Abstract

Three kinds of Ag nano-assemblies have been fabricated separately in a one-step reaction. These are designated as 3D–3D, shell-3/1D and 3D–1D nano-architectures. These nano-architectures were synthesized by polyol reduction method in the presence of polyvinyl pyrrolidone (PVP) at 120, 140, and 160 °C, respectively. During the experiment, controlled temperature decrease has been carried out which successfully developed 3D–3D, and 3D–1D conjunction. The shell-3/1D nano-assembly was successfully developed at 140 °C by gradual decreasing and subsequently increasing of temperature. The size and morphology of each product was characterized by transmission electron microscope (TEM). Surface plasmon resonance (SPR) behavior was analyzed by UV–Vis spectroscopy. The antimicrobial activities were also analyzed for gram positive bacteria like Enterococcus faecalis and Staphylococcus aureus, and gram negative like E. coli 0157:H7 and DH5α by scanned optical density (OD) and Kirby-Bauer process. The OD was measured by taking scanned UV–Vis absorption from 700–300 nm wavelength in LB (Luria–Bertani) broth media. Similarly Kirby-Bauer process was applied over LB agar media. The material was found unique in terms of morphology as well as in displaying its antimicrobial activities both for gram positive and gram negative bacteria.

Similar content being viewed by others

Introduction

Research on Ag nanostructures is exponentially growing after carbon nanotubes [1–3]. This is not only due to its highest thermal and electrical conductivity [4], but also due to ease of synthesis, and potential to produce diverse morphologies [5]. Moreover, every type of morphology is creditable for particular properties, like NWs for transparent conductive electrodes and microprocessors [6], triangular particles for catalysis, and for biological purposes spherical NPs are preferred [7]. Nano-Ag has also applications with reference to energy storage devices, fabrication of nano/micro circuits [6], surface-initiated polymerization [8], biological chips and sensors [9]. Moreover, nano-Ag is biocompatible, antimicrobial and anticarcinogenic material [10]. It is also environmentally more stable as compared to many of other metal nanostructures, like Au, Cu, Pd and Ni, etc. [11, 12].

Taking the advantage of different morphologies of Ag, it was aimed to produce the conjunction of two or more than two morphologies in order to develop the nano-assembly that is preferred for device fabrication. It can be produced by combining fine nanoparticles (fNPs) with bigger nanoparticles (bNPs), fNPs with nanowires (NWs) and growing shell around the surface of NWs and NPs. In this way, unification of two morphologies or two ranges of dimensions could be engineered that might be employed for diverse applications. It is also useful to combine the different properties by merging the materials of different dimensions in form of nano-assembly [13]. For example, the NPs can develop more interaction with biomolecules or organic molecules as compared to NWs and NWs are best candidates which are used to transduce electrical and optical signals. Therefore, nano-assembly of fNPs and NWs would be able to interact with probe molecule and transduce their detectable signals. Such type of nano-assembly is expected to be a design of nanosensor.

Herein, our experiment proved successful to develop the conjunction between different dimensions of Ag nanostructures and thus designed their nano-assemblies. These are designated as 3D–3D, shell-3/1D and 3D–1D nano-assemblies, which were assessed for their potential antimicrobial activities. Herein, the synthesis was accomplished by controlled variation of temperature. The temperature at 120, 140 and 160 °C and its controlled variation was found suitable for the production of 3D–3D, shell-3/1D and 3D–1D nano-assemblies, respectively. The nano-assemblies were first time developed by using simple and one-step methodology that is only temperature based. These nano-assemblies possess the potential to be employed as nanosensor. The material was well characterized by TEM, and UV–visible spectrophotometer. Furthermore, antimicrobial behavior of 3D–3D, and shell-3/1D nano-architectures was also analyzed by UV–vis spectrophotometer and Kirby-Bauer process against gram positive and gram negative bacteria. The Enterococcus and Staphylococcus aureus are gram positive bacteria and E. coli 0157:H7 and DH5α are gram negative bacteria. It has been inferred from the data that 3D–3D and shell-3/1 D nano-architectures obtained at 120 and 140 °C expressed their significant antimicrobial activities both for gram positive and negative bacteria.

Experimental

Materials

AgNO3, ethylene glycol (EG), polyvinylpyrrolidone (PVP), acetone, and ethanol. All chemical were purchased from sigma Aldrich and have 99 % purity. Escherichia coli (ATCC 25922), Staphylococcus aureus (ATTC 6538), Enterococcus faecalis (ATCC 51299) were purchased from American Type Culture Collection and DH5α from Invitrogen (Invitrogen™).

Method

The experiment was carried out by our own developed method. It is mainly based on controlled variation of temperature. Herein, three different temperatures were optimized that is 120, 140 and 160 °C. For each temperature the molar concentration of AgNO3 and PVP was 0.2 and 0.3 M, respectively, in 15 mL EG. The experiment was carried out by preheating 5 mL EG for one hour at each temperature, i.e., 120, 140 and 160 °C, respectively, to remove any water content. The 5 mL solution, each of AgNO3 and PVP were added dropwise within 10–15 min. However, the order of dropping was not kept same, as at 120 °C, the dropping of PVP was started first which was followed by AgNO3 solution. At 140 °C the simultaneous dropping was carried out and at 160 °C dropping of AgNO3 was followed by PVP. At beginning temperature was dropped 15–20 °C then again rose up at its original setting. The material was heated at each original setting for 30–35 min and then heating was gradually decreased to room temperature. The gradual decreased in temperature was aimed to produce and grow fNPs over the surface of NWs and NPs. In case of nanoshell formation, the temperature after decreasing to room temperature was again increased to 140 °C, which was its original setting. Thus, the grown fNPs over nanostructures merged with each other and developed nanoshell. In this way, combination of different dimensions of nanostructures was accomplished, which are given in Table 1.

The antimicrobial activity of as-synthesized nanostructures was determined against bacterial species which are given in “Materials”. Both gram positive and gram negative bacterial species were grown on LB agar and LB broth nutrient at 37 °C for 8 h. The LB agar is composed of tryptone 1 gm, yeast extract 0.5 gm, NaCl 0.5 gm and agar 1.5 gm in 100 mL distilled water and LB broth has same composition as LB agar; however, it does not contain agar. The LB agar was used for Kirby-Bauer process and LB broth for UV–vis spectrophotometer. In each media each bacterial species (inoculum) were cultured and antimicrobial effect of Ag was determined.

Results and discussion

The morphology of the materials was characterized by TEM, which demonstrated and confirmed the formation of NWs at 160 °C having diameter within 60–70 nm and length in few microns. At 160 °C the exclusive product is NWs as shown in Fig. 1a. It has been observed that there are distinct spots showing fNPs of Ag over the surface of NWs. The diameter of these particles is in about 8–10 nm. It was revealed that experimental procedure of gradual decrease in temperature proved helpful to produce nano-assembly, comprising two different dimensions, i.e., 1D and 3D, where 1D is NWs and 3D is fNPs. This is designated as 3D–1D nano-assembly. The fNP has more potential to interact with probe organic molecule or biomolecules as compared to NWs [14] and NWs are suitable to transduce signals. Therefore, nano-assembly was desirable where fNP can serve as anchoring site for probe molecule/agents and NWs could serve the purpose of transducing the signal that may result from the probe and target interaction. In this way, the as-synthesized nano-assembly can act as biosensor to find the target molecules by the interaction of probe and transduce their detectable signals through NWs. It is also expected that at nano-scale level there would be more anchored probe molecules and thus these would increasingly interact with target molecules which would result the strong or easily detectable signal. Therefore, the designed nano-assembly would possess the bio-analytical application.

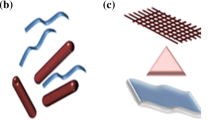

Similarly, the observation under TEM expressed in Fig. 1b and c with reference to experiment carried out at 140 °C, which revealed the formation of NPs as well as NWs, where each structure is enclosed by nanoshell of same materials having diameter about 8 nm. It was also demonstrated that 140 °C is critical temperature for the formation of NWs, as temperature below to this is favorable for the production of NPs and above it is suitable to produce NWs [15]. Therefore, this temperature was found suitable for the production of NPs as well as NWs. In this case, temperature was again gradually decreased which produced fNPs. Moreover, subsequent rise in temperature from room temperature to its original setting proved helpful to merge these fNPs over surface of bNPs and NWs, and thus created shell-like morphology. This kind of nano-assembly is labeled as shell-3/1D. The shell-3/1D nano-assembly has two types of appearances, i.e., coalescence of fNPs in form of shell and making of perfect nanoshell around NPs and NWs. Therefore, both are expressed separately in Fig. 1, b and c, respectively, for clear differentiation. The as-synthesized nanoshell over the same materials is helpful to protect the enclosed nanostructure and it is also expected to express its enhanced catalytic and bioactivity due to significantly reduced size.

The TEM pictures of experiment that was performed at 120 °C are displayed in Fig. 1d, which demonstrated spherical morphology of NPs having diameter 40–45 nm. These NPs are also being adsorbed with fNPs having diameter again about 8 nm. The adsorption of fNPs in each case restricted their agglomeration that is a usual trend of such a small particles. Therefore, the technique proved helpful to limit their coalescence and exposed their surface which is prerequisite for catalytic, antimicrobial and optical behavior. This technique may also be used to immobilize quantum dots over such substrate.

The strategy to fabricate conjunction of fNPs over NWs and bNPs or making the shell of very small diameter over these nanostructures was achieved in single step that is quite advantageous. Since in the separate synthesis of fNPs and bigger nanostructures, and then their merging is a laborious process, which does not assure the production of such unifications. However, in this technique, the synthesis of nano-assembly, its washing and separation from reaction mixture is quite easy due to presence of bigger nanostructures which can easily settle down by centrifugation. Moreover, in separate synthesis some linkers are required for combining different nanostructures to develop the nano-assembly, and in our methodology no such linker is required [16].

The energy dispersive X-rays spectroscopy (EDS) is displayed in Fig. 2 and respective Table 2. It has confirmed that both components in each kind of assembly are constituted by same material that is Ag which is 97 %. The presence of 3 % C is due to the membrane of C over a copper grid (Table 2).

The SPR of fNPs adsorbed over Ag NWs (3D–1D), NWs having shell (shell-3/1D) and fNPs over bNPs (3D–3D) was analyzed by UV–Vis spectrophotometer. The SPR behavior is displayed in Fig. 3. It has been revealed as the nano-assemblies changed from 3D–1D, shell-3/1D and 3D–3D, their SPR absorbance intensively increased along with blue shift. Moreover, it has been seen that longitudinal and trans-sectional SPR of NWs in 3D–1D nano-assembly is not differentiated due to even growth of fNPs around its surface. In case of shell-3/1D nano-assembly, the product obtained at 140 °C showed gradually enhanced SPR and relatively blue shifted. Similarly, the SPR intensity of 3D–3D nano-assembly is again more intense and blue shifted. If the SPR data are compared with smooth respective nanostructures [17] and it was found the SPR is quite more in case of merged nanostructures, because in merged form fNPs has more contribution in SPR character.

Furthermore, the Ag and its nanostructures have well recognized antimicrobial activities [18, 19], but still no study has been carried out that Ag nanostructures synthesized by polyol reduction method does possess such peculiarities. Likewise, the smaller or finer Ag nanostructures are believed to demonstrate more antimicrobial behavior; therefore, we analyzed the antimicrobial behavior of shell-3/1D and 3D–3D nano-assemblies which are smaller and finer nano-assemblies as compared to 3D–1D nano-assembly. Thus, the antimicrobial activities of Ag nano-assemblies, synthesized by polyol reduction method were assayed against gram positive bacteria like Enterococcus faecalis and staphylococcus aureus, and gram negative like E. coli 0157:H7 and DH5α by employing UV–vis spectrophotometer and Kirby-Bauer process whose strains number are given in “Materials”.

In this experiment, LB broth nutrient media were used, where at first UV–vis absorption of shell-3/1D and 3D–3D Ag nano-assemblies were measured and then UV–vis absorption of just bacterial samples was taken for comparative account. In continuation of experiment, the shell-3/1D and 3D–3D Ag nano-assemblies were mixed separately with bacterial samples of gram positive bacteria like Enterococcus feacalis and Staphylococcus aureus, and gram negative bacteria like E. coli 0157:H7 and DH5α for 8 h and then their UV–Vis absorption was noted, which is displayed in Figs. 4 and 5, respectively. The antimicrobial activities of shell-3/1D and 3D–3D Ag nano-assemblies in accordance with above pattern are given in Figs. 4 and 5, respectively. According to the data shown in Figs. 4 and 5, bacteria after 8 h show significant growth, which was demonstrated by linear increase in UV–vis absorption, while pure nano-assemblies designated as shell-3/1D and 3D–3D of Ag showed SPR absorption in region of 410–430 nm, respectively. Both bacterial and nano-Ag absorption seemed to appear in same region that is 410–430. The coincidence of both absorptions in same region is quite useful for analysis purpose, as in case of inactivity both absorptions would add up and in case of activity they would suppress the bacterial absorption along with some change. Similarly, when Ag nano-assemblies were mixed with bacterial samples, the bacterial absorption decreased and nano Ag-SPR absorption red shifted. The decrease of UV–Vis absorption for bacterial sample clearly demonstrated the antimicrobial effects of Ag nanostructures. The red shift might be due to agglomeration of nanostructures over the surface of bacteria [20]. Hence, UV–vis absorption technique confirmed the antimicrobial activity of Ag nanostructures, which were prepared by the polyol reduction method against gram positive and negative bacteria.

To further validate the antimicrobial attributes of Ag synthesized by polyol reduction method, the Kirby-Bauer process was used where nutrient media was LB agar [21]. The results are shown in Figs. 6 and 7, respectively. Each plate is divided into two halves and two kinds of bacteria (inoculum) were grown in each plate and only one kind is grown in each half of the plate. In Fig. 6, the upper part of the plate contains Enterococcus feacalis and the lower part of plate has E. coli 0157:H7 which are gram positive and negative bacteria, respectively. The left part of the plate was tested for shell-3/1D and right part was analyzed for 3D–3D nano-assemblies. Over each part, at the left side the drop of shell-3/1D was dropped and at right side, the drop of 3D–3D nano-assemblies was dropped. In this experiment, 50 μL of each nano-Ag was dropped over the growing lawn of Enterococcus faecalis and E. coli 0157:H7 bacteria over LB agar media. The diameter of drop was approximately 0.7 cm. After incubation period of bacterial culture with Ag nano-assemblies, the clear zone of inhibition was observed which is about 2–2.5 cm measuring diameter for E. coli 0157:H7 and Enterococcus faecalis, respectively.

Similarly, in Fig. 7, the upper part of the plate contains DH5α and lower part of same plate possessed Staphylococcus aureus. Herein, similarly nano-Ag was dropped as according to Fig. 6. In this experiment, 10 µL of each nano-Ag was dropped whose diameter was about 0.25 cm. After incubation period of bacterial culture with Ag nano-assemblies, the clear zone of inhibition of measuring diameter about 1.2–1.5 cm was observed for DH5α and Staphylococcus aureus. The concentration of both solutions was same, which is 100 µg/mL. Moreover, the left part of each plate in Figs. 6 and 7 reflected the effect of shell-3/1D and right part of each plate is observed for 3D–3D nano-assembly. It is clearly reflected from the each plate that colonies of each microbe of gram positive and gram negative bacteria could not grow in the region where aqueous drops of nano-Ag structures were employed. Moreover, at each site of Ag drops over both plates there was clear zone of inhibition, which demonstrated and validated that Ag nano-assemblies produced from polyol reduction method possess typical antimicrobial activities, as it was reflected against gram positive bacteria like Enterococcus and staphylococcus aureus, and gram negative bacteria like E. coli 0157:H7 and DH5α. Furthermore, polyol reduction is a versatile method that has potential to produce the controlled morphology of metal nanostructures, but herein it was proved absolutely unique as it has also potential to produce nano-assemblies. It is also assumed that ionization of nano-Ag produced by polyol method is slow since zone of inhibition is not very enlarged. This trend is believed to be environmentally friendly as cautioned by Smitha Pillai [22], where excess release of Ag+ was reported from physically synthesized Ag nanostructures and that have great toxic effects over fisheries (Table 3).

Conclusions

The three kinds of Ag nano-assemblies designated as 3D–3D, shell-3/1D and 3D–1D were prepared using polyol reduction method under controlled rise and fall of temperature. The gradual decrease of temperature for certain time proved helpful to produce fNPs and establish their interaction with already grown nano-Ag support. It is also concluded that subsequent rise in temperature could merge the fNPs to form shell-3/1D nano-assembly. Thus, our modified polyol reduction strategy proved facile technique to develop interjunction between different dimension and designed unique nano-assemblies. Moreover, the as designed nano-assemblies have potential to immobilize the probe molecule over their surfaces as fine nanoparticles and nanoshells are more prone toward the reactivity and functionalization. The antimicrobial activities of 3D–3D, shell-3/1D were analyzed against gram positive bacteria like Enterococcus and Staphylococcus aureus, and gram negative like E. coli 0157:H7 and DH5α. The results confirmed and validated that chemically synthesized nano-assemblies by polyol reduction method retain their significant antimicrobial behavior.

References

Skrabalak, S.E., Chen, J., Sun, Y., Lu, X., Au, L., Cobley, L.M., Xia, Y.: Gold nanocages: synthesis, properties, and applications. Acc. Chem. Res. 41, 1587–1595 (2008)

Nowack, B., Krug, H.F., Height, M.: 120 years of nanosilver history: implications for policy makers. Environ. Sci. Technol. 45, 1177–1183 (2011)

Lu, D.D., Li, Y.G., Wong, C.P.: Recent advances in nano-conductive adhesives. J. Adhes. Sci. Technol. 22, 815–834 (2008)

Zahoor, A., Teng, Q., Wang, H., Choudhry, M.A., Li, X.: Synthesis and characterization of Ag@polycarbazole coaxial nanocables and their enhanced dispersion behavior. Met. Mater. Int. 17, 417–423 (2011)

Lim, B., Xia, Y.: Metal nanocrystals with highly branched morphologies. Angew. Chem. Int. Ed. 50, 76–85 (2011)

Madaria, A.R., Kumar, A., Zhou, C.: Large scale, highly conductive and patterned transparent films of silver nanowires on arbitrary substrates and their application in touch screens. Nanotechnology 22, 245201–245207 (2011)

Xue, C., Chen, X., Hurst, S.J., Mirkin, C.A.: Self-assembled monolayer mediated silica coating of silver triangular nanoprisms. Adv. Mater. 19, 4071–4074 (2007)

Chen, X.H., Wang, H., Li, H., Li, X.: Fabrication of Ag/polypyrrole coaxial nanocables through common ions adsorption effect. Synth. Met. 156, 346–350 (2006)

Sepúlveda, B., Angelomé, P.C., Lechuga, L.M., Liz-Marzán, L.M.: LSPR-based nanobiosensors. Nanotoday. 4, 244–251 (2009)

Sriram, M.I., Barath, S., Kanth, M., Kalishwaralal, K.: Gurunathan: antitumor activity of silver nanoparticles in Dalton’s lymphoma ascites tumor model. Int. J. Nanomed. 5, 753–762 (2010)

Nicole, C.M., Bernd, N.: Exposure modeling of engineered nanoparticles in the environment. Environ. Sci. Technol. 42, 4447–4453 (2008)

Sun, J., Ma, D., Zhang, H., Liu, X., Han, X., Bao, X., Weinberg, G., Pfander, N., Su, D.: Toward monodispersed silver nanoparticles with unusual thermal stability. J. Am. Chem. Soc. 128, 15756–15764 (2006)

Kim, K., Nilsen, E., Huang, T., Kim, A., Ellis, M., Skidmore, G., Lee, J.B.: Metallic microgripper with SU-8 adaptor as end-effectors for heterogeneous micro/nano assembly applications. Microsyst. Technol. 10, 689–693 (2004)

Maxwell, D.J., Taylor, J.R., Shuming, N.: Self-assembled nanoparticle probes for recognition and detection of biomolecules. J. Am. Chem. Soc. 124(32), 9606–9612 (2002)

Zhang, W., Chen, P., Gao, Q., Zhang, Y., Tang, Y.: High-concentration preparation of silver nanowires: restraining in situ nitric acidic etching by steel-assisted polyol method. Chem. Mater. 20, 1699–1704 (2008)

Zhang, F., Yasin, F.M., Chen, X., Mo, J., Raston, C.L., Zhang, H.: Functional noble metal nanostructures involving pyrene-conjugated-hyaluronan stabilised reduced graphene oxide. RSC Adv. 3, 25166–25174 (2013)

Zahoor, A., Qiu, T., Zhang, J., Li, X.: Synthesis and characterization of Ag@polycarbazole nanoparticles and their novel optical behavior. J. Mater. Sci. 44, 6054–6059 (2009)

Dastjerdi, R., Montazer, M.: A review on the application of inorganic nano-structured materials in the modification of textiles: focus on anti-microbial properties. Colloids Surf B Biointerfaces. 79, 5–18 (2010)

Nakane, T., Gomyo, H., Sasaki, I., Kimoto, Y., Hanzawa, N., Teshima, Y., Namba, T.: New antiaxillary odour deodorant made with antimicrobial Ag-zeolite (silver-exchanged zeolite). Int. J. Cosmet. Sci. 28, 299–309 (2006)

Lok, C.N., Ho, C.M., Chen, R., He, Q.Y., Yu, W.Y., Sun, H.P., Tam, K.H., Chiu, J.F., Che, C.M.: Silver nanoparticles: partial oxidation and antibacterial activities. J. Biol. Inorg. Chem. 12, 527–534 (2007)

Schierholz, J.M., Fleck, C., Beuth, J., Pulverer, G.: The antimicrobial efficacy of a new central venous catheter with long-term broad-spectrum activity. J. Antimicrob. Chemother. 46, 45–50 (2000)

Pillai, S., Behra, R., Nestler, H., Suter Marc, J.F., Sigg, L., Schirmer, K.: Linking toxicity and adaptive responses across the transcriptome, proteome, and phenotype of Chlamydomonas reinhardtii exposed to silver. PNAS 3, 3490–3495 (2014)

Acknowledgments

We gratefully acknowledge the financial support from Higher Education Commission (HEC) of Pakistan and Characterization assistance from Prof. Li Xiaoyu and Dr. Qiu Teng, Department of Material Science and Engineering, Beijing University of Chemical Technology, PR China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Ahmad, Z., Afreen, A., Mehmood, M. et al. One-step synthesis of Ag nano-assemblies and study of their antimicrobial activities. J Nanostruct Chem 5, 325–331 (2015). https://doi.org/10.1007/s40097-015-0164-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40097-015-0164-z