Abstract

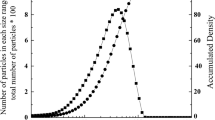

The influence of V2O5 of iron ore during oxidation process was examined by thermogravimetric analysis using a non-isothermal thermogravimetric analysis technology. The oxidation process could be divided into two stages. The kinetic mechanism and apparent activation energy (E) were studied using the Coats–Redfern (C–R) method. The obtained results showed that diffusion model was the best mechanism describing effectively oxidation process of iron ore under different V2O5. The values of E showed a decreasing trend with the increase of V2O5 addition in the whole oxidation process, indicating that the V2O5 was conducive to improve the oxidation kinetic conditions. And the fluctuation amplitude of E at stage II (10.489 kJ/mol) was greater than that at stage I (4.019 kJ/mol). With the amount of V2O5 increasing, microstructure study of pellets indicated that the growth pattern of grains was disrupted, resulting in abnormal grain growth and an increase in porosity. Thus, the loose structure of pellets could facilitate the internal diffusion of reaction gas at this moment. The oxidation kinetic conditions were improved and the values of E decreased ultimately.

Graphical Abstract

Oxidation kinetic analysis of the iron ore with different V2O5 additions.

Similar content being viewed by others

References

Shi Q, Tang J, Chu MS (2023) High-efficiency smelting separation of vanadium–titanium magnetite by electrothermal smelting: parameter optimization and element enrichment mechanism. J Sustain Metall 9:1126–1138. https://doi.org/10.1007/s40831-023-00708-y

Xing ZX, Ma J, Cheng GJ, Yang H, Xue XX (2022) Study on the high-temperature sintering characteristics and sintering mechanism of sea sand vanadium titanomagnetite based on micro-sintering. J Sustain Metall 8:1358–1369. https://doi.org/10.1007/s40831-022-00570-4

Yu JW, Hu N, Xiao HX, Gao P, Sun YS (2021) Reduction behaviors of vanadium-titanium magnetite with H2 via a fluidized bed. Powder Technol 385:83–91. https://doi.org/10.1016/j.powtec.2021.02.038

Tang X, Huang Y, Li Y, Yang Y, Cheng X, Jiao GH, Dai H (2022) The response of bacterial communities to V and Cr and novel reducing bacteria near a vanadium-titanium magnetite refinery. Sci Total Environ 806:151214. https://doi.org/10.1016/j.scitotenv.2021.151214

Zhou M, Jiang T, Yang ST, Xue XX (2015) Sintering behaviors and consolidation mechanism of high-chromium vanadium and titanium magnetite fines. Int J Miner Metall Mater 22:917–925. https://doi.org/10.1007/s12613-015-1150-7

Zhang SS, Wang ZY, Hu P, Rao JT, Zhang JL, Pang J (2022) Distribution behavior of vanadium and titanium between hot metal and high titanium slag relevant to HIsmelt smelting condition. J Mater Res Technol 19:4517–4524. https://doi.org/10.1016/j.jmrt.2022.07.020

Zhu S, Hu JG, Zhang CH, Li S, Chen WH (2023) Process optimization and kinetics of titanium leaching from mechanically activated titanium-bearing blast furnace slag. J Sustain Metall 9:230–239. https://doi.org/10.1007/s40831-022-00640-7

Ariyama T, Takahashi K, Kawashiri Y, Nouchi T (2019) Diversification of the ironmaking process toward the long-term global goal for carbon dioxide mitigation. J Sustain Metall 5:276–294. https://doi.org/10.1007/s40831-019-00219-9

Kang Z, Liao QL, Zhang Z, Zhang Y (2022) Carbon neutrality orientates the reform of the steel industry. Nat Mater 21:1094–1098. https://doi.org/10.1038/s41563-022-01370-7

Zhang YJ, Yue Q, Chai XC, Wang Q, Lu YQ, Ji W (2022) Analysis of process parameters on energy utilization and environmental impact of hydrogen metallurgy. J Clean Prod 361:132289. https://doi.org/10.1016/j.jclepro.2022.132289

Qiu ZY, Yue Q, Yan TY, Wang Q, Sun JC, Yuan YX, Che ZC, Wang YS, Du T (2022) Gas utilization optimization and exergy analysis of hydrogen metallurgical shaft furnace. Energy 263:125847. https://doi.org/10.1016/j.energy.2022.125847

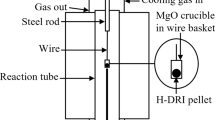

Feng JG, Tang J, Chu MS, Liu PJ, Zhao ZC, Zheng AJ, Wang XA, Han T (2023) Sticking behavior of pellets during direct reduction based on hydrogen metallurgy: an optimization approach using response surface methodology. J Sustain Metall 9:1139–1154. https://doi.org/10.1007/s40831-023-00712-2

Forsmo SPE, Forsmo SE, Samskog PO, Björkman BMT (2008) Mechanisms in oxidation and sintering of magnetite iron ore green pellets. Powder Technol 183:247–259. https://doi.org/10.1016/j.powtec.2007.07.032

Wang S, Guo YF, Jiang T, Yang L, Chen F, Zheng FQ, Xie XL, Tang MJ (2017) Reduction behaviors of iron, vanadium and titanium oxides in smelting of vanadium titanomagnetite metallized pellets. JOM 69:1646–1653. https://doi.org/10.1007/s11837-017-2367-x

Zeng RQ, Wang N, Li W (2023) Non-isothermal oxidation induration mechanism of vanadium titanomagnetite pellets. Powder Technol 34:104012. https://doi.org/10.1016/j.apt.2023.104012

Zhang ZB, Huang F, Xing MM, Wan Q, Gao WY, Gao S, Chen ZY, Cai JH (2018) Mineralogical characteristics of exsolved spinel in the panzhihua V-Ti magnetite deposit, Sichuan: implications for the mineralization process. Acta Geol Sin Engl Ed 92:1784–1794. https://doi.org/10.1111/1755-6724.13677

Fu GQ, Li W, Chu MS, Zhu MY (2020) Influence mechanism of SiO2 on the oxidation behavior and induration process of Hongge vanadium titanomagnetite pellets. Metall Mater Trans B 51:114–123. https://doi.org/10.1007/s11663-019-01734-6

Li W, Wang N, Fu GQ, Chu MS, Zhu MY (2018) Influence of TiO2 addition on the oxidation induration and reduction behavior of Hongge vanadium titanomagnetite pellets with simulated shaft furnace gases. Powder Technol 326:137–145. https://doi.org/10.1016/j.powtec.2017.12.050

Zeng RQ, Li W, Wang N, Fu GQ, Chu MS, Zhu MY (2020) Influence and mechanism of CaO on the oxidation induration of Hongge vanadium titanomagnetite pellets. ISIJ Int 60:2199–2205. https://doi.org/10.2355/isijinternational.isijint-2020-091

Swanepoel S, Garbers-Craig A (2023) Isothermal oxidation kinetics of industrial South African chromite concentrates in air. Miner Eng 202:108263. https://doi.org/10.1016/j.mineng.2023.108263

Sandeep Kumar TK, Viswanathan NN, Ahmed H, Dahlin A, Andersson C, Bjorkman B (2019) Developing the oxidation kinetic model for magnetite pellet. Metall Mater Trans B 50:162–172. https://doi.org/10.1007/s11663-018-1423-4

Li W, Fu GQ, Chu MS, Zhu MY (2017) Oxidation induration process and kinetics of Hongge vanadium titanium-bearing magnetite pellets. Ironmak Steelmak 44:294–303. https://doi.org/10.1080/03019233.2016.1210751

Wang YZ, Zhang JL, Liu ZJ (2019) Mineralogical characteristics and isothermal oxidation kinetics of ironsand pellets. Metals 9:265. https://doi.org/10.3390/met9020265

Sandeep Kumar TK, Viswanathan NN, Ahmed H, Dahlin A, Andersson C, Bjorkman B (2019) Investigation of magnetite oxidation kinetics at the particle scale. Metall Mater Trans B 50:150–161. https://doi.org/10.1007/s11663-018-1459-5

Ayyandurai A, Pal J (2022) Kinetics of carbon oxidation during induration of hematite ore pellet. Min Metall Explor 39:2551–2560. https://doi.org/10.1007/s42461-022-00692-z

Zheng H, Schenk J, Spreitzer D, Wolfinger T, Daghagheleh O (2021) Review on the oxidation behaviors and kinetics of magnetite in particle scale. Steel Res Int 92:2000687. https://doi.org/10.1002/srin.202000687

Qiu GZ, Zhu DQ, Pan J, Wang CG, Guo YF, Jiang T, Hu CF, Clout J, Shu FH (2004) Improving the oxidizing kinetics of pelletization of magnetite concentrate by high press roll grinding. ISIJ Int 44:69–73. https://doi.org/10.2355/isijinternational.44.69

Tang J, Chu MS, Feng C, Li F, Tang YT, Liu ZG (2016) Coupled effect of valuable components in high-chromium vanadium-bearing titanomagnetite during oxidization roasting. ISIJ Int 56:1342–1351. https://doi.org/10.2355/isijinternational.ISIJINT-2016-051

Huang XJ, Mo WL, Ma YY, He XQ, Syls Y, Wei XY, Fan X, Yang XQ, Zhang SP (2022) Pyrolysis kinetic analysis of sequential extract residues from Hefeng subbituminous coal based on the Coats-Redfern method. ACS Omega 7:21397–21406. https://doi.org/10.1021/acsomega.2c00307

Elmay Y, Jeguirim M, Trouvé G, Said R (2016) Kinetic analysis of thermal decomposition of date palm residues using Coats-Redfern method. Energy Sources A 38:1117–1124. https://doi.org/10.1080/15567036.2013.821547

Shi Y, Guo ZQ, Zhu DQ, Pan J, Lu SH (2023) Isothermal reduction kinetics and microstructure evolution of various vanadium titanomagnetite pellets in direct reduction. J Alloys Compd 953:170126. https://doi.org/10.1016/j.jallcom.2023.170126

Prajapati SB, Gautam A, Gautam S (2023) Non-isothermal kinetic study by TGA analysis of printed circuit boards and cotton stalk. Biomass Bioenergy 172:106746. https://doi.org/10.1016/j.biombioe.2023.106746

Fernandez A, Saffe A, Pereyra R, Mazza G, Rodriguez R (2016) Kinetic study of regional agro-industrial wastes pyrolysis using non-isothermal TGA analysis. Appl Therm Eng 106:1157–1164. https://doi.org/10.1016/j.applthermaleng.2016.06.084

Feng JG, Tang J, Chu MS, Zhao ZC, Liu ZG, Li XB, Wang XD, Wang XA (2023) Effect of Cr2O3 on the kinetics mechanism and microstructure of pellet during oxidation roasting process. Steel Res Int 94:2200735. https://doi.org/10.1002/srin.202200735

Hu RZ, Gao SL, Zhao FQ, Shi QZ, Zhang TL, Zhang JJ (2008) Thermal analysis dynamics. Science Press, Beijing, pp 151–155

Acknowledgements

The authors are especially grateful to the National Natural Science Foundation of China (Grant No. 51904063), Science and Technology Plan Project of Liaoning Province (2022JH24/10200027), the Key Research and Development Project of Hebei Province (21314001D), the Seventh Batch of Ten Thousand Talents Plan (ZX20220553) and Central University Basic Scientific Research Business Expenses Special Funds (N2225046).

Author information

Authors and Affiliations

Contributions

JF: investigation, writing-original draft. JT: writing-review and editing. XW: methodology. ZZ: investigation. MC: data curation.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

The contributing editor for this article was Hongmin Zhu.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Feng, J., Tang, J., Wang, X. et al. Effect of V2O5 During Oxidation Roasting of Pellet: Non-isothermal Kinetic Analysis and Microstructure Evolution. J. Sustain. Metall. 10, 110–125 (2024). https://doi.org/10.1007/s40831-023-00777-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40831-023-00777-z