Abstract

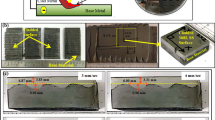

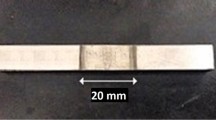

The stainless clad steel plates (SCSPs) are used in several industrial fields such as petroleum and petrochemical industries due to their low cost and good corrosion resistance. In this work, the structural integrity assessment of a welded joint, produced by a hybrid SMAW/GTAW multi-pass welding process of SCSP, was carried out through non-destructive examinations, microstructural observations and mechanical characterization tests. The non-destructive examination showed that the welded zone is free from any sign of defect. The welded joint filled with ER316L revealed the presence of δ-ferrite, which was solidified as skeletal and lathy ferrite under ferritic-austenitic (FA) solidification mode. The microstructure of the weld metal transition zone (WM-TZ) filled with ER309L exhibited the presence of martensitic laths as well as a cellular and columnar structure. It was found that the diffusion of carbon element caused the forming of a decarburized layer in the substrate heat-affected zone (S-HAZ) during the welding process. The observation also revealed the presence of type I and type II boundaries along the fusion line, which are characterized by their martensitic nature. Based on the determination of the WM-TZ dilution percentage, which is equal to 32%, the presence of the martensite was also confirmed by Schaeffler diagram. The high micro-hardness values (~ 429 HV) and the low toughness (~ 22.9J) measured respectively in vicinity of the WM-TZ also confirm the local hardening zone (LHZ) formed on the welded zone after bending tests.

Similar content being viewed by others

Abbreviations

- SCSP:

-

Stainless clad steel plate

- SMAW:

-

Shielded metal arc welding

- GTAW:

-

Gas tungsten arc welding

- SAW:

-

Submerged arc welding

- NDE:

-

Non-destructive examination

- WM:

-

Weld metal

- HAZ:

-

Heat affected zone

- WM-CL:

-

Weld metal clad layer

- WM-TZ:

-

Weld metal transition zone

- BM-S:

-

Base metal substrate

- WM-S:

-

Weld metal substrate

- S-HAZ:

-

Substrate heat-affected zone

- BM-CL:

-

Base metal clad layer

- LHZ:

-

Local hardening zone

- FB:

-

Fusion Boundary

References

Kaya Y, Kahraman N (2013) An investigation into the explosive welding/cladding of Grade A ship steel/AISI 316L austenitic stainless steel. Mater Des (1980-2015):52 367372

Venkateswara Rao N, Madhusudhan Reddy G, Nagarjuna S (2011) Weld overlay cladding of high strength low alloy steel with austenitic stainless steel – structure and properties. Mater Des 32(4):2496–2506

Liu BX, Yin FX, Dai XL, He JN, Fang W, Chen CX, Dong YC (2017) The tensile behaviors and fracture characteristics of stainless steel clad plates with different interfacial status. Mater Sci Eng A 679:172–182

Argade GR, Shukla S, Liu K, Mishra RS (2018) Friction stir lap welding of stainless steel and plain carbon steel to enhance corrosion properties. J Mater Process Technol 259:259–269

Ganesh P, Moitra A, Tiwari P, Sathyanarayanan S, Kumar H, Rai SK et al (2010) Fracture behavior of laser-clad joint of Stellite 21 on AISI 316L stainless steel. Mater Sci Eng A 527(16-17):3748–3756

Li C’a, Qin G, Tang Y, Zhang B, Lin S, Geng P (2020) Microstructures and mechanical properties of stainless-steel clad plate joint with diverse filler metals. J Mater Res Technol

Jing YA, Qin Y, Zang X, Shang Q, Hua S (2014) A novel reduction-bonding process to fabricate stainless steel clad plate. J Alloys Compd 617:688–698

An Q, Fan KY, Ge YF, Liu BX, Liu YC, Wang S et al (2020) Microstructure and mechanical properties of stainless-steel clad plate joints produced by TIG and MAG hybrid welding. J Adhes Sci Technol 34(6):670–685. https://doi.org/10.1080/01694243.2019.1677087

Chen CX, Liu MY, Liu BX, Yin FX, Dong YC, Zhang X et al (2017) Tensile shear sample design and interfacial shear strength of stainless-steel clad plate. Fusion Eng Des 125:431–441

Dhib Z, Guermazi N, Gaspérini M, Haddar N (2016) Cladding of low-carbon steel to austenitic stainless steel by hot-roll bonding: microstructure and mechanical properties before and after welding. Mater Sci Eng A 656:130–141

Tian MJ, Chen H, Zhang YK, Wang T, Zhu ZY (2015) Welding process of composite plate for construction and its welded microstructure and properties. Heat Treat Met 40:110–115

Qiu T, Wu BX, Chen QY, Chen WJ (2013) Analysis on welded joint properties of stainless clad steel plates. Dianhanji/ Electric Welding Machine 43(4):83–87

Li L, Xiao J, Han B, Zhou C, Wang X (2020) Welding L415/316L Bimetal Composite Pipe Using Post-Internal-Welding Process. Trans Indian Inst Metals:1–15

WANG W, WANG Y, LIU M, CHENG F, WU, W. (2010) Microstructure and corrosion resistance of butt joint of 1Cr18Ni9Ti+ Q235 composite plate. Transactions of the China Welding Institution 6

Missori S, Murdolo F, Sili A (2004) Single-pass laser beam welding of clad steel plate. Weld J 83(2):65s–71s

Jiang W, Liu Z, Gong JM, Tu ST (2010) Numerical simulation to study the effect of repair width on residual stresses of a stainless-steel clad plate. Int J Press Vessel Pip 87(8):457–463. https://doi.org/10.1016/j.ijpvp.2010.06.003

Ma H, Qin GL, Geng PH et al (2015) Microstructure characterization and properties of carbon steel to stainless steel dissimilar metal joint made by friction welding. Mater Des 86:587–597

Wang SG, Dong GP, Ma QH (2009) Welding of duplex stainless steel composite plate: influence on microstructural development. Mater Manuf Process 24(12):1383–1388. https://doi.org/10.1080/10426910902997456

Yu WX, Liu BX, Chen CX, Liu MY, Zhang X, Fang W et al (2020) Microstructure and mechanical properties of stainless steel clad plate welding joints by different welding processes. Sci Technol Weld Join 25(7):571–580

David SA, Vitek JM (1989) Correlation between solidification parameters and weld microstructures. Int Mater Rev 34(1):213–245

David SA, Babu SS, Vitek JM (2003) Welding: solidification and microstructure. JOM 55(6):14–20

Trivedi R, David SA, Eshelman MA, Vitek JM, Babu SS, Hong T, DebRoy T (2003) In situ observations of weld pool solidification using transparent metal-analog systems. J Appl Phys 93(8):4885–4895

Bunaziv I, Olden V, Akselsen OM (2019) Metallurgical aspects in the welding of clad pipelines—a global outlook. Appl Sci 9(15):3118

Ghorbel R, Ktari A, Haddar N (2021) Experimental analysis of temperature field and distortions in multi-pass welding of stainless cladded steel. Int J Adv Manuf Technol 113:3525–3542. https://doi.org/10.1007/s00170-021-06788-y

ASME IX (2017) ASME Boiler and Pressure Vessel Code, Section IX: Welding and Brazing Qualifications. An International Code, New York

Kožuh S, GOJI M (2009) Mechanical properties and microstructure of austenitic stainless steel after welding and post-weld heat treatment. Kovove Materiarly 47:253–262

Nelson TW, Lippold JC, Mills MJ (1998) Investigation of boundaries and structures in dissimilar metal welds. Sci Technol Weld Join 3(5):249–255

Ming H, Zhang Z, Wang J, Han EH, Ke W (2014) Microstructural characterization of an SA508–309L/308L–316L domestic dissimilar metal welded safe-end joint. Mater Charact 97:101–115. https://doi.org/10.1016/j.matchar.2014.08.023

Feng Y, Luo Z, Liu Z, Li Y, Luo Y, Huang Y (2015) Keyhole gas tungsten arc welding of AISI 316L stainless steel. Mater Des 85:24–31

Chassignole B (2000) Influence de la structure métallurgique des soudures en acier inoxydable austénitique sur le contrôle non destructif par ultrasons (Doctoral dissertation, Lyon, INSA)

Dhib Z, Guermazi N, Ktari A, Gasperini M, Haddar N (2017) Mechanical bonding properties and interfacial morphologies of austenitic stainless steel clad plates. Mater Sci Eng A 696:374–386

Li K, Li D, Liu D, Pei G, Sun L (2015) Microstructure evolution and mechanical properties of multiple-layer laser cladding coating of 308L stainless steel. Appl Surf Sci 340:143–150

Rathod DW, Pandey S, Aravindan S, Singh PK (2016) Diffusion control and metallurgical behavior of successive buttering on sa508 steel using Ni–Fe alloy and inconel 182. Metallogr Microstruct Anal 5(5):450–460

Kou S (2003) Welding metallurgy. USA, New Jersey, pp 431–446

Wu Y, Patchett BM (1992) Formation of crack-susceptible structures of weld overlay of corrosion resistant alloys. Materials Performance: Sulphur and Energy, pp 283-295

Nelson TW, Lippold JC, Mills MJ (1999) Nature and evolution of the fusion boundary in ferritic-austenitic dissimilar weld metals, Part 1-Nucleation and growth. Weld J-New York 78:329-s

Rowe MD, Nelson TW, Lippold JC (1999) Hydrogen-induced cracwking along the fusion boundary of dissimilar metal welds. Weld J-New York 78:31-s

Nelson TW, Lippold JC, Mills MJ (2000) Nature and evolution of the fusion boundary in ferritic-austenitic dissimilar metal welds—part 2: on-cooling transformations. Weld Res 10:267–277

Acknowledgements

The authors would like to thank SOCOMENIN Company for their support. They equally would like to thank Mr M.T. Hbaieb and A. Badri, staff engineers at SOCOMENIN Company, for their knowledgeable help and support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XI - Pressure Vessels, Boilers, and Pipelines

Rights and permissions

About this article

Cite this article

Ghorbel, R., Ktari, A. & Haddar, N. Microstructure and mechanical property assessment of stainless steel–clad plate joint made by hybrid SMAW-GTAW multi-pass welding process. Weld World 66, 1593–1608 (2022). https://doi.org/10.1007/s40194-022-01301-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-022-01301-9