Abstract

Waste engine oil is a highly pollutant material that requires responsible management. Waste engine oil may cause damage to the environment when dumped into the ground or into water streams including sewers. The Ricinus communis leaves are one of the common wastes abundantly available in Iraq. The present study aims to investigate the performance and effects of Ricinus communis leaves as adsorbent for removing dissolved oil in oil–water emulsion, and the study investigated the effect of different parameters like particle size, pH, initial oil concentration, contact time, adsorbent/adsorbate (g/g) ratio. The maximum removal efficiency of Ricinus communis leaves was 98% at adsorbent particle size (150–300) micron, acidified solution (pH < 2), 90 min for adsorbent concentration of 400 mg/L. Several tests like BET, FTIR and SEM had been conducted for best interpretation of adsorption mechanism in this study. FTIR test displayed good ability of the adsorbent in adsorption of aliphatic and aromatic hydrocarbons. When isotherm study was applied to the results, best fitted data were close to Freundlich isotherm, and the results also had been fitted with kinetic adsorption equations; in the present work, pseudo-second-order equation was the best equation of oil engine uptake.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The problem associated with dissolved oil in water has played a negative role in the surrounding environment. This form of oil cannot be removed easily as floating form so it could pass treatment units and decrease their efficiency. Dissolved oil can form in oil by the presence of detergents [8]; in other words, because detergents contain compounds called “surfactants,” these compounds contain two ends: hydrophobic and hydrophilic [45]. Hydrophilic end attached to water molecules and the other end attached to oil molecules lead to decrease the surface tension of oil drops and disperse them all over solution, especially when there is mixing force like high-speed flow or high pressure [23]. The result is usually known as oil-in-water emulsion [22]. Oil-contaminated wastewater has led to several environmental problems because of its hazardous nature. The volume of oil-contaminated wastewater has increased in streak with the number of petroleum stations required to supply for the increasing number of vehicles. In Iraq, there are more than 500 car-wash facilities, excluding the region of Kurdistan, and some of them release their wastewater as an emulsion to the sewer system before any treatment [32]. Different treatment methods of oil in water were adopted in past time, and one of these methods was liquid–liquid extraction using toluene, ethanol and butanol by adding specific amount of these solvents to oil–water emulsion to extract oil molecules; the validity of these methods depends on type and amount of extracted solvent [36], and the other method was by using centrifugal force to enhance discounting of oil drops from solution toward the upsurface to be removed and then by skimming [19]. Adsorption of oil in water was done in several researches using different adsorbents such as potato peels [43], eggshell [1], bentonite [34] and organoclay [42].

Ricinus communis grows up rapidly up to 6 meters in height which contains leaves with average size of 30 cm [21], and it has resistance to draught and could grow up in different types of soil [39] and is the source of castor oil which contains ricinoleic acid in amount of 85–90%. Ricinoleic acid ((12-hydroxy-cis-9-octadecenoic acid) contains hydroxyl groups and can be hydrogenated to form ricinoleic acid methyl ester which could be reacted with chlorosulfonic acid to produce sodium methyl ester sulfonate that can be used as low-cost sulfonated surfactant [4, 6].

Ricinus had been used for healing accumulation of bloods under skin and wounds [46]; in previous researches, Ricinus communis waste was used for adsorption of Ni+2 [26] and treating Methylene Blue dye [27]. The aim of the present work was the investigation of the adsorption behavior of Ricinus communis leaves as environmentally friendly and inexpensive cost sorbent for the degradation of oil engine emulsion from aqueous solutions. Langmuir, Freundlich and BET models were used for explaining the experimental sorption records. The data were fitted with different types of kinetic models to comprehend the mechanism of biosorption.

2 Materials and methods

2.1 Sorbent and chemicals

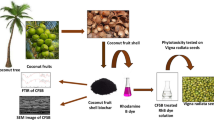

Ricinus communis leaves had been collected in sufficient quantity from Al-Dolab village, Hilla city, Babylon province, Iraq, which are available at much quantities and then sorted from any other unwanted pieces of stalks attached to them. Leaves were cleaned several times with distilled water until no foreign color was noticed, dried in an oven at 100° C for 24 h, allowed to be cooled at room temperature after sieving to particle sizes of 4760–2360, 2360–1200, 1200–600, 600–300 and 300–150 microns (Fig. 1) and then packed into stoppered bottle until use.

For evaluating whether there remains amount of castor oil in the particle solid textures, 80 mg of Ricinus particles at size of 300–150 micron was placed in a flask which contained 200 mL of distilled water and was shaken at 200 rpm for 90 min; then, the sample of solution was tested for COD by Lovibond COD test and the result was zero, meaning the particles could be used in adsorption without any effect on the solution characteristics.

BET test analysis was performed according to ISO-9277-2010 in Iraqi Petroleum Research and Development Center, and the surface area was 1.1175 m2/g for particle size of 300–150 micron. All chemicals used in this study were of analytical grade. HCL and NaOH solutions were used to adjust pH. Oil engine was used as pollutant source with characteristics shown in Table 1. Surfactant compound used in this study was sodium dodecyl sulfate (SDS)—NaC12H25SO4 in chemical formula—it has two ends: hydrophobic part, represented by sulfate and sodium, and hydrophilic part, represented by hydrocarbon tail; when surfactant mixed with water and oil, hydrophobic part of surfactant will be attached with oil drops leading to decrease their surface tension and spreading them in water body as the other surfactant part is water lover.

The oil emulsion was prepared with the desired concentrations of 250,500, 1000 and 2000 mg/L by injecting the required volume of oil and SDS into specific volume of distilled water and then stirring at 200 rpm for about 15 min; after that mixing, oil drops disappeared from water surface and water solution and then milk-like solution was obtained, which exhibited the characteristics of chemically stabilized solution. Diameter distribution of the emulsion was measured at different time intervals to ensure the stability using microscope, and the scanning cycles were set to three times to ensure the accuracy.

2.2 Experimental work

Two hundred milliliters of oil-in-water emulsion in suitable flask was placed in shaker (Jlab model) at 200 rpm, and several parameters were changed in batch study such as contact time, pH, particle size, oil concentration, adsorbent/adsorbate dosage (g/g). Scanning electron microscope (SEM) test for determining the pore sizes and adsorption morphology appearance was conducted, and also FTIR test was conducted for Ricinus leaves before and after adsorption process. Adsorption results data were used for fitting adsorption mechanism with best isotherm and kinetics equations.

2.3 Oil content test

EPA 1664A method was adopted in this research to evaluate oil content in oil–water emulsion after adsorption, and this method is liquid extracted method using n-hexane to dissolve and extract oil in suitable funnel [14]; then, n-hexane layer can be easily separated in beaker from solution because of its lighter density. n-hexane solution in beaker was heated on hot plate at 70 °C and distilled to be used again while oil remained in bottom of the beaker to be weighted, and difference between that weight and weight of blank one was the weight of dissolved oil in solution [28].

3 Results and discussion

Different experiments in batch study were conducted with different parameters to evaluate best conditions leading to high removal efficiency.

3.1 Stability

As can be seen from Fig. 2, the stability of oil engine emulsion was studied under different time intervals with 200 rpm and the size of oil engine droplet is quite stable up to 48 min and then exhibits slight instability later and finally oil engine droplet is separated into the oil and internal phases after 80 min.

3.2 Characterization studies

3.2.1 FTIR test

The FTIR spectroscopic analysis was performed using Shimadzu FTIR 8000 series spectrophotometer at Iraqi Ministry of Science and Technology for Ricinus communis leaves before and after adsorption, and the results are shown in Fig. 3; it can be seen from this figure that as oil is a mixture of different compounds, the FTIR spectrum reveals numerous principal functional groups assigned according to the wave numbers of their peaks. This figure shows peak in the range of 3200–3500 cm−1 and this was due to O–H groups found in oil mixture when hydrocarbon chain attached hydroxyl group toward its molecular structure, and other peak was in the range of 2850–2990 cm−1 which represented C–H groups found in aliphatic hydrocarbon the major oil compounds, and also the other range (1620–1680 cm−1) supported this fact because it refers to (C=C) group in aliphatic hydrocarbon. Range of 1440–1625 cm−1 also appears in this test which refers to C=C bond in aromatic hydrocarbons the other content of oil, (C–O) bond can be noticed also by the range (1000–1300 cm−1) indicated that some hydrocarbons attached Oxygen atom to their structure [24].

3.2.2 SEM test

Scanning electron microscopic test was conducted at Faculty of Pharmacy, Babylon university, and the attachment of oil molecules on the surface of adsorbent is clearly shown in Fig. 4. Grooves appeared in the texture of Ricinus leaves, and they provided good zones and attachment toward adsorbate to form dense layer and cover the texture.

3.3 Effect of particle size

Different particle sizes ranging from 150 to 4760 micron were tested in this study while other parameters were kept constant (pH = 2, 90-min contact time and with 1:5 adsorbent g/adsorbate g), and their results are presented in Fig. 5, which reveals that the removal efficiency decreased with increasing particle size, which is because more smaller particle and more specific area provided for solution and also less mass resistance provided to surrounding stream [3]. This finding was with agreement with finding of [7] and [35]. So particle size in the range of 150–300 micron was adopted in this study.

3.4 Effect of pH

The efficiency of the sorption process is pH dependent owing to the fact that the variation in the pH value leads to difference in the surface properties of the biosorbent and degree of ionization [2]. pH in the range of 2–10 was tested while keeping other parameters constant, and their results are presented in Fig. 6, which shows that acidified solution leads to high removal of dissolved oil compared to moderate or alkalinity state because acidity made attachment of oil drops by surfactant in weakness case so this drops start to separate and catch by solid surfaces of motioned adsorbent particles [17]. These results were in agreement with the finding of [13] who found that increase in pH value leads to decrease in the removal efficiency.

3.5 Effect of initial oil concentration

Different concentrations of oil engine (250, 500, 1000, 2000 and 4000) mg/L with adsorbent mass/adsorbate mass equal to 0.2 were used while other parameters were kept constant, and their results are presented in Fig. 7, which shows that increase in oil concentration leads to decreased removal efficiency because fixed adsorbent dosage means solid surfaces of particles reached their capacity before attaching another quantity of oil content [15, 34]. These results were in agreement with the finding of [3, 37].

3.6 Effect of contact time

As shown in Fig. 8, Ricinus leaves showed removal efficiency increased rapidly for the first 15 min and then slightly increased until reaching its maximum for about 60 min; rapid mass transfer of oil molecules starts by separating and attaching toward the solid surface, building textures of adsorbate molecules on adsorbent surfaces; after that, solid surfaces of particles starts to reach their capacity so removal curve starts to be less effective by time; in this state, the amount of uptake is near zero and adsorption process reaches equilibrium [15].

3.7 Effect of adsorbent dose

From the economic point of view, the evaluation of optimum biosorbent quantity happens to be one of the vital characteristics. Therefore, the dependency of oil engine biosorption on the biosorbent content was investigated by varying the dose of Ricinus leaves particles as can be seen in Fig. 9 which shows good removal efficiency in small adsorbent/adsorbate (g/g) ratio; more than 80% of oil content was removed in 90 min by adsorbent/adsorbate ratio equal to 0.2, and increase in adsorbent weight leads to more available solid surface to more attached oil drops [15]. when the concentration of adsorbent was 400 mg/L and concentration of both surfactant and adsorbate was 2000 mg/L, removal efficiency reached 94%. The adsorbent dosage used was less than that used in different previous researches: 1800 mg/L [30] and 4000 mg/L [5].

3.8 Effect of temperature and thermodynamics

The effect of temperature on adsorption process was investigated in the range of 20–60 °C, and their results are shown in Fig. 10. It can be seen from this figure that slight decrease in oil uptake was noticed by increasing temperature from 20 to 40 °C, and then the oil uptake continues to decrease noticeably by increasing the temperature to 60 °C. The decrease in removal efficiency by increasing temperature means Ricinus particles acted as exothermic adsorbent, and the mass transfer at heating up to high temperature starts to be reversed so portion of oil molecules had been separated from solid surface of adsorbent.

The thermodynamic parameters including change in Gibbs free energy ∆G, enthalpy ∆H and entropy ∆S were determined by using the following equations [41]:

where R is the gas constant = (8.314 J/mol K) and T temperature in (°K).

By using Eqs. (1) and (2), the values of (∆H), (∆S), and (∆G) where (− 10.45), (− 10.14), and (3.06) respectively, the negative sign of (∆H) confirm the exothermic nature of Ricinus [44].

3.9 Isotherm analysis

This analysis explains the behavior of adsorption related to adsorbent capacity by determining the amount of pollutant adsorbed to the available amount of adsorbent in equilibrium state [12]. Multiple models were built to evaluate this capacity, and each model used has special assumptions, and in this study, the analysis investigated applying the well-known models: Langmuir, Freundlich and BET.

3.9.1 Langmuir model

This model assumes monolayer is adsorbed to the solid surface of adsorbent [10, 25] and also adsorption energy is in equal distribution on solid surfaces [11]; two important parameters must be determined in this model: maximum adsorption in equilibrium and rate of adsorption. Langmuir model equation is as follows: [10]

3.9.2 Freundlich model

This isotherm was governed by empirical equation to analyze adsorption capacity and rate of adsorption in heterogeneous surfaces of adsorbent [29], and also this model covered the mechanism of multilayer adsorbed rather than monolayer as in Langmuir model [38]; the equation of Freundlich isotherm is as follows: [20, 29]:

3.9.3 BET isotherm model

This isotherm model is used widely because it can be used for monolayer as well as for multilayer in order to describe the mechanism of adsorption, and also this model can be considered to be applicable for the determination of active surface and pore sizes of adsorbents; it was assumed in this model that the interaction between solid surface of adsorbent and adsorbate molecules is larger than that between molecules of adsorbate neighbor [9].

The linear form of BET model is as follows [16]:

The results of the experimental and theoretical oil engine emulsion biosorption isotherms for Ricinus communis are portrayed in Fig. 11, and their correlation coefficients are presented in Table 2. Based on the values of the regression coefficient (R2), one can infer that the Freundlich equation was the best fitted model for oil engine emulsion biosorption isotherms on the Ricinus communis, thereby illuminating that multilayer adsorption occurred in this process. The reason can be illustrated by the complex composition and molecular size of oil engine. Besides, the Freundlich model constant (1/n) is 0.722 for emulsified diesel oil, revealing the adsorption process was favorable.

3.10 Kinetic analysis

Kinetic models can be helpful in understanding the mechanism of sorption and evaluating the performance of an adsorbent [31]. In this study, the sorption kinetics was modeled using the pseudo-first-order and pseudo-second-order kinetic models.

3.10.1 Pseudo-first-order kinetic model

Linear form of this model was used to fit the increase of (qt) which refers to amount of adsorbate adsorbed at specific interval of time as shown in Fig. 12a. Analysis took place toward the amount adsorbed at equilibrium (qe), and the linear equation is as follows [33]:

3.10.2 Pseudo-second-order kinetic model

In this model, uptake of adsorbate on the structure of adsorbent surface was not in linear form, which pretended the effectiveness of pore size on the adsorption mechanism because if the process obeys this model, it means adsorption was controlled by diffusion of adsorbate molecules into pores [40].

To analyze data with this model, plot of linear form was adopted as follows:

Linear form equation [18]:

The results in Fig. 12b showed good fitting to the experimental adsorption data for concentration ranges between 250 and 2000 mg/L with time, which obey illustrated linear increase in adsorbed quantity of oil on the solid surfaces of adsorbent.

The kinetic parameters for both models were evaluated as shown in Table 3.

4 Conclusion

Oil-in-water emulsion can be formed by mixing oil with water body in the presence of surfactant, and the resultant solution contained dissolved oil which is hard to be treated in conventional units. Ricinus leaves of 150–300 micron showed good ability to adsorb this kind of pollutants in acidified solution, and multilayer of oil molecules was attached to solid surfaces of adsorbent because Freundlich isotherm best fitted the adsorption process, rate of quantity adsorbed increased in nonlinear form as the results of kinetic models adopted in this research. Pseudo-second-order model well fitted the adsorption rate than first-order model.

Abbreviations

- ∆G :

-

Gibbs free energy (KJ mol−1)

- ∆H :

-

Enthalpy (J mol−1)

- ∆S :

-

Entropy (J mol−1)

- Ce:

-

Remaining concentration of adsorbate in solution (mg/L)

- q e :

-

Adsorbate that is adsorbed per weight of adsorbent(mg/mg)

- K L :

-

Langmuir isotherm constant (L/mg)

- Q :

-

Maximum adsorption capacity according to Langmuir isotherm model (mg/g)

- n :

-

Adsorption intensity according to Freundlich isotherm model

- K F :

-

Freundlich isotherm adsorption constant

- K B :

-

BET adsorption rate (L/mg)

- q s :

-

Maximum adsorption capacity according to BET isotherm model (mg/g)

- q t :

-

Adsorption capacity after specific time (mg/g)

- t :

-

Time (min)

- k 1 :

-

Pseudo-first-order constant

- k 2 :

-

Pseudo-second-order constant

References

Abdel-Jabbar NM, Zubaidy EAHA, Mehrvar M (2010) Waste lubricating oil treatment by adsorption process using different adsorbents. World Acad Sci Eng Technol Int J Chem Mol Eng 4(2):141–144

Aksu Z, Donmez G (2003) A comparative study on the biosorption characteristics of some yeasts for Remazol Blue reactive dye. Chemosphere 50:1075–1083

Albarazanjy MG (2017) Treatment of wastewater from oil refinery by adsorption on fluidized bed of stem date. Engineering and Technology Journal, Petroleum Technology Dept., University of Technology, Baghdad, Iraq, 5

Anwar M, Wahyuningsih TD (2017) Synthesis and characterization of dialkanolamides from castor oil (Ricinus communis) as nonionic surfactant. IOP Conf Ser Earth Environ Sci 101:012037. https://doi.org/10.1088/1755-1315/101/1/012037

As’ari RA, Mamat M, Bulat MAAAHK, Zuki HM (2017) Adsorption of oil in water onto modified oil palm mesocarp fibers. J Sustain Sci Manag 2017(2):27–35

Babu K, Maurya NK, Mandal A, Saxena VK (2015) Synthesis and characterization of sodium methyl ester sulfonate for chemically-enhanced oil recovery. Braz J Chem Eng 32(3):795–803. https://doi.org/10.1590/0104-632.20150323s00003642

Behnood R, Anvaripour B, Fard NJH, Farasati M (2013) Application of natural sorbents in crude oil adsorption. Iran J Oil Gas Sci Technol 2:01–11

Chaitanya PS, Rambabu V, Simhadri K (2016) Investigation on effect of water emulsified with diesel by surfactant addition on performance and emission characteristics of diesel engine. Int J Chem Sci 14:2835–2844

Chen Q, Tian Y, Li P, Yan C, Pang Y, Zheng L, Meng X (2017) Study on shale adsorption equation based on monolayer adsorption, multilayer adsorption, and capillary condensation. J Chem 2017:1–11. https://doi.org/10.1155/2017/1496463

Chung H-K, Kim W-H, Park J, Cho J, Jeong T-Y, Park P-K (2015) Application of Langmuir and Freundlich isotherms to predict adsorbate removal efficiency or required amount of adsorbent. J Ind Eng Chem 28:241–246. https://doi.org/10.1016/j.jiec.2015.02.021

Dada AO, Olalekan AP, Olatunya AM (2012) Langmuir, Freundlich, Temkin and Dubinin–Radushkevich isotherms studies of equilibrium sorption of Zn2+ unto phosphoric acid modified rice husk. IOSR J Appl Chem (IOSR-JAC) 3(2278-5736):38–45

Delgado LF, Charles P, Glucina K, Morlay C (2012) The removal of endocrine disrupting compounds, pharmaceutically activated compounds and cyanobacterial toxins during drinking water preparation using activated carbon–a review. Sci Total Environ 435–436:509–525. https://doi.org/10.1016/j.scitotenv.2012.07.046

Elanchezhiyan SS, Prabhu SM, Meenakshi S (2018) Effective adsorption of oil droplets from oil-in-water emulsion using metal ions encapsulated biopolymers: role of metal ions and their mechanism in oil removal. Int J Biol Macromol 112:294–305. https://doi.org/10.1016/j.ijbiomac.2018.01.118

EPA (1999) Method 1664, Revision A: N-Hexane Extractable Material (HEM; Oil and Grease) and Silica Gel Treated N-Hexane Extractable Material (SGTHEM; Non-polar Material) by Extraction and Gravimetry United States Environmental Protection Agency, Office of Water Washington, DC 20460

Fadali OA, Ebrahiem EE, Farrag TE, Mahmoud MS, El-Gami A (2013) Treatment of oily wastewater production from refinery processes using adsorption technique. Minia J Eng Technol. Chemical Engineering Department, Faculty of Engineering, El-Minia University, El-Minia, Egypt & Environment Public Authority, State of Kuwait, 32

Foo KY, Hameed BH (2010) Insights into the modeling of adsorption isotherm systems. Chem Eng J 156(1):2–10. https://doi.org/10.1016/j.cej.2009.09.013

Hamid MA, Onur M (2013) Effects of concentration, temperature, and pH on anionic surfactant adsorption isotherm. Platform—J Eng Sci Soc

Ho KS, McKaf G (1998) The kinetics of sorption of basic dyes fi-om aqueous solution by sphagnum moss peat. Can J Chem Eng 76(4):822–827

Islam S (2006) Investigation of oil adsorption capacity of granular organoclay media and the kinetics of oil removal from oil-in-water emulsions. Master thesis, Texas A&M University, USA

Ismail MGBH, Weng CN, Rahman HA, Zakaria NA (2013) Freundlich Isotherm equilibrium equations in determining effectiveness a low cost absorbent to heavy metal removal in wastewater (Leachate) At Teluk Kitang Landfill, Pengkalan Chepa, Kelantan, Malaysia. J Geogr Earth Sci 1:01–08

Jena J, Gupta AK (2012) Ricinus communis Linn: a phytopharmacological review. Int J Pharm Pharm Sci 4(4):25–29

Kamba EA, Itodo AU, Ogah E (2016) Utilization of different emulsifying agents in the preparation and stabilization of emulsions. Int J Mater Chem 3:69–74. https://doi.org/10.5923/j.ijmc.20130304.01

Krstonosic V, Dokic L, Nikolic I, Dapcevic T, Hadnadjev M (2012) Influence of sodium dodecyl sulphate concentration on disperse and rheological characteristics of oil-in-water emulsions stabilized by OSA starch-SDS mixtures. J Serb Chem Soc 77(1):83–94. https://doi.org/10.2298/jsc100630150k

Kupareva A, Mäki-Arvela P, Grénman H, Eränen K, Sjöholm R, Reunanen M, Murzin DY (2012) Chemical characterization of lube oils. Energy Fuels 27(1):27–34. https://doi.org/10.1021/ef3016816

Langmuir I (1916) The constitution and fundamental properties of solids and liquids. J Am ChemSoc 38:2221–2295

Makeswari M, Santhi T (2013) Optimization of preparation of activated carbon from Ricinus communis leaves by microwave-assisted zinc chloride chemical activation: competitive adsorption of Ni2+ ions from aqueous solution. J Chem. https://doi.org/10.1155/2013/314790

Makeswari M, Santhi T, Ezhilarasi MR (2016) Adsorption of methylene blue dye by citric acid modified leaves of Ricinus communis from aqueous solutions. J Chem Pharm Res 8(7):452–462

Mathew M (2009) A comparison study of gravimetric and ultraviolet fluorescence methods for the analysis of total petroleum hydrocarbons in surface water. Master thesis, The Department of Civil and Environmental Engineering, Northeastern University Boston, Massachusetts

Meroufel B, Benali O, Benyahia M, Benmoussa Y, Zenasni MA (2013) Adsorptive removal of anionic dye from aqueous solutions by Algerian kaolin: characteristics, isotherm, kinetic and thermodynamic studies. J Mater Eviron 4:482–491

Misau MI, El-Nafaty UA, Surajudeen A, Makarfi YI (2015) Oil removal from produced water using surfactant modified eggshell. Int Proc Chem Biol Environ Eng 85:84e92. https://doi.org/10.7763/ipcbee

Mohammed AA, Abed FI, Al-Musawi TJ (2016) Biosorption of Pb(II) from aqueous solution by spent black tea leaves and separation by flotation. Desal Water Treat 57:2028–2039

Mustafa YA, Alwared AI, Ebrahim M (2013) Removal of oil from wastewater by advanced oxidation process/homogenous process. J Eng 19(6):686–694

Nethaji S, Sivasamy A, Mandal AB (2012) Adsorption isotherms, kinetics and mechanism for the adsorption of cationic and anionic dyes onto carbonaceous particles prepared from Juglans regia shell biomass. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-012-0112-0

Okiel K, El-Sayed M, El-Kady MY (2010) Treatment of oil–water emulsions by adsorption onto activated carbon, bentonite and deposited carbon. Egypt J Petrol 20:9–15. https://doi.org/10.1016/j.ejpe.2011.06.002

Onwuka JC, Agbaji EB, Ajibola VO, Okibe FG (2018) Treatment of crude oil-contaminated water with chemically modified natural fiber. Appl Water Sci 8:86

Osman DI, Attia SK, Taman AR (2017) Recycling of used engine oil by different solvent. Egypt J Petrol 27(2):221–225. https://doi.org/10.1016/j.ejpe.2017.05.010

Razavi Z, Mirghaffari N, Rezaei B (2014) Adsorption of crude and engine oils from water using raw rice husk. Water Sci Technol 69(5):947–952. https://doi.org/10.2166/wst.2013.804

Saadi R, Saadi Z, Fazaeli R, Fard NE (2015) Monolayer and multilayer adsorption isotherm models for sorption from aqueous media. Korean J Chem Eng 32(5):787–799. https://doi.org/10.1007/s11814-015-0053-7

Salihu BZ, Gana AK, Apuyor BO (2012) Castor oil plant (Ricinus communis L.): botany, ecology and uses. Int J Sci Res (IJSR) 3(5):1333–1341

Santhi T, Manonmani S (2009) Removal of Methylene blue from aqueous solution by bioadsorption onto Ricinus communis epicarp Activated Carbon. Chem Eng Res Bull 13(1):1–5. https://doi.org/10.3329/cerb.v13i1.2518

Selvi A, Nilanjana D (2015) Remediation of cefdinir from aqueous solution using pretreated dead yeast Candida sp. SMN04 as potential adsorbent: an equilibrium, kinetics and thermodynamic studies. Der Pharmacia Lettre 7(4):74–81

Sulaymon AH, Kassim WMS, Nasir MJ (2011) Organoclay for adsorption of binary system of pollutants from wastewater. J Eng 1(17):149–158

Tontiwachwuthikul P, Zubaidi IA, Rennie E, Schubert S, Seitz M, Selinger-Silva C (2016) Remediation of water from waste lubricating oil spill using potato peels. In: Proceedings of the 3rd international conference on fluid flow, heat and mass transfer, Ottawa, Canada

Vijayakumar G, Tamilarasan R, Dharmendirakumar M (2012) Adsorption, kinetic, equilibrium and thermodynamic studies on the removal of basic dye rhodamine-B from aqueous solution by the use of natural adsorbent perlite. J Mater Environ Sci 1:157–170

Vu TV, Papavassiliou DV (2018) Oil-water interfaces with surfactants: a systematic approach to determine coarse-grained model parameters. J Chem Phys 148(20):204704. https://doi.org/10.1063/1.5022798

Worbs S, Kohler K, Pauly D, Avondet MA, Schaer M, Dorner MB, Dorner BG (2011) Ricinus communis intoxications in human and veterinary medicine-a summary of real cases. Toxins (Basel) 3(10):1332–1372. https://doi.org/10.3390/toxins3101332

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jaber, W.S., Alwared, A.I. Removal of oil emulsion from aqueous solution by using Ricinus communis leaves as adsorbent. SN Appl. Sci. 1, 944 (2019). https://doi.org/10.1007/s42452-019-0970-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-0970-x