Abstract

The present study provides a complete perspective of recyclable molybdovanadophosphoric acid immobilized on kaolin (MVPA/Kaolin), a hybrid material for catalytic degradation of the dye, Chromotrope 2R in water under mild reaction conditions. Novel MVPA/Kaolin was synthesized with an advanced impregnation method. The material was characterized with PXRD, FTIR, ICP-OES, SEM–EDX, TEM, TGA, surface area, porosity, and 31P NMR measurements. The material that can be classified as a Keggin type catalyst, could be used for hydrogen peroxide oxidation of aromatic azo (–N=N–) dyes with –OH and –SO3H functional groups. The degradation showed excellent conversion of 99.1% under optimum conditions of normal pressure and 60 °C temperature. Products like malonic acid and oxalic acid have been identified as the final products with GC–MS analysis. The present work has demonstrated the application of a simple and effective catalyst for degradation of azo dyes and the catalyst had the reusability capacity of up to six cycles without loss in performance.

Article Highlights

-

The hybrid MVPA/Kaolin material presents a novel catalyst for degradation of dyes in water.

-

The characterization of the material yields useful insight into its functioning as a catalyst.

-

MVPA/Kaolin has shown significant catalytic activity with durability and recyclability.

Similar content being viewed by others

1 Introduction

Heteropoly acids (HPA) with their superior redox characteristics and unique Keggin structure, have played an important role in synthesis and applications. These materials contain mesoporous and microporous heteropoly materials and heteropoly anions with oxo-bridged multiple centers. The heteropoly acids have the advantage that they could be used to design new catalytic materials. The only limitation in their utilization is the uncertain surface area and the lack of thermal stability. Many studies have revealed that supporting HPAs on acceptable carriers and impregnating them with appropriate chemical species boost their functionality significantly [1,2,3,4]. The acid and redox characteristics of metals inserted into the HPA framework could be altered to ensure their utilization for varied purposes [2]. For example, their selective oxidation properties could be exploited to create fine chemicals and pharmaceuticals. The vanadium-substituted molybdophosphoric HPAs have shown a good potential for use as catalysts. It has been shown that incorporating vanadium (V) into the Keggin framework results in getting significantly advantageous redox catalysis [5,6,7,8,9,10]. Molybdovanadophosphoric acid, supported on mesoporous material, MCM-41, nano silica ball (NSB), mesoporous carbon (MC), and SBA-15, could be utilized as catalysts in oxidation reactions using the harmless H2O2 as the oxidizing agent [4, 11]. Traditional oxidation procedures employ expensive chemicals and operate at high temperatures with yields being very often limited [12]. This has led to a continuous search for better catalytic materials that could be used under mild reaction conditions for degrading hazardous chemicals in water.

Dyes and pigments are routinely utilized in a large number of chemical industries including textiles, leather, food, paper, plastic and other industries. The effluents from these industries carry a high concentration of these chemicals, many of which are harmful to the environment [13]. The removal of dyes and associated chemicals from these wastewaters has long been a key industrial concern. The current study had the limited goal of degrading the dye, Chromotrope 2R (Acid Red 29) via oxidation in the presence of a catalyst. Chromotrope 2R is an azo dye with the azo group (N=N) as the chromophore and an aromatic structure with functional groups OH and –SO3H. In nature, azo dyes have been recognized as harmful as they are known to be carcinogenic with major environmental effects [14,15,16]. For treatment of such dye-containing wastewater, advanced oxidative degradation has always been considered as an effective, green and sustainable way to combat pollution. Simple Fenton type oxidation processes have been tried very often but have limited application potential. Photochemical oxidation processes such as those utilizing Gd2O3 (15%)–CdO nanocomposite as the catalyst have been tried for the catalytic degradation of Methylene blue [17]. Pure ZnO nanoparticles (NP) and mixed Eu2O3 and ZnO have also been tried for the photocatalytic decomposition of methylene blue and the results showed that 5% Eu2O3 and ZnO NPs showed the highest photocatalytic activity of 96.5% under 180 min of UV irradiation [18]. The degradation pathway of the dye under UV irradiation with synthesized α-Bi2O3 nanorods has also been investigated [19]. The present work on advanced oxidation was undertaken to investigate photocatalytic degradation/mineralization of an azo dye in water. It is to be noted that the photocatalytic process transforms the azo dye into numerous biodegradable intermediates or may completely destroy it, resulting in complete mineralization, yielding the ultimate products, CO2, H2O, and some inorganic salts, making it possible to discharge the final products safely into the environment. The final oxidation produces may include low molecular weight oxygenated molecules, like oxalic acid, acetic acid, propionic acid, ethanol, and others [12].

Adsorption, coagulation, oxidation, reduction, microbiological oxidation, photo catalysis, and biodegradation are some of the well-known strategies for removing colors and pigments from wastewater [9, 18,19,20]. Banerjee and Chattopadhyaya (2017) have described the adsorption process as the effective process for removal of toxic dye like tartrazine (97%) using Agriculture by-product like saw dust [20]. Although these approaches are successful in entirely eliminating or destroying pollutants, there may be issues with incomplete removal, excessive chemical use, being highly expensive and kinetically sluggish to employ, and occasionally resulting in the formation of harmful secondary pollutants [21]. Modified titanium dioxide (TiO2) has established itself as a key photocatalyst in these oxidation processes. However, there are significant drawbacks to TiO2-based photocatalysis that keep it from being widely used. There have been reports of (i) insufficient use of visible light, (ii) hydrophobic pollutants with limited adsorption potential, (iii) a high tendency for products to agglomerate, and (iv) problems with catalyst recovery and reuse in subsequent catalytic cycles [21]. Rafaqat et al. (2022) have well described about the recent progress in treatment of dyes wastewater using microbial-electro-Fenton technology [22].

Biological oxidation techniques for decolorization of industrial effluents are efficient only at low pollutant concentration and cannot be employed for non-biodegradable, poisonous, or inhibiting contaminants. Alkalinity and temperature of the effluents also influence these processes. Although researchers are working to solve the insufficiencies. Thanavel et al. (2018) have worked with Aeromonas hydrophila SK16 and AOPs-H2O2 (4%) were used to assess the effectiveness of a combined biological and Advanced Oxidation Process (Bio-AOP) for the remediation of textile dyes. Reactive Red 180 (RR 180), Reactive Black 5 (RB 5) and Remazol Red (RR) all showed 100% decolorization after Bio-AOP treatment, compared to 72% decolorization after separate treatments [23]. A wide spectrum of organic reactions could be catalyzed using molybdovanadophosphoric acid-based catalysts in the presence of hydrogen peroxide [4]. Hydrogen peroxide is not only an effective oxidant, but is also environmentally beneficial, as its degradation products are solely H2O and O2. Advanced oxidation techniques based on the use of hydrogen peroxide as the low-cost, environmentally benign, highly efficient oxidation agent with an appropriate catalyst (chemical or photochemical oxidation) have become popular in recent years for direct wastewater treatment.

A novel, eco-friendly method is presented here for synthesizing molybdovanadophosphoric acid (MVPA) with kaolin as the support (MVPA/Kaolin) to be used as a catalyst in Chromotrope 2R dye degradation in aqueous solution. The study is reported in several sections. Section 2 describes the experimental sequences of materials, preparation and characterization of MVPA/Kaolin and the actual catalytic degradation process. Section 3 represents the detailed characterization of the catalyst and discusses the catalytic degradation reactions of the dye with process variables like the reaction time, the catalyst loading, etc., along with the suggestion of a dye-degradation mechanism and the reusability of the catalyst. The last Sect. 4 summarizes the findings of the study.

2 Materials and methods

2.1 Materials

Reagents such as, MoO3 (Loba Chemie Pvt. Ltd., Mumbai, India; 99%), V2O5 (Loba Chemie Pvt. Ltd., Mumbai, India; 99%), phosphoric acid (Loba Chemie Pvt. Ltd., Mumbai, India; 90%) and Kaolin (Molychem, Mumbai, India; 95%), hydrogen peroxide (Loba Chemie Pvt. Ltd., Mumbai, India; 30%) were used without further purification.

2.2 Characterization of the hybrid material

The hybrid composites were characterized for two dimensional crystalline structure by means of Powder X-ray diffraction (PXRD; Philips X'pert MPD diffractometer in Almelo, the Netherlands; 2θ 1–10 and 10–80), Fourier Transform Infrared spectroscopy (FT-IR, Perkin–Elmer spectrometer) with pellets made in potassium bromide (KBr), Inductively coupled plasma optical emission spectroscopy (ICP–OES, JY Ultima 2CHR) to determine the metals entering kaolin, N2 adsorption–desorption study at 77 K for BET surface area and pore volume measurement (Micromeritics ASAP-2010, USA), thermogravimetric analysis (TGA, SDT600, TA instrument, USA) using platinum crucibles to quantify the temperature and microstructure of the samples over the range 30–800 °C at a heating rate of 10 °C min−1 in an air atmosphere with a flow rate of 60 cm3 min−1, Scanning electron microscopy-Energy dispersive X-ray (SEM-EDX, LEO–1430, VP, UK) and Transmission electron microscopy (TEM; JEM 2011, Jeol Corporation, Japan) to determine the surface morphology of the material, and 31P Nuclear Magnetic Resonance (31P NMR) for characteristic confirmation.

2.3 Synthesis of molybdovanadophosphoric acid supported on kaolin catalyst (MVPA/Kaolin)

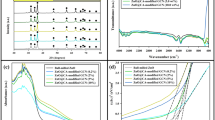

The manufacture of molybdovanadophosphoric acid supported kaolin (MVPA/Kaolin) catalyst is schematically presented in Fig. 1. During the synthesis of MVPA, in a round bottom flask, 22.3 g MoO3 (Loba Chemie, Mumbai, India) and 1.3 g V2O5 (Loba Chemie, Mumbai, India) were combined with 350 ml distilled water. The mixture was then refluxed for 1 h before being added to the flask in three equal aliquots of 1.7 g phosphoric acid (Loba Chemie, Mumbai, India) and 150 ml distilled water. A brilliant orange tinted solution was generated after the mixture was refluxed continuously for 15 h. Then, a homogeneous mixture was made by constantly stirring an aqueous solution of MVPA (0.50 g in 50 ml distilled water) and 1.0 g of kaolin, followed by complete evaporation of the water at 100 °C. The material was dried in an oven at 110 °C for 24 h before being calcined at 500 °C for 2 h. The yield was 3.3 g of MVPA/Kaolin. The elemental composition of the catalyst was determined using inductively coupled plasma-optical emission spectroscopy (ICP-OES). MVPA has a Mo/P ratio of 11.0, indicating a relatively pure heteropoly acid phase [3]. The well-characterized FTIR (KBr) bands were MVPA/Kaolin: 793, 869, 962, 1115, 1404, 1613, 3437 cm−1 and MVPA: 777, 866, 960, 1062, 1615, 1932, 3390 cm−1 MVPA/Kaolin: 793, 869, 962, 1115, 1404, 1613, 3437 cm−1.

2.4 Catalytic oxidation of Chromotrope 2R

The oxidation and subsequent degradation of Chromotrope 2R were carried out in a glass reactor fitted with a condenser. The reaction mixture consisted of (a) 50 ml Chromotrope 2R aqueous solution (2.0 × 10–4 mol L−1), (b) 50 mL H2O2 (10–4 mol L−1), and (c) 5 g L−1 MVPA/Kaolin catalyst. Under normal atmospheric pressure, the mixture was stirred for 60 min at 180 rpm and 60 °C. The mixture was filtered after the reaction was completed to separate the catalyst MVPA/Kaolin. The degradation of the dye was monitored at λmax = 508 nm in the filtrate with UV–Visible spectroscopy (UV-1800, Shimadzu corporation, Japan). The degradation of Chromotrope 2R in percentage was calculated according to the relation:

where C0 and Ct were the initial concentration and the concentration at any time (mol L−1) after the reaction was run for t (min).

Gas chromatography-mass spectroscopy (GC–MS, Agilent, US) measurements were used to identify the products in the reaction mixture. After each reaction, the products were extracted using equal quantities of chloroform and were sonicated for a period of time to separate the organic and aqueous layers. 0.6 µL of the chloroform layer was then injected into the GC–MS for analysis (initial temperature 50 °C, kept for 5 min, increased to 180 °C at 10 °C min−1, kept for 5 min, increased to 250 °C at 10 °C min−1, and kept for 5 min at 250 °C).

3 Results and discussion

3.1 Characterization

3.1.1 Powder X-ray diffraction (XRD)

The results of low angle and high angle mode of powder X-ray diffraction (PXRD) are presented in Fig. 2 showing the characteristic patterns of MVPA [5] and MVPA/Kaolin. The low angle XRD of MVPA revealed a strong XRD peak at 2θ of 0.2° (Fig. 2), while MVPA/kaolin revealed additional peaks attributable to kaolin (0.1°) [3, 8]. Functionalization with kaolin had no effect on the principal reflections due to MVPA, as seen by the wide angle XRD (Fig. 2). XRD peaks at 2θ of 18.1°, 20.3°, 22.6°, 26.9°, 29.1°, 31.6°, 38.0°, 54.3°, 59.9° indicate a significant degree of crystallinity in the MVPA. The MVPA/Kaolin had diffraction peaks at 2θ of 10.7°, 15.2°, 18.6°, 24.1°, 30.7°, 32.6°, 36.1°, 39.4°, 43.9°, 48.1°, 55.7°, 62.7°, 64.9° showing that the material remained crystalline at the atomic level giving rise to reflections at wide angle. Because all of the principal reflections caused by kaolin are also visible in MVPA/Kaolin, it may be resolved that the structural properties of the support material (kaolin) were preserved. This indicates that the crystalline structure of the heterogeneous hybrid material was retained, which would be beneficial in explaining its activity in the subsequent applications.

3.1.2 Scanning Electron Microscopy (SEM)

The SEM micrographs of MVPA and MVPA/Kaolin are shown in Fig. 3. The SEM of MVPA revealed the usual MVPA structural features. MVPA covered the well-ordered layered crystal structure due to kaolin (Fig. 3) with particle size 170 nm in the hybrid composite MVPA/Kaolin. The complex, multi-layered structure is unaltered. Even after incorporating MVPA, the fundamental morphology of the support material might be preserved in the hybrid composite materials. Strong signals for vanadium in the kaolin base could be found in the EDX spectrum of MVPA/Kaolin (Fig. 3d) The layered structure of the catalyst material was well-preserved and the well-organized morphology of the support material could be retained during the fabrication of the catalyst material as well as the subsequent catalytic oxidation of the dye.

3.1.3 Transmission Electron Microscopy (TEM)

The TEM images of MVPA showed well-arranged structure of the material (Fig. 4). The composite material MVPA/Kaolin provides characteristic well-ordered morphology which provide strong evidence that the shape of the support, Kaolin, is retained upon MVPA functionalization [5].

3.1.4 Thermogravimetric analysis (TGA)

The thermo gravimetric curves of the material showed modest weight losses of about 61.5 percent for MVPA in the temperature range 25 to 900 °C (Fig. 5.) The weight loss could be observed as 24.2 percent on loading of MVPA as a hybrid composite in MVPA/Kaolin. In accordance with the literature, ICP data for MVPA and MVPA/Kaolin revealed Mo/P ratios of 11.0 and 12.0 wt%, which are required to manufacture heteropoly acid composite materials [4].

3.1.5 Surface area and pore volume

MVPA and MVPA/Kaolin have BET surface areas of 2.7 and 15.2 m2 g−1, respectively (Table 1). MVPA and MVPA/Kaolin have pore sizes of 85.1 and 162.2 (Å) respectively, and pore volumes of 0.006 and 0.089 cm3 g−1. The BET surface area of MVPA/Kaolin is determined by the support material's basic structure, kaolin. The experimental results might be understood to mean that in the MVPA-modified material, the internal pores and surface of kaolin are filled with MVPA, and the structure of the support is unchanged even after MVPA functionalization [4, 24, 25]. Figure 6 shows the N2 adsorption–desorption isotherms of MVPA and MVPA/Kaolin.

3.1.6 31P Nuclear Magnetic Resonance (31P NMR) spectra

31P MAS NMR spectra (Fig. 7) at 10 kHz for pure MVPA showed a sharp signal, recorded at − 3.28 ppm that could be assigned to P–OH groups associated with phosphomolybdates in MVPA, supported by the existing literature [4, 26].

3.2 Degradation study of Chromotrope 2R dye

3.2.1 Catalytic activity study

The catalytic oxidation of chromotrope 2R has been taken as the model application using synthesized hybrid MVPA/Kaolin catalyst. UV–Vis spectra, showing degradation of Chromotrope 2R dye in the presence of MVPA/Kaolin are presented in Fig. 8.

The primary absorbance band at 508 nm is visible in Chromotrope 2R. The oxidation of Chromotrope 2R with H2O2 occurs once the catalyst is introduced, and the absorbance band decreases, practically leveling out after 60 min (Fig. 8). As oxidation destroys the aromatic structure interacting with the azo group (N=N), OH, and –SO3H9 (GC–MS), the degradation of the dye leads to a few simpler active acid species. In approximately 60 min, 99.1% of Chromotrope 2R was degraded in the presence of the catalyst, MVPA/Kaolin. These results are far superior to those obtained from Fenton degradation of the dye. The current dye degradation method is more straightforward and efficient, and the catalyst may be recovered and reused. When compared to traditional Fenton oxidation techniques, the degradation might be accomplished in a fraction of the time [27]. In this study, the oxidation proceeds with H2O2 in the reactant feed, since the conversion is based on.OH radicals. The OH-radicals originate from O on the catalytic system and H atom cleaved from the substrate (either water or C2R since the reactions were carried out in aqueous solution) as dissolved oxygen is not likely to take part in the oxidation process directly. Participation of dissolved oxygen can also be ruled out since the reaction does not slow down appreciably. The hydroxyl radicals play an important role in the degradation process. The electron acceptor, hydrogen peroxide, in the solution, enhances the formation of hydroxyl radicals and inhibits the electron/hole (e–/H+) pair recombination. The mechanistic pathway for the degradation of the dye, chromotrope 2R, along with the formation of probable intermediates is depicted in Fig. 9. The end products of dye degradation were identified by GC–MS as (i) malonic acid, and (ii) oxalic acid, based on measurements of the reaction products, and these compounds are likely to mineralize to CO2 and H2O.

Degradation of dye pollutants by catalytic process has been regarded as the most efficient green method for removal of organic dyes from contaminated water [15, 17, 22, 23]. The improved toxicity and carcinogenicity of the components, released from industrial effluents, have always been considered as a significant environmental issue and the present work demonstrates one possible approach to control the same. As dyes are widely used in textile and paper industries, and exposure to them and their natural degradation products may lead to skin diseases, eye irritations, etc., including serious carcinogenicity, any process development to convert them to harmless products could be considered as a welcome development in environmental sustainability. The present work has developed a low-cost and easy-handling type catalyst, which has potential to be used for treatment of dyes in water.

A catalyst optimization study was carried out to determine the amount of catalyst, necessary for the degradation of Chromotrope 2R (Table 2). The degradation reaction of Chromotrope 2R was catalyzed by using 1, 3, 5, 8, 10 g L−1 MVPA/kaolin that took 80, 70, 60, 60, and 60 min for completion respectively. The optimum catalyst load was 5 g L−1 resulting in maximum conversion of Chromotrope 2R in 60 min (Fig. 10).

3.2.2 Reusability of the catalyst

The possibility of recycling the catalyst, MVPA/Kaolin, after the initial degradation reaction of Chromotrope 2R was investigated using a set of reaction parameters (50 mL Chromotrope 2R (2.0 × 10–4 mol L−1), 50 mL H2O2 (10–4 mol L−1), and 5 g L−1 MVPA/Kaolin). This series of tests was also used to assess the stability of the catalyst in oxidative degradation reactions, a prerequisite for utilizing the catalyst in real-world applications. The reaction mixture was filtered after the first cycle of the dye catalytic degradation was completed to get the MVPA/Kaolin catalyst. The catalyst was properly rinsed with distilled water several times and the MVPA/Kaolin residue was allowed to dry overnight, calcined at 500 °C for 2 h in a muffle furnace. The MVPA/Kaolin catalyst was recovered and employed as a catalyst in a subsequent run of the catalytic reaction. It was discovered that the reaction can be repeated in six cycles with the same catalyst without much performance loss (Fig. 11).

4 Conclusions

Novel and efficient Keggin type MVPA/Kaolin was successfully synthesized with vanadium-substituted molybdophosphoric heteropoly acids. Characterization studies confirmed the regular layered crystal structure of the hybrid catalyst with thermal stability, increased surface area, pore diameter and pore volume. The catalyst exhibited a high catalytic activity for destroying up to 99.1% of Chromotrope 2R dye in aqueous media by oxidation with H2O2 under optimum reaction conditions. The work has revealed that MVPA/Kaolin catalyst could bring about near complete degradation of the azo dye by converting it to smaller acidic components like malonic acid and oxalic acid, that could undergo further mineralization to CO2 and water. The work establishes MVPA/Kaolin as a potential high-performance catalyst in environmental treatment processes. The recyclability of the eco-friendly catalyst is an additional advantage for its environmental use. The experiments carried out in the laboratory have yielded promising results. For extending the work to actual application in the field, the processes have to be upscaled for use with large volumes of dye-containing wastewater. One area needing immediate attention would be to increase the yield of the catalyst as it will have to be frequently replaced and reused.

Data availability

All data analyzed during this study are included in this published article.

References

Fournier M, Thouvenot R, Rocchiccioli-Deltcheff C (1991) Catalysis by polyoxometalates. Part 1. Supported polyoxoanions of the Keggin structure: spectroscopic study (IR, Raman, UV) of solutions used for impregnation. J Chem Soc Faraday Trans 87(2):349–356. https://doi.org/10.1039/FT9918700349

Parida KM, Mallick S (2008) Hydroxylation of phenol over molybdovanadophosphoric acid modified zirconia. J Mol Catal A Chem 279(1):104–111. https://doi.org/10.1016/j.molcata.2007.10.005

Zhang Q, Lei D, Luo Q, Yang X, Wu Y, Wang J, Zhang Y (2021) MOF-derived zirconia-supported Keggin heteropoly acid nanoporous hybrids as a reusable catalyst for methyl oleate production. RSC Adv 11(2021):8117–8123. https://doi.org/10.1039/D1RA00546D

Mayani SV, Mayani VJ, Kim SW (2013) Synthesis of molybdovanadophosphoric acid supported hybrid materials and their heterogeneous catalytic activity. Mater Lett 111(2013):112–115. https://doi.org/10.1016/j.matlet.2013.08.078

Mizuno N, Misono M (1994) Heteropolyanions in catalysis. J Mol Catal 86(1–3):319–342. https://doi.org/10.1016/0304-5102(93)E0155-A

Hill CL (2003) Comprehensive coordination chemistry II, 2nd edn. Elsevier, Amsterdam, p 679

Neumann R, Khenkin AM (2006) Molecular oxygen and oxidation catalysis by phosphovanadomolybdates. Chem Commun 24:2529–2538. https://doi.org/10.1039/B600711M

Zhang F, Maiping G, Hanqingd GE, Wang J (2007) Hydroxylation of benzene with hydrogen peroxide over highly efficient molybdovanadophosphoric heteropoly acid catalysts. Chin J Chem Eng 15(6):895–898. https://doi.org/10.1016/S1004-9541(08)60021-X

Villabrille P, Romanelli G, Gassa L, Vazquez P, Caceres C (2007) Synthesis and characterization of Fe- and Cu-doped molybdovanadophosphoric acids and their application in catalytic oxidation. App Catal A 324:69–76. https://doi.org/10.1016/j.apcata.2007.03.011

Nagaraju P, Balaraju M, Reddy KM, Prasad PS, Lingaiah N (2008) Selective oxidation of allylic alcohols catalyzed by silver exchanged molybdovanado phosphoric acid catalyst in the presence of molecular oxygen. Catal Commun 9(6):1389–1393. https://doi.org/10.1016/j.catcom.2007.11.038

Rana S, Mallick S, Parida KM (2012) Selective oxidation of benzaldehyde by molecular oxygen over molybdovanadophosphoric acid supported MCM-41. J Porous Mater 19(4):397–404. https://doi.org/10.1007/s10934-011-9487-4

Popova GY, Andrushkevich TV, Semionova EV, Chesalov YA, Dovliova LS, Rogov VA, Parmon VN (2008) Heterogeneous selective oxidation of formaldehyde to formic acid on V/Ti oxide catalysts: the role of vanadia species. J Mol Catal A Chem 283(1–2):146–152. https://doi.org/10.1016/j.molcata.2007.12.019

Mayani VJ, Mayani SV, Kim SW (2017) A sustainable nanocomposite Au(Salen)@CC for catalytic degradation of eosin Y and Chromotrope 2R dyes. Nat Sci Rep 7(2017):7239–7243. https://doi.org/10.1038/s41598-017-07707-6

Kunz A, Peralta-Zamora P, Duran SG (2002) New trends in the treatment of textile effluent. Chem New 25(1):78–82. https://doi.org/10.1590/S0100-40422002000100014

Umbuzeiro GA, Freeman HS, Warren SH, Oliveira DP, Watanade YT, Claxton LD (2004) The contribution of azo dyes to the mutagenic activity of the Cristais River. Chemosphere 60(1):55–64. https://doi.org/10.1016/j.chemosphere.2004.11.100

Sharma KP, Sharma S, Singh PK, Kumar S, Grover R, Sharma PK (2007) A comparative study on characterization of textile wastewaters (untreated and treated) toxicity by chemical and biological tests. Chemosphere 69(1):48–54. https://doi.org/10.1016/j.chemosphere.2007.04.086

Ahmed MA-D, Essawy AA, Diab AK, Mohamed WS (2020) Facile synthesis and characterization of novel Gd2O3–CdO binary mixed oxide nanocomposites of highly photocatalytic activity for wastewater remediation under solar illumination. J Phy Chem Solids. https://doi.org/10.1016/j.jpcs.2020.109666

Mohamed WS, Abu-Dief AM (2018) Synthesis, characterization and photocatalysis enhancement of Eu2O3-ZnO mixed oxide nanoparticles. J Phys Chem Solids. https://doi.org/10.1016/j.jpcs.2018.02.008

Ahmed MA-D, Mohamed WS (2017) α-Bi2O3 nanorods: synthesis, characterization and UV-photocatalytic activity. Mater Res Express 4:035039. https://doi.org/10.1088/2053-1591/aa6712

Banerjee S, Chattopadhyaya MC (2017) Adsorption characteristics for the removal of a toxic dye, tartrazine from aqueous solutions by a low cost agricultural by-product. Arab J Chem 10(2):S1629–S1638. https://doi.org/10.1016/j.arabjc.2013.06.005

Hadjltaief HB, Ameur SB, Costa PD, Zina MB, Galvez ME (2018) Photocatalytic decolorization of cationic and anionic dyes over ZnO nanoparticle immobilized on natural Tunisian clay. Appl Clay Sci 152:148–157. https://doi.org/10.1016/j.clay.2017.11.008

Rafaqat S, Ali N, Torres C, Rittmann B (2022) Recent progress in treatment of dyes wastewater using microbial-electro-Fenton technology. RSC Adv 12(27):17104–17137. https://doi.org/10.1039/d2ra01831d

Thanavel M, Kadam SK, Biradar SP, Govindwar SP, Jeon B-H, Sadasivam SK (2019) Combined biological and advanced oxidation process for decolorization of textile dyes. SN Appl Sci 97:1–16. https://doi.org/10.1007/s42452-018-0111-y

Bordoloi A, Lefebvre F, Halligudi S (2007) Selective oxidation of anthracene using inorganic–organic hybrid materials based on molybdovanadophosphoric acids. J Catal 47(2):166–175. https://doi.org/10.1016/j.jcat.2007.01.020

Mayani VJ, Mayani SV, Kim SW (2012) Development of nanocarbon gold composite for heterogeneous catalytic oxidation. Mater Lett 87:90–93. https://doi.org/10.1016/j.matlet.2012.07.071

Salem IA, El-Ghamry HA, El-Ghobashy MA (2015) Application of montmorillonite–Cu(II)ethylenediamine catalyst for the decolorization of Chromotrope 2R with H2O2 in aqueous solution. Spectrochim Acta Part A 139:130–137. https://doi.org/10.1016/j.saa.2014.11.053

Mayani SV, Mayani VJ, Bhattacharyya KG (2011) Chemistry of phenolic compounds. In: Baruah JB (ed) State of the art, chapter 13. Nova Science Publishers Inc, New York, p 181

Acknowledgements

This research was supported by Department of Chemistry, Marwadi University, Rajkot, Gujarat, India.

Author information

Authors and Affiliations

Contributions

SVM designed the project and developed molybdovanadophosphoric acid supported kaolin hybrid catalyst and its characterization. TP and VJM accomplished the heterogeneous catalytic degradation study, catalyst optimization & recycling activity and degradation products identification. VJM and TP wrote the main manuscript. SVM managed the chemicals, characterization and research team. All the authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Patel, T., Mayani, V.J. & Mayani, S.V. Synthesis and characterization of novel molybdovanadophosphoric acid supported kaolin hybrid catalyst for Chromotrope 2R dye degradation in water. SN Appl. Sci. 4, 312 (2022). https://doi.org/10.1007/s42452-022-05201-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-022-05201-x