Abstract

Hot cracking is one of the main issues in welding of 6xxx aluminum alloys. Aim of this study is to identify the influence of applied vibrations on the hot cracking susceptibility during laser welding. Close-edge welding of EN AW-6082 sheets with and without vibrations was carried out. The total length of the centerline hot cracks and the resulting grain structure of the welds were determined. The silicon and magnesium element distributions were quantified by wavelength dispersive X-ray spectroscopy. The presence of low melting phases close to the centerline was analyzed by differential scanning calorimetry. The results show that the total length of hot cracks was significantly reduced by the applied vibration while the grain size and structure were not affected in the case of the used excitation conditions at a welding velocity of 6 m/min, whereas no significant influence was observed at lower welding velocities. The weld seams do not show an enrichment of silicon and magnesium close to the center line—macrosegregations—or an influence of the excitation on their distributions. The study shows that the avoidance of low melting phase compositions in the seam center is an influencing factor regarding the reduction of the hot cracking susceptibility by vibrations.

Similar content being viewed by others

References

Lippold JC (2015) Welding metallurgy and weldability. John Wiley & Sons Inc, Hoboken

Cross CE (2005) On the origin of weld solidification cracking. In: Böllinghaus T, Herold H (eds) Hot cracking phenomena in welds. (Eds.). Springer Berlin Heidelberg, Berlin, Heidelberg, pp 3–18

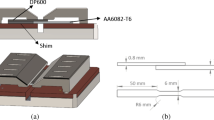

Weller D, Bezençon C, Stritt P, Weber R, Graf T (2013) Remote laser welding of multi-alloy aluminum at close-edge position. Lasers in manufacturing (LiM 2013). Phys Procedia 41:164–168. https://doi.org/10.1016/j.phpro.2013.03.065

Kou S, Le Y (1985) Grain structure and solidification cracking in oscillated arc welds of 5052 aluminum alloy. Metall Trans A 36A:1345–1352

Nakata K, Matsuda F (1995) Evaluations of ductility characteristics and cracking susceptibility of Al alloys during welding. Trans JWRI 24(1):83–94

Tang Z (2014) Heißrissvermeidung beim Schweißen von Aluminiumlegierungen mit einem Scheibenlaser: Strahltechnik Bd. 53. Zugl.: Bremen, Univ., Diss., 2014. Strahltechnik, Bd. 53. BIAS Verlag, Bremen

Schempp P, Cross CE, Schwenk C, Rethmeier M (2012) Influence of Ti and B additions on grain size and weldability of aluminium alloy 6082. Weld World 56(9–10):95–104. https://doi.org/10.1007/BF03321385

Holt M, Olson D, Cross C (1992) Interfacial tension driven fluid flow model for hot cracking. Scr Metall Mater 26(7):1119–1124. https://doi.org/10.1016/0956-716X(92)90240-F

Feurer U (1977) Quality control of engineering alloys and the role of metals science. Delft University of Technology, Delft, pp 131–145

Schaefer M, Kessler S, Fetzer F et al. (2017) Influence of the focal position on the melt flow during laser welding of steel. J Laser Appl 29(1): Paper No. 012010. doi: https://doi.org/10.2351/1.4972098

Schaefer M, Speker N, Weber R et al. (2015) Analysing hot crack formation in laser welding of tempered steel. Paper No. 148. In: Lasers in manufacturing (LIM15), eds.: T. Graf, C. Emmelmann, L. Overmeyer, F. Vollertsen

Jose MJ, Kumar SS, Sharma A (2016) Vibration assisted welding processes and their influence on quality of welds. Sci Technol Weld Join 21(4):243–258. https://doi.org/10.1179/1362171815Y.0000000088

Balasubramanian K, Kesavan D, Balusamy V (2011) Studies on the effect of vibration on hot cracking and grain size in AA7075 aluminum alloy welding. Int J Eng Sci Technol 3(1):681–686

Thavamani R, Balusamy V, Nampoothiri J, Subramanian R, Ravi KR (2018) Mitigation of hot cracking in Inconel 718 superalloy by ultrasonic vibration during gas tungsten arc welding. J Alloys Compd 740:870–878. https://doi.org/10.1016/j.jallcom.2017.12.295

Kim JS, Watanabe T, Yoshida Y (1995) Ultrasonic vibration aided laser welding of Al alloys: improvement of laser welding-quality. J Laser Appl: 38–46

Gao H, Agarwal G, Amirthalingam M, Hermans MJM (2017) Hot cracking investigation during laser welding of high-strength steels with multi-scale modelling approach. Sci Technol Weld Join 23(4):287–294. https://doi.org/10.1080/13621718.2017.1384884

Woizeschke P, Radel T, Nicolay P, Vollertsen F (2017) Laser deep penetration welding of an aluminum alloy with simultaneously applied vibrations. Lasers Manuf Mater Process 4(1):1–12. https://doi.org/10.1007/s40516-016-0032-9

Radel T (2018) Mechanical manipulation of solidification during laser beam welding of aluminum. Welding in the World 62(1):29–38. https://doi.org/10.1007/s40194-017-0530-1

Cao X, Wallace W, Poon C, Immarigeon JP (2003) Research and progress in laser welding of wrought aluminum alloys. I. Laser welding processes. Mater Manuf Process 18(1):1–22. https://doi.org/10.1081/AMP-120017586

Kammer C (1995) Aluminium-Taschenbuch: Grundlagen und Werkstoffe. Aluminium-Verlag Düsseldorf

David SA, Vitek JM (1989) Correlation between solidification parameters and weld microstructures. Int Mater Rev 34(5):213–245. https://doi.org/10.1179/imr.1989.34.1.213

Zhang J, Weckman DC, Zhou Y (2008) Effects of temporal pulse shaping on cracking susceptibility of 6061-T6 aluminum Nd:YAG laser welds: use of temporal pulse shaping may make it possible to laser weld 6061-T6 aluminum hermetic packages without the need for filler material 87: 18–30

Mondolfo LF (1976) Aluminum alloy: structure and properties. Butter Worths. Boston Press, London

Acknowledgements

This work was accomplished within the Center of Competence for Welding of Aluminum Alloys (Centr-Al).

Funding

Funding by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation, project number 267927324) is gratefully acknowledged. The “BIAS ID” numbers are part of the figures and allow the retraceability of the results with respect to the mandatory documentation required by the funding organization.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission IV - Power Beam Processes

Rights and permissions

About this article

Cite this article

Radel, T., Woizeschke, P. Reduction of hot cracking susceptibility during laser welding of aluminum by vibrations. Weld World 63, 599–606 (2019). https://doi.org/10.1007/s40194-018-00680-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-018-00680-2