({t}_{\mathrm{ion}}\sim 1)\) as a high cation transference number minimizes electrolyte concentration polarization during the charging/discharging process, resulting in higher power density. Eventhough, PECH-based electrolytes could exhibited a cation transference number upto 0.79 practically[70], ways of boosting the Li+ transference number should be researched.

-

(c)

Mechanical strength: PECH-based electrolytes are supposed to have a minimum of 30 MPa mechanical strength to endure the stresses created during the numerous charging/discharging cycles, which is crucial for electrode isolation. The mechanical characteristics of PECH-based electrolytes could be improved by using fillers, crosslinking procedures, mixing with different polymers, and other approaches.

-

(d)

Window potential stability (WP): Window potential stability in batteries refers to the potential difference and range at which the PEs do not react, alter, or degrade in any way during battery operation or storage. By subtracting the reduction potential from the oxidation potential, WP is calculated. The reduction potential must be smaller than the anode lithium metal embedding potential, and the oxidation potential must be greater than the cathode cation embedding potential. PECH electrolytes, for example in LIBs, should have a broad window potential of up to 4–5 V vs. Li/Li+ to be well-matched with electrodes.

-

(e)

Chemical and thermal stability: PECH-electrolytes are chemically inert to battery components such as active materials, current collectors, and others unless corrosive additives are introduced. Hence, the additives, including salts, used to increase the effectiveness of PECH electrolytes should be carefully chosen to avoid undesirable side reactions. Furthermore, the additives are expected to be thermally stable or not impair the thermal stability of PECH systems, as some applications require higher temperature resistance.

5.2 Ion transport in PECH-based electrolytes

The -O- functional motifs, available along the backbones of the PECH, facilitate the dissolution of salts in the host and create host-salt complexes. In dissolving salts, the lattice energy of salts also plays a significant role as salts with lower lattice energy, easily dissociate in PECH host. Hence, salts with lower lattice energy are required for efficient dissociation and salt-host complexation. In addition to -O- functional motifs, graft polymerization (nucleophilic substitution reactions) could be used to construct additional functional motifs in PECH polymers. The ionic conductivity of a material, for example, PECH electrolytes, could be computed as shown in Eqn. (1) [69]:

where \(\sigma\) is the ionic conductivity, q is electric charge, \(\mu\) is ion mobility and n is an effective number of mobile ions. As depicted in Eq. (1), the conductivity of PECH electrolytes is related to the effective number of mobile ions, the electric charge, and the ability of the ionic species to move. In PECH electrolytes, n and \(\mu\) strongly depend on the extent of salt dissolution in PECH host and the segmental mobility of PECH chains, respectively. The crystallinity of PECH governs its local motion which is vital in creating free volumes for ion mobility, and ion migration from one motif area to the other or jumping from one -O- motif group to the other either between chains or within a chain under the influence of an electric field. It was discovered that temperature strongly impacts the conductivity of PECH electrolytes as thermal energy creates free volumes when elevated. PECHs temperature-dependent conductivity could be described either by the VTF equation or the Arrhenius equation. The empirical VTF conduction mechanism can be expressed by Eq. (2) [68, 69]:

where \({\sigma }_{0}\) is the pre-exponential factor, associated with n in Eq. (1), B is the conductivity activation energy, and T0 is equilibrium Tg (T0 \(\approx\) Tg—50 K). In the VTF equation, \(\sigma\) versus 1/T graphs are often nonlinear, revealing the ionic conducting mode takes place via ion jumping and local motion of polymeric chains [68, 69]. The Arrhenius conduction mechanism can be expressed by Eq. (3) [69]:

where Ea is the activation energy.

Materials that exhibit linear Arrhenius variations reveal that ion transport occurs via a simple hopping mechanism decoupled from polymer chain breathing.

6 Opportunities, and challenges of lithium batteries

LIBs are extensively used in diverse technologies ranging from small-scale to large-scale ESSs, including satellites, electric vehicles, personal appliances, and other gadgets [71] due to their outstanding performances like higher energy contents, specific energy of 250–300 Wh/kg and an energy density of 600–700 Wh/L, longer shelf life, low self-discharge rate, and others, resulting in large investments. A graphite anode with a theoretical capacity of 372 mAh/g may be nearly fully used in such a device, yielding a practical capacity of around 360 mAh/g [72]. However, as graphite-based anode battery systems are insufficient for satisfying the demand for higher energy content, new anode and cathode materials should be developed, and even cells may be built beyond the lithium intercalation concept (i.e. with Li-free or bare copper current collector anode) [73]. In this regard, metallic lithium anode has emerged as the most realistic choice to replace graphite-based anodes due to its ultrahigh capacity of 3,860 mAh/g (about 10 times that of graphite) and lowest electrochemical potential of -3.040 V compared to the typical hydrogen electrode. Cells in lithium-free battery systems could be constructed with Lithium Transition Metal Oxide (LMO) cathodes and bare copper current collector anodes (Li-LMO system), where all of the lithium comes from LMO. The weight and thickness of cells could be dramatically reduced in such cell building techniques by removing graphite anodes and thus the electrolytes required to fill the pores of graphite, increasing cell-specific energy, and also employing bare copper current collector anode will significantly reduce cell costs associated with lithium and the processing to thin foils [73]. It should be noted that several institutes and research organizations all over the world are working hard on the Li-LMO system. For example, a Solid Energy System company developed pilot size 3.4 Ah pouch cells with energy densities of 450 Wh/kg and 1200 Wh/L recently. However, the excess lithium requirement to compensate for its high reactivity has a significant impact on the total increase in specific energy and cost reduction of Li-LMO batteries. In addition to the Li-LMO system, lithium batteries could be built with lithium metal anodes and non-lithium containing material cathodes such as elemental sulfur, and the Li–S system increases specific energy to 600 Wh/kg while maintaining a low volumetric energy density comparable to LIBs due to the low density of lithium and sulfur [74]. Due to the exceptionally cheap cost of sulfur in comparison to LMO cathode materials, the cost of Li–S cells can be further reduced. As a result, LMBs such as Li-LMO and Li–S, have a significant advantage over LIBs in terms of energy density and cost, presenting a major possibility for long-range and low-cost applications including EVs in the future. However, numerous obstacles must be overcome before high-energy, low-cost LMBs become a viable technology. The primary impediments are the long-standing issues of limited cycle life and safety concerns with lithium metal anodes. We, generally, trust that lithium batteries will have indefinite possibilities in the future if its shortcomings are solved.

7 Conclusion

PECH is synthesized from ECH monomers through catalytic ring-opening chemical reactions. PECH membranes have been investigated as salt hosts in electrolyte systems due to their many intrinsic characteristics such as the -O- functional group at the backbone of the polymer chains, its lower Tg, and sufficient mechanical strength. In this paper, the present state of PECH-based electrolytes in lithium-based energy storage systems is summed up. PECH could be used to make polymer electrolytes either in their pristine form or in combination with additional additives. However, the pristine form of PECH-based electrolytes had low ionic conductivity at ambient temperature because of its structural rigidity, thus additives such as various polymers that can be coupled in the blend, copolymer, or crosslink form, and plasticizers are employed in conjugation with PECH to increase its performance. The electrochemical performances of PECH could be improved by plasticizing the system with liquid plasticizers, albeit at the expense of mechanical strength. Some research has been done on PECH-based electrolytes in both solid and gel state battery systems, with a particular focus on the copolymer of ECH and EO, and the research efforts done on preparing PECH-based electrolytes are not satisfactory in comparison to their many appealing features, and thus some gaps need to be filled. For electrolytic applications, some of the issues that could be addressed include PECH conversion into usable derivatives, as well as the structure and surface nature of PECH hosts. For example, if surface modification along the alkyl chloride group is carried out with some polar groups such as -OH- or with some oligomers with long chains, the attributes such as functional groups, structure, and surface nature of the polymer might potentially be altered, enhancing the performances of the electrolytes. Furthermore, to the best of our knowledge, the effect of both active and passive nanofillers on the electrochemical performances of PECH-based electrolytes has never been studied. In addition to this, the effect of polymer blending (i.e. blending PECH with other homopolymers or copolymers) has received little attention, and the combined effect of plasticizers and nanofillers has yet to be explored. Moreover, there are few reports of PECH-based electrolytes being used in other metal batteries or energy storage systems. PECH-based electrolytes are prepared by chemically modifying PECH membranes via copolymerization and crosslinking reactions, as well as nucleophilic substitution reactions along its alkyl chloride groups, or physically modifying PECH membranes via blending the polymer with other polymers or copolymers, incorporating nanofillers, plasticizers, and ionic liquids, could improve system performance, including conductivity. PECH is projected to play an important role in next-generation ESSs and other applications due to its structure and presence of its reactive alkyl chloride group. To summarize, PECH derivatives offer several benefits to energy storage systems, and their performance can be significantly enhanced by performing proper surface modification using a nucleophilic substitution reaction, reinforcing its derivative components, and blending PECH with other polymers, including copolymers.

References

Liu B, Huang Y, Cao H, Zhao L, Huang Y, Song A et al (2018) A novel porous gel polymer electrolyte based on poly(acrylonitrile-polyhedral oligomeric silsesquioxane) with high performances for lithium-ion batteries. J Memb Sci 545:140–149

Sun C, Liu J, Gong Y, Wilkinson DP, Zhang J (2017) Recent advances in all-solid-state rechargeable lithium batteries. Nano Energy 33:363–386

Yang J, Wang X, Zhang G, Ma A, Chen W, Shao L et al (2019) High-performance solid composite polymer electrolyte for all solid-state lithium battery through facile microstructure regulation. Front Chem 7:1–11

Morris MA, An H, Lutkenhaus JL, Epps TH (2017) Harnessing the Power of plastics: nanostructured polymer systems in lithium-ion batteries. ACS Eng Lett. 2(8):1919–1936

Dhatarwal P, Choudhary S, Sengwa RJ (2018) Electrochemical performance of Li+-ion conducting solid polymer electrolytes based on PEO–PMMA blend matrix incorporated with various inorganic nanoparticles for the lithium ion batteries. Compos Commun 10:11–17

Balogun MS, Yang H, Luo Y, Qiu W, Huang Y, Liu ZQ et al (2018) Achieving high gravimetric energy density for flexible lithium-ion batteries facilitated by core-double-shell electrodes. Energy Environ Sci 11(7):1859–1869

Zhou L, Zhang K, Hu Z, Tao Z, Mai L, Kang YM et al (2018) Recent Developments on and Prospects for Electrode Materials with Hierarchical Structures for Lithium-Ion Batteries. Adv Energy Mater 8(6):1–23

Chen C, Xie X, Anasori B, Sarycheva A, Makaryan T, Zhao M et al (2018) MoS2-on-MXene Heterostructures as Highly Reversible Anode Materials for Lithium-Ion Batteries. Angew Chemie - Int Ed. 57(7):1846–1850

Ma Y, Li LB, Gao GX, Yang XY, You Y (2016) Effect of montmorillonite on the ionic conductivity and electrochemical properties of a composite solid polymer electrolyte based on polyvinylidenedifluoride/polyvinyl alcohol matrix for lithium ion batteries. Electrochim Acta 187:535–542

Elia GA, Bernhard R, Hassoun J (2015) A lithium-ion oxygen battery using a polyethylene glyme electrolyte mixed with an ionic liquid. RSC Adv 5(27):21360–21365. https://doi.org/10.1039/C4RA17277A

Liang S, Yan W, Wu X, Zhang Y, Zhu Y, Wang H et al (2018) Gel polymer electrolytes for lithium ion batteries: Fabrication, characterization and performance. Solid State Ionics 318:2–18

Jiang Y, Li F, Mei Y, Ding Y, Pang H, Zhang P (2021) Gel polymer electrolyte based on hydrophilic–lipophilic TiO2-modified thermoplastic polyurethane for high-performance Li-ion batteries. J Mater Sci 56(3):2474–2485

Arya A, Sharma AL (2020) A glimpse on all-solid-state Li-ion battery (ASSLIB) performance based on novel solid polymer electrolytes: a topical review. J Mater Sci 55(15):6242–6304

Volkov VI, Yarmolenko OV, Chernyak AV, Slesarenko NA, Avilova IA, Baymuratova GR et al (2022) Polymer electrolytes for Lithium-ion batteries studied by NMR techniques. Membranes 12(4):416

Wang Y, Song S, Xu C, Hu N, Molenda J, Lu L (2019) Development of solid-state electrolytes for sodium-ion battery–A short review. Nano Mater Sci. 1(2):91–100

Kim J-J, Yoon K, Park I, Kang K (2017) Progress in the Development of Sodium-Ion Solid Electrolytes. Small Method. 1(10):1700219

El Moctar I, Ni Q, Bai Y, Wu F, Wu C (2018) Hard carbon anode materials for sodium-ion batteries. Funct Mater 11(6):1830003

Zhao C, Liu L, Qi X, Lu Y, Wu F, Zhao J et al (2018) Solid-state sodium batteries. Adv Energ Mater 17(8):1703012

Bocharova V, Sokolov AP (2020) Perspectives for polymer electrolytes: a view from fundamentals of ionic conductivity. Macromolecules 53(11):4147–4151

Han X, Shanks RA, Pavel D (2005) The synthesis and thermal properties of polyepichlorohydrin side-chain liquid crystal polymers. Eur Polym J 41(5):984–991. https://doi.org/10.1016/j.eurpolymj.2004.11.038

Notohara H, Urita K, Moriguchi I. Tin oxide electrodes in Li and Na-ion batteries. In: Orlandi MO (ed) Tin Oxide Materials. Elsevier Inc.; 2020. 411–439: https://doi.org/10.1016/B978-0-12-815924-8.00014-1

Pelz A, Grünebaum M, Wiemhöfer HD. Hybrid electrolytes for lithium ion and post lithium ion batteries. Encycl Interfacial Chem Surf Sci Electrochem. 2018;660–673. doi:https://doi.org/10.1016/B978-0-12-409547-2.14190-3

Gunawardane K. Capacitors as energy storage devices-simple basics to current commercial families. In: Kularatna N (ed) Energy Storage Devices for Electronic Systems: Rechargeable Batteries and Supercapacitors. Elsevier Inc.; 2015. 137–148https://doi.org/10.1016/B978-0-12-407947-2.00004-3

Christen T, Carlen MW (2000) Theory of ragone plots. J Power Sour 91(2):210–216. https://doi.org/10.1016/S0378-7753(00)00474-2

Sundén B. Battery technologies. In: Sundén B (ed) Hydrogen, Batteries and Fuel Cells. 2019;57–79: https://doi.org/10.1016/B978-0-12-816950-6.00004-X

Shi Y, Eze C, Xiong B, He W, Zhang H, Lim TM et al (2019) Recent development of membrane for vanadium redox flow battery applications: a review. Appl Energ 238:202–224

Liao H, Chen H, Zhou F, Zhang Z (2020) A novel SiO2 nanofiber-supported organic–inorganic gel polymer electrolyte for dendrite-free lithium metal batteries. J Mater Sci 55(22):9504–9515

Wang R, Cui W, Chu F, Wu F (2020) Lithium metal anodes : present and future. J Energ Chem. https://doi.org/10.1016/j.jechem.2019.12.024

Zhu K, Wang C, Chi Z, Ke F, Yang Y, Wang A et al (2019) How far away are lithium-sulfur batteries from Commercialization? Front Energy Res. https://doi.org/10.3389/fenrg.2019.00123

Seh ZW, Sun Y, Zhang Q, Cui Y (2016) Designing high-energy lithium–sulfur batteries. Chem Soc Rev 45:560–563

Ji X, Lee KT, Nazar LF (2009) A highly ordered nanostructured carbon-sulphur cathode for lithium-sulphur batteries. Nat Mater 8(6):500–506. https://doi.org/10.1038/nmat2460

Li Z, He Q, Xu X, Zhao Y, Liu X, Zhou C et al (2018) A 3D nitrogen-doped graphene/TiN nanowires composite as a strong polysulfide anchor for Lithium-sulfur batteries with enhanced rate performance and high areal capacity. Adv Mater 30(45):1–8. https://doi.org/10.1002/adma.201804089

Kolosnitsyn V, Karaseva E (2008) Lithium-sulfur batteries: Problems and solutions. Russ J Electrochem 44:506–509. https://doi.org/10.1134/S1023193508050029

Shukla G, Ferrier RC (2021) The versatile, functional polyether, polyepichlorohydrin: History, synthesis, and applications. J Polym Sci 59(22):2704–2718. https://doi.org/10.1002/pol.20210514

Hu X, Fan J, Yue CY (2001) Ring-opening polymerization of epichlorohydrin and its copolymerization with other alkylene oxides by quaternary catalyst system. J Appl Polym Sci 80(13):2446–2454. https://doi.org/10.1002/app.1351

Goulart Silva G, Lemes NHT, Polo Da Fonseca CN, De Paoli MA (1996) Solid state polymeric electrolytes based on poly (epichlorohydrin). Solid State Ion 93(1–2):105–116. https://doi.org/10.1016/S0167-2738(96)00493-6

Brochu S, Ampleman G (1996) Synthesis and characterization of glycidyl azide polymers using isotactic and chiral poly(epichlorohydrin)s. Macromolecules 29(17):5539–5545. https://doi.org/10.1021/ma951839f

Guanaes D, Bittencourt E, Eberlin MN, Sabino AA (2007) Influence of polymerization conditions on the molecular weight and polydispersity of polyepichlorohydrin. Eur Polym J 43(5):2141–2148. https://doi.org/10.1016/j.eurpolymj.2007.02.016

Hong S, Wang Y, Kim N, Lee SB (2021) Polymer-based electrolytes for all-solid-state lithium–sulfur batteries: from fundamental research to performance improvement. J Mater Sci 56(14):8358–8382. https://doi.org/10.1007/s10853-021-05832-2

Yang CC, Lin SJ, Hsu ST (2003) Synthesis and characterization of alkaline polyvinyl alcohol and poly(epichlorohydrin) blend polymer electrolytes and performance in electrochemical cells. J Power Sour 122(2):210–218. https://doi.org/10.1016/S0378-7753(03)00429-4

Tan SJ, Zeng XX, Ma Q, Wu XW, Guo YG (2018) Recent advancements in Polymer-based composite electrolytes for rechargeable lithium batteries. Electrochem Energy Rev 1(2):113–138. https://doi.org/10.1007/s41918-018-0011-2

Fonseca CP, Guedes CGF, Rosa DS, Neves S (2004) Influence of LiClO4 on the thermal, mechanical, and morphological properties of P(DMS-co-EO)/P(EPI-co-EO) blends. J Appl Polym Sci 93(3):1230–1235. https://doi.org/10.1002/app.20557

Ju JL, Gu QC, Xu HS, Yang CZ (1998) Ionic conductivity of new dual-phase polymer electrolyte composed of poly(epichlorohydrin-co-oxirane) and NBR. J Appl Polym Sci 70(2):353–357

Kim GT, Appetecchi GB, Carewska M, Joost M, Balducci A, Winter M et al (2010) UV cross-linked, lithium-conducting ternary polymer electrolytes containing ionic liquids. J Power Sour 195(18):6130–6137

Rupp B, Schmuck M, Balducci A, Winter M, Kern W (2008) Polymer electrolyte for lithium batteries based on photochemically crosslinked poly(ethylene oxide) and ionic liquid. Eur Polym J 44(9):2986–2990. https://doi.org/10.1016/j.eurpolymj.2008.06.022

Porcarelli L, Gerbaldi C, Bella F, Nair JR (2016) Super soft All-ethylene oxide polymer electrolyte for safe All-solid lithium batteries. Sci Rep 6:1–14. https://doi.org/10.1038/srep19892

Han P, Zhu Y, Liu J (2015) An all-solid-state lithium ion battery electrolyte membrane fabricated by hot-pressing method. J Power Sour 284:459–465. https://doi.org/10.1016/j.jpowsour.2015.03.058

Snyder JF, Carter RH, Wetzel ED (2007) Electrochemical and mechanical behavior in mechanically robust solid polymer electrolytes for use in multifunctional structural batteries. Chem Mater 19(15):3793–3801. https://doi.org/10.1021/cm070213o

Ben Youcef H, Garcia-Calvo O, Lago N, Devaraj S, Armand M (2016) Cross-linked solid polymer electrolyte for All-solid-state rechargeable lithium batteries. Electrochim Acta 220:587–594

Gazotti WA, Spinacé MAS, Girotto EM, De Paoli MA (2000) Polymer electrolytes based on ethylene oxide-epichlorohydrin copolymers. Solid State Ionic 130(3–4):281–291. https://doi.org/10.1016/S0167-2738(00)00550-6

Lee KJ, Park JT, Koh JH, Min BR, Kim JH (2009) Graft polymerization of poly(epichlorohydrin-g-poly((oxyethylene) methacrylate)) using ATRP and its polymer electrolyte with KI. Ionics 15(2):163–167. https://doi.org/10.1007/s11581-008-0245-9

Nithya H, Selvasekarapandian S, Arun Kumar D, Sakunthala A, Hema M, Christopherselvin P et al (2011) Thermal and dielectric studies of polymer electrolyte based on P(ECH-EO). Mater Chem Phys 126(1–2):404–408. https://doi.org/10.1016/j.matchemphys.2010.10.047

Rodrigues LC, Barbosa PC, Silva MM, Smith MJ (2007) Electrochemical and thermal properties of polymer electrolytes based on poly(epichlorohydrin-co-ethylene oxide-co-ally glycidyl ether). Electrochim Acta 53(4):1427–1431. https://doi.org/10.1016/j.electacta.2007.03.030

Kohjiya S, Horiuchi T, Miura K, Kitagawa M, Sakashita T, Matoba Y et al (2000) Polymer solid electrolyte from amorphous poly[epichlorohydrin-co-(ethylene oxide)]/ lithium perchlorate complex. Polym Int 49(2):197–202

Choudhury S, Saha T, Naskar K, Stamm M, Heinrich G, Das A (2017) A highly stretchable gel-polymer electrolyte for lithium-sulfur batteries. Polymer 112:447–456. https://doi.org/10.1016/j.polymer.2017.02.021

Lin D, Liu W, Liu Y, Lee HR, Hsu PC, Liu K et al (2016) High ionic conductivity of composite solid polymer electrolyte via in situ synthesis of monodispersed SiO2 nanospheres in poly(ethylene oxide). Nano Lett 16(1):459–465. https://doi.org/10.1021/acs.nanolett.5b04117

Duan H, Yin YX, Zeng XX, Li JY, Shi JL, Shi Y et al (2018) In-situ plasticized polymer electrolyte with double-network for flexible solid-state lithium-metal batteries. Energy Storage Mater 10:85–91. https://doi.org/10.1016/j.ensm.2017.06.017

Yao P, Yu H, Ding Z, Liu Y, Lu J, Lavorgna M et al (2019) Review on Polymer-based composite electrolytes for lithium batteries. Front Chem. https://doi.org/10.3389/fchem.2019.00522

Subba Reddy CV, Sharma AK, Narasimha Rao VVR (2002) Effect of plasticizer on electrical conductivity and cell parameters of PVP + PVA + KClO3 blend polymer electrolyte system. J Power Sour 111(2):357–360. https://doi.org/10.1016/S0378-7753(02)00040-X

Choi NS, Lee YG, Park JK, Ko JM (2001) Preparation and electrochemical characteristics of plasticized polymer electrolytes based upon a P(VdF-co-HFP)/PVAc blend. Electrochim Acta 46(10–11):1581–1586. https://doi.org/10.1016/S0013-4686(00)00756-8

Prabakaran P, Manimuthu RP, Gurusamy S, Sebasthiyan E (2017) Plasticized polymer electrolyte membranes based on PEO/PVdF-HFP for use as an effective electrolyte in lithium-ion batteries. Chin J Polym Sci 35(3):407–421. https://doi.org/10.1007/s10118-017-1906-9

Hou X, Siow KS (2000) Mechanical properties and ionic conductivities of plasticized polymer electrolytes based on ABS/PMMA blends. Polymer 41(24):8689–8696. https://doi.org/10.1016/S0032-3861(00)00270-6

Nithya H, Selvasekarapandian S, Selvin PC, Kumar DA, Hema M, Kawamura J (2012) Laser Raman and conductivity studies of plasticized polymer electrolyte P(ECH-EO):propylenecarbonate: γ-butyrolactone:LiClO4. J Solid State Electrochem 16(5):1791–1797. https://doi.org/10.1007/s10008-011-1610-6

Nithya H, Selvasekarapandian S, Selvin PC, Kumar DA, Hema M (2011) Structural and ionic conductivity studies on P(ECH-EO):γ-BL:LiClO4 plasticized polymer electrolyte. Ionics 17(7):587–593. https://doi.org/10.1007/s11581-011-0603-x

Nithya H, Selvasekarapandian S, Christopher Selvin P, Arun Kumar D, Kawamura J (2012) Effect of propylene carbonate and dimethylformamide on ionic conductivity of P(ECH-EO) based polymer electrolyte. Electrochim Acta 66:110–120. https://doi.org/10.1016/j.electacta.2012.01.056

Chen C, Chen Z (2022) Novel poly(epichlorohydrin)-based matrix for monolithic ionogel electrolyte membrane with high lithium storage performances. RSC Adv 12:12160–12165. https://doi.org/10.1039/D2RA00110A

Guyomard-Lack A, Delannoy PE, Dupré N, Cerclier CV, Humbert B, Le Bideau J (2014) Destructuring ionic liquids in ionogels: enhanced fragility for solid devices. Phys Chem Chem Phys 16(43):23639–23645. https://doi.org/10.1039/C4CP03187C

Long L, Wang S, Xiao M, Meng Y (2016) Polymer electrolytes for lithium polymer batteries. J Mater Chem A 4(26):10038–10069. https://doi.org/10.1039/C6TA02621D

Zhang Q, Liu K, Ding F, Li W, Liu X, Zhang J (2017) Safety-reinforced Succinonitrile-based electrolyte with interfacial stability for High-performance lithium batteries. ACS Appl Mater Int 9(35):29820–29828. https://doi.org/10.1021/acsami.7b09119

Ge X, Song F, Du A, Zhang Y, Xie B, Huang L et al (2022) Robust Self-standing Single-ion polymer electrolytes enabling High-safety magnesium batteries at elevated temperature. Adv Energy Mater 12(31):2201. https://doi.org/10.1002/aenm.202201464

Xiong H, Dufek EJ, Gering KL (2018) Batteries. Comprehensive Energy Systems 2(5):629–662

Betz J, Bieker G, Meister P, Placke T, Winter M, Schmuch R (2019) Theoretical versus practical energy: a plea for more transparency in the energy calculation of different rechargeable battery systems. Adv Energy Mater 9(6):1–18. https://doi.org/10.1002/aenm.201803170

Schmuch R, Wagner R, Hörpel G, Placke T, Winter M (2018) Performance and cost of materials for lithium-based rechargeable automotive batteries. Nat Energy 3(4):267–278. https://doi.org/10.1038/s41560-018-0107-2

Hagen M, Hanselmann D, Ahlbrecht K, Maça R, Gerber D, Tübke J (2015) Lithium-Sulfur Cells: The Gap between the State-of-the-Art and the Requirements for High Energy Battery Cells. Adv Energy Mater 5(16):1401986. https://doi.org/10.1002/aenm.201401986

Funding

A funding declaration is mandatory for publication in this journal. Please confirm that this declaration is accurate, or provide an alternative.

Author information

Authors and Affiliations

Contributions

All authors listed have significantly contributed to the development and the writing of this article.

Corresponding author

Ethics declarations

Conflict of interest

This study was not funded by any organization and the authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Amogne, N., Ayele, D., Habtu, N. et al. Insights into the use of polyepichlorohydrin polymer in lithium battery energy storage/conversion devices: review. SN Appl. Sci. 5, 7 (2023). https://doi.org/10.1007/s42452-022-05234-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-022-05234-2