Abstract

In open-pit mines located in cold regions north of the 38°N latitude, there are significant freeze–thaw phenomena in slope rocks. This study conducted freeze–thaw cycle tests, considering the number of freeze–thaw cycles and the freezing temperature, on sandy mudstone commonly found in the slopes of open-pit mines. The investigation focused on the effects of freeze–thaw cycles on the physical and mechanical properties and acoustic emission (AE) characteristics of sandy mudstone. The results show that, with an increase in the number of freeze–thaw cycles and a decrease in freezing temperature, the sandy mudstone specimens exhibit nonlinear exponential changes in mass loss rate, P-wave velocity loss rate, peak strain, uniaxial compressive strength (UCS) and elastic modulus, and the amplitude of these changes gradually decreases. The stress–strain curves of specimens shift gradually from apparently brittle to plastic. Simultaneously, the microstructure changes from dense to loose, the micro surface transitions from flat to rough, and cracks and pore defects gradually develop. The peak AE ringing counts, cumulative AE ringing counts, crack initiation stress, and crack damage stress of the specimens all decrease with an increase in the number of freeze–thaw cycles and a decrease in freezing temperature. This suggests a shift from brittle failure to ductile failure. However, the ratio of crack initiation stress and crack damage stress to peak stress does not vary significantly with the number of freeze–thaw cycles and freezing temperature.

Article Highlights

-

(1)

The impact of freeze-thaw cycles on the physical and mechanical properties of sandy mudstone is explicated, taking into account both the number of freeze-thaw cycles and freezing temperature.

-

(2)

The mechanism of freeze-thaw effects on physical and mechanical properties of sandy mudstone is revealed.

-

(3)

The process of crack evolution during uniaxial compression of sandy mudstone under freeze-thaw cycles is elucidated.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

1 Introduction

Abandoned open-pit mines are the leftover abandoned land generated after the completion of open-pit mining, which has a significant impact on the ecological environment and geomorphological landscape (Apostu et al. 2020; Blanchette and Lund 2016; Jiang et al. 2021; Li et al. 2022; Redondo Vega et al. 2021). Backfilling is the most direct way to deal with abandoned open-pit mines, but there are shortcomings such as the difficulty in obtaining backfill materials, the large amount of work, the high cost, and the time-consuming process (Cao et al. 2021; Song et al. 2016; Waitkus 2022). At the same time, abandoned open-pit mines are also a huge spatial resource, and the rational use of abandoned open-pit mines can be realized quickly and inexpensively through direct renovation. The current modes of transforming and utilizing abandoned open-pit mines mainly include agricultural production, tourism development, and recreation. For example, the Fraser abandoned open-pit iron mine in Minnesota, USA, was used as an experimental base for salmon cage farming. The world's largest plant greenhouse exhibition hall, Eden Garden in Cornwall, UK, was built in an abandoned clay mine. The Haizhou National Mining Park in China was transformed from an abandoned open-pit mine. The World Trade Pit Hotel in Tianma Mountain, Shanghai, China, built in an abandoned quarry pit. And the Six Continuous Lakes Theme Park in Guangzhou, China, which was built by connecting six separate abandoned open-pit quarries. In addition, abandoned open-pit mines have the potential to be converted into pumped storage systems, which are currently the most mature and cost-effective power source for peak energy storage (Krassakis et al. 2023; Luo et al. 2022; Pujades et al. 2016; Wessel et al. 2020).

The renovation of abandoned open-pit mines starts with ensuring slope stability. Many open-pit mines are located in the cold regions north of the 38°N latitude, where the seasonal and diurnal temperature differences are large, and freezing and thawing are significant. Mechanical properties of rocks in the slope are damaged under the influence of freezing and thawing, leading to a decline in slope stability and increasing the risk of geologic disasters such as landslides (Huang et al. 2020; Liu et al. 2020a, b; Luo et al. 2015; Paronuzzi and Bolla 2022; Qi et al. 2021). At present, the research on the physical and mechanical properties of rocks under the influence of freezing and thawing is mostly carried out in terms of the nature of the rocks themselves and the external environment. The properties of rocks themselves refer to lithology, porosity and water content. Luo et al. (2014) investigated the freeze–thaw damage characteristics of altered and unaltered diabases and found that the freeze–thaw damage of altered diabase increased significantly due to the change of mineral composition of the diabase during its alteration. Yin et al. (2023) revealed the freeze–thaw damage patterns of yellow sandstone with different water contents by scanning electron microscopy (SEM), noting that dry rocks exhibit crack propagation, while water-saturated rocks display pore and crack propagation. Park et al. (2015) compared the SEM images of diorite, basalt, and tuff before and after freeze–thaw cycles and found that the microstructure of diorite and basalt did not show remarkable changes, while tuff exhibited particle collapse and crack initiation and propagation phenomena. Qiu et al. (2020) conducted freeze–thaw cycle tests on coal gangue concrete (CGC) with coal gangue coarse aggregate replacement rates of 0%, 20%, 40%, and 60%, and found that relative quality, relative compressive strength, and relative dynamic modulus of elasticity of the CGC decrease rapidly with increasing the coal gangue replacement. They pointed out that the replacement rate should be less than 40% when the CGC is used in a cold area. Huang et al. (2022)adopt the discrete element method to evaluate the impact of freeze–thaw cycles on the mechanical properties of rock, indicating that freeze–thaw cycles have a significant impact on samples with larger porosity and smaller initial UCS. Chen et al. (2004) investigated the freeze–thaw damage of welded tuff caused by rock saturation through changes in the UCS, P-wave velocity, porosity, and appearance of the specimens. The experimental results showed that when the initial saturation is maintained below 60%, the rock properties remain unchanged, but when the initial saturation exceeds 70%, the rock is significantly damaged. Weng et al. (2023) analyzed the changes in major principal strain and minor principal strain of sandstones with different saturations during freeze–thaw cycles with temperature, and found that the sandstones exhibit heterogeneous frost deformation behaviors during the freeze–thaw cycle, and the coefficient of linear thermal expansion, maximum frost heave strain and residual frost heave strain of the sandstones tend to increase exponentially with increasing the degree of saturation, but these three parameters are different from one another along the minor and major principal strain directions.

External environmental factors generally refer to external factors such as freezing temperature, number of freeze–thaw cycles and hydrochemical conditions. Temperature controls the degree of phase change of water within the rock, the number of freeze–thaw cycles determines the cumulative degree of structural damage within the rock, and the ambient hydrochemical conditions affect the changes in the mineral components within the rock. Zhang et al. (2022)found that the sandstone specimen without freeze–thaw cycles is relatively intact with dense granules and cementation, and the number and size of pores inside the sandstone increase with increasing the freeze–thaw cycles by SEM tests. Yu et al. (2023) analyzed the SEM images of Sichuan sandstone after different freeze–thaw cycles and found that as the number of freeze–thaw cycles increased, the sandstone structure became increasingly loose, mainly manifested in the increase in interparticle pores, crack expansion, and the destruction of cement between particles. Lin et al. (2020) monitored the change of frost-heaving pressure in the joint under cyclic process using membrane pressure sensors in the joint and noted that the peak frost-having pressure increases exponentially with the decrease of temperature and decreases exponentially with the increase of freeze–thaw cycles. In addition, they concluded that the frost-heaving deterioration of jointed rock mass is mainly due to the gradual expansion and evolution of cracks driven by the water–ice phase change and volume expansion in the joints based on SEM image analysis. Zhang et al. (2019) investigated the deterioration of sandstone under quasi-static and dynamic loading conditions and found that an increase in the number of cycles would lead to an increase in the internal pore spaces, and the strengths and Young’ s modulus under quasi-static and dynamic loading conditions both decreased by increasing freeze–thaw cycles. Moreover, under dynamic loading condition, the strain based brittleness index increased with an increase in freeze–thaw cycles. Chen and Lin (2023) analyzed the shear performances of freeze–thaw multi-fractured rock mass by direct shear tests, and found that the values of geological strength index (GSI) and mi both decrease with the increase of freeze–thaw cycles and the decreasing rate is also lowering. Yahaghi et al. (2021) investigated the deterioration and failure mechanisms of Tasmanian sandstones subjected to various freeze–thaw cycles in UCS using a 3D hybrid finite-discrete element method, and found that the main failure pattern of sandstone without subjecting to freeze–thaw cycles was axial splitting. The increasing number of freeze–thaw cycles causes the macroscopic cracks to propagate, interact and coalesce in the shear behavior resulting in the final shear fracture pattern. Wu et al. (2023) conducted triaxial compression tests on homologous sandstone specimens after corrosion action of acidic, alkaline or neutral solution and cyclic freeze–thaw action, and found that the peak stress, peak strain and modulus of sandstone decreased with increasing freeze–thaw cycles. The strong acid solution damaged the sandstone to the greatest extent, and the precipitates produced by the reaction between the strong alkaline solution and the specimens adhere to the specimen surface, pores, and fissures, thereby inhibiting further damage and deterioration.

Although scholars have achieved rich results in the study of physical and mechanical properties of rocks under freeze–thaw action, the research mostly focus on rocks with high strength and low clay mineral content, and less on soft rocks with high clay mineral content. The strata in the slopes of open-pit mines are mostly dominated by soft rocks with high clay mineral content such as sandy mudstone and mudstone (Zhao et al. 2020; Li et al. 2023; Yang et al. 2023), so it is necessary to carry out the research on the physical and mechanical properties of soft rocks under freeze–thaw effects. In this study, the sandy mudstone of open-pit mine slopes in cold regions was taken as the research object, and the freeze–thaw cycle tests with different freezing temperatures and cycles were carried out. The mass and P-wave velocity of sandy mudstone under different freeze–thaw cycle conditions were measured. The damage of freeze–thaw action on the microstructure of sandy mudstone was studied through scanning electron microscope. The mechanical characteristics of sandy mudstone under the influence of freeze–thaw were analyzed using UCS tests and AE monitoring systems. The research results can provide a reference for the slope treatment in the process of transforming and utilizing abandoned open-pit mines.

2 Testing procedures and methods

In this section, the testing procedures and methods are briefly expounded. Firstly, the preparation and the basic physical and mechanical properties of sandy mudstone specimens are introduced. Then, the testing methods and equipment are introduced, including freeze–thaw cycle tests, physical parameter tests, microstructure tests, and UCS tests. The testing equipment and procedure are shown in Fig. 1.

2.1 Specimens preparation

The sandy mudstone in this study was taken from the slope of an open-pit mine in Xinjiang Autonomous Region, China. The mineral composition and content are shown in Table 1. The sandy mudstone is mainly composed of clay minerals and quartz. The proportion of clay minerals (nontronite and kaolinite) reached 39.7%.

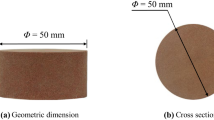

Due to the high clay minerals in the sandy stone, which is prone to disintegration and expansion when exposed to water, the samples were drilled by the pneumatic drilling method and processed into Ф50 × 100 mm cylindrical specimens. In order to avoid the experimental error caused by the dispersion of sandy mudstone, the P-wave velocities of specimens were detected. The specimens with similar P-wave velocities were selected as the test objects. The basic physical and mechanical properties of the sandy mudstone were tested, and the basic physical and mechanical parameters of the standard specimens of sandy mudstone obtained are shown in Table 2.

2.2 Test methods

2.2.1 Freeze–thaw cycle tests

Freeze–thaw cycle test can simulate periodic climate changes under natural conditions, so as to achieve the rapid realization of the freezing and thawing process of rock samples. Due to the disintegration of the sandy mudstone, the XY-QDR-50 fully automatic low-temperature freeze–thaw test machine was used for the freeze–thaw cycle tests, and the air freezing and air thawing method was chosen. According to the temperature conditions in the area where the open-pit mine is located, the thawing temperature of these freeze–thaw cycle tests was set to 20 ℃, while the freezing temperatures (T) were − 5 ℃, − 10 ℃, − 15 ℃, − 20 ℃, and the number of cycles (N) were 1, 10, 20, and 30 times, respectively. Four freezing temperatures and four cycles are orthogonal to each other, resulting in a total of 16 experimental conditions. Four specimens were used for each experimental condition, one for the SEM tests and three for non-destructive physical parameter measurements and UCS tests to reduce the randomness of the tests.

Referring to Regulation for testing the physical and mechanical properties of rock (DZ/T 0276.8–2015) and reported literature (Chen and Lin 2023; Shen et al. 2016; Tang et al. 2022; Yin et al. 2023), the constant temperature time of freezing and thawing during the freeze–thaw cycles of sandy mudstone was set to 4 h. The sandy mudstone specimens were wrapped in cling film throughout the freeze–thaw cycle to ensure that the water content of the specimens was basically stable during the freeze–thaw cycle.

2.2.2 Physical parameter tests

The mass of the specimen is an important index reflecting the changes in physical properties of the specimen before and after freeze–thaw cycles. The mass loss rate of sandy mudstone specimens is obtained by comparing the mass of specimens before and after freeze–thaw cycles under different freeze–thaw cycle conditions, and the calculation equation is as follows:

where Qf is the mass loss rate of the sandy mudstone specimen, m0 is the mass of the sandy mudstone specimen before the freeze–thaw cycles, and mf is the mass of the sandy mudstone specimen after the freeze–thaw cycles.

The velocity of ultrasonic waves inside the rock is affected by the structure, mineral composition, water content, and so on. Ultrasonic waves encountered in the rock internal pores, cracks and other defects will occur reflection, scattering and bypassing phenomena, thereby reducing the speed when the ultrasonic wave propagation in the rock. The change of P-wave velocity in rocks can reflect the internal structural integrity of rocks and the development of defects (Xue et al. 2019; Zhu et al. 2021). The P-wave velocity loss rate of sandy mudstone specimens is obtained by comparing the P-wave velocity of specimens before and after freeze–thaw cycles under different freeze–thaw cycle conditions, and the calculation equation is as follows:

where Pf is the P-wave velocity loss rate, V0 is the P-wave velocity of the sandy mudstone specimen before freeze–thaw cycles, and Vf is the P-wave velocity of the sandy mudstone specimen after freeze–thaw cycles.

The mass and P-wave velocity of sandy mudstone specimens after freeze–thaw cycles were tested to obtain the changes of these two physical parameters before and after the freeze–thaw cycles. The mass of the specimens was measured by an electronic scale with a minimum value of 0.01 g. The P-wave velocity of the specimens was measured by an HC-U81 concrete ultrasonic detector.

2.2.3 Microstructure tests

The macroscopic physical and mechanical properties of rocks are essentially affected by the microstructural characteristics of rocks. Therefore, studying the microstructural characteristics of sandy mudstone specimens after freeze–thaw cycles can provide a basis for the analysis of their macroscopic physical and mechanical properties. The SEM tests were carried out by the VEGA3 SEM developed by TESCAN. The sandy mudstone specimens after freeze–thaw cycles were cut into cubic samples of about 1 cm × 1 cm × 0.3 cm and dried. Wherein the cubic samples were selected from the interior of the specimens. The microstructure of the sandy mudstone cubic samples was observed with magnifications of 500 and 3000 times, respectively.

2.2.4 UCS tests

UCS tests were performed on sandy mudstone specimens subjected to different freeze–thaw cycles, three specimens per experimental condition. The UCS tests were conducted using a testing system consisting of two parts: MTS816 electro-hydraulic servo rock testing system and Micro II Express AE monitoring system. The loading mode was selected as axial displacement loading, and the loading rate was 0.2 mm/min.

3 Results

3.1 Freeze–thaw effects on physical properties

3.1.1 Freeze–thaw effects on mass

The variation curves of mass loss rates of sandy mudstone specimens with the number of freeze–thaw cycles at different freezing temperatures are shown in Fig. 2a. At different freezing temperatures, the mass loss rates of sandy mudstone specimens increase nonlinearly exponentially with the increase in the numbers of freeze–thaw cycles, and the amplitude of the increase in mass loss rates gradually decreases with the increase in the numbers of freeze–thaw cycles. When the freezing temperature is − 20 ℃ and the number of freeze–thaw cycles is 30, the mass loss rate of the specimens increases to a maximum of 0.504%. The mass loss rates are fitted with exponential functions, and the fitting degrees (R2) are all greater than 0.97.

The variation curves of mass loss rates of sandy mudstone specimens with the freezing temperature for different numbers of freeze–thaw cycles are shown in Fig. 2b. The mass loss rates of sandy mudstone specimens increased nonlinearly exponentially with decreasing freezing temperature for different numbers of freeze–thaw cycles. When the freezing temperature is lower than − 10 ℃, the amplitude of the increase in mass loss rates decreased dramatically. The mass loss rates are fitted with exponential functions, and the fitting degrees are all greater than 0.96.

3.1.2 Freeze–thaw effects on P-wave velocity

The variation curves of P-wave velocity loss rates of sandy mudstone specimens with the numbers of freeze–thaw cycles at different freezing temperatures are shown in Fig. 3a. At different freezing temperatures, the P-wave velocity loss rates of sandy mudstone specimens increases nonlinearly exponentially with the increase in the numbers of freeze–thaw cycles, and the amplitude of the increase in P-wave velocity loss rates gradually decreases with the increase in the numbers of freeze–thaw cycles. When the freezing temperature is − 20 ℃ and the number of freeze–thaw cycles is 30, the P-wave velocity loss rate of the specimens increases to a maximum of 22.44%. The P-wave velocity loss rates are fitted with exponential functions, and the fitting degrees are all greater than 0.99.

The variation curves of P-wave velocity loss rates of sandy mudstone specimens with the freezing temperature for different numbers of freeze–thaw cycles are shown in Fig. 3b. The P-wave velocity loss rates of sandy mudstone specimens increased nonlinearly exponentially with decreasing freezing temperature for different numbers of freeze–thaw cycles. When the freezing temperature is lower than − 10 ℃, the amplitude of the increase in P-wave velocity loss rates decreased dramatically. The P-wave velocity loss rates are fitted with exponential functions, and the fitting degrees are all greater than 0.95.

3.2 Freeze–thaw effects on microstructure

Figure 4 shows the microstructure of a natural sandy mudstone specimen at 500 and 3000 times magnification. At a magnification of 500 times, the natural sandy mudstone is relatively complete and dense, and the surface is relatively flat around the large sandy particles. At a magnification of 3000 times, there are sheet-like clay like cementitious materials on the surface of natural sandy mudstone, and the overall structure is dense without obvious damage defects.

3.2.1 Effects of freeze–thaw cycles on microstructure

Figure 5 shows the microstructure of sandy mudstone specimens magnified 500 and 3000 times for different numbers of freeze–thaw cycles at a freezing temperature of − 20 ℃. When the number of freeze–thaw cycles is 1, the surface of the sandy mudstone is rough in some areas and the clay cement is loose, but remained generally intact. When the number of freeze–thaw cycles is 10, several cracks appear on the surface of the sandy mudstone at 500 times, and a small amount of cement peels off. The damage and peeling phenomenon of the cement can be more clearly observed at 3000 times. When the number of freeze–thaw cycles is 20 and 30, at 500 times, large flaky spalling appears on the surface of the sandy mudstone, the overall surface is rough, and there are obvious cracks. At 3000 times, most of the surface structure of the sandy mudstone shows loose characteristics, while the development of pores and crack structures is obvious, indicating that the microstructure of the sandy mudstone has been severely damaged under the freeze–thaw cycles. These phenomena indicate that when the freezing temperature is certain, as the number of freeze–thaw cycles increases, cracks and pore structure inside the sandy mudstone gradually develop, the microstructure changes from dense to loose, and the surface changes from flat to rough.

3.2.2 Effect of freezing temperature on microstructure

Figure 6 shows the microstructure of sandy mudstone specimens magnified 500 and 3000 times at different freezing temperatures when the number of freeze–thaw cycles is 20. When the freezing temperature is − 5 ℃, the phenomenon of cement damage and peeling appears on the surface of the sandy mudstone at 500 times, and some pores can be found at 3000 times. When the freezing temperature is − 10 ℃, the microstructure of the sandy mudstone becomes loose under freeze–thaw cycles, and the overall surface is relatively rough. As the freezing temperature decreases to − 15 ℃ and − 20 ℃, the damage to the microstructure caused by freeze–thaw cycles becomes more pronounced, the microstructure integrity of the sandy mudstone further decreases, and the structural defects such as pores and cracks develop significantly. These phenomena indicate that when the number of freeze–thaw cycles is certain, the damage to the microstructure of sandy mudstone by freeze–thaw cycles gradually increases with the decrease of freezing temperature, and the structural defects such as pores and cracks develop more significantly.

3.3 Freeze–thaw effects on uniaxial mechanical properties

3.3.1 Freeze–thaw effects on stress–strain curves

The stress–strain curves of sandy mudstone specimens under different freeze–thaw cycles are shown in Fig. 7a–d. The stress–strain curves are classified into two types of characteristic curves based on their characteristics, as shown in Fig. 7e. The Type I characteristic curve reflects the stress–strain characteristics of the sandy mudstone under natural conditions, fewer freeze–thaw cycles and higher freezing temperatures conditions, while the Type II characteristic curve reflects the stress–strain characteristics of the sandy mudstone under more freeze–thaw cycles and lower freezing temperatures conditions. Both types of characteristic stress–strain curves exhibit four typical stages: the compaction stage (i), the elastic deformation stage (ii), the plastic deformation stage (iii), and the post-destruction stage (iv).

Comparing the Type I characteristic curve with the Type II characteristic curve, it can be found that the Type I characteristic curve exhibits obvious brittle characteristics, while the Type II characteristic curve exhibits plastic characteristics. Compared to the Type I characteristic curve, the Type II characteristic curve has a larger strain in the compacting stage. The slope of the elastic deformation stage of the sandy mudstone decreases gradually with the increase of the number of freeze–thaw cycles and the decrease of the freezing temperature, indicating that freeze–thaw cycles have an damaging effect on the deformation resistance of sandy mudstone. The Type II characteristic curve exhibits greater ductility during the plastic deformation stage. The Type I characteristic curve rapidly drops during the post-destruction stage, showing brittle characteristics. While the strain softening phenomenon after the peak of Type II characteristic curve exhibits obvious plastic characteristics as the number of freeze–thaw cycles increases and the freezing temperature decreases.

3.3.2 Freeze–thaw effects on UCS

The UCS changes of sandy mudstone specimens under different freeze–thaw cycle conditions is shown in Fig. 8.

As can be seen from Fig. 8a, the UCS of sandy mudstone specimens under different freezing temperatures shows a nonlinear exponential decrease with the increase in the numbers of freeze–thaw cycles, and the amplitude of the decrease in UCS gradually decreases with the increase in the numbers of freeze–thaw cycles. When the freezing temperature is − 20 ℃ and the number of freeze–thaw cycles is 30, the UCS of the specimens decreases to a minimum of 11.03 MPa. The UCS is fitted with exponential functions, and the fitting degrees are all greater than 0.99.

As can be seen from Fig. 8b, the UCS of sandy mudstone specimens shows a nonlinear exponential decrease with decreasing freezing temperature under different numbers of freeze–thaw cycles, and the amplitude of the decrease in UCS gradually decreases with the decrease in the freezing temperature. The UCS is fitted with exponential functions, and the fitting degrees are all greater than 0.96.

3.3.3 Freeze–thaw effects on elastic modulus

Due to the slope of the elastic deformation stage of the rock stress–strain curve is often not a constant, the International Society of Rock Mechanics has proposed three methods to define the elastic modulus (Ec):

-

(1)

The tangent slope of the stress–strain curve at a stress value of half of the UCS is taken as the modulus of elasticity, i.e., the tangent modulus.

-

(2)

The slope of the line connecting the stress–strain curve at a stress value of half of the UCS with the origin is taken as the elastic modulus, i.e., the secant modulus.

-

(3)

The average slope of the stress–strain curve during the elastic deformation stage is taken as the elastic modulus, i.e., the average modulus.

In this study, the first method was chosen to define the elastic modulus of the sandy mudstone. The variation curves of elastic modulus of sandy mudstone specimens under different freeze–thaw cycle conditions are shown in Fig. 9.

From Fig. 9a, it can be seen that the elastic modulus of sandy mudstone specimens under different freezing temperatures shows a nonlinear exponential decrease with the increase in the numbers of freeze–thaw cycles, and the amplitude of the decrease in elastic modulus gradually decreases with the increase in the numbers of freeze–thaw cycles. When the freezing temperature is − 20 ℃ and the number of freeze–thaw cycles is 30, the elastic modulus of the specimens decreases to a minimum of 1.37 GPa. The elastic modulus is fitted with exponential functions, and the fitting degrees are all greater than 0.99.

From Fig. 9b, it can be seen that the elastic modulus of sandy mudstone specimens shows a nonlinear exponential decrease with decreasing freezing temperature under different numbers of freeze–thaw cycles, and the amplitude of the decrease in elastic modulus gradually decreases with the decrease in the freezing temperature. The elastic modulus is fitted with exponential functions, and the fitting degrees are all greater than 0.96.

3.3.4 Freeze–thaw effects on peak strain

The variation curves of peak strain (εc) of sandy mudstone specimens under different freeze–thaw cycle conditions are shown in Fig. 10.

As can be seen from Fig. 10a, the peak strain of sandy mudstone specimens under different freezing temperatures shows a nonlinear exponential increase with the increase in the numbers of freeze–thaw cycles, and the amplitude of the increase in peak strain gradually decreases with the increase in the numbers of freeze–thaw cycles. When the freezing temperature is − 20 ℃ and the number of freeze–thaw cycles is 30, the peak strain of the specimens increases to a maximum of 1.34%. The peak strain is fitted with exponential functions, and the fitting degrees are all greater than 0.96.

As can be seen from Fig. 10b, the peak strain of sandy mudstone specimens shows a nonlinear exponential increase with decreasing freezing temperature under different numbers of freeze–thaw cycles, and the amplitude of the increase in peak strain gradually decreases with the decrease in the freezing temperature. The peak strain is fitted with exponential functions, and the fitting degrees are all greater than 0.91.

3.4 Freeze–thaw effects on macroscopic failure characteristics

Figure 11 shows the uniaxial compression failure mode and schematic diagram of a natural sandy mudstone specimen. It can be seen that the sandy mudstone specimen without freeze–thaw cycles exhibits a typical columnar splitting failure mode under uniaxial compression, that is, there is a single fracture surface that penetrates the sandy mudstone specimen in the axial loading direction, and there are almost no secondary cracks near the main crack.

Table 3 presents the uniaxial compressive failure modes and schematic diagrams of sandy mudstone specimens under different freeze–thaw conditions. Comparing the uniaxial failure mode of the natural sandy mudstone specimen, it can be found that the numbers of freeze–thaw cycles and freezing temperature have obvious effects on the uniaxial failure modes of sandy mudstone specimens. When the numbers of freeze–thaw cycles are small and the freezing temperatures are high, the uniaxial failure mode of sandy mudstone specimens are basically the same as that of the natural sandy mudstone specimen, with the splitting failure mode dominating. There is a main crack that penetrates vertically the specimens, exhibiting brittle tensile failure. With the increase of the number of freeze–thaw cycles and the decrease of the freezing temperature, the main crack on the surface of the sandy mudstone specimens shows an angle with the axial loading direction, and the failure mode gradually shifts towards shear failure. At the same time, secondary cracks appear near the main crack. When the number of freeze–thaw cycles further increases to more than 20 times and the freezing temperature decreases to below − 15 ℃, multiple intersecting shear cracks appear on the surface of the sandy mudstone specimens, and the degree of fracture of the specimens significantly increases. At the same time, there is a phenomenon of loose debris peeling near the main crack, which reduces the flatness of the shear surface. In addition, the decrease in freezing temperature accelerates the influence of freeze–thaw cycles on the uniaxial failure mode of sandy mudstone specimens. That is, at lower freezing temperatures, as the number of freeze–thaw cycles increases, the uniaxial failure mode of sandy mudstone specimens changes more quickly to shear failure, and the number of cracks and the degree of fracture of the specimens increase more significantly.

3.5 Freeze–thaw effects on AE characteristics

The occurrence of macroscopic cracks and ultimate failure of sandy mudstone specimens under load is essentially the result of the expansion, development, and penetration of microscopic pores inside the rock specimens. The degree of crack development during compressive fracture process of sandy mudstone specimens can be divided by three characteristic thresholds: crack initiation stress (σci), crack damage stress (σcd) and peak stress (σc). Among them, the crack initiation stress indicates the initiation of new cracks inside the specimen. The crack damage stress indicates that the internal cracks of the specimen have expanded and developed, and begin to penetrate. The peak stress indicates that the microscopic cracks inside the specimen penetrate through and accumulate to form macroscopic cracks, and the specimen enters the post-destruction stage.

In this study, the slope mutation features of the cumulative AE ringing counts-time characteristic curves were used to determine the crack initiation stress and crack damage stress of sandy mudstone specimens. Figure 12 shows the time-domain characteristic curves of stress and AE ringing counts of a natural sandy mudstone. As can be seen from Fig. 12, when the time is 177 s, the AE ringing counts of the sandy mudstone specimen start to increase, indicating the initiation of new cracks inside the specimen. The slope of the corresponding cumulative AE ringing counts curve begins to suddenly increase. At this time, the corresponding stress value on the stress time-domain curve is the crack initiation stress. When the time is 223 s, the value of the AE ringing counts significantly increases, indicating that the cracks expand and develop vigorously, and start to penetrate through gradually. The slope of the corresponding cumulative AE ringing counts curve further increases. At this time, the corresponding stress value on the stress time-domain curve is the crack damage stress.

The time-domain curves of stress and AE ringing counts of sandy mudstone specimens under different freeze–thaw cycle conditions are shown in Fig. 13. The crack initiation and extension of sandy mudstone specimens during uniaxial compression can be divided into crack compaction stage, elastic deformation stage, stable crack extension stage, unstable crack extension stage, and post-peak failure stage based on the time-domain characteristics of AE ringing counts and the trend of cumulative ringing counts. Among them, the AE signals are less in the crack compaction stage and the elastic deformation stage, which are the quiet period of AE. The AE signals start to grow steadily in the stable crack expansion stage, which is the low-amplitude growth period of AE. In the unstable crack extension stage, the AE signals grow rapidly, and this stage is the high-amplitude growth period of AE. The AE signals remain at a high level during the post-peak failure stage, which is the stable growth period of AE.

Figure 14 shows the variation curves of crack initial stress and crack damage stress under different freeze–thaw cycles. From Fig. 14, it can be seen that the crack initiation stress and crack damage stress of sandy mudstone decrease with the increase of freeze–thaw cycles and the decrease of freezing temperature. When the freezing temperature is − 20 ℃ and the number of freeze–thaw cycles is 30, the crack initial stress of the specimens decreases to a minimum of 7.24 MPa, and the crack damage stress of the specimens decreases to a minimum of 9.27 MPa. The freeze–thaw cycles have a significant impact on the initiation, extension, and penetration of compressive cracks in sandy mudstone specimens. The increase in the number of freeze–thaw cycles and the decrease in freezing temperature cause greater damage to sandy mudstone specimens, leading to an increase in initial pore defects inside the specimens, a decrease in the bearing capacity of the specimens, and a decrease in its crack initiation and damage threshold.

4 Discussions

4.1 Mechanism of freeze–thaw effects on physical and mechanical properties

From the test results in Sect. 3.1.1, it can be seen that the mass loss rate of sandy mudstone specimens increases nonlinearly exponentially with the increase in the number of freeze–thaw cycles and the decrease in freezing temperature. As the number of freeze–thaw cycles increases and the freezing temperature decreases, the amplitude of the increase in the mass loss rate gradually decreases. During the freeze–thaw cycle, when the temperature drops, there is a temperature gradient between the surface and the interior of the specimen, which leads to an inconsistent deformation of surface shrinkage and internal non shrinkage (Yin et al. 2023), resulting in tensile stress on the surface of the specimen. At the same time, unfrozen water in the internal pores of the specimen migrates to the frozen area (i.e., the surface of the specimen) and freeze to expand, resulting in frost heave force (Zhang et al. 2022; Jia et al. 2020). Particle peeling occurs on the surface of the specimen under the combined effect of the tensile stress caused by the temperature gradient and the frost heave force caused by the water freezing (Liu et al. 2020a, b). When the freezing temperatures are the same, the mass loss of the sandy mudstone specimens during the initial freeze–thaw cycles is caused by the combined effect of both. The internal pores of the specimens continue to develop with the increase of the number of freeze–thaw cycles (Lin et al. 2020; Yu et al. 2023). However, due to the lack of water replenishment during the freeze–thaw cycles of the sandy mudstone specimens in this experiment, the damage caused by the pore water frost heave force gradually decreases, and the magnitude of the increase in mass loss rate decreases accordingly. When the number of freeze–thaw cycles is the same and the freezing temperature is − 5 ℃, there is still a large amount of pore water unfrozen due to the influence of the pore size distribution of the specimens (Liu et al. 2016; Zou et al. 2023). When the freezing temperature is lowered from − 5 ℃ to − 10 ℃, the content of unfrozen water inside the specimens decreases greatly, and most of the pore water freezes and expands, causing damage to the specimens and leading to a rapid increase in the rate of specimen mass loss. After the freezing temperature drops to − 10 ℃, there is only a small amount of unfrozen water inside the specimens. As the freezing temperature further decreases, the growth of damage caused by unfrozen water freezing gradually slows down, leading to a decrease in the magnitude of the increase in the mass loss rate of the specimens.

Similar to the change of mass loss rate, when the freezing temperature is the same, with the increase of the number of freeze–thaw cycles, the internal pores of the sandy mudstone specimens gradually expand and penetrate under the action of the frost heave force, and more structural damage defects are formed, which leads to the decrease of the P-wave velocity. At the same time, the structural damage defects also reduce the bearing capacity and deformation resistance of the sandy mudstone specimens and increase the overall plasticity of the specimens, which lead to a decrease in the UCS, a decrease in the elasticity modulus, and an increase in the peak strain. Due to the lack of water replenishment during the experiment, as the number of freeze–thaw cycles increases, the magnitude of the increase in frost heave force gradually decreases, thereby slowing down the accumulation of internal damage in the specimens, resulting in a decrease in the magnitude of the increase in the P-wave velocity loss rate and the peak strain, as well as the decrease in the magnitude of the decrease in the UCS and the elastic modulus. When the number of freeze–thaw cycles is the same, as the freezing temperature decreases, the proportion of pore water freezing inside the specimens increases, resulting in greater frost heave force and causing greater damage, so that the P-wave velocity, UCS and elasticity modulus are reduced and the peak strain is increased. When the freezing temperature is below − 10 ℃, the content of unfrozen water inside the specimens significantly decreases, and the magnitude of the damage growth caused by the decrease in temperature decreases.

Furthermore, compared to the sandy mudstone specimens under natural condition, fewer freeze–thaw cycles and higher freezing temperatures conditions, the sandy mudstone specimens at more freeze–thaw cycles and lower freezing temperatures have more structural damage defects, lower UCS, smaller elastic modulus, and greater peak strain (Zhang et al. 2022). At the same time, more structural damage defects increase the frictional resistance during post-peak failure, suppress the relative sliding of the macroscopic fracture surface, and retard the decrease in stress. These resulted in two types of characteristic stress–strain curves shown in Fig. 7 for sandy mudstone specimens under natural conditions and different freeze–thaw cycles.

4.2 Law of freeze–thaw effects on AE characteristics

4.2.1 AE ringing counts and cumulative AE ringing counts

As can be seen in Fig. 13, the freeze–thaw cycles have a significant effect on the AE ringing counts and cumulative AE ringing counts of the sandy mudstone specimens. At the same freezing temperature, there is a significant increase in the time distribution of AE ringing events in the crack compaction stage of sandy mudstone specimens with the increase in the number of freeze–thaw cycles. For example, at a freezing temperature of − 10 °C, the distribution time is extended from 58 s (N = 0) to 146 s (N = 30). The peak value of AE ringing counts decreases overall with the increase of the number of freeze–thaw cycles. For instance, the peak AE ringing count of the natural sandy mudstone specimen is 10.79 × 103. At a freezing temperature of − 20 °C, the peak AE ringing counts decreased to 7.88 × 103 (N = 1), 4.57 × 103 (N = 10), 2.79 × 103 (N = 20), and 2.49 × 103 (N = 30) for each number of freeze–thaw cycles, respectively. When the peak value of AE ringing counts decreased with the increase of the number of freeze–thaw cycles, the failure time of the specimens shows a significant increase, the energy accumulated in the stress deformation of the sandy mudstone specimens gradually changes from the instantaneous release of brittle failure to the gradual release of ductile failure. In addition, the cumulative AE ringing counts shows an overall decreasing trend with the increase in the number of freeze–thaw cycles. This is because more freeze–thaw cycles cause greater damage to the sandy mudstone specimens, which reduces their deformation resistance and bearing capacity, and reduces the accumulated energy during the deformation process, resulting in a decrease in the cumulative energy release during crack extension and a decrease in the cumulative AE ringing counts.

At the same number of freeze–thaw cycles, there is a significant increase in the time distribution of AE ringing events in the crack compaction stage of sandy mudstone specimens as the freezing temperature decreases. For example, the distribution time is extended from 86 s (T = − 5 °C) to 131 s (T = − 20 °C) when the number of freeze–thaw cycles is 20. The peak value of AE ringing counts decreases with the decrease of freezing temperature, and the failure time of the sample increases, indicating that the brittleness of the sandy mudstone specimens decreases with the decrease of freezing temperature, and gradually shows the characteristics of ductile plasticity damage. In addition, there is an overall decreasing trend in cumulative AE ringing counts with decreasing freezing temperature. This is due to the fact that the lower the freezing temperatures, the greater the temperature stress gradient and the higher the proportion of pore water freezing, which brings greater damage to the sandy mudstone specimens, reducing their deformation resistance and bearing capacity, and reducing the accumulated energy during the deformation process, resulting in a decrease in the cumulative energy release during crack extension and a decrease in the cumulative AE ringing counts.

It is worth noting that the number of freeze–thaw cycles has a more significant impact on the AE ringing counts and cumulative AE ringing counts of sandy mudstone specimens than the freezing temperature. Meanwhile, the freezing temperature and the number of freeze–thaw cycles have a mutually reinforcing effect on the AE characteristic parameters of sandy mudstone specimens. At lower freezing temperatures, the number of freeze–thaw cycles has a more significant effect on the AE characteristic parameters of sandy mudstone specimens, and vice versa.

4.2.2 Crack initial stress, crack damage stress and peak stress

Figure 15 shows the variation curves of stress ratio under different freeze–thaw cycles. From Fig. 15a and b, it can be seen that the ratio of crack initiation stress to peak stress in the sandy mudstone specimen is maintained at 65.68–74.32% and the ratio of crack damage stress to peak stress is maintained at 84.04–93.11% under different freezing temperatures and number of freeze–thaw cycles. These indicate that the crack initiation stress and the ratio of crack damage stress to peak stress of sandy mudstone do not vary significantly with the number of freeze–thaw cycles and freezing temperature, but remain fluctuating at a certain level.

5 Conclusions

In this study, sandy mudstone on the slope of an open-pit mine in Xinjiang Autonomous Region was taken as the research object. Based on the freeze–thaw cycle tests considering the two influencing factors of freeze–thaw cycle number and freezing temperature, physical parameter tests, microstructure tests, and UCS tests were conducted. The following conclusions can be drawn from the analysis and discussion of the experiments:

-

(1)

With the increase of the number of freeze–thaw cycles and the decrease of the freezing temperature, the mass loss rate, P-wave velocity loss rate, UCS, elastic modulus, and peak strain of the sandy mudstone specimens all change nonlinearly exponentially, and the amplitude of these changes gradually decreases. Meanwhile, the microstructure changes from dense to loose, the micro surface changes from flat to rough, and cracks and pore defects gradually develop, indicating an increase in freeze–thaw damage.

-

(2)

As the number of freeze–thaw cycles increases and the freezing temperature decreases, the stress–strain curves of specimens gradually transition from the Type I characteristic curve with obvious brittle characteristics to the Type II characteristic curve with plastic characteristics. At the same time, the uniaxial failure mode shifts from splitting failure to shear failure, with a significant increase in the number of cracks and the degree of rupture.

-

(3)

The peak AE ringing counts, cumulative AE ringing counts, crack initiation stress, and crack damage stress of the sandy mudstone specimens during uniaxial compression all decrease with an increase in the number of freeze–thaw cycles and a decrease in freezing temperature, signifying a shift from brittle failure to ductile failure. However, the ratio of crack initiation stress and crack damage stress to peak stress remains relatively constant across varying the number of freeze–thaw cycles and freezing temperature.

Data Availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Apostu IM, Lazar M, Faur F (2020) A model to evaluate the flooding opportunity and sustainable use of former open-pits. Sustainability 12(21):9275

Blanchette ML, Lund MA (2016) Pit lakes are a global legacy of mining: an integrated approach to achieving sustainable ecosystems and value for communities. Curr Opin Environ Sustain 23:28–34

Cao SH, Chen SZ, Shang T, Yang M (2021) Comprehensive utilization model of oil storage and energy storage of abandoned open-pit. China Min Mag 30(6):89–94

Chen YF, Lin H (2023) Deterioration laws of Hoek-Brown parameters in freeze–thaw multi-fractured rock mass. Theoret Appl Fract Mech 123:103716

Chen TC, Yeung MR, Mori N (2004) Effect of water saturation on deterioration of welded tuff due to freeze-thaw action. Cold Reg Sci Technol 38(2–3):127–136

Huang SB, Lu ZX, Ye ZY, Xin ZK (2020) An elastoplastic model of frost deformation for the porous rock under freeze- thaw. Eng Geol 278:105820

Huang CC, Zhu C, Ma YF, Hewage SA (2022) Investigating mechanical behaviors of rocks under freeze–thaw cycles using discrete element method. Rock Mech Rock Eng 55(12):7517–7534

Jia HL, Ding S, Zi F, Dong YH, Shen YJ (2020) Evolution in sandstone pore structures with freeze-thaw cycling and interpretation of damage mechanisms in saturated porous rocks. Catena 195:104915

Jiang B, Zhang B, Li L, Zhao Y, Jia L (2021) Analysis of microbial community structure and diversity in surrounding rock soil of different waste dump sites in fushun western opencast mine. Chemosphere 269:128777

Krassakis P, Karavias A, Zygouri E, Roumpos C, Louloudis G, Pyrgaki K, Koukouzas N, Kempka T, Karapanos D (2023) Gis-based assessment of hybrid pumped hydro storage as a potential solution for the clean energy transition: the case of the Kardia lignite mine, western Greece. Sensors 23(2):593

Li L, Zhang B, Jiang B, Zhao Y, Qian G, Hu X (2022) Potentially toxic elements in weathered waste-rocks of Fushun western opencast mine: distribution, source identification, and contamination assessment. Environ Geochem Health 44(6):1813–1826

Li JD, Gao Y, Yang TH, Zhang PH, Zhao Y, Deng WX, Liu HL, Liu FY (2023) Integrated simulation and monitoring to analyze failure mechanism of the anti-dip layered slope with soft and hard rock interbedding. Int J Min Sci Technol 33:1147–1164

Lin H, Lei DX, Zhang CS, Wang YX, Zhao YL (2020) Deterioration of non-persistent rock joints: A focus on impact of freeze–thaw cycles. Int J Rock Mech Min Sci 135:104515

Liu QS, Huang SB, Kang YS, Pan YC (2016) Study of unfrozen water content and frost heave model for saturated rock under low temperature. Chinese J Rock Mech Eng 35(10):2000–2012

Liu CJ, Deng JR, Yu ST, Li P, Lin Y (2020) Effect of freezing and thawing on microstructure damage and dynamic flexural tension of granite. Rock Mech Rock Eng 53(8):3853–3858

Liu XY, Yi L, Feng D, Yan ZL (2020) Tensile mechanical behavior and fracture characteristics of sandstone exposed to freeze-thaw treatment and dynamic loading. Int J Mech Sci 226:107405

Luo XD, Jiang N, Zuo CQ, Dai ZW, Yan ST (2014) Damage characteristics of altered and unaltered diabases subjected to extremely cold freeze–thaw cycles. Rock Mech Rock Eng 47(6):1997–2004

Luo XD, Jiang N, Fan XY, Mei NF, Luo H (2015) Effects of freeze–thaw on the determination and application of parameters of slope rock mass in cold regions. Cold Reg Sci Technol 110:32–37

Luo PJ, Han XQ, Chen N (2022) Study on complexity planning model of pumped storage in abandoned open-pit mine: a case study of Fushun open-pit mine. Front Earth Sci 10:808371

Park J, Hyun CU, Park HD (2015) Changes in microstructure and physical properties of rocks caused by artificial freeze–thaw action. Bull Eng Geol Environ 74(2):555–565

Paronuzzi P, Bolla A (2022) In-depth field survey of a rockslide detachment surface to recognise the occurrence of gravity-induced cracking. Eng Geol 302:106636

Pujades E, Willems T, Bodeux S, Orban P, Dassargues A (2016) Underground pumped storage hydroelectricity using abandoned works (deep mines or open pits) and the impact on groundwater flow. Hydrogeol J 24(6):1531–1546

Qi WW, Yang WT, He XL, Xu C (2021) Detecting Chamoli landslide precursors in the southern Himalayas using remote sensing data. Landslides 18(10):3449–3456

Qiu JS, Zhou YX, Vatin NL, Guan X, Sultanov S, Khemarak K (2020) Damage constitutive model of coal gangue concrete under freeze-thaw cycles. Construct Build Mater 264:120720

Redondo Vega JM, Melón Nava A, Peña Pérez SA, Santos González J, Gómez Villar A, González Gutiérrez RB (2021) Coal pit lakes in abandoned mining areas in León (NW Spain): characteristics and geoecological significance. Environ Earth Sci 80(24):792

Shen YJ, Yang GS, Rong TL, Liu H, Lv WY (2016) Proposed scheme for freeze-thaw cycle tests on rock. Chinese J Geotech Eng 38(10):1775–1782

Song ZL, Fan JF, Qi WH, Yang XC, Wang JG, Ji YS (2016) Study on the surface coal mine green mining technology and appraising index system. J China Coal Soc 41(S2):350–358

Tang XH, Tao SJ, Li P, Rutqvist J, Hu MS, Sun L (2022) The propagation and interaction of cracks under freeze-thaw cycling in rock-like material. Int J Rock Mech Min Sci 154:105112

Waitkus AK (2022) Sustainable reclamation practices for a large surface coal mine in shortgrass prairie, semiarid environment (Wyoming, USA): case study. Int J Coal Sci Technol 9:32

Weng L, Zhang HL, Wu ZJ, Xu XY, Zhang CY, Li MY, Liu QS (2023) Heterogeneous frost deformation of partially saturated sandstones due to the freeze–thaw cycle. Rock Mech Rock Eng

Wessel M, Madlener R, Hilgers C (2020) Economic feasibility of semi-underground pumped storage hydropower plants in open-pit mines. Energies 13(16):4178

Wu J, Lu YN, Wang KB, Cai Y, Xiao C (2023) Combined effects of freeze–thaw cycles and chemical corrosion on triaxial mechanical properties of sandstone. Geomech Geophys Geo-Energy Geo-Resour 9(1):57

Xue GL, Yilmaz E, Song WD, Cao S (2019) Mechanical, flexural and microstructural properties of cement-tailings matrix composites: effects of fiber type and dosage. Compos Part B Eng 172:131–142

Yahaghi J, Liu H, Chan A, Fukuda D (2021) Experimental and numerical studies on failure behaviours of sandstones subject to freeze-thaw cycles. Transp Geotech 31:100655

Yang GY, Chen YL, Liu XY, Yang R, Zhang YF, Zhang JL (2023) Stability analysis of a slope containing water-sensitive mudstone considering different rainfall conditions at an open-pit mine. Int J Coal Sci Technol 10:64

Yin TB, Lu JF, Yu Y, Wu Y, Wang JH, Men JQ (2023) Fracture behavior of yellow sandstone under freeze–thaw cycles with varied saturation states: An investigation of mode I fracture. Geomech Energy Environ 36:100502

Yu J, Zhang Q, Jia CJ, Lei MF, Zhao CY, Pang RF, Li Z, Zeng T (2023) Experimental and DEM simulations of the mechanical properties of rock under freeze–thaw cycles. Cold Reg Sci Technol 211:103866

Zhang J, Deng HW, Taheri A, Ke B, Liu CJ (2019) Deterioration and strain energy development of sandstones under quasi-static and dynamic loading after freeze-thaw cycles. Cold Reg Sci Technol 160:252–264

Zhang Q, Liu Y, Dai F, Jiang RC (2022) Experimental assessment on the fatigue mechanical properties and fracturing mechanism of sandstone exposed to freeze-thaw treatment and cyclic uniaxial compression. Eng Geol 306:106724

Zhao HZ, Tian Y, Guo QY, Li MJ, Wu JW (2020) The slope creep law for a soft rock in an open-pit mine in the Gobi region of Xinjiang, China. Int J Coal Sci Technol 7(2):371–379

Zhu QQ, Li DY, Wang WJ (2021) Mechanical behavior and permeability evolution of sandstone with confining pressure after dynamic loading. Geomech Geophys Geo-Energy Geo-Resour 7(3):81

Zou YY, Jiang HQ, Wang EL, Liu XC, Du SL (2023) Variation and prediction of unfrozen water content in different soils at extremely low temperature conditions. J Hydrol 624:129900

Funding

This work was financially supported by the National Key R&D Program of China (2022YFC2903902), the Xinjiang Uygur Autonomous Region Science and Technology Major Program (No. 2023A01002), the National Natural Science Foundation of China (52304102), the Postgraduate Research & Practice Innovation Program of Jiangsu Province (KYCX23_2666), and the Graduate Innovation Program of China University of Mining and Technology (2023WLKXJ186).

Author information

Authors and Affiliations

Contributions

Y. C. conceived and designed the research. The testing plan was proposed by Y. C. and G. Y. Testing, data collection, and analysis were performed by G. Y., Q. X., P. W. and Y. Z. The first draft of the manuscript was written by G. Y. and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethics approval

This research did not involve human subjects or animal experimentation. As a result, no ethics approval was required for this study. Any potential conflicts of interest were disclosed and managed in accordance with the ethical standards of our institution.

Consent to publish

The authors agree to the publication of the manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yang, G., Chen, Y., Xie, Q. et al. Physical and mechanical characteristics deterioration and crack evolution of sandy mudstone in an open-pit mine under multiple freeze–thaw cycles. Geomech. Geophys. Geo-energ. Geo-resour. 10, 87 (2024). https://doi.org/10.1007/s40948-024-00808-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-024-00808-3