Abstract

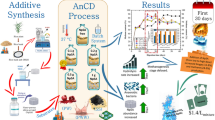

In this study, hazelnut shells, orange peel, and melon seeds were selected as raw materials in the preparation of activated carbon. Various activators at different concentrations under two activation temperatures of 300 °C and 500 °C were utilized. All produced adsorbents and a commercial activated carbon as a reference were used for the adsorption of acetic acid from its aqueous solutions in the various initial concentrations. The effect of the amounts of adsorbents was also studied. Removal efficiencies (Re%) and adsorption capacities (Qe) were experimentally determined. Langmuir, Freundlich, and Temkin isotherms were modelled, and their parameters were calculated. The surface area, pore volumes, and average pore width of the activated carbons were characterized by N2 adsorption at 77.35 K using the BET, t-plot, and BJH methods, respectively. The highest BET surface area of the activated carbon from hazelnut shells was obtained as 717.738 m2/g at 500 °C activation temperature and 60% H3PO4 concentration. SEM images and FTIR analyses were investigated. It was found that activated carbons of hazelnut shells and orange peel showed higher efficiencies than commercial activated carbon.

Similar content being viewed by others

Introduction

Activated carbon is the common name of carbonaceous materials having a large surface area, high surface reactivity, and suitable pore structure. It is widely used not only as an adsorbent for the removal of organic chemicals and metal ions from air, gases, potable water, and wastewater, but also as a catalyst or a catalyst support in the catalytic processes (Yahya et al. 2015) Therefore, an activated carbon can play important roles in the chemical, pharmaceutical, and food industries. Although there is no limit for the raw materials to produce activated carbon, cheap materials with lower inorganic and higher carbon content are preferred. A raw material used for this purpose can be mineral, botanic, or polymer-based. Particularly, wastes of agricultural materials are highly favoured as raw materials (Alaya et al. 2000; Singh et al. 2003; Ghorbani et al. 2020). In this way, some of the wastes are removed during the low-cost production of activated carbon (Muhammad et al. 2020; Belhamdi et al. 2016; Naushad et al. 2016). In the literature, there are many studies on the production of activated carbon from various agricultural wastes such as coconut husk (Kirubakaran et al. 1991), rice bran (Suzuki et al. 2007), pomegranate seed (Uçar et al. 2009), and nutshell (Hayashi et al. 2002). In the previous study of our group, we investigated the removal of biophenols from olive mill wastewater by activated carbon (Senol et al. 2017).

The activation process is very important because of determining the adsorbent characteristics. Production of activated carbon is carried out with a physical or chemical activation stage and a carbonization stage processing at temperatures of 300–800 °C under an inert atmosphere. In the physical activation method, a raw material is treated at high temperatures (800–1000 °C) under a CO2 or steam atmosphere. On the other hand, some compounds such as H3PO4, H2SO4, ZnCl2, MgCl2, AlCl3, KOH, K2CO3, KClO3, NaOH, Na2CO3, and NH4Cl are used in the chemical activation of raw materials (Özsin et al. 2019; Amirza et al. 2017; Sayğılı et al. 2015; Karaboyacı et al. 2017). According to the comparative articles, chemical activation has many advantages in the preparation of activated carbon and adsorption processes. For example, carbonization occurs at lower temperatures, on larger surface areas, in shorter times, and finishes with higher yields. However, this kind of activation includes a washing stage and can cause corrosiveness (Soleimani and Kaghazchi 2007; Gómez-Serrano et al. 2005; Ahmadpour et al. 1996).

In the point of acetic acid adsorption onto agricultural-based activated carbons, there are some studies working with maize cobs (Dina et al. 2012), sweet lemon peel, pineapple peel (Bhoy et al. 2018), watermelon peel (López-Velandia et al. 2014), Acacia nilotica (Elhussien and Isa 2015), and bitter leaf (Vernonia amygdalina) (Sintayehu et al. 2016). According to earlier studies, adsorption capacity grows with the adsorbent amount and initial acid concentration at the first, but then it reduces significantly because acid molecules aggregate onto adsorbent material (Adekola et al. 2017). Interaction between sorbate and sorbent systems is gravitational, and operation is heterogeneous and exothermic (Bi et al. 2008). In several studies, Langmuir, Freundlich, Temkin, and Dubinin–Radushkevich isotherms were employed for adsorption of activated carbon prepared from agricultural wastes (López-Velandia et al. 2014; Sintayehu et al. 2016; Chukwuemeka-Okorie et al. 2021; Adekola et al. 2017; Zhanga et al. 2020).

In this study, we investigated whether hazelnut shell, orange peel, and melon seeds are available as raw materials to prepare activated carbons for recycling of acetic acid from an aqueous medium, how activation parameters such as temperature, type, and concentration of chemical activator, adsorbent amount affect activated carbon yield and adsorption capacity, and which adsorption isotherm is useful for the processes. The specific surface area, pore volume, and pore size of samples were investigated. To determine the effectiveness of the activated carbons, functional groups of the products were detected by FTIR analyses. SEM images were used for the visualization of surface porosities.

Materials and methods

Agricultural wastes used in this work were obtained from different cities in Turkey. Hazelnut shells, orange peels, and melon seeds were brought from Giresun, Fethiye, and Adana, respectively. H3PO4 and ZnCl2 were purchased from Merck Millipore and used as chemical activators separately. Commercial activated carbon and glacial acetic acid were also purchased from the same firm. Carbonization and activation processes were performed with an Elektromag branded high-temperature furnace under a nitrogen atmosphere.

Preparations of the raw materials

All raw materials were washed with distilled water to remove the impurities, dried at room temperature, crushed, and sieved into a particle size of 50–100 µm. After this procedure, they were stored in closed containers in a dry, cool, and dark place.

Preparation of the activated carbons

Activated carbons were prepared in three ways. In one of these ways, a chemical activator was not used. In the other two ways, the effects of H3PO4 and ZnCl2 were investigated as chemical activators on the carbonization and adsorption processes.

Without activator

Subsieve particles of 100 µm sieving of prepared raw materials were weighted at 20 g. One gram of each was carbonized in the preheated furnace at temperatures of 300 °C and 500 °C under an inert atmosphere. During the one-hour carbonization and the cooling after the carbonization, the nitrogen flow rate was set to 50 mL/min. The cooled samples were washed with distilled water until their neutralization and dried in an oven at 100 °C. Then, all samples were sieved to 50 µm, and subsieve products were stored.

With ZnCl2

The prepared raw materials were sieved to 100 µm and weighed at 20 g. One gram of each subsieve material was wetted with 2 g of ZnCl2/water solutions prepared at the concentrations of 30% and 60% (w/w). Wet mixtures were dried in the oven heated up to 100 °C. Dry samples were carbonized and cooled in the same way as the procedure for activated carbon production without an activator. After the operation, cool samples were washed with 0.5 M HCl solution to remove excess ZnCl2 and then distilled water several times. At the end, all washed samples were dried again, crushed, sieved to 50 µm, and stored.

With H3PO4

Experimental procedure for activation of raw materials using H3PO4 to produce activated carbon was parallel to the procedure written above. However, the samples were washed with only distilled water to clean from an excess activator chemical.

Adsorption of acetic acid

For the comparison of adsorption capacities of the produced activated carbons, experiments were started with different initial concentrations (4%, 6%, 8%, and 10% (w/w)) of acetic acid. Four millilitres of each acid solution and 0.1 g of each activated carbon were added into an Erlenmeyer flask. All mixtures were shaken for 2 h in a water bath at ambient temperature until the equilibrium. The mixtures were filtered with filter paper, and the filtrates were titrated with 0.1 N NaOH.

Characterization of the activated carbons

Specific surface areas of activated carbon samples were determined with N2–BET method at 77.35 K using Quantachrome Instrument NOVA 3200e. The BET surface areas (SBET) of the activated carbon samples were calculated from the N2 adsorption isotherms using the BET equation (SBET = St/ma, where St is the total surface area and ma the mass of the sample). The adsorption data were obtained in a relative pressure, P/Po, range of 10–5 to 1. The micropore volumes of the activated carbon samples were calculated by applying the t-plot method. Besides, the total pore volume (Vt) and the average pore width of the samples were determined by using Barrett, Joyner, and Halenda (BJH) method. The average pore width was calculated by assuming a cylindrical shape of pores from the BET surface area and pore volume, d = 4Vt/SBET. The FTIR spectra were recorded using an infrared spectrometer (Perkin Elmer100). Scanning electron microscopy (SEM) analysis of samples was performed with FEI Quanta FEG-450.

Results and discussion

Activation yields

Activation yields for each raw material and experimental condition were calculated with Eq. 1 and are given in Table 1. The higher temperatures bring lower yields. The reason is the separation of volatile ingredients from the raw materials during carbonization. According to the yields, hazelnut shell has a lower amount of volatile substances and a larger amount of carbon than other raw materials. The yield also increased with the activator concentration due to the amount of the activator absorbed in the raw material. Besides these, whether using an activator and type of the activator affected the raw materials differently. In many instances, using an activator decreases the yield at higher temperatures especially. A possible reason for this case can be the volatility of activator chemicals. It is seen that ZnCl2 is useful for hazelnut shells and H3PO4 is useful for orange peel in general. On the other hand, melon seeds were very unstable at 500 °C. As a result of activation experiments, it was figured out that hazelnut shell is the most available agricultural waste with and without an activator chemical. Temperature is the major parameter. The activation stage processed at 300 °C gave a better yield than at 500 °C. The concentration of the activator chemical comes after the temperature, but it affects the yield positively in contrast to the temperature. Accordingly, the hazelnut shell showed the best result (64.22%) after the activation at the 300 °C with the ZnCl2 activator in the concentration of 60%.

Adsorption capacities

We selected four instances from Table 1 for the comparison of activator types, concentrations, and temperatures for each raw material and compared them with a commercial activated carbon. As another parameter of the process, the initial concentration of acetic acid was also changed. Adsorption capacity (Qe) and removal efficiency (Re) at the equilibrium were calculated with Eqs. 2 and 3 and are presented in Fig. 1.

Adsorption capacity (Qe) equals the amount of adsorbate per unit weight of adsorbent at the equilibrium and its unit is mg/g or mole/g depending on the concentrations of adsorbate in the solution at the initial conditions (C0) and the equilibrium (Ce). Adsorbate concentrations are given with the unit of mg/L or mole/L generally. V is the volume of the adsorbate solution in the unit of L. It was used that g for the adsorbent amount and mg for the adsorbate amount in this study. Removal efficiency (Re) is a percentage that represents the operation yield.

It was appeared that hazelnut shell-based activated carbon is more powerful than others for the adsorption. Acid removal efficiencies of the adsorbents from hazelnut shell and orange peel are higher for the diluted acid solutions in all processes. Maximum efficiencies were 14.75% and 13.78% for hazelnut shell and orange peel processed with H3PO4 activator in the concentration of 60% at the temperature of 500 °C for 4% initial concentration of acid solution, respectively. The adsorbents prepared in this condition have better efficiencies than the commercial material.

It seems that hazelnut shell is a better raw material to produce activated carbon and the removal of acetic acid. The temperature of carbonization and concentration of acid solution have important roles in the operation. The efficiency of the adsorption is related to temperature directly but to saturation adversely. These behaviours are alike to the knowledge from early studies (Dina et al. 2012; Sintayehu et al. 2016; Adekola et al. 2017; Mundhe et al. 2015). The type of activator chemical shows different effects on various raw materials.

Carbonization temperature was the major parameter of the adsorption stage. Processing at the temperature of 500 °C gave better results by a wide margin in just the same way as in activation yield. In fact, removal efficiency has a higher value in this case because a very porous structure forms while volatile compounds are vanishing. For this reason, adsorption capacities and removal efficiencies are going up at the higher temperatures.

With regard to chemical activators, H3PO4 is a preferable compound for first two raw materials at the same temperatures. A high concentration of the activator affected the efficiency positively in general due to the same way of the temperature. On the other hand, ZnCl2 is more useful for activation of melon seeds. Melon seeds are also different from those in the view of the initial acid concentration. It was determined that removal efficiencies of activated carbons from melon seeds did not affect from initial concentrations of the acid solution.

Effect of the adsorbent weight was studied for activated carbon produced from hazelnut shell (Fig. 2). The experiment which we used 0.1 g of activated carbon has the minimum removal efficiency (14.75%) but the maximum adsorption capacity (590 mg/g). With the increase of adsorbent amount, higher percentages were achieved. The efficiency remained at the same value (43.3%) for the adsorbent after 0.9 g. On the other hand, adsorption capacity decreased. In our studies, the amount of the acetic acid adsorbed was 590 mg onto 0.1 g of adsorbent, while 1772 mg of acetic acid molecules adsorbed onto 1 g of adsorbent. Briefly, the more amount of adsorbent gets the more amount of adsorbate until removal efficiency remains unchanged. The results in this topic are matching with those in the literature (Sintayehu et al. 2016; Adekola et al. 2017).

Adsorption isotherms

According to the Langmuir isotherm, a monolayer of adsorbate occurs in some places of adsorbent and there is no energy transfer between adsorbate molecules on the surface. It is useful to explain the transportation of metal ions between liquid and solid phases. Langmuir isotherm is given by:

A linear form of the equation is

or

where Qm is the monolayer adsorption capacity (mg/g or mol/g), KL is a constant related to the free energy of adsorption, and meanings of other terms are same with in the calculation of the adsorption yield.

A dimensionless separation factor is denoted with RL and calculated with Eq. 7.

Langmuir isotherm is favourable for an adsorption process and has an RL value between 0 and 1. If RL is greater than 1, Langmuir isotherm is unfavourable. Besides, RL = 0 indicates irreversible adsorption and RL = 1 indicates linear adsorption.

Freundlich isotherm is used for adsorption onto the heterogeneous surface and expressed that the adsorption rate reduces from the beginning of adsorption to the equilibrium due to saturation of adsorbate. Its equation is

and when we take its logarithm, it transforms into

In this Eq. (9), KF and 1/n are constants about the relative adsorption capacity of an adsorbent and intensity of the adsorption, respectively. In the case of 1/n equal to 1, the distribution of adsorbate among the phases is independent of the concentration. 1/n is less than 1 for normal adsorption and bigger than 1 for cooperative adsorption.

Temkin isotherm is another widely used adsorption isotherm. However, this isotherm overlooks the very lower and higher concentrations. It is stated that the heat of adsorption decreases linearly. It is expressed with the equation of

to simplify the equation,

Then,

where R is 8.314 J × mol−1 × K−1, T is the temperature in Kelvin, bT is the Temkin isotherm constant for a sorbate–sorbent system, and KT is the Temkin isotherm constant about uniform binding energy (Dada et al. 2012; Alade et al. 2012).

In the light of the knowledge above, we illustrate Langmuir, Freundlich, and Temkin isotherms for acetic acid adsorption onto three activated carbons in Figs. 3, 4, and 5, respectively.

It is explained that a single layer of the adsorbate molecules occurs onto adsorbent by Langmuir isotherm. The isotherm supposes that heat of energy distributes homogeneously and there is no energy transfer between adsorbate molecules. As can be seen from Table 2, R2 values of Langmuir isotherms which drew for hazelnut shell have higher values but maximum adsorbate amount adsorbed until the equilibrium was nearly same for first two raw materials. However, the isotherm has no meaning for adsorption onto activated carbon from melon seeds. Therefore, it can be declared that acetic acid molecules do not occur a single layer on melon seed-based activated carbons.

Freundlich and Temkin isotherms of all experiments have R2 values between 0.90 and 1. It is understood that the pressure is an important factor for the saturation in the experiments. According to Table 2, Freundlich isotherms drew for hazelnut shell have bigger n values. It means that sorption surface is very heterogeneous. Sorption process on the material needs more energy because its KT values are bigger which means that binding energies are higher.

It is found that adsorption capacity is related to many parameters strongly. Thus, a specific sorbate–sorbent system can be in accordance with different isotherms in various conditions. In some experiments, process might be finished even though equilibrium has not consisted. In that case, the situation causes unrealistic shaped isotherms.

Nonetheless, our findings about heterogeneity of the sorbate–sorbent systems, tendency to gravitational interaction, and Langmuir separation factors (RL) are in a similar manner with the literature (Elhussien and Isa 2015; Sintayehu et al. 2016; Bi et al. 2008).

BET analyses of the produced activated carbon

In this study, it was seen that activated carbons from hazelnut shells showed better removal efficiencies than the activated carbon from orange peel and melon seeds. For this reason, BET surface area measurements of activated carbons from hazelnut shells were carried out. BET surface area, total pore volume, and micropore volume of the activated carbons prepared at different conditions are given in Table 3. It was observed that the samples impregnated with 30% H3PO4 solution at 300 and 500 °C had lower values of surface area (Table 3, entries 1 and 3). In addition, the samples carbonized at 300 °C gave relatively lower results (270.872 m2/g). The activated carbon from the hazelnut shell, which was impregnated with 60% H3PO4 and carbonized at 500 °C, had the highest BET area, 717.738 m2/g. The specific surface area of commercial powdered activated carbon used in this study is SBET ≥ 800 m2/g. It was determined that the BET surface area values increased as the H3PO4 concentration and carbonized temperature increased (Table 3, entry 4). Micropore volume and total pore volume were similarly increased. As it is shown in Table 3, as the activation temperature increased, micropore volumes increased. However, the effect of H3PO4 concentration was lower on micropore volume. The N2 adsorption isotherms of activated carbons prepared with different H3PO4 concentrations and activation temperatures are shown in Fig. 6.

In the literature, it was shown that using higher concentrations of phosphoric acid in the impregnation process resulted in higher BET surface areas but likely tended to decrease after the maximum point was reached. Besides, activation temperature is an important parameter of the BET surface area. Studies have shown that as the activation temperature increases, the surface area increases but decreases at very high temperatures. The maximum activation temperature is usually reported as 500 °C. The decrease in surface area above 500 °C may be due to the degradation of the phosphate and polyphosphate bridges or precipitation of the obtained carbon samples. (Yang et al. 2011; Guo and Rockstraw 2006; Patnukao and Pavasant 2008; Demiral and Şamdan 2016). Although the surface area of activated carbon is generally between 400 and 1000 m2/g, this value may change in special-purpose productions (Morgan and Fink 1989). In a study by Kumaş and Sayın, the highest BET surface area was obtained as 1071.29 m2/g for the material carbonized at 500 °C and 65% H3PO4 (Kumaş and Sayın 2016). Çuhadar (2005) investigated the pore structures and surface areas of activated carbons produced from hazelnut shells at relatively low temperatures (300, 400, and 500 °C) and for different H3PO4 concentrations (30, 40, 50, and 60 wt%). It was determined that the sample impregnated with 60% H3PO4 and carbonized at 400 °C had the highest BET area of 596 m2/g (Çuhadar 2005). Özer and Çam (2002) produced activated carbon from sugar beet pulp treated with H3PO4 (30%) and carbonized at different temperatures (300–500 °C). The highest BET value (104.6 m2 /g) was obtained when the carbonization temperature was 500 °C (Özer and Çam 2002). In another study by Yagşi, the surface area of activated carbon produced from apricot stones by chemical activation technique using phosphoric acid was investigated and the highest BET area was found at 709 m2/g at 500 °C (Yagşi 2004). The results obtained in this study are similar to those obtained by other researchers.

SEM analyses of the produced activated carbon

Images of the raw materials and products were taken by scanning electron microscopy (SEM) and examined their pore structures. SEM images of hazelnut shell and orange peel taken before the activation processes are shown in Fig. 7a. In Fig. 7b, c, SEM images of the activated carbons produced from hazelnut shells and orange peel using ZnCl2 and H3PO4 chemical activators in the concentration of 60% are also shown. The differences in the morphology of the untreated and treated materials were observed clearly. Surfaces of untreated raw materials were found to be highly regular except for a few cracks. Figure 7b, c shows that pores and pinholes with a wide range of dimensions occurred with the effects of the activation processes, and in particular, the adsorbent in Fig. 7c had high surface areas.

Hazelnut shell and orange peel raw materials resulted in better yields during the activation stages than the melon seeds. Although the highest yields were observed at the temperature of 300 °C with two activator chemicals in concentrations of 60%, it was determined that the surface area increased at 500 °C in SEM images. There is an inversely proportional interaction between carbon yield and surface area. This observation is supported by the BET surface area of the activated carbon. In addition, these results are in agreement with the literature data (Kumaş and Sayın 2016; Çuhadar 2005).

FTIR analyses of the activated carbon

FTIR spectrum analyses of untreated and treated hazelnut shells were used to determine the chemical bonds of the raw materials (Figs. 8, 9). The differences were observed in the major functional groups of the raw materials in addition to the physical structure. Figure 8 shows FTIR spectrums of the materials untreated and treated with ZnCl2 in the concentration of 30% (w/w). The broad band at nearly 3300–3400 cm−1 shows the presence of O–H stretching vibration of alcohol, phenol, or carboxylic acid. The band between 2700 and 2900 cm−1 represents C–H stretching vibration in the methyl group. The band at 1700 cm−1 shows C=O vibrations from carbonyl compounds (esters, ketones, or carboxylic acids). The strong band at about 1600 cm−1 can be assigned to C=C aromatic ring stretching vibration. Another strong band at 1200 cm−1 can be caused by from C–O stretching vibration of alcohols, aliphatic ethers, and phenols. It was observed that the peaks at 1700 cm−1 and 1600 cm−1 weakened and the bands at 3300 cm−1, 2700–2900 cm−1, and 1200 cm−1 became more noticeable after being treated with ZnCl2.

Figure 9 shows the FTIR spectrums after the activation with H3PO4 in two different concentrations. The spectra are approximately very similar for two different concentrations. The peaks at 900–1200 cm−1 represent the hydrogen-bonded P=O, O–C stretching vibrations in P–O–C linkage, and P=O (OH). It was observed that some bands (3300 cm−1 and 1700 cm−1) in the active carbon without an activator disappeared or weakened after the activation with H3PO4.

Conclusion

Activated carbon has a wide range of usage as a natural adsorbent. In this study, the removal of acetic acid from an aqueous medium was accomplished using activated carbons prepared from hazelnut shells, orange peel, and melon seeds. The maximum removal efficiency was found at 14.75% with the hazelnut shell which was activated using 60% H3PO4 at 500 °C (Fig. 1). Both activated carbons from the hazelnut shell and orange peel showed better removal efficiencies than the commercial activated carbon. We found that activation yield was affected by the carbonization temperature negatively because of volatile compounds and from the concentration of activator chemicals positively due to the increasing weight of raw material. Removal efficiency increased with the increasing temperature in contrast to the increasing initial acid concentrations. At higher temperatures, volatile compounds of raw materials moved away from the materials under activation and a higher extent of porosity was achieved. Higher concentrations of the activator chemical resulted in higher adsorption capacities. Morphologies of adsorbents were observed in the SEM images, and the FTIR analyses of the materials showed the presence of phosphoric acid groups. The specific surface areas of activated carbon samples from hazelnut shells were determined with the N2–BET method. The highest BET surface area of the activated carbon was obtained as 717.738 m2/g at 500 °C activation temperature and 60% H3PO4 concentration. Adsorption capacity increased with rising the adsorbent amount; however, removal efficiency decreased. Effects of the activator chemicals had a great effect on the adsorption isotherms and efficiencies of sorbent–sorbate systems. According to the isotherms, it was understood that acetic acid molecules do not occur monolayer onto activated carbon produced from melon seed and binding energies are higher onto heterogeneous surface of hazelnut shell based activated carbon especially.

References

Adekola FA, Oba IA (2017) Biosorption of formic and acetic acids from aqueous solution using activated carbon from shea butter seed shells. Appl Water Sci 7(6):2727–2736

Ahmadpour A, Do DD (1996) The preparation of active carbons from coal by chemical and physical activation. Carbon 34(4):471–479

Alade AO, Amuda OS, Afolabi AO, Adelowo FE (2012) Adsorption of acenaphthene unto activated carbon produced from agricultural wastes. J Environ Sci Technol 5(4):192–209

Alaya MN, Girgis BS, Mourad WE (2000) Activated carbon from some agricultural wastes under action of one-step steam pyrolysis. J Porous Mater 7:509–517

Amirza MAR, Adib MMR, Hamdan R (2017) Application of agricultural wastes activated carbon for dye removal—an overview. In: International symposium on civil and environmental engineering MATEC web of conferences, vol 103, pp 1–12

Belhamdi B, Merzougui Z, Trari M, Addoun A (2016) A kinetic, equilibrium and thermodynamic study of l-phenylalanine adsorption using activated carbon based on agricultural waste (date stones). J Appl Res Technol 14:354–366

Bhoy KT, Upkare MM, Satpute SR, Chavan PV (2018) Adsorption studies on acetic acid using anionic resin and activated charcoal from pineapple peels and sweet lemon peels. Int J Res Eng Sci Manag 1(8):98–106

Bi MIG, Yapo AJ, Ello AS, Diabaté D, Trokourey A (2008) Adsorption of acetic and benzoic acids from aqueous solutions on activated carbon. J Soc Ouest-Afr Chim 26:53–57

Chukwuemeka-Okorie HO, Ekuma FK, Akpomie KG, Nnaji JC, Okereafor AG (2021) Adsorption of tartrazine and sunset yellow anionic dyes onto activated carbon derived from cassava sievate biomass. Appl Water Sci 11(27):1–8

Çuhadar Ç (2005) Production and characterization of activated carbon from hazelnut shell and hazelnut husk. In: Partial fulfillment of the requirements for the degree of master of science in chemical engineering

Dada AO, Olalekan AP, Olatunya AM, Dada O (2012) Langmuir, Freundlich, Temkin and Dubinin-Radushkevich isotherms studies of equilibrium sorption of Zn2+ unto phosphoric acid modified rice husk. IOSR J Appl Chem 3(1):38–45

Demiral I, Şamdan CA (2016) Preparation and characterisation of activated carbon from pumpkin seed shell using H3PO4. Anadolu Univ J Sci Technol A Appl Sci Eng 17(1):127–138

Dina DJD, Ntieche AR, Ndi JN, Ketcha Mbadcam J (2012) Adsorption of acetic acid onto activated carbons obtained from maize cobs by chemical activation with zinc chloride (ZnCl2). Res J Chem Sci 2(9):42–49

Elhussien MH, Isa YM (2015) Acetic acid adsorption onto activated carbon derived from pods of acacia nilotica var astringens (sunt tree) by chemical activation with ZnCl2. J Nat Sci Res 5(10):42–49

Ghorbani F, Kamari S, Zamani S, Akbari S, Salehi M (2020) Optimization and modeling of aqueous Cr(VI) adsorption onto activated carbon prepared from sugar beet bagasse agricultural waste by application of response surface methodology. Surf Interfaces 18:1–12

Gómez-Serrano V, Cuerda-Correa EM, Fernández-González MC, Alexandre-Franco MF, Macías-García A (2005) Preparation of activated carbons from chestnut wood by phosphoric acid-chemical activation. Study of microporosity and fractal dimension. Mater Lett 59(7):846–853

Guo Y, Rockstraw DA (2006) Physical and chemical properties of carbons synthesized from xylan, cellulose, and kraft lignin by H3PO4 activation. Carbon 44:1464–1475

Hayashi J, Horikawa T, Takeda I, Muroyama K, Ani FN (2002) Preparing activated carbon from various nutshells by chemical activation with K2CO3. Carbon 40(13):2381–2386

Karaboyacı M, Tama B, Şencan A, Kılıç M (2017) Recycling of rose wastes to activated carbon with ecological precursor. Bilge Int J Sci Technol Res 1(1):1–8

Kirubakaran CJ, Krishnaiah K, Seshadri SK (1991) Experimental study of the production of activated carbon from coconut shells in a fluidized bed reactor. Ind Eng Chem Res 30(11):2411–2416

Kumaş C, Sayın ZE (2016) Activated carbon production from hazelnut shells using phosphoric acid and boron. In: 16th international symposium on environmental issues and waste management in energy and mineral production, Istanbul, Turkey, 5–7 October

López-Velandia C, Moreno-Barbosa JJ, Sierra-Ramirez R, Giraldo L, Moreno-Piraján JC (2014) Adsorption of volatile carboxylic acids on activated carbon synthesized from watermelon shells. Adsorpt Sci Technol 32(2–3):227–242

Morgan I, Fink CE (1989) Activated carbon production. Chem Ind Eng 2:219

Muhammad B, Javed A, Nousahd H, Muhammad U, Shaukat S, Daud A (2020) Removal of Pb(II) from wastewater using activated carbon prepared from the seeds of Reptonia buxifolia. J Serb Chem Soc 85:265–277

Mundhe KS (2015) Adsorption study of acetic acid using low cost biosorbent. Int J Curr Microbiol Appl Sci 4(12):66–72

Naushad M, Khan MR, Al-Othman ZA, Al-Muhtaseb AH et al (2016) Water purification using cost effective material prepared from agricultural waste: kinetics, isotherms, and thermodynamic studies. Clean: Soil, Air, Water 44(8):1036–1045

Özer A, Çam G (2002) The determination of surface area and color adsorption capacity of activated carbon from sugar beet pulp treated with phosphoric acid. F Ü Müh Bil Der 14(1):191–197

Özsin G, Kılıç M, Varol EA, Pütün AE (2019) Chemically activated carbon production from agricultural waste of chickpea and its application for heavy metal adsorption: equilibrium, kinetic, and thermodynamic studies. Appl Water Sci 9(56):1–14

Patnukao P, Pavasant P (2008) Activated carbon from Eucalyptus camaldulensis Dehn bark using phosphoric acid activation. Bioresour Technol 99:8540–8543

Sayğılı H, Güzel F, Önal Y (2015) Conversion of grape industrial processing waste to activated carbon sorbent and its performance in cationic and anionic dyes adsorption. J Clean Prod 93:84–93

Senol A, Hasdemir IM, Hasdemir B, Kurdas I (2017) Adsorptive removal of biophenols from olive mill wastewaters (OMW) by activated carbon: mass transfer, equilibrium and kinetic studies. Asia-Pac J Chem Eng 12(1):128–146

Singh KP, Mohan D, Sinha S, Tondon GS, Gosh D (2003) Color removal from wastewater using low-cost activated carbon derived from agricultural waste material. Ind Eng Chem Res 42:1965–1976

Sintayehu YD, Lencha LT (2016) Adsorption and kinetic optimization study of acetic acid from aqueous solutions using activated carbon developed from Vernonia amygdalina wood. Am J Phys Chem 5(6):128–132

Soleimani M, Kaghazchi T (2007) Agricultural waste conversion to activated carbon by chemical activation with phosphoric acid. Chem Eng Technol 30(5):649–654

Suzuki RM, Andrade AD, Sousa JC, Rollemberg MC (2007) Preparation and characterization of activated carbon from rice bran. Bioresour Technol 98(10):1985–1991

Uçar S, Erdem M, Tay T, Karagöz S (2009) Preparation and characterization of activated carbon produced from pomegranate seeds by ZnCl2 activation. Appl Surf Sci 255(21):8890–8896

Yagşi NU (2004) Production and characterization of activated carbon from apricot stones. In: Partial fulfillment of the requirements for the degree of master of science in the Department of Chemical Engineering

Yahya MA, Al-Qodah Z, Ngah CWZ (2015) Agricultural bio-waste materials as potential sustainable precursors used for activated carbon production: a review. Renew Sustain Energy Rev 46:218–235

Yang R, Liu G, Xu X, Li M, Zhang J, Hao X (2011) Surface texture, chemistry and adsorption properties of acid blue 9 of hemp (Cannabis sativa L.) bast-based activated carbon fibers prepared by phosphoric acid activation. Biomass Bioenergy 35:437–445

Zhanga B, Wua Y, Cha L (2020) Removal of methyl orange dye using activated biochar derived from pomelo peel wastes: performance, isotherm, and kinetic studies. J Dispers Sci Technol 41:125–136

Acknowledgements

The authors would like to acknowledge Istanbul University-Cerrahpasa for financial support.

Funding

This study was funded by Scientific Research Projects Coordination Unit of Istanbul University-Cerrahpasa, project number: 22691. The funder had no role in study design, data collection and analysis, decision to publish, or preparation of the manuscript.

Author information

Authors and Affiliations

Contributions

IMH designed the experimental work, analysed and interpreted the data, supervised the whole research work, and wrote the manuscript. SG carried out the experiments and contributed to the analysis of the data. EY edited the manuscript. BH interpreted the data and wrote and edited the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest regarding the publication of this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hasdemir, İ.M., Yılmazoğlu, E., Güngör, S. et al. Adsorption of acetic acid onto activated carbons produced from hazelnut shell, orange peel, and melon seeds. Appl Water Sci 12, 271 (2022). https://doi.org/10.1007/s13201-022-01797-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-022-01797-y