Abstract

Nanocomposite containing vanadium oxide (V2O5) and magnetite (Fe3O4) doped with nickel (Ni) ion were synthesized according to the formula of Ni0.1Fe2.9O4 /V2O5. The obtained composition was characterized by XRD, FTIR, FESEM. The FESEM micrograph shows that the existence of two different phases related to V2O5 and Ni-Magnetite. Moreover,the roughness parameters have values of 281, 85 and 385nm for roughness average Ra, root mean square roughness Rq, Maximum height of roughness RT respectively. Moreover, the magnetic behavior of the sample was studied, and we found that by adding V2O5 to Ni dopped magnetite, the curie temperature value was lowered from 750 oC to 625 oC. The activation energy was calculated and found to be 0.22 eV and 0.08 eV for 1000 Hz and 3MHz respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Through the past decades, significant attention has been given to nanomaterial. More recently, optical, magnetic, electrical, and mechanical properties of these materials are studying to be used in many technological applications such as in solar cells, laser and electronic devices [1, 2]. Among the ferrites, the magnetite has attracted attention in the field of dielectric materials because they have high magnetic and electric properties [3]. magnetite shows a spinel structure. It consists of a oxygen closed packing cubic structure [4] where octahedral and tetrahedral sites are inhabited by the different metal cations. The formula for the magnetite structure is given by AB2O4 where A and B are cations with various oxidation state. The spinel structure is written as [A2+ 1−i B 3+ i ]M [A2+ i B 2+ 1−iB3+]YO4 where M and Ysuffixes stick for the tetrahedral and octahedral sites, respectively, and i is the inversion parameter. So, for i = 0 the spinel is normal, while for i = 1 inverse and for 0 <i< 1 mixed spinel [5]. The inversion degree depends on the types of metallic cation A, as well as the cation size or the synthesis method [6]. The form of magnetite at room temperature is [Fe3+]A[Fe2+Fe3+]BO4 which related to is inverse spinel [7,8,9,10]. One of the best efficient methods to improve magnetite properties is doping [10]. As the magnetic properties affected by cation distribution, as Fe2+, Fe3+and Ni2+over available sites. Based on previous studies, we found that when Ni2+ dopped magnetite, the saturation magnetization increased while coercivity decreased [11]. In other hand, V2O5 has been widely investigated owing to its low sintering temperature and also has excellent dielectric properties [12,13,14,15]. Among the transition metal-like oxides, V2O5 appears to be the most promising. V2O5 is one beyond the transition metal oxides that is receiving greater attention because of its unique chemical and physical characteristics, which make it more useful as we approach the realm of nanoparticles. The oxidation states of vanadium span from +2 to +5, and they are all stable within a certain composition range. Naturally these compositions, V2O5 possesses the greatest oxidation state in vanadium, followed by VO, VO2, V2O3, as well as V6O11 [16]. The structural and electrical phase transitions of vanadium pentoxide, which show the metal to semiconductor (MIS) [17] and metal to insulator (MIT) transitions, are also well known [18]. Electrochromic devices [19, 20], and other similar devices are often made of V2O5.

These characteristics make vanadium oxide a great option for luminous and microwave applications [21]. We anticipate that a novel compound with the required magnetic and electric characteristics will be produced by combining the two distinct phases of Ni doped magnetite and vanadium oxide in a single composite matrix, in line with the earlier research.

The goal of this study is to synthesize Ni0.1Fe2.9O4, V2O5 nanoparticles and a nanocomposite of Ni0.1Fe2.9O4 and V2O5. Studies are conducted on their morphology, structural, electrical, and magnetic characteristics. Without a doubt, this is an initial effort to investigate the Ni0.1Fe2.9O4/V2O5 nanocomposite.

Procedure

Materials

The chemicals used for preparing samples are of purity 99.9%. Ammonium metavanadate, oxalic acid dihydrate, nitric acid, ferrous chloride tetrahydrate (FeCl2·4H2O), Nickel chloride tetrahydrate (NiCl2·4H2O), ferric chloride hexahydrate (FeCl3·6H2O), and deionized water are gotten from Sigma Aldrich Company.

Synthesis methods

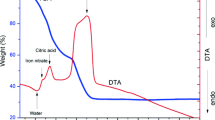

V2O5 nanostructure preparation technique

Figure 1 shows that V2O5 was synthesized by dissolving Ammonium metavanadate in deionized water. After that 1.2g of the oxalic acid dihydrate was added drop by drop into the solution, then the temperature was raised up to 80 oC. Then pH value was increased to 8 by adding Ammonium hydroxide (NH4oH). Then the resultant solution transferred into 100ml teflon container. Finally, the obtained produced was then calcinated for 5hrs at 190 oC.

Preparation of Ni0.1 Fe2.6O4 nanoparticles.

Figure 2 shows synthesis of Ni-doped magnetite by co-precipitation method. At the beginning, suitable amounts of (FeCl3·6H2O), (FeCl2·4H2O), and (NiCl2·4H2O) were dissolved in deionized water. After that, the pH was adjusted to be 13 under strong stirring for 15 min. Lastly, the obtained precipitate was washed by ethanol and distilled water several times and then dried at 80 °C.

V2O5/Ni0.1Fe2.9O4 nanocomposite preparation

V2O5 / Ni0.1Fe2.9O4 was synthesized by milling equal amount of single phase V2O5 and Ni0.1 Fe2.9O4 nanostructured samples for 2h.

Samples characterization

Prepared samples were characterized by XRD (X-Ray diffraction) in the range 2θ (20o ≤ 2θ ≤ 80o) for Bragg angles. FT-IR spectrometer in range 4000 – 400 cm-1 was used for studying the bond groups. Surface study and morphology of the prepared samples by using Field emission scanning electron microscopy (FESEM). The roughness parameters were obtained and estimated by the Gwyddion 2.45 program as well as micrographs of the produced materials obtained through FESEM analysis. LCR meter (Hioki 3532, Japan) was used for measuring the electrical properties at different frequencies and temperatures. Homemade setup of Fraday's method was used for studying the magnetic susceptibility as a function of temperature. In Faraday method:(Using the non-homogeneous field approach. The Faraday balance was created for solid samples that might be single crystal, polycrystalline, or nearly anything else. A tiny amount of the sample was kept in an appropriate tube that was connected to the balance. To prevent the magnetic sample from being drawn to one of the magnet pole pieces and being moved laterally while the tube is being held vertically, it must be hefty. It is possible for a non-homogeneous field with an axis of symmetry to exist if a magnet's poles were inclined toward one another. A material would experience a force along this axis if it were now put in an area of maximal inhomogeneous magnetic field where the intensity of the field (H) varied quickly with movement along the axis of symmetry (x). The most practical approach was this one. There was just a little amount of material needed, therefore density didn't need to be determined separately. Pierre Curie utilized the technique a lot, and many researchers have subsequently employed conventional measures. The force would alter and \(\left(\frac{dH_x}{dz}\right)\)would vary while moving the sample a tiny distance up or down.

Results and discussions

XRD

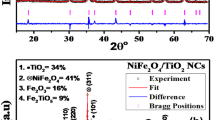

XRD of V2O5, Ni0.1 Fe2.9O4 nanostructured samples as well as V2O5/Ni0.1Fe2.9O4 nanocomposite were studied through Fig. 3. From the figure, we noticed that the primary distinctive peaks can be shown to be connected to the cubic structure of pure Ni0.1 Fe2.9O4 appeared at 2θ= 35.516o, 62.690o and corresponded to (311) and (440) miller indices, respectively. Whereas the principal peaks related to the orthorhombic crystal structure of pure V2O5 existed at 2θ = 15.349o, 21.712o, 25.562o, 26.127o, 31.005o and 34.02o which are complemented to (200), (101), (201), (110), (400) and (310) respectively. For V2O5/Ni0.1Fe2.9O4 nanocomposite , All indexed peaks were related to either, V2O5 or Ni0.1Fe2.9O4 that related to ICDD card number [00-041-1426] or [01-087-2336] respectively. It is noticed that after adding V2O5 content, the peak intensities of Ni0.1Fe2.9O4 decreased. Furthermore, no secondary phases present indicated that, the sample prepared successfully in dingle phase and free of any impurities. Crystal structure related to prepared samples was calculated by using Scherer's equation [22].

Where D is crystallite size (nm) , 0.9 is the shape factor, λ (nm) is the X-rays wavelength, while βhkl is related to full width half maximum (FWHM) and θ is the Bragg angle. The crystallite size of prepared samples was found to be 35, 50 and 42 nm for V2O5, Ni0.1Fe2.9O4 nanostructured samples and V2O5/Ni0.1Fe2.9O4 nanocomposite respectively. Our results demonstrate that V2O5 content leading to shrink the crystallites size and increasing the degree of lattice distortion.

These obtained data shows that by increasing V2O5 content, the crystallite size decreased as the lattice distortion increased. As a result, V2O5 appears to have a less crystallinity than Ni doped magnetite nanoparticles. This behavior is attributed to the various preparation techniques.

FTIR spectrum

Figure 4 displays characteristic bands related to V2O5/Ni0.1Fe2.9O4 nanocomposite. Peak at 470 cm-1 is related to stretching of oxygen atom between vanadium atoms as well as Ni-O in Ni dopped magnetite phase [23]. While absorption peak around 550 cm-1 is associated to metal-oxygen bond in spinel phase [24]. V-O-V a symmetric stretching bridge was observed around1000Cm-1. Stretching of oxygen-vanadium bond V=O appears nearly wavenumber of 1050 cm-1 [25]. Peaks at 1600 and 3500 cm-1 were related to bending and vibration mode of O-H of absorbed water in molecule respectively.

Morphological study

SEM was used to determine the surface morphology of the samples of Ni0.1Fe2.9O4, and V2O5/Ni0.1Fe2.9O4 nanocomposite as shown in Fig. 5a-c. The prepared sample's morphology is displayed in Fig. 5. As seen in Fig. 5a, the effective and simple coprecipitation approach yields uniform nanorod shape as well as a nearly spherical nanoparticle monolayer that has self-assembled. It seemed clumped because there was no surfactant present and because of the very tiny crystallites of 50 nm in crystallite size. The sample's magnetic property is what caused the aggregation. According to Fig. 5b, the original vanadium oxide was created as small, tightly packed grains with a narrow size distribution. Surface roughness and porosity appear to be high. SEM micrograph of V2O5/Ni0.4Fe2.6O4 nanocomposite was shown in Fig. 5c. The uniform rod like shapes particles were related to the structure of Ni0.1Fe2.9O4. From another hand, particles with large and non- uniform crystal structure were related to V2O5 nanostructure. The main causes of the topographic shift are surface flaws and a crystallographic mismatch between vanadium oxide and Mn-magnetite.

Figure 6a-c displays the surface roughness of Ni0.1Fe2.9O4 , V2O5 nanostructure and V2O5/Ni0.1Fe2.9O4 nanocomposite, while Table 1 reports the roughness parameters. It is obvious that roughness roughness average (Ra) increased from 22.1 significantly to 266.4, although root mean square roughness changed 66.36 to 84 nm after adding V2O5 to Ni0.1Fe2.9O4 . Also, the greatest roughness (Rt) has values of 517.6, 619.6 and 576nm in height for Ni0.1Fe2.9O4 , V2O5 nanostructure and V2O5/Ni0.1Fe2.9O4 nanocomposite respectively, while the values of highest roughness valley (Rv) are 239.4, 221.9 and 266 nm in depth for for Ni0.1Fe2.9O4 , V2O5 nanostructure and V2O5/Ni0.1Fe2.9O4 nanocomposite respectively . The significant variance in the values of Rt and Rv indicates the inhomogeneity of the roughness components. In other words, notches and heights could both be referred to be parts of the surface topography. The contribution ratios of heights and notches on the surface topography have a significant impact on how the surrounding materials interact. Notches are essential for chemical bonding even though heights are preferred for physical connection. This method is a result of how notches and heights have changed over time. The number of notches increases when low crystalline V2O5 is incorporated into the Ni-magnetite grains. Moreover, the crystallographic flaws that are present on the grain surface serve as ionic traps for the surrounding ions [26, 27]. For the degradation of dyes or interaction with cellular walls, the capacity to form chemical interactions with the surrounding environment is essential. In addition, the heights encourage physical adhesion, which is important for starting the chemical one [28]. A useful approach to alter the surface topography and enhance the efficiency of dye removal is compositional contribution control.

Magnetic properties V2O5/Ni0.1Fe2.6O4 nanocomposite

The magnetic behavior of Ni0.1Fe2.6O4 nanoparticles and V2O5/Ni0.1Fe2.9O4 nanocomposite was observed in Fig. 7a,b. As shown in the figure, the relation between molar magnetic susceptibility as a function of temperature for different values of magnetic field intensities. The magnetic susceptibility decreases with increasing temperature as well as field intensities until reaching to zero value (Curie temperature). As, temperature increased, thermal energy increased too. Consequently, disordering of dipoles increased which associated with lowering of molar magnetic susceptibility. Even though, increasing value of magnetic field, alignment of dipoles can't be comparable with infield direction. Curie temperature of the obtained values were found to be about 750 and 625 oC for Ni0.1Fe2.6O4 nanoparticles and V2O5/Ni0.1Fe2.9O4 nanocomposite respectively. it is observed that, by adding V2O5 to Ni dopped magnetite, the curie temperature value was lowered from 750 o C to 625 oC. This is attributed to diamagnetic nature of V2O5 [29]. Hence, the magnetic behavior of V2O5 was enhanced.

The obtained data in Fig. 8a, b were related to the relation between molar magnetic susceptibility as a function of temperature of Ni0.1Fe2.9O4 nanoparticles and V2O5/Ni0.1Fe2.9O4 nanocomposite. The straight part of figure fitted well with Curie-Weiss law, as, in paramagnetic region the reciprocal of molar magnetic susceptibility is directly proportional with temperature. From the above relation, some magnetic parameters as, curie constant (c), curie Weiss constant (θ) as well as effective magnetic moment (μeff) were calculated by the following equations [30].

Where C represents the curie constant while obtained from reciprocal of slope of straight part from Fig. 8a, b. While, curie Weiss constant is obtained from the intercept of the straight part in Fig. 8a, b. All magnetic costants were calculated and listed below in Table 1. The obtained magnetic constants were scheduled in Table 2. It could be noticed that by adding, there is a fatal change in magnetic parameters, which is suitable for various applications. Finally, the presence of diamagnetic behavior related to V2O5 at all the indicated temperatures can be used to clarify the magnetic properties of the nanocomposite V2O5/Ni0.1Fe2.9O4 nanocomposite [30]. On the other hand, we discovered that V2O5 has a limited ferromagnetic aspect attributable to the slight presence of V+4 inside the sample, furthermore to grain growth being facilitated by the substantial number of cation vacant positions introduced mostly by presence of V+5

From the previous data, we conclude that, the magnetic behavior of V2O5 can be enhanced by adding a material with magnetic nature such as Ni doped magnetite. The magnetic performance of magnetite is correlated to the distribution of cations between A and B sites [31]. In another word, we can consider that, the obtained nanocomposite, has a ferrimagnetic nature and can be used in several applications.

Dielectric study of V2O5/Ni0.1Fe2.9O4 nanocomposite.

There are many parameters affecting on dielectric properties of nanomaterial compounds. As, crystal structure, grain size, frequency and chemical composition. The chemical and physical information of sample can be known through the following equation [32].

ε ′: Dielectric constant which represents quantity of stored energy due to polarization in dielectric sample.

ε ′′: Dielectric loss which represents energy dissipated in form of heat in dielectric compound.

The behavior of dielectric constant as well as dielectric loss were studied through Fig. 9a, b and Fig. 10a, b. As shown in figures, the dielectric constant in addition to the dielectric loss increased as temperature increases, while their values decreased by increasing frequency.

ε ′ and ε′′ Values increasing with decreasing frequency value. At very high values of frequency, their values decreases and becomes nearly independent on frequency.

The great significance of dielectric constant related to the low frequency range is attributed to existence of four fundamental polarization types, ionic, electronic, dipolar and interfacial polarization while at high frequency range, only electronic as well as ionic polarization are dominated.

The obtained behavior of dipolar and interfacial polarization can be studied through Maxwell-Wanger interfacial and Koop's models [33, 34]. These models supposed that, dielectric materials consist of conducting grains separating by non-conducting grains boundaries. Once electric field is used, the charge carriers migrate through grains easily and gathered at grain boundaries, consequently, interfacial polarization is existed. At low frequency range, the charge carries which collected at boundaries can follow direction of applied field easily, so, polarization as well as dielectric constant increased. While, at high frequency range, the charge carries at boundaries cannot follow the applied field direction so, polarization decreased and dielectric constant decreased too. The presence of V2O5 decreased value of dielectric constant of Ni doped magnetite due to increase of grain size of obtained sample. As the dielectric losses decreased at high frequency range, so, our sample is appropriate for high frequency devices.

Increasing values of dielectric constant and dialectic loss with temperature for all frequency values were attributed to rise of mobility of charge carriers. At low range of temperature, dipoles unable to orient themselves in applied field direction, as they don’t have the sufficient energy which required for orientation. Although, as temperased raised, the energy required for dipoles orientation existed and charge carries follow the applied field direction, consequently, polarization increased and both of dielectric constant as well as dielectric loss also increased.

Figure 11a, b Observes the relation between ac conductivity and temperature for different values of frequencies. The ac conductivity increased with increasing frequency and temperature. The behavior of frequency can be understood according to Maxwell-Wagner model. In this model, the grain boundaries act as potential barriers, for low frequency, charge carriers move freely inside grains until they accumulated at grain boundaries. The conductivity in this range is related to hopping and tunneling mechanism of charge carriers. As frequency increased, the charge carriers have sufficient energy for hopping and migration between grains [35]. As, temperature increased the thermal energy of charge carriers increased and the activated charge carriers can hopping between grain boundary easily, as a result, the conductivity increased. And the material follows semiconductor trend [36].

The conductivity of semiconductors follows Arrhenius equation which is given by the following relation [35,36,37,38].

Where:

σ is conductivity at certain temperature

σ o is a constant

T is the absolute temperature

E g is activation energy

K B is Boltzmann constant

The activation energy has been calculated from slope of straight line from Fig. 11a,b And found to be 0.19 and 0.22 eV at 1000 Hz 0.2 and 0.08 eV at 3MHz for Ni0.1Fe2.9O4 nanoparticles and V2O5/Ni0.1Fe2.9O4 nanocomposite respectively. The addition of V2O5 causes an increase in activation energy. This conclusion is a result of the faults that V2O5 has introduced into the nanocomposite. These flaws serve as sites for free carrier scatter and provide obstructions in conduction, which lower ac conductivity. It is clearly that, as the frequency increased the value of activation energy decreased. As, at high frequency the charge carriers have sufficient energy for hopping between grain boundaries and hence, low value of activation energy is required.

Types of conduction mechanisms can be understood through Jonscher's power law which is given by the following equation

Where

σ ac : is Ac conductivity

A: Temperature dependent constant

w: Angular frequency

S: Dimensionless exponent factor which has values varies between 0≤S≤1

The value of S gives information about the interaction of charge carriers with surrounding lattice Fig. 12. Shows variation of S with respect to temperature. For all values of S were inserted between zero and one. This is attributed to hopping conduction mechanism. The decreasing of S at high temperature indicating that the conduction mechanism follow correlated barrier hopping (CPH) model. Increasing S value with increasing temperature, reveals the existence of tunneling of small polaron and conduction mechanism follow (SPT) model, and this is occurred in materials has degree of lattice distortion and this may be attributed to V2O5 which is caused lattice distortion of host matrix (Ni0.1Fe2.9O4)

Conclusion

Nanocomposite based on V2O5/Ni-magnetite was synthesized by milling equal amount of single phase V2O5 and Ni0.1 Fe2.9O4 nanostructured samples. The surface morphology study showed that the nanocomposite has high average roughness as well as root mean square roughness. According to the activation energy values which are 0.22 eV and 0.08 eV for 1000 Hz and 3M Hz respectively we concluded that the sample follow semiconductor behavior. Based on the relation between conductivity and angular frequencies, the conduction mechanism in the prepared nanocomposite is related to hopping and small polaron tunnelling mechanism. Finally, the aim of this work is achieved which is synthesis nanocomposite has high magnetic and electric properties.

References

Hu, J., Shi, G., Ni, Z., Zheng, L., Chen, A.: J. Phys. B. 407, 2205 (2012)

Zhao, J., Harmer, M.P.: Am. J. Ceram. Soc. 71, 113 (1988)

Thomas, G., Wolfgang, W., Michael, S.P., Bernhard, K., Simon, P.: AIP Adv. 6, 025119 (2016)

Lebourgeois, R., Dugueyb, S., Ganne, J.P., Heintz, J.M.: J. Magn. Magn. Mater. 312 (2007)

Jean, J.H., Lee, C.H.: JJAP. 38, 3508 (1999)

Jean, J.H., Lee, C.H.: JJAP. 40, 2232 (2001)

Artur, R., Aleksandra, S.: Sensors. 15, 20069 (2015)

Ramadan, R., Ismail, A.M.: J. Inorg. Organomet. Polym. Mater. (2022). https://doi.org/10.1007/s10904-021-02176-x

El-Masry, M.M., Ramadan, R.: Appl. Phys. A. 128, 110 (2022)

Lin, H., Huang, C.P., Li, W., Ni, C., Ismat Shah, S., Yao-Hsuan, T.: Appl. Catal. B Environ. 68, 1 (2006)

Ramadan, R., Alzaidy, G.A., Almutairi, F.N., Uskoković, V.: Appl. Phys. A. 129, 753 (2023). https://doi.org/10.1007/s00339-023-06976-5

Chu, J., Kong, Z., Dengyu, L., Zhang, W., Wang, X., Yu, Y., Li, S., Wang, X., Xiong, S., Mab, J.: Mater. Lett. 166, 179–182 (2016)

Ramadan, R., El-Masry, M.M.: J. Aust. Ceram. Soc. (2023). https://doi.org/10.1007/s41779-023-00932-5

Ramadan, R., Almutairi, F.N., Alzaidy, G.A.: Ceram. Int. 49, 29520–29533 (2023)

Ramadan, R., Shafaay, A.S.: J. Water Process Eng. 54, 103958 (2023)

Ramana, C.V., Smith, R.J., Hussain, O.M., Massot, M., Julien, C.M.: Surf. Interface Anal. 37, 406–411 (2005)

Sharma, R.K., Saini, S.K., Singh, M., Reddy, G.B.: AIP Conf. Proc. 1731, 80011 (2016)

Senthil Kumar, N., Sethu Raman, M., Chandrasekaran, J., Priya, R., Chavali, M., Suresh, R.: Mater. Sci. Semicond. Process. 41, 497–507 (2016)

Pan, A., Bin, W.H., Yu, L., Zhu, T., Lou, X.W.(D.): ACS Appl. Mater. Interfaces. 4, 3874–3879 (2012)

Arman, M.M., Ramadan, R.: J. Mater. Sci. Mater. Electron. 34, 1365 (2023). https://doi.org/10.1007/s10854-023-10721-2

Lin, K.Y.A., Lin, T.Y.: Water, Air, Soil Pollut. 229, 10 (2018)

Nagaraju, P., Vijayakumar, Y., Ramana, R., Deshpande, U.P.: RSC Adv. 9, 16515 (2019)

Zhu C, Li Y, Yang Y, Chen Y, Yang Z, Wang P, Feng W, 2020 Inorg. Chem. Commun. 115 107850.

Zhu, B., Cheng, H., Qin, Y., Ma, J., Kong, Y., Komarneni, S.: Purif. Technol. 233, 116057 (2020)

Shen, K., Cui, Y., Zhang, D., Liu, M., Huang, H., Sha, X., et al.: J. Environ. Chem. 8, 104125 (2020)

Wu, Z., Huang, W., Shan, X., Li, Z.: Int. J. Biol. Macromol. 143, 325 (2020)

Ramadan, R.: Appl. Phys. A. 125, 586 (2019)

Li, Z., Ma, Y., Qi, L.: Nanotechnology. 27, 485601 (2016)

Xiaoming, F.: Adv. Mater. Res. 873, 164 (2014)

Ramadan, R.: Appl. Phys. A. 129, 125 (2023). https://doi.org/10.1007/s00339-022-06376-1

Berlin, J., Joy, K.: Phys. B. 457, 182 (2015)

Shengzhao, W., Jun, S.: J. Sol-Gel. Sci. Technol. 67, 339 (2013)

Ahmed, M.A., Bishay, S.T., Ramadan, R.: Nanosci. Nanotechnol. 9, 064 (2015)

Kang, Y.G., Yoon, H., Lee, C.S., Kim, E.J., Chang, Y.S.: Water Res. 151, 413 (2019)

Soltani, N.F., Saljooqi, A., Mostafavi, A., Shamspur, T.: Ecotoxicol. Environ. Saf. 189, 109886 (2020)

Dong, L., Li, M., Zhang, S., Si, X., Bai, Y., Zhang, C.: Desalination. 476, 114227 (2020)

Mousavi, M., Habibi, Y.A.: Mater. Chem. Phys. 163, 421 (2015)

Ghaedi, M., Hajjati, S., Mahmudi, Z., Tyagi, I., Agarwal, S., Maity, A., et al.: Chem. Eng. J. 268, 28 (2015)

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The author declare that they have no known conflict of interest or competing financial interests or personal relationships that could have appeared to influence the work reported in this paper ‘Enhancement the physical properties of V2O5/Ni0.1Fe2.9O4 nanocomposite’.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ramadan, R. Enhancement the physical properties of V2O5/Ni0.1Fe2.9O4 nanocomposite. J Aust Ceram Soc (2024). https://doi.org/10.1007/s41779-024-01051-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41779-024-01051-5