Abstract

A numerical model based on the particle finite element method (PFEM) combined with a hypoplastic constitutive model is proposed for the analysis of soft soil excavations by means of single and multiple excavation tools. The PFEM allows to efficiently account for large deformations of the excavated soil material and free surfaces characterizing the simulation of tool–soil interaction during excavation. The utilization of a hypoplastic model, formulated in rate form, allows for a straightforward coupling with the standard velocity-based PFEM. Furthermore, effects such as pressure and density dependency of the soil stiffness are consistently incorporated into the formulation. The solution of the governing equations is performed implicitly, while an adaptive sub-stepping scheme is employed for the explicit time integration of the constitutive equation. Thus, the accuracy of the solution is improved at both global and local (constitutive) levels. The performance of the method is evaluated by means of the numerical re-analysis of selected geotechnical benchmark examples and soft soil excavations in 2D and 3D setups.

Similar content being viewed by others

References

Coetzee CJ (2000) Forced granular flow. Master’s thesis, Stellenbosch: Stellenbosch University. URL http://scholar.sun.ac.za/handle/10019.1/51764

Anagnostou G (2008) Some remarks concerning EPB and slurry shields. In: Development of urban areas and geotechnical engineering (St. Petersburg)

Kushwaha R, Chi L, Shen J (1993) Analytical and numerical models for predicting soil forces on narrow tillage tools. Canad Agric Eng 35(3):183

Reece AR (1964) Paper 2: the fundamental equation of earth-moving mechanics. In: Proceedings of the institution of mechanical engineers, conference proceedings 179(6):16. https://doi.org/10.1243/PIME_CONF_1964_179_134_02

Payne P (1956) The relationship between the mechanical properties of soil and the performance of simple cultivation implements. J Agric Eng Res 1(1):23

Callaghan JO’, Farrelly K (1964) Cleavage of soil by tined implements. J Agric Eng Res 9(3):259

Swick W, Perumpral J (1988) A model for predicting soil-tool interaction. Journal of Terramechanics 25(1):43. https://doi.org/10.1016/0022-4898(88)90061-4. URL http://www.sciencedirect.com/science/article/pii/0022489888900614

Dechao Z, Yusu Y (1992) A dynamic model for soil cutting by blade and tine. J Terramech 29(3):317. https://doi.org/10.1016/0022-4898(92)90003-3

Ibarra S, McKyes E, Broughton R (2005) A model of stress distribution and cracking in cohesive soils produced by simple tillage implements. J Terramech 42(2):115. https://doi.org/10.1016/j.jterra.2004.08.002

Terzaghi K (1943) Theoretical soil mechanics. Wiley, Hoboken

Karmakar S, Kushwaha RL (2006) Dynamic modeling of soil-tool interaction: an overview from a fluid flow perspective. J Terrramech 43(4):411. https://doi.org/10.1016/j.jterra.2005.05.001

Hu Y, Randolph MF (1998) A practical numerical approach for large deformation problems in soil. Int J Numer Anal Meth Geomech 22(5):327. https://doi.org/10.1002/(SICI)1096-9853(199805)22:5<327::AID-NAG920>3.0.CO;2-X

Osher S, Fedkiw R (2006) Level set methods and dynamic implicit surfaces, vol 153. Springer, berlin

Abo-Elnor M, Hamilton R, Boyle J (2003) 3D dynamic analysis of soil-tool interaction using the finite element method. J Terramech 40(1):51. https://doi.org/10.1016/j.jterra.2003.09.002

Abo-Elnor M, Hamilton R, Boyle J (2004) Simulation of soil–blade interaction for sandy soil using advanced 3D finite element analysis. Soil Tillage Res 75(1):61. https://doi.org/10.1016/S0167-1987(03)00156-9

Shen J, Jin X, Li Y, Wang J (2009) Numerical simulation of cutterhead and soil interaction in slurry shield tunneling. Eng Comput 26(8):985. https://doi.org/10.1108/02644400910996862

Coetzee CJ (2014) Discrete and continuum modelling of soil cutting. Comput Part Mech 1(4):409. https://doi.org/10.1007/s40571-014-0014-7

Cundall P, Strack O (1979) Discrete numerical model for granular assemblies. Geotechnique 29:47

Shmulevich I, Asaf Z, Rubinstein D (2007) Interaction between soil and a wide cutting blade using the discrete element method. Soil Tillage Res 97(1):37. https://doi.org/10.1016/j.still.2007.08.009

Coetzee C, Els D (2009) Calibration of granular material parameters for DEM modelling and numerical verification by blade–granular material interaction. J Terrramech 46(1):15. https://doi.org/10.1016/j.jterra.2008.12.004

Dang T, Wessels N, Nguyen N, Hackl K, Meschke G (2017) A coupled computational approach for the simulation of soil excavation and transport in earth-pressure balance shield machines. J Multiscale Comput Eng (in print)

von Wolffersdorff PA (1996) A hypoplastic relation for granular materials with a predefined limit state surface. Mech Cohes Frict Mater 1(3):251. https://doi.org/10.1002/(SICI)1099-1484(199607)1:3<251::AID-CFM13>3.0.CO;2-3

Oñate E, Idelsohn SR, Del Pin F, Aubry R (2004) The particle finite element method: an overview. Int J Comput Methods 1(02):267

Franci A, Oñate E, Carbonell JM (2016) Unified Lagrangian formulation for solid and fluid mechanics and FSI problems. Comput Methods Appl Mech Eng 298:520. https://doi.org/10.1016/j.cma.2015.09.023

Franci A (2016) Unified lagrangian formulation for fluid and solid mechanics, fluid–structure interaction and coupled thermal problems using the pfem. Ph.D. thesis, UPC Barcelona. http://www.springer.com/br/book/9783319456614

Carbonell JM, Onate E, Suarez B (2010) Modeling of ground excavation with the particle finite-element method. J Eng Mech 136(4):455

Edelsbrunner H, Mücke EP (1994) Three-dimensional alpha shapes. ACM Trans Graph 13(1):43. https://doi.org/10.1145/174462.156635

Idelsohn S, Mier-Torrecilla M, Oñate E (2009) Multi-fluid flows with the particle finite element method. Comput Methods Appl Mech Eng 198(33):2750. https://doi.org/10.1016/j.cma.2009.04.002

Dang T, Meschke G (2014) An ALE-PFEM method for the numerical simulation of two-phase mixture flow. Comput Methods Appl Mech Eng 278:599

Oñate E, Rossi R, Idelsohn SR, Butler KM (2010) Melting and spread of polymers in fire with the particle finite element method. Int J Numer Meth Eng 81(8):1046. https://doi.org/10.1002/nme.2731

Idelsohn S, Marti J, Limache A, Oñate E (2008) Unified Lagrangian formulation for elastic solids and incompressible fluids: application to fluid-structure interaction problems via the PFEM. Comput Methods Appl Mech Eng 197(19):1762. https://doi.org/10.1016/j.cma.2007.06.004

Carbonell J, Oñate E, Suarez B (2013) Modelling of tunnelling processes and rock cutting tool wear with the particle finite element method. Comput Mech 52(3):607

Salazar F, Irazabal J, Larese A, Oñate E (2016) Numerical modelling of landslide-generated waves with the particle finite element method (PFEM) and a non-Newtonian flow model. Int J Numer Anal Meth Geomech 40(6):809. https://doi.org/10.1002/nag.2428.Nag.2428

Idelsohn S, Nigro N, Limache A, Oñate E (2012) Large time-step explicit integration method for solving problems with dominant convection. Comput Methods Appl Mech Eng 217:168

Rodolfo Idelsohn S, Marcelo Nigro N, Marcelo Gimenez J, Rossi R, Marcelo Marti J (2013) A fast and accurate method to solve the incompressible Navier–Stokes equations. Eng Comput 30(2):197

Gimenez JM, Nigro NM, Idelsohn SR (2014) Evaluating the performance of the particle finite element method in parallel architectures. Comput Part Mech 1(1):103

Nigro NM, Gimenez JM, Idelsohn SR (2014) Recent advances in the particle finite element method towards more complex fluid flow applications. In: Numerical simulations of coupled problems in engineering (Springer), pp 267–318

Bal AL, Hoppe U, Dang T, Hackl K, Meschke G (2018) Underground Space. A hypoplastic particle finite element model for cutting tool–soil interaction simulations: numerical analysis and experimental validation (in print)

Kolymbas D (1991) An outline of hypoplasticity. Arch Appl Mech 61(3):143. https://doi.org/10.1007/BF00788048

Kolymbas D, Wu W (1993) Introduction to hypoplasticity, Modern approaches to plasticity pp. 213–223

Tejchman J, Herle I (1999) A class A prediction of the bearing capacity of plane strain footings on sand. Soils Found 39(5):47

Maier T (2004) Comparison of non-local and polar modelling of softening in hypoplasticity. Int J Numer Anal Meth Geomech 28(3):251. https://doi.org/10.1002/nag.334

Tejchman J (2004) FE-analysis of patterning of shear zones in granular bodies for earth pressure problems of a retaining wall. Arch Hydro-Eng Environ Mech 51(4):317

Trinh BT, Hackl K (2012) Performance of mixed and enhanced finite elements for strain localization in hypoplasticity. Int J Numer Anal Meth Geomech 36(9):1125. https://doi.org/10.1002/nag.1042

Tejchman J, Bauer E (2005) Fe-simulations of a direct and a true simple shear test within a polar hypoplasticity. Comput Geotech 32(1):1. https://doi.org/10.1016/j.compgeo.2004.11.004

Wojcik M, Tejchman J (2009) Modeling of shear localization during confined granular flow in silos within non-local hypoplasticity. Powder Technol 192(3):298. https://doi.org/10.1016/j.powtec.2009.01.021

Böhrnsen J, Antes H, Ostendorf M, Schwedes J (2004) Silo discharge: measurement and simulation of dynamic behavior in bulk solids. Chem Eng Technol 27(1):71

Aubram D, Rackwitz F, Wriggers P, Savidis S (2015) An ALE method for penetration into sand utilizing optimization-based mesh motion. Comput Geotech 65:241. https://doi.org/10.1016/j.compgeo.2014.12.012

Zhang K, Hopperstad O, Holmedal B, Dumoulin S (2014) A robust and efficient substepping scheme for the explicit numerical integration of a rate-dependent crystal plasticity model. Int J Numer Meth Eng 99(4):239. https://doi.org/10.1002/nme.4671

Sloan SW (1987) Substepping schemes for the numerical integration of elastoplastic stress-strain relations. Int J Numer Meth Eng 24(5):893. https://doi.org/10.1002/nme.1620240505

Wood WL, Bossak M, Zienkiewicz OC (1980) An alpha modification of Newmark’s method. Int J Numer Meth Eng 15(10):1562. https://doi.org/10.1002/nme.1620151011

Calvo N, Idelsohn SR, Oñate E (2003) The extended Delaunay tessellation. Eng Comput 20(5/6):583. https://doi.org/10.1108/02644400310488763

Oñate E, Franci A, Carbonell JM (2014) Lagrangian formulation for finite element analysis of quasi-incompressible fluids with reduced mass losses. Int J Numer Meth Fluids 74(10):699

Nicot F, Darve F (2007) Basic features of plastic strains: From micro-mechanics to incrementally nonlinear models. Int J Plast 23(9):1555. https://doi.org/10.1016/j.ijplas.2007.01.010

Gudehus G (1996) Stoffgesetze. In: Smoltczyk U (ed) Grundbautaschenbuch, 5th edn. Ernst & Sohn, Berlin, pp 159–187

Bauer E (1996) Calibration of a comprehensive hypoplastic model for granular materials. Soils Found 36(1):13. https://doi.org/10.3208/sandf.36.13

Kolymbas D, Herle I, Von Wolffersdorff PA (1995) Hypoplastic constitutive equation with internal variables. Int J Numer Anal Meth Geomech 19(6):415. https://doi.org/10.1002/nag.1610190604

Niemunis A (2003) Extended hypoplastic models for soils, vol. 34 (Institut fuer Grundbau und Bodenmechanik der Ruhr-Universitaet Bochum). http://www.pg.gda.pl/~aniem/pap-zips/habb-30-7-2003.pdf

Wu W, Bauer E (1994) A simple hypoplastic constitutive model for sand. Int J Numer Anal Meth Geomech 18(12):833

Fellin W, Ostermann A (2002) Consistent tangent operators for constitutive rate equations. Int J Numer Anal Meth Geomech 26(12):1213. https://doi.org/10.1002/nag.242

Dadvand P, Rossi R, Oñate E (2010) An object-oriented environment for developing finite element codes for multi-disciplinary applications. Arch Comput Methods Eng 17:253

Anaraki KE (2008) Hypoplasticity investigated: parameter determination and numerical simulation. Master’s thesis, TU Delft. https://repository.tudelft.nl/islandora/object/uuid:71e5eb73-06ca-48d2-b442-ce2639f995fc?collection=education

Colliat-Dangus JL, Desrues J, Foray P (1988) Triaxial testing of granular soil under elevated cell pressure. In: Advanced triaxial testing of soil and rock. ASTM International, pp 290–310

Nakai T (1985) Finite element computations for active and passive earth pressure problems of retaining wall. Soils Found 25(3):98

Nakai T, Matsuoka H (1983) Shear behaviors of sand and clay under three-dimensional condition. Soils Found 23(2):26

Głębowicz K (2006) Hypoplastic modelling of pre-failure behaviour of sand against experimental data. Arch Hydro Eng Environ Mech 53(1):31

Whitlow R (2001) Basic soil mechanics. Prentice Hall, Upper Saddle River

Gibbs HJ (1957) Research on determining the density of sands by spoon penetration testing. In: Proceedings of the 4th International conference on SMFE, vol 1, pp 35–39

Shiau J, Augarde C, Lyamin A, Sloan S (2008) Finite element limit analysis of passive earth resistance in cohesionless soils. Soils Found 48(6):843. https://doi.org/10.3208/sandf.48.843

Acknowledgements

Financial support was provided by the German Science Foundation (DFG) in the framework of Subproject C4 of the Collaborative Research Center SFB 837. The first author has been supported by the German Academic Exchange Service (DAAD). This support is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

\(\alpha \)-Bossak time integration scheme

In the \(\alpha \) -Bossak integration method [51], nodal accelerations \(\dot{\bar{\varvec{v}}}\) are interpolated within a time step \([t_{n},t_{n+1}]\) and evaluated at time \(t_{n+1-\alpha } = (1-\alpha )t_{n+1} + \alpha t_{n}\) via

The end-of-step nodal accelerations \({\dot{\bar{\varvec{v}}}}_{n+1}\) and displacements \(\bar{\varvec{u}}_{n+1}\) are computed according to

where \(\alpha \), \(\beta \) and \(\gamma \) are the integration parameters of the method.

Linearization of the balance of momentum equation

The rate of the element internal forces vector \(~^e\!\dot{\varvec{f}}^{TL}_\mathrm{int}\) can be written in terms of the time derivative of the first Piola–Kirchhoff stress tensor \(\dot{\varvec{\sigma }}_{PK1}\) as

which is a non-symmetric stress measure, i.e., one base points to the initial configuration \(\varOmega _{0}\) while the other base underlies in the current one \(\varOmega _{n}\).

A full pull back transformation of \(\dot{\varvec{\sigma }}_{PK1}\) yields the material rate of the symmetric second Piola–Kirchhoff stress tensor \(\dot{\varvec{S}}\)

where \(\varvec{F} = \frac{\displaystyle \partial \varvec{x}}{\displaystyle \partial \varvec{X}}\) is the gradient of deformation tensor. In the following, minor symmetries of the fourth-order stiffness tensor \(\varvec{C}\) is assumed in the pre and post-multiplication of operators by the deformation gradient tensor \(\varvec{F}\). Inserting Eq. (33) into (32) and applying the chain rule of differentiation yields

In the following, the subscript \(()_\mathrm{int}\) will be dropped and introduced only when necessary. The term \(^e\!\dot{\varvec{f}}^{TL}_{m}\) in the right-hand-side of Eq. (34) describes the material response of the body via a constitutive law, written in compact form as

where \(\varvec{C}_{0}\) is a fourth-order constitutive tensor with its basis in the undeformed configuration and \(\dot{\varvec{E}}\) the rate of the Green Lagrangian strain tensor.

Substitution of Eq. (35) into Eq. (34) yields

In order to extract the nodal velocities from \(~^e\!\dot{\varvec{f}}_{m}^{TL}\) in Eq. (36), it is now convenient to introduce the time rate of the Green Lagrangian strain \(\dot{\varvec{E}}\) expressed by

The algebraic manipulation of the right-hand-side of Eq. (37) together with the definition of the time derivative of spatial coordinates \(\dot{\varvec{x}} = \varvec{v} = \varvec{N}\bar{\varvec{v}}\), allows to re-write \(\dot{\varvec{E}}\) as

where \(\varvec{B}_{0}\) is the strain–displacement matrix computed in the initial configuration \(\varOmega _{0}\). Inserting Eq. (38) into Eq. (36) yields

Next, the geometric part of the rate of element internal forces \(~^e\!\dot{\varvec{f}}_{g}^{TL}\) (see Eq. (34) is considered. Inserting the definition of the rate of the deformation gradient \( \dot{\varvec{F}} = \frac{\displaystyle \partial \varvec{N}}{\displaystyle \partial \varvec{X}}\bar{\varvec{v}}\) into \(~^e\!\dot{\varvec{f}}_{g}^{TL}\) yields

The consistent linearization of the material and geometric parts of the rates of internal forces Eqs. (40) and (41), respectively, is performed by means of the Gateaux derivative. The end-of-step increment \(~^e\!\Delta \dot{\varvec{f}}^\mathrm{int}_{n+1}\) expressed in TL framework (the index \((\cdot )^{TL}\) is herein omitted) is computed as follows

Integrating Eq. (42) over a time increment \(\Delta t\) yields

To this end, the linearization of the relevant terms has been performed in TL description. To construct the UL formulation, push-forward transformations are applied over Eq. (43) (see reference [25]). The end-of-step increment \(\Delta {~^e\!\varvec{f}}^\mathrm{int}_{n+1}\) expressed in UL description reads

where \(~^e\!\varvec{K}^{m}_{n+1}\) and \(~^e\!\varvec{K}^{g}_{n+1}\) are defined as in Sect. 2.1. The remaining terms to be linearized from Eq. (5) correspond to the element vector of dynamic forces \(~^e\!\varvec{f}^{UL}_\mathrm{dyn} \), written in lumped format as

The increment vector of the dynamic forces is evaluated at time \(t_{n+1-\alpha }\) by means of the directional derivative of \(~^e\!\varvec{f}^{UL}_\mathrm{dyn}\) with respect to the nodal accelerations \(\Delta \dot{\bar{\varvec{v}}}_{n+1-\alpha }\)

We attempt to reformulate the increment of nodal accelerations \(\Delta \dot{\bar{\varvec{v}}}_{n+1-\alpha }\) in Eq. (46) in terms of the end-of-step velocities increment \(\Delta {\bar{\varvec{v}}}_{n+1}\), by means of the \(\alpha \)-Bossak approximations (29), (30) and the chain rule of differentiation

Finally, replacing Eq. (47) into Eq. (45) yields the linearized form of the vector of dynamic forces

Von Wolffersdorff Hypoplastic model

In this work, the formulation proposed in [22] is employed. The stress evolution is described by the expression

where \(\varvec{L}\) and \(\varvec{N}\) are written as

with \(\frac{\displaystyle \varvec{\sigma }}{\displaystyle \text {tr}(\varvec{\sigma })}\) as the normalized stress ratio, \(\varvec{II}\) is the fourth-order symmetric unit tensor, \(\varvec{\sigma }^{*} = \dfrac{\varvec{\sigma }}{\text {tr}(\varvec{\sigma })} -\dfrac{1}{3}\varvec{I}\) is the deviatoric normalized stress ratio, \(\varvec{I}\) the second-order unit tensor and the term \(\dfrac{1}{\dfrac{\varvec{\sigma }}{\text {tr}(\varvec{\sigma })}: \dfrac{\varvec{\sigma }}{\text {tr}(\varvec{\sigma })}}\) is a factor employed to reflect the reduction of incremental stiffness for stress paths deviating from the isotropic path [58].

The rate of the Cauchy stress \(\dot{\varvec{\sigma }}\) is related to the Jaumann stress rate \(\mathring{\varvec{\sigma }}\) via

where \(\varvec{w}= \frac{1}{2}\left( \nabla \varvec{v} - \nabla \varvec{v}^{T}\right) \) is the spin tensor, i.e., the skew-symmetric part of the velocity gradient.

The concept of incremental nonlinearity, relevant for the description of granular soils, is connected to the continuous dependence of the stiffness tensor \(\varvec{C}\) on the direction of deformation \(\dfrac{\varvec{d}}{||\varvec{d}||}\) [54]

A hypoplastic critical state surface \(f_{H}(\varvec{\sigma })\) is explicitly defined by means of the functions \( a(\varphi _{c})\) and \(F(\varvec{\sigma }^{*})\)

where \(\theta \) denotes the Lode angle. It is noted that the function \(F(\varvec{\sigma }^{*})\) is derived in compliance with the Matsuoka–Nakai limit criterion \(f_{MN}\)[58].

To complete the model description, the evolution of the void ratio \(\dot{e}\) is formulated as

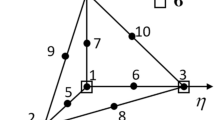

The admissible range of the void ratio e is bounded by three pressure-dependent compression curves \(e_{i}(p_{s})\), \(e_{c}(p_{s})\), \(e_{d}(p_{s})\) [white area in Fig. 17)], defined by the relation

\(e_{i}(p_{s})\) and \(e_{d}(p_{s})\) define the upper and lower bounds for e at a given mean skeleton pressure \(p_{s}\), respectively. \(e_{c}(p_{s})\) denotes the pressure-dependent critical void ratio, \(e_{i0}\), \(e_{c0}\), \(e_{d0}\) are the corresponding values for \(e_{i}(p_{s})\), \(e_{c}(p_{s})\), \(e_{d}(p_{s})\) at zero pressure, \(h_{s}\) is the skeleton granular hardness, and the coefficient n reflects the sensitivity of the granular skeleton to the variations of \(p_{s}\).

Characteristic features observed in the behavior of granular materials, such as pressure- and density-dependent stiffness and volumetric dilatancy, are properly accounted for through the stiffness scaling factors \(f_{b}(p_{s})\) (the so-called barotropy factor) and \(f_{e}(e)\), \(f_{d}(e)\), denoted as density factors [56]:

\(f_{b}(p_{s})\) and \(f_{e}(e)\) control the incremental stiffness of the soil in nonlinear dependence of the pressure \(p_{s}\) and void ratio e, respectively.

The scalar function \(f_{d} (e)\)\( (0\le f_{d}(e)\le 1)\), which can be interpreted as a weighting function of the nonlinear component \(\varvec{N}||\varvec{d}||\) in Eq. (49), governs the transition of the soil to the critical state. In the case of \(f_{d}(e) =0\) (implying \(e=e_{d}\)), the soil is in the densest possible state and its behavior can be approximated as hypoelastic [56]. When \(f_{d}(e) =1\) (implying \(e=e_{c}\)), the soil reached the critical state.

Sub-stepping integration algorithm

-

1.

Initialize the scheme by setting \(\alpha ^{1}= \alpha ^{0}\), \(NS= 1\), \({e}^{i+1,1}_{n+1}= e^{i}_{n+1}\) and \(\varvec{\sigma }^{i+1,1}_{n+1}= \varvec{\sigma }^{i}_{n+1}\). In this work, the initial sub-step reduction factor is set to \(\alpha _{0} = 1/8\).

-

2.

In sub-step k of increment \(i+1\) two forward-Euler (FWE) evaluations of Eqs. (49) and (59) are performed: First, the rates \(\dot{e}^{i+1,k}_{n+1}= \dot{e}^{i+1,k}_{n+1}({e}^{i+1,k}_{n+1}, \varvec{d}^{i+1}_{n+1})\) and \(\mathring{\varvec{\sigma }}^{i+1,k}_{n+1} = \mathring{\varvec{\sigma }}^{i+1,k}_{n+1}\left( e^{i+1,k}_{n+1},\varvec{\sigma }^{i+1,k}_{n+1}\right) \) are computed. These estimations are utilized to determine the intermediate void ratio and the stresses at sub-step \(k + \frac{1}{2}\)

$$\begin{aligned} \varvec{\sigma }^{i+1,k + \frac{1}{2}}_{n+1}&= \varvec{\sigma }^{i+1,k}_{n+1} + \Delta t^{i+1,k}_{n+1}\dot{\varvec{\sigma }}^{i+1,k}_{n+1},\end{aligned}$$(64)$$\begin{aligned} e^{i+1,k + \frac{1}{2}}_{n+1}&= e^{i+1,k}_{n+1} + \Delta t^{i+1,k}_{n+1}\dot{e}^{i+1,k}_{n+1}, \end{aligned}$$(65)with

$$\begin{aligned} \dot{\varvec{\sigma }}^{i+1,k}_{n+1}= \mathring{\varvec{\sigma }}^{i+1,k}_{n+1} + \varvec{w}_{n}\varvec{\sigma }^{i+1,k}_{n+1} + \varvec{\sigma }^{i+1,k}_{n+1}\varvec{w}^{T}_{n}. \end{aligned}$$(66)In Eq. (66), the spin tensor \(\varvec{w}_{n}\) is evaluated at the previous time step [25] and the rate of deformation tensor \(\varvec{d}^{i+1}_{n+1}(\varvec{v}^{i+1}_{n+1})\) is considered to remain constant throughout the iteration step \(i+1\) as in [49].

The estimates from Eqs. (64) and (65) are inserted again into Eqs. (49) and (59) and further utilized to obtain the rates

$$\begin{aligned} \mathring{\varvec{\sigma }}^{i+1,k+\frac{1}{2}}_{n+1}&= \mathring{\varvec{\sigma }}^{i+1,k+\frac{1}{2}}_{n+1}\left( e^{i+1,k + \frac{1}{2}}_{n+1},\varvec{\sigma }^{i+1,k + \frac{1}{2}}_{n+1}\right) , \end{aligned}$$(67)$$\begin{aligned} \dot{e}^{i+1,k + \frac{1}{2}}_{n+1}&= \dot{e}^{i+ 1,k + \frac{1}{2}}_{n+1}\left( e^{i+1,k + \frac{1}{2}}_{n+1}, \varvec{d}^{i+1}_{n+1}\right) . \end{aligned}$$(68)The material time derivative of the Cauchy stress computed as

$$\begin{aligned} \dot{\varvec{\sigma }}^{i+1,k+\frac{1}{2}}_{n+1}&= \mathring{\varvec{\sigma }}^{i+1,k+\frac{1}{2}}_{n+1} + \Delta t^{i+1,k}_{n+1}\left( \varvec{w}_{n}\varvec{\sigma }^{i+1,k+\frac{1}{2}}_{n+1}\right. \nonumber \\&\quad \left. + \varvec{\sigma }^{i+1,k+\frac{1}{2}}_{n+1}\varvec{w}^{T}_{n}\right) . \end{aligned}$$(69) -

3.

Compute the relative stress error \(E_{\sigma }\) in terms of the Cauchy stress rates at sub-steps k and \(k + \frac{1}{2}\):

$$\begin{aligned} E_{\sigma } = \frac{\left| \left| \dot{\varvec{\sigma }}^{i+1,k+\frac{1}{2}}_{n+1} - \dot{\varvec{\sigma }}^{i+1,k}_{n+1}\right| \right| \Delta t^{i+1,k}_{n+1}}{\left| \left| \varvec{\sigma }^{i+1,k}_{n+1} + \dfrac{\Delta t}{2}\left( \dot{\varvec{\sigma }}^{i+1,k+\frac{1}{2}}_{n+1} + \dot{\varvec{\sigma }}^{i+1,k}_{n+1} \right) \right| \right| }, \end{aligned}$$(70)and check the stress error \(E_{\sigma }\le {\hbox {tol}}_{\sigma }\) against the tolerance (usually \(10^{-5}\le {\hbox {tol}}_{\sigma }\le 10^{-2})\).

-

4.

If the relative stress error \(E_{\sigma } > tol_{\sigma }\), the current sub-step is not accepted. A recalculation of the sub-stepping procedure, starting from step 2, is performed using a reduced trial value \(\alpha ^{k}\), estimated according to

$$\begin{aligned} \alpha ^{k} = \max \,\left\{ 0.1,0.8 * \left( \frac{{\hbox {tol}}_{\sigma }}{E_{\sigma }}\right) ^{\frac{1}{2}}\right\} \alpha ^{k}. \end{aligned}$$(71)If \(E_{\sigma }\le {\hbox {tol}}_{\sigma }\) the sub-step is accepted. Compute the updated values of stresses and void ratio, at the end of sub-step \(k+1\), employing the rates at sub-step k and \(k + \frac{1}{2}\) given by:

$$\begin{aligned} \varvec{\sigma }^{i+1,k+1}_{n+1}&{=} \varvec{\sigma }^{i+1,k}_{n+1} {+} \frac{1}{2}\Delta t^{k}\left( \dot{\varvec{\sigma }}^{i+1,k {+} \frac{1}{2}}_{n+1} {+} \dot{\varvec{\sigma }}^{i+1,k}_{n+1}\right) , \end{aligned}$$(72)$$\begin{aligned} {e}^{i+1,k+1}_{n+1}&= {e}^{i+1,k}_{n+1} + \frac{1}{2}\Delta t^{k}\left( \dot{e}^{i+1,k+\frac{1}{2}}_{n+1} + \dot{e}^{i+1,k}_{n+1}\right) , \end{aligned}$$(73)If \(\sum ^{NS}_{k = 1} \alpha ^{k} < 1\) and \(NS < NS_{\max }\), where \(NS_{\max }\) is the user-defined maximum allowable number of sub-steps per iteration, increase the sub-step number NS by one \(NS = NS + 1\) and proceed to the next sub-step \(k+1\). An initial trial value for \(\alpha ^{k+1}\) is made in accordance with

$$\begin{aligned} \alpha ^{k+1} = \text {min}\left\{ \alpha ^{k}, 1 - \sum ^{k}_{p = 1} \alpha ^{p}\right\} , \end{aligned}$$(74) -

5.

When the sub-stepping process is complete (i.e., \(\sum ^{NS}_{k = 1} \alpha ^{k} = 1\)), the increments at the end of the iteration step \(i+1\) (i.e., \(\Delta {\varvec{\sigma }}^{i+1}_{n+1}\) and \(\Delta {e}^{i+1}_{n+1}\)) correspond then to the increments \(\Delta {\varvec{\sigma }}^{i+1,k+1}_{n+1}\) and \(\Delta {e}^{i+1,k+1}_{n+1}\) estimated from the last successful sub-step.

-

6.

After the time integration of the relevant variable is complete for iteration step \(i+1\), a projection to the nodes of the increments \(\Delta {\varvec{\sigma }}^{i+1}_{n+1}\) and \(\Delta {e}^{i+1}_{n+1}\) is performed (see Sect. 2.3). A loop over all elements is carried out, and the following operations are executed:

-

Projection of the increments to the nodes and update of total values (\(\varvec{\sigma }^{i+1}_{n+1}\), \(e^{i+1}_{n+1}\)) by means of Eq. (14).

Rights and permissions

About this article

Cite this article

Bal, A.R.L., Dang, T.S. & Meschke, G. A 3D particle finite element model for the simulation of soft soil excavation using hypoplasticity. Comp. Part. Mech. 7, 151–172 (2020). https://doi.org/10.1007/s40571-019-00271-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-019-00271-y