Abstract

To study the combined effects of freeze–thaw cycles and chemical corrosion on deterioration mechanism of triaxial mechanical properties of sandstone in cold regions, triaxial compression tests were carried out on homologous sandstone specimens after corrosion action of acidic, alkaline or neutral solution and cyclic freeze–thaw action, by taking the pH value of the hydrochemical solution and the number of freeze–thaw cycles as control parameters. The failure mode of triaxial compression is shear-slip failure, and the deviatoric stress–strain curves can be divided into four stages of compaction, linear elastic, yield, and failure. The stress–strain curves and deterioration law of triaxial mechanical properties were analyzed. With the increase of freeze–thaw cycles, the peak stress, peak strain and modulus all decrease, the deterioration degree of the rock specimens increases, and the yield plateau and plastic characteristics in the yield stage become weaker. The strong acid solution shows the largest degree of damage, and the peak stress, peak strain and modulus decreased significantly. The precipitates produced by the reaction between the strong alkaline solution and the specimens adhere to the specimen surface, pores, and fissures, thereby inhibiting further damage and deterioration. Confining pressure is an essential factor affecting the rock mechanical properties. As confining pressure increases, the strength and deformation-resistant ability of specimens increase, and the yield stage on the stress–strain curve is more obvious. The sensitivity of acidic solution to the deterioration of mechanical properties of sandstone is obviously greater than that of alkaline solution. These results provide a theoretical basis for the construction of geotechnical engineering structures in cold regions.

Highlights

-

Under the combined effects of freeze–thaw cycles and chemical corrosion, the triaxial compressive failure mode of the sandstone specimens is shear failure.

-

Both freeze–thaw cycles and chemical corrosion cause damage and deterioration of mechanical properties of sandstone specimens.

-

The damage effect of mechanical properties increases as the number of freeze–thaw cycles increases, while the damage deterioration of rock specimens in acidic solution is larger than that in alkaline solution.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

More complicated geotechnical engineering problems have been encountered in the progressive construction process of cold region projects, such as the railway and highway, the West to East Gas Transportation, the South to North Water Diversion, the water conveyance pipeline, and the traffic tunnels in the central and western regions of China (Jia et al. 2022; Hutchinson et al. 1993). The most severe problem in cold region projects is the engineering disaster caused by the freeze–thaw cycles (Zhao et al. 2022a, b). Synchronously, with the rapid development of the modern industry of China and some other countries, the consumption of fossil fuels continues to rise, resulting in a sharp increase in the emission of polluting gases in the atmosphere, leading to the aggravation of environmental pollution and global warming (Zhang et al. 2017; Ghobadi and Babazadeh 2015). The problem of acid rain caused by environmental pollution and global warming is a global environmental problem of significant concern, leading a deterioration of geotechnical mechanical properties and causing serious disasters (Miao et al. 2016; Cai et al. 2016). It is of great significance to study the deterioration law and damage mechanism of triaxial mechanical properties of sandstone under the combined effects of freeze–thaw cycles and chemical corrosion for geotechnical engineering construction in the cities with rapid industrial development in cold regions (Bayram 2012).

Investigation on the effect law of chemical corrosion and cyclic freeze–thaw on the physical and mechanical properties of rocks has attracted the attention of scholars all around the world and has made significant progress and fruitful results (Ftdc et al. 2022; Sinclar et al. 2015). Most of the research has focused on a single factor analysis of the number of freeze–thaw cycles or the chemical corrosion. Water chemistry changes the mineral composition of rocks and increases pore volumes, thus decreasing rock strength (Deng et al. 2018). Related studies on the effects of chemical solutions on the deterioration of physical and mechanical properties of rock materials, such as mineral components, porosity, and mechanical strength characteristics of uniaxial and triaxial tests, etc., have been carried out and determined (Lu et al. 2018; Jamshidi et al. 2013; Al-Omari et al. 2015). The deterioration of macro-mechanical properties and microscopic mechanisms of sandstone with three-point bending tests, thin-section identification, and energy spectrum analysis under chemical corrosion conditions have been evaluated. The cyclic freeze–thaw processes cause fractures to extend after thermal expansion and contraction of rock masses, and the fracture extension reduces the strength of the rock masses (Wang et al. 2019; Meng et al. 2021). The durability, mass, pore volume of rock and soil with different number of freeze–thaw cycles have been analyzed (Eslami et al. 2018; Li et al. 2018; Li et al. 2019; Yang et al. 2019; Yue et al. 2022). There are also some achievements that consider the combined effect of the two factors. The mechanical deterioration properties, porosity, durability, energy evolution law and dissipation model of rock specimens was examined under combined freeze–thaw cycles and chemical corrosion (Zhang et al. 2019, 2022; Chen et al. 2021). Jamshidi et al. 2016 evaluated the durability of Gerdoee travertine after freeze–thaw cycles in fresh water and sodium sulfate solution by decay function models. Han et al. 2017 conducted macroscopic mechanical property tests on sandstone and granite and analyzed the damage model of the specimens with different freeze–thaw cycles under hydrochemical corrosion. Abdelhamid et al. 2020 estimated the deterioration rate of some carbonate rocks under repeated frost damage process.

Due to the complex climate and groundwater environment at low temperature, as well as the significant difference of geotechnical structures, hydrochemical corrosion (chemical field), freeze–thaw cycles (temperature field) and triaxial stress state (stress field) have significant effects on the mechanical properties of the rock masses (Li et al. 2019). Scholars have gradually progressed from the single factor analysis of chemical corrosion or freeze–thaw cycles to the combined effect analysis of chemical corrosion, cyclic freeze–thaw, complex stress on the properties of rock physics.

In this work, based on the practical engineering in rock slope of Fuyin expressway, in Xian, Shaanxi Provence, northwest of China, the sandstone specimens which were saturated in acidic solution (H2SO4), alkaline solution (NaOH), and neutral solution (Na2SO4) of different concentrations (pH) were subjected to freeze–thaw action with different cycles (N), then triaxial compression tests were carried out at different confining pressure (σ3). The characteristics of deviatoric stress (σ1–σ3) and strain (ε) curve, the damage variable Dn and the degradation of strength parameters (friction coefficient f and cohesion c) were analyzed. Preliminary comparative analysis of the sensitivity of acidic solution, alkaline solution, and neutral solution to the deterioration of mechanical properties of sandstone was carried out. The research results from this work could provide a reference and theoretical basis for the development and utilization of geotechnical engineering structures in seasonally frozen soil regions.

2 Experimental method

2.1 Specimen preparation and treatment

The rock used in the study is sandstone, obtained from the rock slope engineering of Fuyin expressway in Xian, Shaanxi Provence, northwest of China, with grayish-white color and fine-grained homogeneous structure. The rock shows a good integrity, without primary cracks. The average dry density is 2417.72 kg/m3. The diameter of the cylindrical rock specimens is 50 mm (error ≤ 0.3 mm) and the height is 100 mm (error ≤ 0.05 mm). The deviation of the two ends perpendicular to the cylinder axis is no more than 0.25°, according to the triaxial compression testing standard. The grouping of the specimens is shown in Fig. 1.

-

(1)

Dry rock specimens are first prepared. The selected specimens were put in the oven and dried at 105 °C for 48 h to a constant weight. The mass change rate of the rock sample was required to be no more than 0.1% in the next 24 h. Then the mass of the rock specimens was weighed and recorded. The saturated rock specimens are also prepared. Put the dry rock specimens into the air extraction container, seal the container, extract the air in the container at a pressure of 0.1 MPa, extract for 2 h and then inject distilled water into the vacuum, and continue pumping for 4 h until no bubbles overflow, and then soak the specimens in water for more than 24 h, weigh the saturated specimens in the air and in the water. The saturated water content and porosity of rock specimens are obtained.

-

(2)

The water chemical environment of the rock masses is mainly groundwater circulation or atmospheric rainfall infiltration. Due to the regional differences in engineering geology and hydrogeological conditions, water often has different pH values and complex ionic compositions, and most groundwater environments contain ions such as Na+, Mg+, K+, SO42−, Cl−, NO3−. Analysis of local water quality test data shows that the water environment of the sampling site can be characterized by cation Na + and anion SO42−. Therefore, the acid H2SO4 solution, neutral Na2SO4 solution, and alkaline NaOH solution with an initial concentration of 0.01 mol/L were used to simulate the main ionic components in the water of the rock masses. Five sets of solution with different pHs (3, 5, 7, 9, 11) were obtained by solution dilution to simulate the water chemistry environment.

-

(3)

Na2SO4 solution was used to replace the complex ionic composition in water environment, and 5 groups of pH values were set, among which pH values of 3, 5, 7, 9, 11 respectively represent strong acidic, acidic, neutral, weakly alkaline and alkaline water chemical environment. The initial concentration of Na2SO4 solution was 0.1 mol L−1. H2SO4 and NaOH were added to the solution respectively to configure the acidic solution and the alkaline solution. In order to balance the total number of ions, Na2SO4 of the same mass was added to the neutral solution. Soak the rock specimens for 20 days, as shown in Fig. 1c. During this period, the pH value of the solution was tested every 5 days to ensure that the solution was stable at the design pH value, and the rock specimens were taken out to test the diameter, height, mass and sound wave every 5 days.

2.2 Experimental apparatus and design

2.2.1 Experimental apparatus

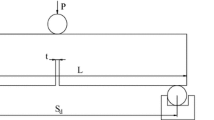

The main experimental methods used in this work are the cyclic freeze–thaw test and the triaxial compression test. Cyclic freeze–thaw tests were conducted by using the constant temperature and constant humidity SFDR-11 freeze–thaw cycle chamber produced by the Tianjin Gangyuan Instrument Factory of China. As shown in Fig. 2a, its freeze–thaw cycle temperature range is − 30 °C ~ + 30 °C, with an accuracy of ± 0.1 °C, and the maximum power is 9 kW. Triaxial compression tests were conducted by using the RMT-301 rock and concrete mechanical test system developed by the Wuhan Institute of Geomechanics, Chinese Academy of Sciences. As shown in Fig. 2b, its maximum axial load is 1500 kN with a loading rate of 0.01 ~ 90 kN/s, and the maximum confining pressure is 50 MPa, with a loading rate range of 0.001 ~ 1 MPa/s. Axial and lateral displacements can be up to 50 mm.

2.2.2 Experimental design

Rock specimens were prepared, considering solutions with five pHs, five freeze–thaw cycles, and four confining pressure conditions. The Diagram of test procedures is shown in Fig. 3.

The experimental design is shown in Table 1.

2.2.2.1 Freeze–thaw cycles test

Containers filled with aqueous chemical solutions of different pHs and saturated sandstone specimens were placed in the SFDR-11 freeze–thaw cycle test chamber. The temperature range of the freeze–thaw cycle test was set to − 20 °C ~ + 20 °C, and the single freeze–thaw cycle was 24 h (simulating the freeze–thaw cycle of the natural environment), of which the cooling and frost-heave was 12 h, and the heating and melting was 12 h. Damage of sandstone specimens cannot be hardly found when there are few freeze–thaw cycles, but the more the freeze–thaw cycles, the more damage will appear, this will lead to the failure of specimens before the triaxial tests. According to many freeze–thaw tests (Lian et al. 2023), the freeze–thaw rate was kept constant, and the number of freeze–thaw cycles was set to N = 10, 20, 30, 40, and 50, as shown in Table 1. During the test, the specimen was taken out after every ten freeze–thaw cycles, the apparent characteristics of the specimen were observed, and the physical parameters including diameter, height and sound wave were measured.

2.2.2.2 Triaxial compression test

Based on the practical engineering in rock slope of Fuyin expressway of China and engineering data statistics (Wang et al 2022), the conventional triaxial compression tests were carried out under different design confining pressure of 1, 2, 3 and 4 MPa, as shown in Table 1. Triaxial compression test was carried out after the synergistic action of chemical corrosion and freeze–thaw cycle under the design conditions. The triaxial test device and triaxial pressure source are added to form a triaxial test system. Unlike true triaxial tests, where confining pressures are applied by pressure oil, the specimen is in a state equal to σ2 and σ3. First, install the specimen according to the requirements of the triaxial test system, then the confining pressure σ3 was applied to the design value at a loading rate of 0.05 MPa/s by applying oil pressure. After that, the one-time continuous loading method was used to apply an axial stress at a loading rate of 0.1 MPa/s, during which σ3 remained constant. The RMT-301 testing system automatically recorded the force–displacement curve until the specimen was completely ruptured. Based on data analysis, the deviatoric stress–strain relationship of the specimens can be plotted.

3 Experimental results and analysis

3.1 Experimental results

The physical parameters of the sandstone specimens subjected the freeze–thaw cycles and chemical corrosion when N = 20 are shown in Table 2.

The P-wave velocities of the saturated sandstone specimens under the combined effects of various freeze–thaw cycles and chemical corrosion conditions are shown in Fig. 4. It is shown that:

-

(1)

With the increasing number of the freeze–thaw cycles (N), the P-wave velocity of the sandstone decreased under the combined effects of freeze–thaw cycles and chemical solution. This indicates that the deterioration of mechanical properties of sandstone increases significantly with the increase of the number of freeze–thaw cycles in saturated water-chemical corrosion environment.

-

(2)

There are differences in the magnitude and variation degree of P-wave velocity of sandstone specimens saturated with different chemical solutions. The P wave velocity of rock specimens saturated with strong acid solution decreases the fastest, while saturated with the strong alkaline solution decreases the slowest. That is, under the same freeze–thaw conditions, the smaller the pH value of the aqueous chemical solution, the faster the P wave velocity decreases, and the smaller the wave velocity value. It shows that the strong acid solution has the greatest degradation degree of rock mechanical properties, while the strong alkaline solution has the least degradation degree.

The damaged sandstone specimens of the triaxial compression failure test are shown in Fig. 5. The apparent failure characteristics of sandstone specimens under triaxial compression can be summarized as follows.

-

(1)

The failure mode of sandstone specimens is shear slip failure. Theoretically, shear slip failure is due to the continuous development and accumulation of shear slip between sandstone particles until a visible fracture is formed at the macroscopic level, eventually leading to shear slip failure of the entire specimen. The shear fracture of the specimen is roughly along the diagonal line of the two ends of the specimen, and there are locally fragmented rock chips, as shown in Fig. 5a. The actual failure surface of rock specimens is not always flat, and the shear failure angle is different from that predicted by Coulomb criterion. In general, the higher the confining pressure is, the better the flatness of the fracture surface is.

-

(2)

Due to the combined effects of chemical corrosion and freeze–thaw cycles, the structure and mineral composition of the rock will change. As a result, its pore volume increases, and fractures extend from the surface to inerior. As the number of freeze–thaw cycles increases, the number of surface cracks at the time of specimen failure also increases, and spalling becomes more apparent, as shown in Fig. 5b. The degradation of the physical and mechanical properties of rock specimens starts from the outside to the inside. Specifically, the specimen soaked in the acid solution with pH = 5 after undergoing 50 freeze–thaw cycles has the most cracks, and its degree of degradation is the largest, as shown in Fig. 5c.

-

(3)

After soaking in the alkaline solution, a clear layer of white precipitates appears on the surface of the rock specimens, as shown in Fig. 5d.

Mineral composition identification and element detection of original sandstone specimens were carried out by powder crystal X-ray diffraction analysis and SEM scanning electron microscopy in this work. Sandstone is a typical sedimentary rock, with the main mineral composition of SiO2 (quartz), KAlSi3O8 (feldspar), and various metal mineral cations such as Na+, K+, Al3+, Mg2+, Ca2+ and so on (Zhao et al. 2022a, b; Bi et al. 2023). Different chemical reactions occur with different aqueous chemical solutions.

When in acidic Na2SO4 solution, the following chemical reactions occur:

When in acidic H2SO4 solution, the following chemical reactions occur:

When in alkaline NaOH solution, the following chemical reactions occur:

When the rock specimen is immersed in a neutral solution with pH = 7, reactions (1)–(5) will occur. The generated K + and Na + will cause damage and strength deterioration, softening the sandstone specimen. The white precipitates of Ca(OH)2 and Mg(OH)2 attach to the surface of the specimen and fill the cracks to a certain extent, thereby slowing down further reactions. Reactions (6)–(11) will occur in the H2SO4 solution, and most of the generated products are in a free state, resulting in a further increase in rock porosity. Therefore, the acid solution has a strong corrosive effect on the sandstone. Reactions of (12)–(15) occur first in the NaOH solution, cations Al3+, Ca2+ and Mg2+ in the rock and anions OH− and SiO32− in the solution are more easily reacted to form slightly soluble precipitation, which are attached to the surface, pores, and cracks of the rock, inhibiting the damage and deterioration inside the specimen.

During the freeze–thaw cycles, the cyclic rise and fall of temperature will speed up the reactions between mineral components and chemical solutions. When the temperature drops, the pore water inside the rock specimen freezes and creates frost heaving forces, enlarging the microscopic pores and cracks and increasing damage. When the temperature rises, the pore water in the rock flows, water content increases, chemical reactions accelerate, and ion exchange becomes active. After repeated freezing and thawing, the surface of the specimen becomes soft and spalling appears, and the deterioration damage gradually develops from the surface to the interior. It is apparent that the effects of chemical corrosion and freeze–thaw cycles to the damage and degradation of physical and mechanical properties of sandstone specimens promote each other.

3.2 Analysis of deviatoric stress–strain data

3.2.1 Deviatoric stress–strain curves under different freeze–thaw cycles

Figure 6 shows the relationship between deviatoric stress and strain under the conditions of constant pH and confining pressure σ3. The effect of the number of freeze–thaw cycles on mechanical properties of rock specimens in a complex water chemical corrosion environment was analyzed.

Figure 6 shows the following characteristics.

-

(1)

The deviatoric stress vs. strain curves of the specimens all show a similar shape and can be roughly divided into four stages: compaction stage, linear elastic stage, yield stage, and failure stage (Eberhardt et al.1998). In the initial compaction stage, small defects (pores, fissures) inside the specimen are gradually compacted, the modulus increases rapidly with the increase of deviatoric stress, and the curve is concave. In the linear elastic stage, the curve is approximately linear, and as the number of freeze–thaw cycles N increases, the elastic modulus decreases. In the yield stage, the compressive modulus decreases gradually with continuous loading, decreasing to zero at the peak stress. Failure occurs instantaneously at the peak stress, with continuous deformation afterwards.

-

(2)

From the overall macroscopic perspective, under constant solution pH and confining pressure σ3, the peak deviatoric stress and elastic modulus of the rock gradually decrease with the increase of the freeze–thaw cycles. The linear elastic stage of the specimen becomes shorter, and the strain at peak stress is reduced. In other words, the strength and deformation resistance of the specimens are significantly reduced. The yield plateau and plastic characteristics in the yield stage become weaker, and the strength after the peak deviatoric stress decreases rapidly. The entire loading process shows that the changes occur fast in the beginning and then slows down.

-

(3)

Under acid (Fig. 6a, b) and alkaline (Fig. 6c, d) conditions, the deviatoric stress–strain curves of the rock specimens show consistent behavior. Under the combined actions of water chemical corrosion and freeze–thaw cycles, the deterioration of the structure and the degradation of mechanical properties of the rock specimens starts from the surface and accumulates with time until the irreversible damage occurs.

3.2.2 Deviatoric stress–strain curves under different chemical corrosion conditions

Figure 7 shows the deviatoric stress–strain curves under constant freeze–thaw cycles of 20 and constant confining pressure σ3. The effect of water chemical corrosion on mechanical properties of rock specimens in a complex freeze–thaw cycles environment was analyzed.

Figure 7 shows the following characteristics.

-

(1)

The overall trend of the deviatoric stress–strain curves of the rock specimens is similar, which can also be divided into four stages: compaction stage, linear elastic stage, yield stage, and failure stage. Macroscopically, the elastic modulus and strength of rock specimens in alkaline solution are greater than those in acidic solution, that is, En(NaOH) > En(Na2SO4) > En(H2SO4), Δσ(NaOH) > Δσ(Na2SO4) > Δσ(H2SO4).

-

(2)

When the confining pressure is low (Fig. 7a σ3 = 1 MPa, (b) σ3 = 2 MPa), the specimen in the solution of pH = 3 first reaches the peak stress and the specimen in the solution of pH = 11 reaches the peak stress the last. The corrosion rate v of the solution on the mechanical properties of the specimens follows the order of v(H2SO4) > v(Na2SO4) > v(NaOH). It shows that in low stress environment, the damage to the rock in the strong acid solution is the most significant, and the damage to the rock in the strong alkaline corrosive environment is the least.

-

(3)

When the confining pressure is large (Fig. 7c σ3 = 3 MPa, (d) σ3 = 4 MPa), the elastic modulus and peak stress of the specimens in the strong alkaline solution with pH = 11 are the largest, which are significantly larger than those of the specimens in pH = 7 and pH = 9 solutions. This further proves that the chemical reaction speed in the strong alkaline solution is relatively fast. The reaction product quickly reaches saturation and then precipitates and adheres to the surface and pores and fissures of the specimens, forming a white layer of precipitates.

3.2.3 Deviatoric stress vs. strain curves under different confining pressure

Figure 8 shows the deviatoric stress vs. strain curves under the condition of constant pH and freeze–thaw cycles N = 20. The effects of different confining pressure on the mechanical properties under specific chemical corrosion and freeze–thaw cycles was analyzed.

Figure 8 shows the following characteristics.

-

(1)

The deviatoric stress–strain curves among different rock specimens are similar. The curves can be divided into four stages again: compaction stage, linear elastic stage, yield stage, and failure stage. In general, confining pressure σ3 is the most critical factor affecting the rock stress–strain behavior. The sensitivity and consistency of its influence on the stress–strain curve are significantly greater than that of the pH value of the chemical solution and the freeze–thaw cycles N.

-

(2)

When the solution pH value and the freeze–thaw cycle N are constant, the peak stress and elastic modulus corresponding to confining pressure from 1 to 4 MPa increase from small to large. It shows that under the same chemical solution and freeze–thaw cycle conditions, confining pressure significantly influences the strength and stiffness of the specimens. The larger the confining pressure, the larger the compressive strength and the elastic modulus.

-

(3)

When the pH value of the solution and the freeze–thaw cycle N are constant, the strain at peak stress of the rock specimens increases as the confining pressure increases. This shows that under the same corrosion and freeze–thaw cycle conditions, confining pressure σ3 significantly impacts the mechanical properties of rock specimens. With increasing confining pressure, the yield plateau and plastic change characteristics in the yield stage become more apparent, and the ability of the rock specimen to resist plastic deformation gradually increases.

4 Degradation of mechanical properties of sandstone

4.1 Damage variables of rock specimens

It is well known that the degradation of rock mechanical properties is mainly caused by the continuous propagation and coalescence of micropores and cracks in the rock. In addition, freeze–thaw cycles and chemical corrosion of water promote the propagation and penetration of pores and fractures. At the same time, rock mineral composition and structure change, eventually leading to the damage and deterioration of the strength and hardness of the rock. According to the theory of damage mechanics, the method based on the rock elastic modulus can be used to define the damage variable Dn, which is expressed as:

where E0 is the elastic modulus of the initial intact specimen, MPa; En is the modulus of elasticity after hydrochemical solution and freeze–thaw cycles, MPa.

The experimental data was progressed without considering the initial damage to the specimen. The elastic modulus of the specimen after hydrochemical solution and freeze–thaw cycles is substituted into Eq. (16), and the evolution of Dn is plotted in Fig. 9, where a consistent trend is observed.

Figure 9 shows the following characteristics.

-

(1)

Under the same solution pH, the damage variable Dn of the specimens gradually increases with increasing number of freeze–thaw cycles. When N = 40 and pH = 3, the damage accumulation in the rock specimen reaches the maximum (Dn = 0.194), with large fluctuation. When N = 50, the specimen is completely failed in the compressive failure stage, with spalling of rock pieces, Dn decreases as a result. When N = 50, the damage accumulation in specimens in alkaline solution and neutral solution reaches the maximum value. Damage variables corresponding to pH = 9, pH = 11, and pH = 7 is 0.218, 0.195, and 0.174, respectively.

-

(2)

With the same number of freeze–thaw cycles, when the specimens are in acidic solution, the lower the pH, the greater the degree of damage and deterioration. When the pH remains unchanged, increasing freeze–thaw cycles N increases the difference in the damage variable Dn of the specimens (Fig. 9, N = 50), which further indicates that the number of freeze–thaw cycles impacts the damage and deterioration to the rock. Therefore, the damage and deterioration of rock specimens are not only related to the corrosion of hydrochemical solutions but also to freeze–thaw cycles. These two factors play a similar role in impacting the change of the mechanical properties of the rock.

4.2 Strength parameters of rock specimens

It can be seen from the stress–strain curves that the triaxial shear failure process of the rock specimens is similar under the combined action of different chemical solutions and freeze–thaw cycles. The specimens exhibit brittle failure characteristics and the strength parameters can be expressed as,

where F is the slope of the σ1–σ3 curve; R is the intercept of the σ1–σ3 curve on the σ1 axis, which is equivalent to the uniaxial compressive strength of the specimen (MPa); f and c are the coefficient of friction (%) and cohesion (MPa) of the sandstone specimens, respectively.

The relationship between the principal stress and the deviator stress of the rock specimens is obtained from the triaxial compression tests. The friction coefficient and cohesion are calculated according to Eq. (17–18), as listed in Table 3.

Using data in Table 3, the histogram of friction coefficient f and cohesion c of sandstone specimens with different pH values when N = 20 is obtained, as shown in Fig. 10.

The following conclusions can be drawn from Fig. 10.

-

(1)

The combined effects of freeze–thaw cycles and chemical corrosion increase the friction coefficient f of sandstone. In general, the corrosion of the acidic solution and alkaline solution environment increases the pore size, propagates the cracks and dissolves mineral components of sandstone, and the skeleton structure becomes more pronounced. Therefore, the friction coefficient f of rock specimens under the triaxial stress state increases. The specimen has the largest porosity corroded by the strong acidic solution, so f is the largest. In the alkaline solution, since the precipitates adhere to the surface of the rock and the internal walls of pores and fissures, further chemical reactions are inhibited, so f does not continue to increase after it increases to a certain extent.

-

(2)

The combined actions of freeze–thaw cycles and chemical corrosion reduce the cohesion c of the rock. After the freeze–thaw cycles, the corrosion of the acidic solution or the alkaline solution causes the pores inside the rock to enlarge, the cracks to extend, and the mineral components to dissolve. As the molecular force between the minerals decreases, the cohesion decreases. When the rock specimen is corroded in strong acid solution, the mineral components are more dissolved, and the cohesion is smaller. When the rock specimen is corroded in strong alkaline solutions, precipitates adhere to the rock surface and the walls of pores and fissures, increasing the molecular force between the minerals. Therefore, the cohesion of the rock is higher than that of the weak alkaline solution.

-

(3)

Under the same freeze–thaw conditions, the mechanical properties of rock specimens are deteriorated to different degrees by strong acid and alkaline solutions. Compared with the neutral solution (Na2SO4, pH = 7), the change of damage variable in the strong acid solution (pH = 3) is 0.329 (35.644%), and the change of cohesion is 3.772 MPa (29.127%). In the strong alkaline solution (pH = 11), the change of damage variable is 0.215 (23.293%), and the change of cohesion is 1.717 MPa (13.259%). It can be seen that the degree of deterioration of the friction coefficient and cohesion of the rock by the acidic solution is greater than that of the alkaline solution. That is, the deterioration of the mechanical properties of the rock by the acidic solution is more severe.

-

(4)

Under the same freeze–thaw conditions, the concentrations of acidic and alkaline solutions have different sensitivities to the deterioration of mechanical properties of rock specimens. In the acidic solution (H2SO4), from pH = 5 to pH = 3, the deterioration change of friction coefficient is 0.253 (25.325%), and the deterioration change of cohesion is 2.833 MPa (23.586%). In alkaline solution (NaOH), from pH = 9 to pH = 11, the deterioration change of friction coefficient is 0.005 (0.441%), and the deterioration change of cohesion is 0.761 MPa (7.267%). It can be seen that the acid solution is more sensitive to the deterioration of the rock friction coefficient and cohesion than the alkaline solution. The acid solution concentration significantly affects the deterioration of rock mechanical properties.

5 Conclusions

Both freeze–thaw cycles and chemical corrosion cause damage and deterioration of mechanical properties of sandstone specimens. Based on the three factors of freeze–thaw cycles N, pH value of the chemical solution, and confining pressure σ3, the deterioration law of the mechanical properties of the rock specimens was analyzed by carrying out triaxial compression tests on sandstone specimens under the combined effects of freeze–thaw cycles and chemical corrosion. The following conclusions can be drawn from this work.

-

(1)

Under the combined effects of freeze–thaw cycles and chemical corrosion, the triaxial compressive failure mode of the sandstone specimens is shear failure. As a result, the damage deterioration starts from the surface of the specimens to the interior. Specimens soaked in acid solution have the most cracks when they are failed, exhibiting severe damage from both ends and spalling rock pieces.

-

(2)

From the macroscopic perspective, the cumulative damage increases as the number of freeze–thaw cycles increases. With increasing freeze–thaw cycles, the peak deviator stress and elastic modulus of the specimens gradually decrease, the linear elastic stage becomes shorter, and the strain at peak stress also decreases. The yield plateau and plastic characteristics in the yield stage are weakened.

-

(3)

Overall, the damage and deterioration of sandstone specimens in acidic solution is larger than that in alkaline solution. The effect of water chemical solution on the deterioration of rock mechanical properties follows the order of H2SO4 > Na2SO4 > NaOH. Therefore, rock specimens in strong acidic solutions are the most degraded. The alkaline solution reacts with the rock minerals, and the resultant precipitates adhere to the surface of the specimens, inhibiting further chemical reactions.

-

(4)

Confining pressure σ3 is the most critical factor affecting the stress–strain relationship of the rock, showing good consistency. Therefore, as confining pressure σ3 increases, the compressive strength, peak stress, and ductile characteristics of the rock increase significantly, and the yield plateau and plastic characteristics in the yield stage become more apparent.

-

(5)

The combined effects of freeze–thaw cycles and chemical corrosion increase the pore size, extend the cracks, and dissolves the minerals, making the skeleton structure to be more prominent. As a result, these effects cause an increase in friction coefficient f and a decrease in cohesion c of the rock. The degree of deterioration and degradation sensitivity of the acid solution to friction coefficient f and cohesion c are significantly greater than that of the alkaline solution.

Data availability

Not applicable.

References

Abdelhamid M, Li D, Ren GF et al (2020) Estimating deterioration rate of some carbonate rocks used as building materials under repeated frost damage process, China. Adv Mater Sci Eng. https://doi.org/10.1155/2020/3826128

Al-Omari A, Beck K, Brunetaud X et al (2015) Critical degree of saturation: a control factor of freeze–thaw damage of porous limestones at Castle of Chambord, France. Eng Geol 185:71–80. https://doi.org/10.1016/j.enggeo.2014.11.018

Bayram F (2012) Predicting mechanical strength loss of natural stones after freeze–thaw in cold regions. Cold Regions Sci Technol 83–84:98–102. https://doi.org/10.1016/j.coldregions.2012.07.003

Bi J, Ning L, Zhao Y et al (2023) Analysis of the microscopic evolution of rock damage based on real-time nuclear magnetic resonance. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-023-03238-x

Cai YY, Yu J, Fu GF et al (2016) Experimental investigation on the relevance of mechanical properties and porosity of sandstone after hydrochemical erosion. J Mt Sci 13(11):2036–2068. https://doi.org/10.1007/s11629-016-4007-2

Chen YL, Xiao P, Du X et al (2021) Study on damage constitutive model of rock under freeze-thaw-confining pressure-acid erosion. Appl Sci 11:9431. https://doi.org/10.3390/app11209431

Deng HW, Yu ST, Deng JR (2018) Damage characteristics of sandstone subjected to coupled effect of freezing-thawing cycles and acid environment. Adv Civil Eng. https://doi.org/10.1155/2018/3560780

Eberhardt E, Stead D, Stimpson B et al (1998) Identifying crack initiation and propagation thresholds in brittle rock. Can Geotech J 35(2):222–233. https://doi.org/10.1139/cgj-35-2-222

Eslami J, Walbert C, Beaucour A-L, Bourges A, Noumowe A (2018) Influence of physical and mechanical properties on the durability of limestone subjected to freeze-thaw cycles. Constr Build Mater 162:420–429. https://doi.org/10.1016/j.conbuildmat.2017.12.031

Ftdc A, Pmv B, Lhg A et al (2022) Water/rock interactions, chemical weathering and erosion, and supergene enrichment in the Tapira and Catalo I alkalinecarbonatite complexes, Brazil. J Geochem Explor 237:106999. https://doi.org/10.1016/j.gexplo.2022.106999

Ghobadi MH, Babazadeh R (2015) An investigation on the effect of accelerated weathering on strength and durability of Tertiary sandstones (Qazvin province, Iran). Environ Earth Sci 73(8):4237–4250. https://doi.org/10.1007/s12665-014-3708-5

Han T, Shi J, Chen Y, Cao X (2017) Physical and mechanical properties of marble under the combined effects of chemical solutions and freeze–thaw cycles. Geotech Test J 40(6):20160225. https://doi.org/10.1520/GTJ20160225

Hutchinson AJ, Johnson JB, Thompson GE et al (1993) Stone degradation due to wet deposition of pollutants. Corosion Sci 34(11):1898. https://doi.org/10.1016/0010-938X(93)90025-C

Jamshidi A, Nikudel MR, Khamehchiyan M (2013) Predicting the long-term durability of building stones against freeze-thaw using a decay function model. Cold Reg Sci Technol 92:29–36. https://doi.org/10.1016/j.coldregions.2013.03.007

Jamshidi A, Nikudel MR, Khamehchiyan M et al (2016) Evaluation of the durability of Gerdoee travertine after freeze–thaw cycles in fresh water and sodium sulfate solution by decay function models. Eng Geol. https://doi.org/10.1016/j.enggeo.2016.01.004

Jia P, Mao S, Qian Y et al (2022) The dynamic compressive properties and energy dissipation law of sandstone subjected to freeze-thaw damage. Water 14(22):3632. https://doi.org/10.3390/w14223632

Li JL, Rennie B, Zhou KP (2018) Experimental investigations on the effects of ambient freeze-thaw cycling on dynamic properties and rock pore structure deterioration of sandstone - ScienceDirect. Cold Reg Sci Technol 154:133–141. https://doi.org/10.1016/j.coldregions.2018.06.015

Li S et al (2019) Effect of acid-temperature-pressure on the damage characteristics of sandstone. Int J Rock Mech Mining Sci 122:104079. https://doi.org/10.1016/j.ijrmms.2019.104079

Li X, Dengxing Q, Luo Y, Ma R, Kun X, Wang G (2019) Damage evolution model of sandstone under coupled chemical solution and freeze-thaw process. Cold Reg Sci Technol 162:88–95. https://doi.org/10.1016/j.coldregions.2019.03.012

Lian SL, Zheng K, Zhao Yu et al (2023) Investigation the effect of freeze–thaw cycle on fracture mode classification in concrete based on acoustic emission parameter analysis. Constr Build Mater 362:129789. https://doi.org/10.1016/j.conbuildmat.2022.129789

Lu YN, Li XP, Chan A (2018) Damage constitutive model of single flaw sandstone under freeze-thaw and load. Cold Reg Sci Technol 159:20–28. https://doi.org/10.1016/j.coldregions.2018.11.017

Meng F, Zhai Y, Li Y et al (2021) Research on the effect of pore characteristics on the compressive properties of sandstone after freezing and thawing. Eng Geol 286:106088. https://doi.org/10.1016/j.enggeo.2021.106088

Miao SJ, Cai MF, Guo QF et al (2016) Damage effects and mechanisms in granite treated with acidic chemical solutions. Int J Rock Mech Min Sci 88:77–86. https://doi.org/10.1016/j.ijrmms.2016.07.002

Sinclar SA, Pham N, Richard A, T, et al (2015) Influence of freeze-thaw dynamics on internal geochemical evolution of low sulfide waste rock. Appl Geochem J Int Assoc Geochem Cosmochem 61:160–174. https://doi.org/10.1016/j.apgeochem.2015.05.017

Wang L, Li N, Qi J et al (2019) A study on the physical index change and triaxial compression test of intact hard rock subjected to freeze-thaw cycles. Cold Reg Sci Technol 160:39–47

Wang CL, Zhao Y, Ning L, Bi J (2022) Permeability evolution of coal subjected to triaxial compression based on in-situ nuclear magnetic resonance. Int J Rock Mech Min Sci 159:105213. https://doi.org/10.1016/j.ijrmms.2022.105213

Yang X, Jiang A, Li M (2019) Experimental investigation of the time-dependent behavior of quartz sandstone and quartzite under the combined effects of chemical erosion and freeze–thaw cycles. Cold Reg Sci Technol 161:51–62. https://doi.org/10.1016/j.coldregions.2019.03.008

Yue J, Huang X, Zhao L et al (2022) Study on the factors affecting cracking of earthen soil under dry shrinkage and freeze–thaw conditions. Sci Rep 12(1):1816. https://doi.org/10.1038/s41598-022-05946-w

Zhang Y, Li Q, Zhang F et al (2017) Estimates of economic loss of materials caused by acid deposition in China. Sustainability 9(4):488. https://doi.org/10.3390/su9040488

Zhang FR, Jiang AN, Jiang ZB et al (2019) Experimental study of damage and creep property of rock under coupled chemical corrosion and freeze-thaw cycle. Rock Soil Mech 40(10):3879–3888. https://doi.org/10.16285/j.rsm.2019.0209

Zhang Y, Wu X, Guo Q et al (2022) Research on the mechanical properties and damage constitutive model of multi-shape fractured sandstone under hydro-mechanical coupling. Minerals. https://doi.org/10.3390/min12040436

Zhao Y, Lian SL, Bi J et al (2022a) Study on freezing-thawing damage mechanism and evolution model of concrete. Theor Appl Fract Mech 121:103439. https://doi.org/10.1016/j.tafmec.2022.103439

Zhao Y, Lian SL, Bi J et al (2022b) Investigation of the mechanical behavior and continuum damage model of sandstone after freezing–thawing cycle action under different immersion conditions. Bull Eng Geol Env 81(12):505. https://doi.org/10.1007/s10064-022-03005-2

Funding

This work was supported by the National Natural Science Foundation of China (41907259), the Hubei Provincial Natural Science Foundation of China (2022CFB948) and the Innovation and Entrepreneurship Projects for College Students of China (202210528018).

Author information

Authors and Affiliations

Contributions

JW provided the concept and edited the draft of manuscript. Y-nL conducted the literature review and wrote the first draft of the manuscript. YC, K-bW and CX carried out experiments. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

Not applicable.

Consent to publish

The Author confirms that the work described has not been published before and is not under consideration for publication elsewhere, its publication has been approved by all co-authors and the responsible authorities at the institution where the work is carried out.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wu, J., Lu, Y., Wang, K. et al. Combined effects of freeze–thaw cycles and chemical corrosion on triaxial mechanical properties of sandstone. Geomech. Geophys. Geo-energ. Geo-resour. 9, 57 (2023). https://doi.org/10.1007/s40948-023-00588-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-023-00588-2