Abstract

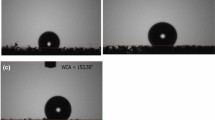

We developed polyurethane foams (PU) filled with eucalyptus charcoal residue (ECR) (5, 10, 20, and 30% by wt) for diesel sorption from seawater. The PU foams were characterized by FTIR, FT-Raman, SEM, density, TGA, contact angle, diesel S500 and S10 sorption, and recyclability. The ECR addition altered PU chemical structure, inducing new chemical bonds and probably altering cross-linking ability of the foams, as indicated by FTIR. FT-Raman spectra of PU-ECR foams showed shifts associated with filler dispersion and interaction with the matrix; besides, its addition decreased the foam pore size and density. The ECR addition did not significantly change the thermal behavior of PU foam and increased hydrophilicity in low ECR content and hydrophobicity in high ECR content samples. Experimental results showed adequate oil sorption capacity, and the optimal amount was 30% (by wt) ECR, which enhanced the diesel sorption from 4.1 and 5.9 g.g−1 to 9.6 and 8.8 g.g−1 for diesel S500 and S10, respectively. The Langmuir sorption isotherm was the best-fitting model to describe oil sorption. Reusability of the PU + 30% ECR was examined through 34 and 39 cycles for diesel S500 and S10, and about 50% of the initial sorption capacity remained at the end. The results indicated the success of developing a sustainable material and demonstrating feasibility in practical applications of PU-ECR foam for spilled oil removal from seawater or treatment of oily effluents.

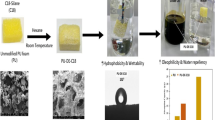

Graphical abstract

Similar content being viewed by others

References

Narayanan P, Ravirajan A, Umasankaran A, Prakash DG, Kumar PS (2018) Theoretical and experimental investigation on the removal of oil spill by selective sorbents. J Ind Eng Chem 63:1–11

Keshawy M, Farag RK, Gaffer A (2020) Egyptian crude oil sorbent based on coated polyurethane foam waste. Egypt J Pet 29:67–73

Pena PGL, Northcross AL, de Lima MAG, de Rêgo RCF (2020) The crude oil spill on the Brazilian coast in 2019: the question of public health emergency. Rep Public Health 36:e00231019

Le QP, Olekhnovich RO, Uspenskaya MV, Vu THN (2021) Study on polyvinyl chloride nanofibers ability for oil spill elimination. Iran Polym J 30:473–483

Keshavarz A, Zilouei H, Abdolmaleki A, Asadinezhad A, Nikkahah AA (2016) Impregnation of polyurethane foam with activated carbon for enhancing oil removal from water. Int J Environ Sci Technol 13:699–710

Tayeb AM, Farouq R, Mohamed OA, Tony MA (2020) Oil spill clean-up using combined sorbents: a comparative investigation and design aspects. Int J Environ Anal Chem 100:311–323

Ge J, Zhao HY, Zhu HW, Huang J, Shi L-A, Yu S-H (2016) Advanced sorbents for oil-spill cleanup: recent advances and future perspectives. Adv Mater 28:10459–10490

Saleem J, Adil Riaz M, Gordon M (2018) Oil sorbents from plastic wastes and polymers: a review. J Hazard Mater 341:424–437

Góes MM, Garcia JC, Rosa SLF, Mauricio MR, Carvalho GM (2020) New magnetic polyurethane hybrid composite for oil sorption. Plast Rubber Compos 49:10–17

Hoang AT, Bui XL, Pham XD (2018) A novel investigation of oil and heavy metal adsorption capacity from as-fabricated adsorbent based on agricultural by-product and porous polymer. Energy Sourc Part A: Recov Util Environ Eff 40:929–939

Navarathna CM, Bombuwala Dewage N, Keeton C, Pennisson J, Henderson R, Lashley B, Zhang X, Hassan EB, Perez F, Mohan D, Pittman CU Jr, Mlsna T (2020) Biochar adsorbents with enhanced hydrophobicity for oil spill removal. ACS Appl Mater Interf 12:9248–9260

Pagnucco R, Phillips ML (2018) Comparative effectiveness of natural by-products and synthetic sorbents in oil spill booms. J Environ Manage 225:10–16

Santos OSH, da Silva MC, Yoshida MI (2017) Synthesis and performance of different polyurethane foams as oil sorbents. J Appl Polym Sci 134:1–8

Bowen HJM (1970) Absorption by polyurethane foams; new method of separation. J Chem Soc A: Inorg, Phys, Theor 1082–1085

Lee A, Deng Y (2015) Green polyurethane from lignin and soybean oil through non-isocyanate reactions. Eur Polym J 63:67–73

Oribayo O, Feng X, Rempel GL, Pan Q (2017) Synthesis of lignin-based polyurethane/graphene oxide foam and its application as an absorbent for oil spill clean-ups and recovery. Chem Eng J 323:191–202

Gandara M, Mulinari DR, Monticeli FM, Capri MR (2020) Sugarcane bagasse fibers reinforced in polyurethane for sorption of vegetal oil. J Nat Fibers 1–12

Khalilifard M, Javadian S (2020) Magnetic superhydrophobic polyurethane sponge loaded with Fe3O4@oleic acid@graphene oxide as high performance adsorbent oil from water. Chem Eng J 408:127369

Hoang PH, Hoang AT, Chung NH, Dien LQ, Nguyen XP, Pham XD (2018) The efficient lignocellulose-based sorbent for oil spill treatment from polyurethane and agricultural residue of Vietnam. Energy Sourc Part A: Recover Util Environ Eff 40:312–319

Santos OSH, Coelho da Silva M, Silva VR, Mussel WN, Yoshida MI (2017) Polyurethane foam impregnated with lignin as a filler for the removal of crude oil from contaminated water. J Hazard Mater 324:406–413

Abdollahi M, Hosseini A (2014) Charcoal. Encycl Toxicol Third Ed 1:779–781

Raj Somera L, Cuazon R, Kenneth Cruz J, Joy Diaz L (2019) Kinetics and isotherms studies of the adsorption of Hg(II) onto iron modified montmorillonite/polycaprolactone nanofiber membrane. IOP Conf Ser: Mater Sci Eng 540:1–8

Maia LS, da Silva AIC, Carneiro ES, Monticelli FM, Pinhati FR, Mulinari DR (2021) Activated carbon from palm fibres used as an adsorbent for methylene blue removal. J Polym Environ 29:1162

Balarak D, Bandani F, Shehu Z, Ahmed NJ (2020) Adsorption properties of thermally treated rice husk for removal of sulfamethazine antibiotic from pharmaceutical wastewater. J Pharm Res Int 32:84–92

Tan IAW, Ahmad AL, Hameed BH (2009) Adsorption isotherms, kinetics, thermodynamics and desorption studies of 2,4,6-trichlorophenol on oil palm empty fruit bunch-based activated carbon. J Hazard Mater 164:473–482

Keshavarz A, Zilouei H, Abdolmaleki A, Asadinezhad A (2015) Enhancing oil removal from water by immobilizing multi-wall carbon nanotubes on the surface of polyurethane foam. J Environ Manage 157:279–286

Stanzione M, Oliviero M, Cocca M, Errico ME, Gentile G, Avella M, Lavorgna M, Buonocore GG, Verdolotti L (2020) Tuning of polyurethane foam mechanical and thermal properties using ball-milled cellulose. Carbohydr Polym 231:115772

Monir MU, Abd Aziz A, Kristanti RA, Yousuf A (2020) Syngas production from co-gasification of forest residue and charcoal in a pilot scale Downdraft reactor. Waste Biomass Valorization 11:635–651

Martín-Alberca C, Zapata F, Carrascosa H, Ortega-Ojeda FE, García-Ruiz C (2016) Study of consumer fireworks post-blast residues by ATR-FTIR. Talanta 149:257–265

Trovati G, Sanches EA, Neto SC, Mascarenhas YP, Chierice GO (2010) Characterization of polyurethane resins by FTIR, TGA, and XRD. J Appl Polym Sci 115:263–268

Włodarczyk D, Piszczyk Ł, Strankowska J (2016) Polyurethane nanocomposites containing reduced graphene oxide, FTIR, Raman, and XRD studies. J Spectrosc 2016(7520741):7520741

George S (2001) Infrared and Raman characteristic group frequencies: tables and charts. Wiley, Chichester

Cao H, Qi F, Liu R, Wang F, Zhang C, Zhang X, Chai Y, Zhai L (2017) The influence of hydrogen bonding on N-methyldiethanolamine-extended polyurethane solid-solid phase change materials for energy storage. RSC Adv 7:11244–11252

Wolinska-Grabczy A, Kaczmarczyk B, Jankowski A (2008) Investigations of hydrogen bonding in the poly(urethane-urea)-based membrane materials by using FTIR spectroscopy. Polish J Chem Technol 10:53–56

Wang FC, Feve M, Lam TM, Pascault J-P (1994) FTIR analysis of hydrogen bonding in amorphous linear aromatic polyurethanes. II. Influence of styrene solvent. J Polym Sci Part B Polym Phys 32:1315–1320

Kerr T, Duncan K, Myers L (2013) Post fire materials identification by micro-Raman spectroscopy and principal components analysis. J Anal Appl Pyrolys 102:103–113

Bolcu C, Vlase G, Vlase T, Albu P, Nicolae D, Sisu E (2013) Thermal behavior of some polyurethanes reticulated by aminated maltose. J Therm Anal Calorim 113:1409–1414

Gupta TK, Singh BP, Tripathi RK, Dhakate SR, Singh VN, Mathur RB (2015) Superior nano-mechanical properties of reduced graphene oxide reinforced polyurethane composites. RSC Adv 5:16921–16930

Li H, Liu L, Yang F (2012) Hydrophobic modification of polyurethane foam for oil spill cleanup. Mar Pollut Bull 64:1648–1653

Szycher M (2013) Szycher’s handbook of polyurethanes, 2nd edn. CRC Press

Daussin BR, Elwell M, Van der Wal HR, Berthevas P, Brown M, Casati F, Farrissey W, Fosnaugh J, de Genova R, Herrington R, Hicks J, Hinze K, Hock K, Hunter D, Jeng L, Laycock D, Lidy W, Mispreuve H, Moore R, Nafziger L, Norton M, Parrish D, Priester R, Skaggs K, Stahler L, Sweet F, Thomas R, Turner R, Wiltz G, Woods T, Christenson CP, Schrock AK (2004) Flexible polyurethane foams. In: Lee S, Ramesh N (eds) Polymeric foams. CRC Press

Sharma R, Sheth PN (2018) Multi reaction apparent kinetic scheme for the pyrolysis of large size biomass particles using macro-TGA. Energy 151:1007–1017

Souza AG, De Lima GF, Rodrigues RCLB, Cesarino I, Leão AL, Rosa DS (2021) A new approach for conversion of eucalyptus lignocellulosic biomass into cellulose nanostructures: a method that can be applied in industry. J Nat Fiber 18:1–11

Askari F, Barikani M, Barmar M, Shokrolahi F, Vafayan M (2015) Study of thermal stability and degradation kinetics of polyurethane–ureas by thermogravimetry. Iran Polym J 24:783–789

Van Den Berg MEH, Kuster S, Windhab EJ, Adamcik J, Mezzenga R, Geue T, Sagis LMC, Fischer P (2018) Modifying the contact angle of anisotropic cellulose nanocrystals: effect on interfacial rheology and structure. Langmuir 34:10932–10942

Singh S, Jelinek R (2020) Solar-mediated oil-spill cleanup by a carbon dot-polyurethane sponge. Carbon N Y 160:196–203

Anju M, Renuka NK (2020) Magnetically actuated graphene coated polyurethane foam as potential sorbent for oils and organics. Arab J Chem 13:1752–1762

Amorim FV, Padilha RJR, Vinhas GM, Luiz MR, Souza NC, Almeida YMB (2021) Development of hydrophobic polyurethane/castor oil biocomposites with agroindustrial residues for sorption of oils and organic solvents. J Colloid Interf Sci 581:442–454

Huang J, Yan Z (2018) Adsorption mechanism of oil by resilient graphene aerogels from oil-water emulsion. Langmuir 34:1890–1898

Eze SI, Akpomie KG, Ezeofor CC, Osunkunle AA, Maduekwe OB, Okenyeka OU (2019) Isotherm and kinetic evaluation of Dialium guineense seed husk and its modified derivative as efficient sorbent for crude oil polluted water treatment. Water Conserv Sci Eng 4:21–31

Martins LS, Zanini NC, Maia LS, Souza AG, Barbosa RFS, Rosa DS, Mulinari DR (2021) Crude oil and S500 diesel removal from seawater by polyurethane composites reinforced with palm fiber residues. Chemosphere 267:129288

Martins LS, Maciel F, Mulinari DR (2020) Influence of the granulometry and fiber content of palm residues on the diesel S-10 oil sorption in polyurethane/palm fiber biocomposites. Result Mater 8:100143

Visco A, Quattrocchi A, Nocita D, Montanini R, Pistone A (2021) Polyurethane foams loaded with carbon nanofibers for oil spill recovery: mechanical properties under fatigue conditions and selective absorption in oil/water mixtures. Nanomaterials 11:735

Piotrowska-Kirschling A, Szelągowska-Rudzka K, Karczewski J, Brzeska J (2021) Application of shrimp waste for the synthesis of polyurethane–chitosan materials with potential use in sorption of oil micro-spills in water treatment. Sustainability 13:5098

Ren L, Qiu Z, Wang Z, Yang D, Zhou D, Zhang T (2019) Preparation of biomass carbon/polyurethane foams for selective oil/water absorption. J Dispers Sci Technol 41:1872–1878

Acknowledgements

This research was funded by Fundação de Amparo à Pesquisa do Estado do Rio de Janeiro (E-26/260.026/2018 and E-26/010.001800/2015), Fundação de Amparo à Pesquisa do Estado de São Paulo (2018/11277-7, 2018/25512-8, and 2013/07793-6), and Conselho Nacional de Desenvolvimento Científico e Tecnológico (305819/2017-8 and 407822/2018-6; INCT-INFO). The authors thank the CAPES (Code 001), UFABC, Multiuser Central Facilities (UFABC), TA Instruments, and REVALORES Strategic Unit.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Maia, L.S., Zanini, N.C., de Souza, A.G. et al. Effective oil spill cleaned up with environmentally friendly foams filled with eucalyptus charcoal residue. Iran Polym J 31, 383–398 (2022). https://doi.org/10.1007/s13726-021-00997-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-021-00997-8