Abstract

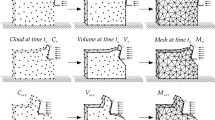

Underground construction involves all sort of challenges in analysis, design, project and execution phases. The dimension of tunnels and their structural requirements are growing, and so safety and security demands do. New engineering tools are needed to perform a safer planning and design. This work presents the advances in the particle finite element method (PFEM) for the modelling and the analysis of tunneling processes including the wear of the cutting tools. The PFEM has its foundation on the Lagrangian description of the motion of a continuum built from a set of particles with known physical properties. The method uses a remeshing process combined with the alpha-shape technique to detect the contacting surfaces and a finite element method for the mechanical computations. A contact procedure has been developed for the PFEM which is combined with a constitutive model for predicting the excavation front and the wear of cutting tools. The material parameters govern the coupling of frictional contact and wear between the interacting domains at the excavation front. The PFEM allows predicting several parameters which are relevant for estimating the performance of a tunnelling boring machine such as wear in the cutting tools, the pressure distribution on the face of the boring machine and the vibrations produced in the machinery and the adjacent soil/rock. The final aim is to help in the design of the excavating tools and in the planning of the tunnelling operations. The applications presented show that the PFEM is a promising technique for the analysis of tunnelling problems.

Similar content being viewed by others

References

Archard JF (1953) Contact and rubbing of flat surfaces. J Appl Phys 24:981–988

Arrea M, Ingraffea AR (1982) Mixed-mode crack propagation in mortar and concrete. Cornell University, Ithaca

Carbonell JM, Oñate E, Suárez B (2010) Modeling ofground excavation with the particle finite-element method. J Eng Mech ASCE 136:455–463

Carbonell JM (2009) Modeling of ground excavation with the particle finite element method. PhD thesis, Universitat Politècnica de Catalunya (UPC), Dec 2009

Chiara B (2001) Fracture mechanisms induced in a brittle material by a hard cutting identer. Int J Solids Struct 38:7747–7768

Edelsbrunner H, Mucke EP (1994) Three dimensional alpha shapes. ACM Trans Gr 13:43–72

Hartmann S, Oliver J, Weyler R, Cante JC, Hernández JA (2009) A contact domain method for large deformation frictional contact problems. Part 2: numerical aspects. Comput Methods Appl Mech Eng 198:2607–2631

Holm R (1946) Electric contacts. Almquist and Wiksells, Stockholm

Idelsohn S, Calvo N, Oñate E (2003) Polyhedrization of an arbitrary 3D point set. Comput Method Appl Mech Eng 192:2649–2667

Idelsohn SR, Oñate E, Del Pin F (2004) The particle finite element method a powerful tool to solve incompressible flows with free-surfaces and breaking waves. Int J Numer Methods Eng 61:267–307

Khoei AR, Gharehbaghi SA (2007) The superconvergence patch recovery technique and data transfer operators in 3d plasticity problems. Finite Elem Anal Des 43:630–648

Labra C, Rojek J, Oñate E, Zárate F (2008) Advances in discrete element modelling of underground excavations. Acta Geotechnica 3:317–322

Oliver X, Cervera M, Oller S, Lubliner J (1990) Isotropic damage models and smeared crack analysis of concrete. In: N. Bicanic, H. Mang (eds) Second international conference on computer aided analisys and design of concrete structures, vol 2. Zell am See, Austria, pp 945–958

Oliver X, Cante JC, Weyler R, González C, Hernández J (2007) Particle finite element methods in solid mechanics problems. In: Oñate E, Owen R (Eds) Computational plasticity. Springer, Berlin, pp 87–103

Oliver J, Hartmann S, Cante JC, Weyler R, Hernández JA (2009) A contact domain method for large deformation frictional contact problems. Part 1: theoretical basis. Comput Methods Appl Mech Eng 198:2591–2606

Oller S, Mecánica Fractura (2001) Un enfoque global. Edicions UPC, CIMNE

Oñate E, Rojek J (2004) Combination of discrete element and finite element methods for dynamic analysis of geomechanics problems. Comput Methods Appl Mech Eng 193:3087–3128

Oñate E, Idelsohn SR, Del Pin F (2004) The particle finite element method. An overview. Int J Numer Methods Eng 1(2):964–989

Oñate E, Idelsohn SR, Celigueta MA (2006) Lagrangian formulation for fluid-structure interaction problems using the particle finite element method. Verification and validation methods for challenging multiphysics problems, CIMNE, pp 125–150

Oñate E, Idelsohn SR, Celigueta MA, Rossi R (2008) Advances in the particle finite element method for the analysis of fluid-multibody interaction and bed erosion in free surface flows. Comput Methods Appl Mech Eng 197(19–20):1777–1800

Oñate E, Celigueta MA, Idelsohn SR, Salazar F, Suárez B (2011) Possibilities of the particle finite element method for fluid-soil-structure interaction problems. Comput Mech 48(3):307–318

Rabinowicz E (1995) Friction and wear of materials. Wiley, New York

Rojek J, Oñate E, Labra C, Kargl H (2011) Discrete element simulation of rock cutting. Int J Rock Mech Min Sci 48(6):996–1010

Rojek J, Oñate E, Kargl H, Labra C, Akerman U, Lammer E, Zárate F (2008) Prediction of wear of roadheader picks using numerical simulations. Geomechanik und Tunnelbau, 1:4754

Rots JG, Nauta P, Kusters GMA, Blaauwendraad J (1985) Smeared crack approach and fracture localization in contrete. Heron 30:1–48

Wriggers P (2008) Nonlinear finite element methods. Springer, New York

Wriggers P (2006) Computational contact mechanics second edition. Springer, Heidelberg

Zavarise G, Wriggers P, Nackenhorst U (2006) A guide for engineers to computational contact mechanics. Consorzio TCN scarl, 2006

Zienkiewicz OC, Taylor RL (2000) The finite element method for solid and structural mechanics, vol 2. Elsevier Butterworth-Heinemann, London

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Carbonell, J.M., Oñate, E. & Suárez, B. Modelling of tunnelling processes and rock cutting tool wear with the particle finite element method. Comput Mech 52, 607–629 (2013). https://doi.org/10.1007/s00466-013-0835-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-013-0835-x