Abstract

The commercialization of microbial fuel cell technology is limited by high operating costs and low electricity production due to poor electron transfer to the anode. Operational costs can be lowered by utilizing waste materials, and cell performance can be improved by anode modification. This study investigated how anode modification with iron compounds changed the efficiency of energy generation and the microbiome of microbial fuel cells fueled with waste volatile fatty acids from a full-scale anaerobic digestion. Anode modification with 2.5 g Fe2O3/m2 increased the power density, current density, and voltage by 3.6-fold, 1.8-fold, and 1.4-fold, respectively. In the microbial fuel cell influent, propionic, enanthic, and iso-caproic acids predominated (60, 15, and 13% of all volatile fatty acids, respectively); in the outflow, propionic (71%) and valeric acids (17%) predominated. In anodic biofilms, Acidovorax sp. were most abundant; they have a great capacity for volatile fatty acids decomposition, and their abundance doubled in the microbial fuel cell with an iron-modified anode. The presence of iron significantly increased the abundance of the genera Pseudomonas and Geothrix, which were mainly responsible for electricity production. These results indicate that anode modification with iron changes the anode microbiome, favoring efficient volatile fatty acids metabolism and a greater abundance of electrogens in the biofilm, which ensures better electricity generation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In response to increased energy demand and out of concern for the natural environment, microbial fuel cells (MFCs) are of great interest to researchers. These cells, in addition to their main function of generating electricity, can also contribute to wastewater treatment (Liang et al. 2018). To generate electricity, microorganisms capable of biocatalysis can transform the organic compounds contained in wastewater (Ghasemi et al. 2011).

Carbon electrodes are commonly used electron acceptors in MFC. They can take various forms, such as brushes, rods, felts, and structures such as canvases. The most important characteristic of these electrodes is that they should have the largest possible number of microchannels to allow the penetration and flow of substances into the electrode (Greenman et al. 2021). Additionally, low resistance, high electrical conductivity, and a large specific surface area are also desirable (Zhou et al. 2011). It has been shown that increases in the efficiency of energy production by a microbial cell are closely related to increases in coverage of the anode with microorganisms. Electron transport at the anode is improved by the growth of a biofilm (Cornejo et al. 2015). The coverage of the electrode with microorganisms can be improved by increasing the specific surface area and reducing the charge transfer resistance by the applications of different anode materials and modifying the electrodes, e.g., with metal oxides (Nosek et al. 2020). These oxides significantly improve the efficiency of electron transport in an MFC by serving as electrical conductors inside biological membranes or by accumulating on the surface of bacterial cells (Karn et al. 2009). The presence of iron oxides in the environment increases the expression of genes encoding type-c cytochromes (Kato et al. 2013), which intensifies electron transfer processes in the anode regions. Iron (III) oxide in a nano-colloidal form created a network of connections between organisms, increasing their mutual adhesion, which raised the power generated in the cell by up to 50-fold (Savla et al. 2020). Zheng et al. (2022) investigated the effect of iron added to the medium to improve the efficiency of MFC. The experiment was conducted in a single-chamber MFC with a carbon brush as an anode. The cell achieved the highest power of 391.11 ± 9.4 mW/m2 at the lowest dose of magnetite Fe3O4 of 4.5 g/L. Yu et al. (2019) modified the graphite felt with Fe3O4 by bonding it to the surface with a polytetrafluoroethylene emulsion. This modification improved the power density in soil MFC by 1.7 times compared to the control. Tripathi et al. (2022) used dots coated with different doses (0.25, 0.5, 0.75, and 1 mg/cm2) of iron (II, III) oxide (Fe3O4) as an anode. The anodes were synthesized using a hydrothermal-assisted probe sonication method. The maximum power density (440.01 mW/m2) was observed in the MFC at the highest Fe3O4 dose of 1 mg/cm2––it was about 1.5 times higher than that of the MFC with an anode made of pure graphite sheet. Up to now, mainly pure substrates have been used in MFCs, such as glycerol (Tremouli et al. 2016), glucose (Christwardana et al. 2018), or acetate (Ullah and Zeshan 2020), which ensured successful electricity production. Recently, waste substances have started to be used, including municipal wastewater, landfill leachate, and volatile fatty acids (VFAs) from primary sludge treatment; this approach offers the benefit of energy recovery from waste products.

From an engineering point of view, combining technologies like anaerobic digestion (AD) and MFC to generate energy from waste is beneficial. When organic compounds are decomposed in AD, VFAs are formed, which can serve as a carbon source for MFC microorganisms to simultaneously generate electricity. For example, Hou et al. (2020) used a digestion tank as the anodic chamber for an MFC process (AD-MFC) to treat food waste. They found that a combined AD-MFC system supported with algae in the cathode chamber produced biogas with a methane content twice as high as that produced by AD alone and 34% higher than that produced by AD-MFC. Additionally, the algae-supported MFC maintained a high voltage of 490 mV for 20 days. Combining AD and an MFC in one system can help with the early detection of VFA concentrations that are too high for the AD process. Schievano et al. (2018) reported that when the concentration of VFAs in the chamber increased to 4000 mg acetate/L, the voltage dropped, which was associated with the inhibition of the activity of microorganisms. Another study used a continuous process with hydrogen/VFA generation in the first stage and electricity generation in an MFC in the second. The combined system was able to reduce COD by 90%, and the maximum power density achieved with the system was 22.26 mW/m2 (Pant et al. 2013). Choi et al. (2011) used VFA from the fermentation of food waste in a two-chamber and a single-chamber MFC. They observed that acetic acid and propionic acid were consumed most rapidly and that the voltage and power density reached 533 mV and 240 mW/m2, respectively. When only butyrate and valerate were present in the cell, the voltage dropped to 390 mV, indicating that electron deposition with these VFAs was lower in comparison with the deposition with VFAs with shorter chain lengths. Acetate alone was removed more rapidly than acetate in a mixture with other VFAs, suggesting that the other VFAs may have inhibited acetate degradation. In another study by Freguia et al. (2010), a synthetic VFA mixture based on the composition of digested sludge from domestic wastewater treatment was used. For power generation from the VFAs, mainly acetate and propionate were utilized, while butyrates, valerates, and caproic acids were utilized to a lesser extent. To the best of the authors’ knowledge, no studies were conducted with real VFA in MFCs with Fe-modified anodes.

Energy generation in an MFC is closely related to the species composition of the anode biofilm. Typically, mixed cultures make good synergistic consortiums because each species plays a specific role in the degradation of complex organic compounds. Some bacteria are responsible for breaking down complex compounds into simple ones and others for protecting the biofilm from environmental stress (Costerton 2007). Xin et al. (2019) tested the use of food waste hydrolysate as an electron donor in an MFC. They found that the main genera were Rummeliibacillus, Burkholderia, Enterococcus, and Clostridium and that the electrogenesis efficiency (0.977 kWh/kg COD) was higher than that of a single carbon source MFC. Syntrophic interactions between fermentation species and exoelectrogens played a key role in the generation of electricity by the anode biofilm. He et al. (2021) used sludge fermentation liquid (SFL) and fruit waste extracts (FWE) in MFC. The mixture of SFL and FWE promoted the presence of the genera Clostridium, Alicycliphilus, Thermomonas, Geobacter, Paludibaculum, Pseudomonas, Taibaiella, and Comamonas, which collaborated to degrade COD and generate electricity. Analysis of the VFAs in the wastewater of the MFC fed FWE indicated that synergistic interactions of microorganisms led to substrate bioconversion and bioelectricity production. In studies using the PCR-DGGE technique, in which real or synthetic VFAs were used in MFCs, microorganisms of the genera Geobacter, Comammonas, Pseudomonas, Xanthomonas, Sphingobacterium, and Pelobacter were present in the biofilm that developed on unmodified electrodes (Freguia et al. 2010, Choi et al. 2011). However, their percent abundance in the biomass could not be determined, due to the limitations of the method. To ensure an in-depth analysis of the microbial community, the most advanced molecular techniques, such as next-generation sequencing, should be used that allow determining the percentages of all bacteria in the community even those that are present in low numbers, but can be of great importance for the process efficiency (Dubey et al. 2022). These advanced methods have not been used to investigate how modifying the anode with iron affects the relationships between organic degraders and electrogens in the anodic biofilm of MFCs fed with real VFAs.

Even though energy can be efficiently produced in MFC by using pure, quickly metabolized substrates such as glucose or acetate, the economic aspects of the process should be improved. Using complex waste substrates does not involve the costs associated with pure substrates and is in line with the assumptions of a circular economy. However, these substrates tend to reduce the efficiency and energy generation potential of the process. A potential means of offsetting these reductions is the use of modified anodes. It is also important to determine which microorganisms guarantee effective energy production under these conditions. So far no studies were presented on the use of VFA in MFC with MFC coated with iron oxide, none were the metabolism of VFA and microbial structure of anodic consortium analyzed to focus on how the substrates from waste VFAs are used in MFC and indicate the main players involved in the metabolism of real mixed organic compounds and energy generation. Therefore, the objectives of this study were to assess the possibility of using VFAs from the full-scale AD of primary sludge for electricity generation in an MFC with an iron-modified anode and to investigate the influence of iron on the microbial composition of the anodic biofilm and VFA removal.

This study was carried out in northeastern Poland from September 2021 to March 2022.

Materials and methods

MFC configuration

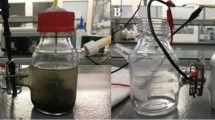

The tests were performed in two separate reactors made of transparent acrylic glass (Fig. 1). Each of them contained anode and cathode chambers (active volume 1 L), which were connected by a transverse, cylindrical conductor in which a Nafion N-117 proton exchange membrane (Alfa Aesar) was placed. The membrane area was 8.5 cm2. Before use, the membrane was rinsed for half an hour in acetone and then rinsed with distilled water, soaked in 1 M HCl for 30 min, and rinsed with distilled water. Due to membrane clogging, once a week, the membrane was cleaned in 1 M HCl and rinsed with distilled water (for details, see Nosek and Cydzik-Kwiatkowska 2020). The electrodes were made of 10 × 10 cm carbon felt (CGT Carbon GmbH). The external electrical circuit was made of stainless steel wire and connected to a 4.7 kΩ resistor. The cathode chamber was filled with a catholyte containing 1.5 mg of NaCl and 38 mL of phosphate buffer in 1 L of distilled water. The cathode chamber was continuously aerated with an airflow rate (20 mL/min).

Anode modification

The control reactor (MFCcontrol) was operated with an unmodified anode (pure carbon felt). In the second reactor (MFCFe), an anode made of carbon felt was modified by the deposition of 0.05 g of iron (III) oxide (Chempur, Poland). For modification, a suspension containing 0.05 g of metal oxide and 100 mL of distilled water was prepared. The suspension was placed in an ultrasonic bath for 15 min, the carbon felt was immersed in the slurry and autoclaved (Prestige Medical, 1.1 bar, and 121 °C). After autoclaving for 1 h, the anode was dried at 80 °C. If it was determined that the iron deposition on the electrode was less than 95%, the procedure was repeated.

The degree of Fe deposition on the anode (\(n\)) was determined by measuring the Fe concentration using the Hach Lange LCK 320 cuvette test, and then subtracting the final concentration of Fe in the liquid (after deposition) from the initial concentration, according to the following formula (Eq. 1):

where Fe0 is the initial concentration of Fe, and Fe1 is the concentration of iron remaining in the liquid after deposition.

MFC operation

The anode chambers in both MFCs were inoculated with 50 mL of anaerobic sludge from the digestion chambers of the “Łyna” wastewater treatment plant in Olsztyn (20°29’E 53°47’N). As a substrate, a mixture of volatile fatty acids (VFAs) from the digestion of primary sludge in the wastewater treatment plant was used. The VFA mixture was poured through a 2 mm sieve to remove large suspensions and stored at 4 °C. The VFA mixture was characterized by 2298 mg COD/L; 788 mg CH3COOH/L; 35.5 mg N-NH4/L. The VFA mixture was diluted to 400 mg COD/L and adjusted to pH 7 with 1 M HCl (anolyte). The anolyte was replaced daily and the volumetric exchange rate was 50%. After a two-week acclimatization period of MFCs, the experiment was carried out for 18 cycles.

Physico-chemical analyses

In samples taken from the anode chamber, the following values were determined: COD (dichromate method), VFA (direct distillation), N-NH4 (direct Nesslerization) according to APHA (1992), and pH and alkalinity (TitroLine, Donserv). The voltage produced in the MFC was measured with a multimeter (True-RMS). The 6600 Counts PC-LINK program was used to save the data; changes in the generated voltage were recorded every minute. The current intensity was calculated using Ohm’s law on the basis of the external resistance. The power curves were determined by changing the external resistance in the range of 0–27 000 Ω. The VFA composition was determined using a Varian CP-3800 chromatograph (Bułkowska et al. 2021). Spectroscopic characterization of the surface of pure carbon felt after sonication in the ultrasound batch and carbon felts modified with a dose of Fe2O3 was performed using a Quanta FEG 250 Scanning Electron Microscope (SEM/EDX, Quanta FEG 250, FEI).

Abiotic test of iron release

To monitor iron release from the carbon felt, a biomass-free test was performed. For this purpose, an anode modified as described above was placed in a measuring vessel with a volume of 1 L. As a substrate, synthetic wastewater (Coelho et al. 2000) without iron was used; the pH was adjusted to match the pH of the VFA mixture. The measuring vessel was sealed to maintain anaerobic conditions. The experiment was carried out for 18 cycles, in parallel to the operation of both MFCs used in the study. After each cycle, 0.5 L of wastewater was removed and replaced with fresh substrate. The iron content in the collected supernatant was determined using the Hach Lange LCK320 cuvette test using a Hach Lange DR 3900 spectrophotometer (Hach Lange, Germany).

Microbial analyses

FastDNA SPIN Kit for Soil (MP Biomedicals) was used to isolate DNA from inoculum and100 µg of biofilm scratched from the anodes at the end of the experiment. Isolations were performed in duplicate and DNAs from each repetition were mixed. The quality and quantity of the DNA were assessed using NanoDrop spectrometer (Thermo Scientific). For amplification of the DNA, a primer set 515F/806R (5’- GTGCCAGCMGCCGCGGTAA-3’/5’—GGACTACHVGGGTWTCTAAT-3’) targeting the hypervariable region (V4) of bacterial and archaeal 16S rDNA genes was used (Caporaso et al. 2011). The amplicons were sequenced at Research and Testing Laboratory (USA) using the MiSeq platform. The sequences were analyzed as described in Świątczak and Cydzik-Kwiatkowska (2018). The raw sequences were deposited in the NCBI Sequence Read Archive (SRA) as BioProject PRJNA834909.

Statistical analyses

For statistical analysis, Statistica (13.3, StatSoft) was used. For the analysis of COD and NH4-N, results from the whole experimental period were taken. The voltages were analyzed for the seven cycles obtained during the experiment. For analysis of variance, one-way ANOVA was used followed by Tukey’s test (HSD). Molecular data were analyzed using MicrobiomeAnalyst (Dharival et al. 2017, Chong et al. 2020). The number of reads was not normalized, because in the complex microbial communities, bacteria with a low abundance may be of great importance (McMurdie and Holmes 2014).

The Shannon index of diversity is calculated according to the formula (Eq. 2):

where p—the proportion of the entire community made up of species. ln(p)—natural logarithm from p (Shannon 1948).

Results and discussion

Abiotic test of iron release

The amount of iron deposited on the anode was 50 mg Fe2O3, which corresponds to 34.9 mg of iron. The iron release test carried out without the presence of biofilm on the anode showed that only divalent iron was present in the effluent, which indicates the reducing conditions in the measuring vessel. The total amount of iron released from the electrode and removed with wastewater after 18 cycles was 2.46 mg Fe. It means that after the experiment, 7.05% of all iron that was used for the anode modification was removed. However, it should be noted that the calculated amount of iron removed is only an estimate, as the amount of iron released from the abiotic anode may differ from that released from the inhabited anode.

Electricity generation

The deposition of iron (III) oxide on the carbon felt was verified with an electron microscope. Both SEM (Fig. 1 SM) images and EDS analyses (Fig. 2SM) showed that iron oxide was successfully and regularly deposited on the electrode. The degree of iron deposition on the electrode was 99.1%.

In both MFCs, the voltage surges were observed at the beginning of each new cycle (Fig. 2) to on average 150 ± 68 mV and 226 ± 32 mV in the MFCcontrol and MFCFe, respectively. In the MFCcontrol, the voltage gradually decreased to about 57 ± 39 mV after 5 h. In this reactor, a less stable generation of electricity was observed, as evidenced by the standard deviations. The average value of the output voltage from the cell for all cycles was 52 ± 20 mV. In MFCFe, the voltage decreased gradually for about 10 h and then stabilized at about 40–50 mV. The average value of the voltage in the MFCFe was 75 ± 41 mV. The voltages recorded in the MFCFe were significantly higher (ANOVA–Tukey’s HSD post hoc test, p = 0.0006) than in the MFCcontrol (Fig. 3SM). The presence of iron on the anode not only improved electricity generation but also resulted in a more stable reactor operation in comparison with MFCcontrol as can be concluded from the standard deviations. The previous study has shown that in the presence of Fe ions on the surface of the anode, Fe3C is formed, which promotes the adsorption of flavin (Sun et al. 2022). Flavins mediate electron transfer between the substrate and cells. The direct contact of flavin with cell membrane proteins results in a strong direct electron transfer that stimulates mediation and direct electrochemical processes. This positive effect of iron is also observed for complex chemical compounds containing iron. The use of MgFe2O4 as a modifier of stainless steel anode in MFC designed to remove Congo red allowed to obtain 20% higher voltages than in the control reactor with the unmodified anode (Khan et al. 2021).

The power and polarization curves were determined in the stable period of operation of the MFCs (the fourth cycle of voltage measurements). Polarization curves were determined by changing the external resistance in the MFC and registering the voltage generated by the cell. Based on Ohm’s law, the maximum power of the cell was obtained. In MFCcontrol, the maximum power was nearly four times lower (Fig. 3a) than the power obtained in the MFCFe (Fig. 3b). The positive effect of modification of anode with iron was also observed in the studies by Sayed et al. (2020) in which wastewater containing 700 mg COD/L was used as a substrate. In the case of a cell with an unmodified anode, a power density of 40 mW/m2 and a current density of 71 mA/m2 were obtained. After the anode was modified with iron, the power density and the current density doubled.

In our study, the low power densities can be related to the high internal resistances of the MFCs. The internal resistance of the MFCFe was 7088.4 Ω (Fig. 3d) and was 1.25 times higher than in MFCcontrol (Fig. 3c). Internal resistance consists of ohmic losses, activation losses, bacterial metabolic losses, and concentration losses (Logan et al. 2006). A previous study on the effect of iron on the ohmic resistance of MFC has shown that the addition of 4.5 and 9.0 g Fe3O4/L of the substrate fed to MFC reduced the ohmic resistance 1.50 and 1.08 times, compared to the control. On the other hand, at the dose of 18.0 g/L, the resistance was increased because the excess iron negatively affected the adhesion of electrogens (Zheng et al. 2022). Nevertheless, in our research, the MFCFe obtained higher power despite the higher internal resistance.

In general, the use of VFAs produced during fermentation increases the conductivity of the anolyte, which resulted in a reduction in the resistance of ion flow through the membrane and the flow of electrons through the anolyte (Raychaudhuri and Behera 2021). However, an important operating parameter of the MFC is also the concentration of the organics in the reactor. Our previous study has shown that high organic loadings favor membrane clogging and thus obstruct MFC operation (Nosek and Cydzik-Kwiatkowska 2020). Therefore, in our study, the concentration of COD in the MFC at the beginning of the cycle was low and averaged 0.26 ± 0.017 g COD/L. This allowed stable electricity generation without the necessity of often membrane cleaning. This low concentration caused, however, that the electricity obtained in MFCs was lower than in other studies. Chatzikonstantinou et al. (2018) tested the use of food residue biomass in the dual-chamber MFC by applying concentrations of organics as high as 14.0 g COD/L. The highest power density of 29.6 mW/m2 and the corresponding current density of 88 mA/m2 were observed for 6 g COD/L.

COD, VFA, and ammonium removal

COD concentrations in the MFC effluents fluctuated in the initial period of operation, reaching about 170 and 230 mg/L in MFCcontrol and MFCFe, respectively. During the period of stable operation of the MFCs, the concentration of COD in the outflow ranged from 100 to 140 mg/L and the average COD removal efficiency was 54.3 ± 9.8% and 48.8 ± 9.5% for MFCcontrol and MFCFe, respectively. No significant differences were observed in COD removal efficiency between the reactors (Fig. 4SM). The mean concentrations of ammonium in the outflow were 5.4 ± 0.8% and 4.4 ± 0.8% for MFCcontrol and MFCFe, respectively. The ammonium concentrations in the MFCFe outflow were significantly lower (ANOVA–Tukey’s HSD post hoc test, p = 0.0025) than in the MFCcontrol showing a positive effect of iron presence on the ammonium metabolism (Fig. 5SM). In anaerobic environments, in the presence of Fe(III), NH4+ is an electron donor and is oxidized to NO2− by reduction in Fe(III) to Fe(II) according to the formula (Huang and Jaffé, 2015) (Eq. 3).

Zhu et al. (2022) tested the effect of five Fe (III) compounds (Fe2O3, Fe3O4, Fe(OH)3, Fe-citrate, and pyrite) on the anaerobic ammonium oxidation. The highest improvement in ammonium removal efficiency was observed after the addition of 20 mM Fe2O3—the effluent ammonium concentration dropped drastically from 104.79 mg/L to 52.3 mg/L.

The VFA removal efficiency in both reactors was similar and remained at the level of 60.4 ± 16.9% and 50.2 ± 26.3%, in MFCcontrol and MFCFe, respectively. Analysis of the VFA profile in the inflow and outflow of the MFCs revealed that propionic acid was the major component (Fig. 4). Its share in anolyte and MFCFe outflow was 60–65%, while in the outflow from MFCcontrol, its share reached 80%. In the raw wastewater, a high proportion of iso-caproic and enanthic acids (15 and 14%, respectively) was observed, but in the MFC outflows, the proportion of these acids decreased to below 5%. The outflow from MFCFe showed a higher share of valeric acid (26%) compared to the outflow from MFCcontrol. In earlier studies regarding the fermentation of waste activated sludge, along with the increase in the dose of nano-zero valent iron in the feed in fermentation reactors, the share of individual acids in the production of VFA increased, while in the control reactor, acetic acid predominated (98%) (Luo et al. 2014). Our study confirms the positive effect of Fe on the synthesis of medium-chain length VFAs also in MFC reactors. The effluent from MFC reactors with Fe-modified anodes can be a valuable source of carbon for crucial processes in biological wastewater treatment. For example, Janczukowicz et al. (2013) reported that propionic acid and valeric acid can be effectively used for denitrifications of high concentrations of nitrates from wastewater (over 90% efficiency with an initial concentration of 15.2 mg/L). On the other hand, the efficiency of phosphorus removal was lower when propionic and valeric acids were used than when acetic acid was used. Propionic and valeric acids present in MFC effluent can be converted during fermentation to produce polyhydroxyvalerate (PHV) polymer (Carvalheira and Duque 2021).

Biofilm analyses

The anode biofilm from MFCs was subjected to molecular analysis. The total number of readings per both MFC samples and inoculum was over 20 000 (Tab. 1). The numbers of OTU and Shannon index indicate that anode modification with Fe lowered the diversity of anodic biofilm by over 20% in comparison with MFCcontrol. Similar results were obtained in studies, in which Fe (II) was directly added to the feed introduced to MFC reactors. The presence of 100 µM and 200 µM Fe in the anolyte decreased the Shannon index to 3.72, 4.71 in comparison with 5.21 observed in the control MFC (Liu et al. 2017). The lower microbial diversity in the MFCFe biofilm may result from the fact that the presence of iron particles could be toxic to some microorganisms. The toxicity of metal oxides was recently described in a review by Niño-Martínez et al. (2019). The authors indicated that metals and metal oxides with small particle size showed greater antimicrobial activity and that their toxicity may result from both the electrostatic attraction of negatively charged pathogens and positively charged nanoparticles and the release of ions that are toxic to bacteria (Niño-Martínez et al. 2019). Apparently, in the present study, the interactions between the iron(III) oxide particles and microorganisms inhabiting the anode caused some of the microorganisms to disappear from the biofilm as a result of community adaptation.

In the inoculum, unclassified bacteria had the largest share (38%), followed by Methanobacteriales (9%) and Burkholderiales (9%). At the genus level, Methanobacterium sp. (9%), Hydrogenophaga sp. (9%), Candidatus Cloacimonas acidaminovorans (7%), and Metanosaeta sp. (3%) were most abundant, but all these microorganisms disappeared from the anodic biofilm during the experiment. At the anodes in both MFCs, at the end of the study, the most abundant group of microorganisms at the class level were Betaproteobacteria, including Burkholderiales (24% in MFCcontrol and 47% in MFCFe), and Gammaproteobacteria, including Pseudomonadales (12% in MFCcontrol and 27% in MFCFe) (Fig. 5).

The presence of iron on the anode positively affected the abundance of Burkholderiales and Pseudomonadales in the microbiome, which was about two times higher in the MFCFe than in the MFCcontrol (Fig. 5). The higher abundance of Burkholderiales in MFCFe could be due to the fact that some species of this order are metal persistent and participate in the biotransformation of metal oxides (e.g., Fe and Mn) and support biocorrosion (Beech and Gaylarde 1999). On the other hand, the results showed the sensitivity of Rhodocyclales and Clostridiales to the presence of Fe, because the share of those bacteria in MFCFe was 10 and 5 times lower, respectively, than in the control.

The most numerous genus in anodic biofilms was Acidovorax followed by Pseudomonas and Acinetobacter (Fig. 6). Acinetobacter sp. presence was not affected by the presence of Fe on the anode and remains at about 8%, but the abundance of the other two genera was higher on Fe-modified anodes. Acidovorax sp. could utilize different carbon sources such as ethanol, methanol, glucose, or sodium acetate (Nalcaci et al. 2011), and it was observed on biocathodes in MFCs (Sun et al. 2012). Members of the genus Acidovorax are facultative microorganisms, that reduce nitrate and oxidize iron most likely indirectly through the reactive nitrogen species produced during the denitrification process (Klueglein et al. 2015). The study on native rock samples indicated that there was a strong correlation between the abundance of Acidovorax sp. and Fe-containing pyrite. Acidovorax sp. colonies were attached to the rock samples and single cells were surrounded by exopolysaccharides containing ferric iron which may have enhanced the bio-oxidation of metallic sulfides (Escudero et al. 2020). Members of Pseudomonas sp. are also able to reduce Fe(III) and were proven to effectively utilize various hexose and pentose sugars through anode respiration (Ali et al. 2017). Both the ability to utilize various organics and preference toward Fe in the environment decided that in the present study, Acidovorax sp. and Pseudomonas sp. abundances increased twice in MCF with the Fe-modified anode. In the case of Acidovorax sp., it caused that they constituted nearly half of all bacteria in the biofilm on the Fe-modified anode. Members of Pseudomonas sp. hydrolyze sugars and generate VFAs. Previous studies in digesters indicate that the growth of Pseudomonas sp. in biomass was stimulated by the presence of peroxydisulfate and Fe(II) or zero valent iron (Luo et al. 2020).

The presence of iron on the anode significantly increased the number of microorganisms belonging to the genera Brevundimonas, Geothrix, and Leucobacter zeae. The increased presence of Geothrix sp. is advantageous for electricity generation because members of Geothrix sp. can secrete redox-active electron shuttles with separate redox potentials of − 0.2 V and 0.3 V. The compound with the lower midpoint potential was identified as riboflavin and it was responsible for 20 to 30% of electron transfer activity in MFC (Mehta-Kolte and Bond 2012). Better conditions for growth for Geothrix sp. on iron-modified anode can be also explained by the fact that they use iron in their metabolism. Coates et al. (1999) indicated that Geothrix fermentans was able to grow with VFA such as acetate, lactate, propionate, or fumarate as alternative electron donors using Fe(III) as the acceptor of electron and oxidized long-chain FA using Fe(III) as the sole electron acceptor. Brevundimonas sp. is a facultative anaerobic bacterium whose presence has been reported on the biocathode in the presence of Cr(VI) (Romo et al. 2019), but its role in MFC has not yet been elucidated. However, a positive effect of iron on selected metabolic changes in Brevundimonas sp. was observed. In some Brevundimonas strains, the efficiency of H2 production from sugars increased in the reactor to which Fe(II) was dosed (Bao et al. 2013).

The abundance of Zoogloea sp. (Rhodocyclales order) decreased significantly in MFC with the iron-modified anode to below 0.3% in comparison with 9.14% in the control MFC. Earlier studies indicate that in aerobic conditions, Zoogloea sp. may be abundant in biomass despite high iron concentrations in the environment. For example, in the aerobic granules from the reactor operated at the Fe concentration in the wastewater at the level of 6 mg Fe(III)/L, Zoogloea sp. accounted for nearly 70% of all bacteria (Zou et al. 2021). In our research, the decrease in the share of Zoogloea sp. w MFC with modified anode indicates that this genus lost in competition with facultative, Fe-oxidizing bacteria that predominated in the biofilm.

Conclusion

In this study, waste VFA from the fermentation of primary sludge was used in MFC with an iron-modified anode for electricity generation and the structure of the anode microbiome was determined. The study showed that the power obtained from MFCFe was 3.6 times higher than in MFCcontrol, and the efficiency of COD removal was 50%. The main VFA components in the MFC outflows were propionic acid; a high proportion of valeric acid was observed in the outflow from MFCFe. The presence of iron on the anode promoted the presence of electrogens such as Pseudomonas sp. and Geothrix sp. and VFA degrades such as Acidovorax sp. Moreover, the proportion of Brevundimonas sp. and Leucobacter sp. in MFCFe was significantly higher than in MFCcontrol. However, in MFCFe, Zoogloea sp. was replaced by other iron-reducing microorganisms. Research indicates that waste VFA can be effectively used to produce electricity, and the confluence of MFC with AD may give good results in bioenergy in the future.

References

Ali N, Anam M, Yousaf S, Maleeha S, Bangash Z (2017) Characterization of the electric current generation potential of the Pseudomonas aeruginosa using glucose, fructose, and sucrose in double chamber microbial fuel cell. Iran J Biotechnol 15(4):216–223. https://doi.org/10.15171/ijb.1608

APHA (1992) Standard Methods for the Standard Methods for the Examination of Water and Wastewater, 18th ed.; American Public Health Association (APHA), American Water Works Association (AWWA), Water Pollution Control Federation (WPCF): Washington, DC, USA

Bao MD, Su HJ, Tan TW (2013) Dark fermentative bio-hydrogen production: effects of substrate pre-treatment and addition of metal ions or L-cysteine. Fuel 112:38–44. https://doi.org/10.1016/j.fuel.2013.04.063

Beech IB, Gaylarde CC (1999) Recent advances in the study of biocorrosion: an overview. Rev Argent Microbiol 30(3):117–190. https://doi.org/10.1590/S0001-37141999000300001

Bułkowska K, Mikucka W, Pokój T (2021) Enhancement of biogas production from cattle manure using glycerine phase as a co-substrate in anaerobic digestion. Fuel 317:123456. https://doi.org/10.1016/j.fuel.2022.123456

Caporaso JG, Lauber CL, Walters WA, Berg-Lyons D, Lozupone CA, Turnbaugh PJ, Fierer N, Knight R (2011) Global patterns of 16S rRNA diversity at a depth of millions of sequences per sample. Proc Natl Acad Sci USA 108(Supplement 1):4516–4522. https://doi.org/10.1073/pnas.1000080107

Carvalheira M, Duque AF (2021) From food waste to volatile fatty acids towards a circular economy. In: Laranjo M (ed) Fermentation-Processes, Benefits and Risks. IntechOpen, United Kingdom, pp 165–185

Chatzikonstantinou D, Tremouli A, Papadopoulou K, Kanellos G, Lampropoulos I, Lyberatos G (2018) Bioelectricity production from fermentable household waste in a dual-chamber microbial fuel cell. Waste Manag Res 36(11):1037–1042. https://doi.org/10.1177/0734242X18796935

Choi J, Chang HN, Han J-I (2011) Performance of microbial fuel cell with volatile fatty acids from food wastes. Biotechnol Letter 33:705–714. https://doi.org/10.1007/s10529-010-0507-2

Chong J, Liu P, Zhou G, Xia J (2020) Using microbiomeanalyst for comprehensive statistical, functional, and meta-analysis of microbiome data. Nat Protoc 15(3):799–821. https://doi.org/10.1038/s41596-019-0264-1

Christwardana M, Frattini D, Accardo G, Yoon SP, Kwon Y (2018) Optimization of glucose concentration and glucose/yeast ratio in yeast microbial fuel cell using response surface methodology approach. J Power Sources 402:402–412. https://doi.org/10.1016/j.jpowsour.2018.09.068

Coates JD, Ellis DJ, Gaw CV, Lovley DR (1999) Geothrix fermentans gen. nov., sp. Nov., a novel Fe(III)-reducing bacterium from a hydrocarbon-contaminated aquifer. Int J Syst Bacteriol 49(4):1615–1622. https://doi.org/10.1099/00207713-49-4-1615. (PMID: 10555343)

Coelho MAZ, Russo C, Araujo OQF (2000) Optimization of a sequencing batch reactor for biological nitrogen removal. Water Res 34(10):2809–2817. https://doi.org/10.1016/S0043-1354(00)00010-5

Cornejo JA, Lopez C, Babanova S, Santoro C, Artyushkova K, Ista L, Chuler AJ, Atanassov P (2015) Surface modification for enhanced biofilm formation and electron transport in Shewanella anodes. J Electroche Soc 162(9):H597

Costerton JW (2007) The Biofilm Primer. Springer, Berlin-New York, p 70

Dhariwal A, Chong J, Habib S, King I, Agellon LB, Xia J (2017) MicrobiomeAnalyst––a web-based tool for comprehensive statistical, visual and meta-analysis of microbiome data. Nucleic Acids Res 45(W1):W180–W188. https://doi.org/10.1093/nar/gkx295

Dubey A, Malla MA, Kumar A (2022) Role of Next-generation sequencing (NGS) in understanding the microbial diversity. In: Kumar A, Choudhury B, Dayanandan S, Khan ML (eds) Molecular genetics and genomics tools in biodiversity conservation. Springer, Singapore, pp 307–328

Escudero C, del Campo A, Ares JR, Sánchez C, Martínez JM, Gómez F, Amils R (2020) Visualizing microorganism-mineral interaction in the iberian pyrite belt subsurface: the Acidovorax case. Front Microbiol 11:572104. https://doi.org/10.3389/fmicb.2020.572104

Freguia S, The EH, Boon N, Leung KM, Keller J, Rabaey K (2010) Microbial fuel cells operating on mixed fatty acids. Bioresour Technol 101(4):1233–1228. https://doi.org/10.1016/j.biortech.2009.09.054

Ghasemi M, Shahgaldi S, Ismail M, Kim BH, Yaakob Z, Daud WRW (2011) Activated carbon nanofibers as an alternative cathode catalyst to platinum in a two-chamber microbial fuel cell. Int J Hydrog Energy 36(21):13746–13752. https://doi.org/10.1016/j.ijhydene.2011.07.118

Greenman J, Gajda I, You J, Mendis BA, Obata O, Pasternak G, Ieropoulos I (2021) Microbial fuel cells and their electrified biofilms. Biofilm 3:100057. https://doi.org/10.1016/j.bioflm.2021.100057

He J, Xin X, Pei Z, Chen L, Chu Z, Zhao M, Wu X, Li B, Tang X, Xiao X (2021) Microbial profiles associated improving bioelectricity generation from sludge fermentation liquid via microbial fuel cells with adding fruit waste extracts. Bioresour Technol 337:125452. https://doi.org/10.1016/j.biortech.2021.125452

Hou Q, Yang Z, Chen S, Pei H (2020) Using an anaerobic digestion tank as the anodic chamber of an algae-assisted microbial fuel cell to improve energy production from food waste. Water Res 170:115305. https://doi.org/10.1016/j.watres.2019.115305

Huang S, Jaffé PR (2015) Characterization of incubation experiments and development of an enrichment culture capable of ammonium oxidation under iron-reducing conditions. Biogeosciences 12(3):769–779. https://doi.org/10.5194/bg-12-769-2015

Janczukowicz W, Rodziewicz J, Czaplicka K, Kłodowska I, Mielcarek A (2013) The effect of volatile fatty acids (VFAs) on nutrient removal in SBR with biomass adapted to dairy wastewater. J Environ Sci Health Part A 48(7):809–816. https://doi.org/10.1080/10934529.2013.744658

Karn B, Kuiken T, Otto M (2009) Nanotechnology and in situ remediation: a review of the benefits and potential risks. Environ Health Perspect 117(12):1813–1831. https://doi.org/10.1289/ehp.0900793

Kato S, Hashimoto K, Watanabe K (2013) Iron-oxide minerals affect extracellular electron-transfer paths of Geobacter spp. Microbes Environ. https://doi.org/10.1264/jsme2.ME12161

Khan N, Anwer AH, Khan MD, Azam A, Ibhadon A, Khan MZ (2021) Magnesium ferrite spinels as anode modifier for the treatment of Congo red and energy recovery in a single chambered microbial fuel cell. J Hazard Mater 410:124561. https://doi.org/10.1016/j.jhazmat.2020.124561

Klueglein N, Picardal F, Zedda M, Zwiener C, Kappler A (2015) Oxidation of Fe (II)-EDTA by nitrite and by two nitrate-reducing Fe (II)-oxidizing Acidovorax strains. Geobiology 13:198–207. https://doi.org/10.1111/gbi.12125

Liang P, Duan R, Jiang Y, Zhang X, Qiu Y, Huang X (2018) One-year operation of 1000-L modularized microbial fuel cell for municipal wastewater treatment. Water Res 141:1–8. https://doi.org/10.1016/j.watres.2018.04.066

Liu Q, Liu B, Li W, Zhao X, Zuo W, Xing D (2017) Impact of ferrous iron on microbial community of the biofilm in microbial fuel cells. Front Microbiol 8:920. https://doi.org/10.3389/fmicb.2017.00920

Logan BE, Hamelers B, Rozendal R, Schröder U, Keller J, Freguia S, Aelterman P, Verstraetate W, Rabaey K (2006) Microbial fuel cells: methodology and technology. Environ Sci Technol 40(17):5181–5192. https://doi.org/10.1021/es0605016

Luo J, Feng L, Chen Y, Li X, Chen H, Xiao N, Wang D (2014) Stimulating short-chain fatty acids production from waste activated sludge by nano zero-valent iron. J Biotechnol 187:98–105. https://doi.org/10.1016/j.jbiotec.2014.07.444

Luo J, Huang W, Zhu Y, Guo W, Yibing L, Wu L, Zhang Q, Wu Y, Fang F, Cao J (2020) Influences of different iron forms activated peroxydisulfate on volatile fatty acids production during waste activated sludge anaerobic fermentation. Sci Total Environ 705:135878. https://doi.org/10.1016/j.scitotenv.2019.135878

McMurdie PJ, Holmes S (2014) Waste not, want not: why rarefying microbiome data is inadmissible. PLoS Comput Biol 10(4):e1003531. https://doi.org/10.1371/journal.pcbi.1003531

Mehta-Kolte MG, Bond DR (2012) Geothrix fermentans secretes two different redox-active compounds to utilize electron acceptors across a wide range of redox potentials. Appl Environ Microbiol 78(12):6987–6995. https://doi.org/10.1128/AEM.01460-12

Nalcaci OO, Böke N, Ovez B (2011) Potential of the bacterial strain Acidovorax avenae subsp. avenae LMG 17238 and macro algae Gracilaria verrucosa for denitrification. Desalination 274(1–3):44–53. https://doi.org/10.1016/j.desal.2011.01.067

Niño-Martínez N, Salas Orozco MF, Martínez-Castañón GA, Torres Méndez F, Ruiz F (2019) Molecular mechanisms of bacterial resistance to metal and metal oxide nanoparticles. Int J Mol Sci 20(11):2808. https://doi.org/10.3390/ijms20112808

Nosek D, Cydzik-Kwiatkowska A (2020) Microbial structure and energy generation in microbial fuel cells powered with waste anaerobic digestate. Energies 13(18):4712. https://doi.org/10.3390/en13184712

Nosek D, Jachimowicz P, Cydzik-Kwiatkowska A (2020) Anode modification as an alternative approach to improve electricity generation in microbial fuel cells. Energies 13(24):6596. https://doi.org/10.3390/en13246596

Pant D, Arslan D, Van Bogaert G, Gallego YA, De Wever H, Diels L, Vanbroekhoven K (2013) Integrated conversion of food waste diluted with sewage into volatile fatty acids through fermentation and electricity through a fuel cell. Environ Technol 34(13–14):1935–1945. https://doi.org/10.1080/09593330.2013.828763

Raychaudhuri A, Behera M (2021) Enhancement of bioelectricity generation by integrating acidogenic compartment into a dual-chambered microbial fuel cell during rice mill wastewater treatment. Process Biochem 105:19–26. https://doi.org/10.1016/j.procbio.2021.03.003

Romo DMR, Gutiérrez NHH, Pazos JOR, Figueroa LVP, Ordóñez LAO (2019) Bacterial diversity in the Cr (VI) reducing biocathode of a microbial fuel cell with salt bridge. Rev Argent Microbiol 51(2):110–118. https://doi.org/10.1016/j.ram.2018.04.005

Savla N, Anand R, Pandit S, Prasad R (2020) Utilization of nanomaterials as anode modifiers for improving microbial fuel cells performance. J Renew Mater 8(12):1581–1605

Sayed ET, Alawadhi H, Elsaid K, Olabi AG, Adel AM, Bin Tamim ST, Alafranji GHM, Abdelkareem MA (2020) A carbon-cloth anode electroplated with iron nanostructure for microbial fuel cell operated with real wastewater. Sustainability 12(16):6538. https://doi.org/10.3390/su12166538

Schievano A, Colombo A, Cossettini A, Goglio A, D’Ardes V, Trasatti S, Cristiani P (2018) Single-chamber microbial fuel cells as on-line shock-sensors for volatile fatty acids in anaerobic digesters. Waste Manage 71:785–791. https://doi.org/10.3390/su12166538

Shannon CE (1948) A mathematical theory of communication. The Bell Syst Techn J 27(3):379–423

Sun Y, Wei J, Liang P, Huang X (2012) Microbial community analysis in biocathode microbial fuel cells packed with different materials. AMB Expr 2:21. https://doi.org/10.1186/2191-0855-2-21

Sun X, Wu X, Shi Z, Li X, Qian S, Ma Y, Sun W, Guo C, Li CM (2022) Electrospinning iron-doped carbon fiber to simultaneously boost both mediating and direct biocatalysis for high-performance microbial fuel cell. J Power Sources 530:231277. https://doi.org/10.1016/j.jpowsour.2022.231277

Świątczak P, Cydzik-Kwiatkowska A (2018) Performance and microbial characteristics of biomass in a full-scaleaerobic granular sludge wastewater treatment plant. Environ Sci Pollut Res 25:1655–1669. https://doi.org/10.1007/s11356-017-0615-9

Tremouli A, Vlassis T, Antonopoulou G, Lyberatos G (2016) Anaerobic degradation of pure glycerol for electricity generation using a MFC: the effect of substrate concentration. Waste Biomass Valorization 7(6):1339–1347. https://doi.org/10.1016/j.jpowsour.2022.231277

Tripathi B, Pandit S, Sharma A, Chauhan S, Mathuriya AS, Dikshit PK, Gupta PK, Singh RC, Sahni M, Pant K, Singh S (2022) Modification of graphite sheet anode with iron (II, III) oxide-carbon dots for enhancing the performance of microbial fuel cell. Catalysts 12(9):1040. https://doi.org/10.3390/catal12091040

Ullah Z, Zeshan S (2020) Effect of substrate type and concentration on the performance of a double chamber microbial fuel cell. Water Sci Technol 81(7):1336–1344. https://doi.org/10.2166/wst.2019.387

Xin X, Hong J, Liu Y (2019) Insights into microbial community profiles associated with electric energy production in microbial fuel cells fed with food waste hydrolysate. Sci Total Environ 670:50–58. https://doi.org/10.1016/j.scitotenv.2019.03.213

Yu B, Li Y, Feng L (2019) Enhancing the performance of soil microbial fuel cells by using a bentonite-Fe and Fe3O4 modified anode. J Hazard Mater 377:70–77. https://doi.org/10.1016/j.jhazmat.2019.05.052

Zheng X, Hou S, Amanze C, Zeng Z, Zeng W (2022) Enhancing microbial fuel cell performance using anode modified with Fe3O4 nanoparticles. Bioprocess Biosyst Eng 45:877–890. https://doi.org/10.1007/s00449-022-02705-z

Zhou M, Chi M, Luo J, He H, Jin T (2011) An overview of electrode materials in microbial fuel cells. J Power Sources 196(10):4427–4435. https://doi.org/10.1016/j.jpowsour.2011.01.012

Zhu TT, Lai WX, Zhang YB, Liu YW (2022) Feammox process driven anaerobic ammonium removal of wastewater treatment under supplementing Fe (III) compounds. Sci Total Environ 804:149965. https://doi.org/10.1016/j.jcis.2006.09.011

Zou J, Yu F, Chen J, Mannina G, Li Y (2021) Influence of ferric iron dosing on aerobic granular sludge: granule formation, nutrient removal and microbial community. J Chem Technol Biotechnol 96:1277–1284. https://doi.org/10.1002/jctb.6640

Acknowledgements

The study was partially financed by the Minister of Science and Higher Education (Statutory project 29.610.024-110) and the Polish National Science Center (Grant Number 2016/21/B/NZ9/03627). The language correction of the manuscript was financially supported by the Minister of Education and Science under the program entitled “Regional Initiative of Excellence” for the years 2019–2023, Project No. 010/RID/2018/19, amount of funding 12.000.000 PLN.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare.

Human participants or animal

This article does not contain any studies with human participants or animal performed by any of the authors.

Additional information

Editorial responsibility: Samareh Mirkia.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nosek, D., Samsel, O., Pokój, T. et al. Waste volatile fatty acids as a good electron donor in microbial fuel cell with the iron-modified anode. Int. J. Environ. Sci. Technol. 20, 13021–13032 (2023). https://doi.org/10.1007/s13762-023-04850-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-023-04850-8