Abstract

Epoxies offer many advantages in structural applications compared with other adhesives. However, their highly cross-linked structure leads to brittle materials, with low toughness and poor impact resistance. Usually, core–shell and reactive liquid rubbers are incorporated into industrial epoxy adhesives to overcome these limitations. Although important studies have been published in this field, it still lacks in the literature a comprehensive comparison between the effects of incorporating each type of rubber into the same epoxy matrix. Additionally, these reports usually focus on the behavior of the adhesive bulk, neglecting the effect of tougheners inclusion on the adhesively bonded joints fracture energy. Aiming to fill this gap, in this work, we prepared epoxy adhesives reinforced with core–shell rubber particles (CSR) or with a reactive liquid rubber (carboxyl-terminated polybutadiene-co-acrylonitrile—CTBN), at constant rubber contents in both formulations. Then, the toughened adhesives were investigated with respect to their thermomechanical behavior, as well as their adhesion performance. Bulk properties were characterized by uniaxial tensile tests and dynamic mechanical analysis, while the practical adhesion was investigated with single-lap shear and peeling tests. Finally, we assessed the adhesively bonded joints fracture energy in a customized experiment. The results showed that CTBN incorporation improved the adhesively bonded joints fracture energy by almost 816%, while CSR increased it by 550%. However, CTBN decreased the Tg of epoxy adhesives from 160 up to 130 °C, while CSR incorporation revealed no significant influence on Tg. Practical adhesion was increased by incorporation of both tougheners. In short, CTBN-containing samples revealed to be more efficient, even in smaller concentrations.

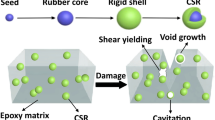

Graphic abstract

Similar content being viewed by others

Availability of data and material

All the raw data and supporting materials cannot be provided.

Code availability

Not applicable.

References

Bagheri R, Marouf BT, Pearson RA (2009) Rubber-toughened epoxies: a critical review. Polym Rev 49:201–225

Baldan A (2012) Adhesion phenomena in bonded joints. Int J Adhes Adhes 38:95–116

Gouveia JR, Garcia GES, Antonino LD, Tavares LB, dos Santos DJ (2020) Epoxidation of kraft lignin as a tool for improving the mechanical properties of epoxy adhesive. Molecules 25:2513

Jin FL, Li X, Park SJ (2015) Synthesis and application of epoxy resins: a review. J Ind Eng Chem 29:1–11

Quan D, Ivankovic A (2015) Effect of core-shell rubber (CSR) nano-particles on mechanical properties and fracture toughness of an epoxy polymer. Polymer 66:16–28

Akbari R, Beheshty MH, Shervin M (2013) Toughening of dicyandiamide-cured DGEBA-based epoxy resins by CTBN liquid rubber. Iran Polym J 22:313–324

Chae GS, Park HW, Lee JH, Shin S (2020) Comparative study on the impact wedge-peel performance of epoxy-based structural adhesives modified with different toughening agents. Polymers 12:1549

Baek D, Sim KB, Kim HJ (2021) Mechanical characterization of core-shell rubber/epoxy polymers for automotive structural adhesives as a function of operating temperature. Polymers 13:734

Giannakopoulos G, Masania K, Taylor AC (2011) Toughening of epoxy using core-shell particles. J Mater Sci 46:327–338

Hashemi-Nasirabad M, Salehi-Mobarakeh H, Mahdavian A (2018) Improvement of UF/fiberglass mat properties used in roofing shingles through emulsion polymers and nanoclay addition. Iran Polym J 27:67–76

Sanei M, Mahdavian AR, Torabi S, Salehi-Mobarakeh H (2017) Efficient modification of nanosilica particles in preparation of anti-scratch transparent polyacrylic films through miniemulsion polymerization. Polym Bull 74:1879–1898

Gharieh A, Mahdavian AR, Salehi-Mobarakeh H (2014) Preparation of core-shell impact modifier particles for PVC with nanometric shell thickness through seeded emulsion polymerization. Iran Polym J 23:27–35

Quan D, Carolan D, Rouge C, Murphy N, Ivankovic A (2017) Carbon nanotubes and core-shell rubber nanoparticles modified structural epoxy adhesives. J Mater Sci 52:4493–4508

Chaudhary S, Iqbal N, Mangla V, Kumar D, Roy PK (2015) Strain rate sensitivity of toughened epoxy. Iran Polym J 24:871–881

Chikhi N, Fellahi S, Bakar M (2002) Modification of epoxy resin using reactive liquid (ATBN) rubber. Eur Polym J 38:251–264

Januszewski R, Dutkiewicz M, Nowicki M, Szołyga M, Kownacki I (2021) Synthesis and properties of epoxy resin modified with novel reactive liquid rubber-based systems. Ind Eng Chem Res 60:2178–2186

Zhou W, Cai J (2012) Mechanical and dielectric properties of epoxy resin modified using reactive liquid rubber (HTPB). J Appl Polym Sci 124:4346–4351

Zhao K, Song XX, Liang CS, Wang J, Xu SA (2015) Morphology and properties of nanostructured epoxy blends toughened with epoxidized carboxyl-terminated liquid rubber. Iran Polym J 24:425–435

Achary PS, Latha PB, Ramaswamy R (1990) Room temperature curing of CTBN-toughened epoxy adhesive with elevated temperature service capability. J Appl Polym Sci 41:151–162

Tripathi G, Srivastava D (2007) Effect of carboxyl-terminated poly(butadiene-co-acrylonitrile) (CTBN) concentration on thermal and mechanical properties of binary blends of diglycidyl ether of bisphenol-A (DGEBA) epoxy resin. Mater Sci Eng A 443:262–269

Jianwen Z, Yizhou H, Hong W, Yi H (2019) Practical technology of toughening epoxy resin: influence of toughening agents on mechanical and heat properties. Int J Ind Manuf Syst Eng. https://doi.org/10.11648/j.ijimse.20190402.11

Tripathi G, Srivastava D (2008) Studies on the physico-mechanical and thermal characteristics of blends of DGEBA epoxy, 3,4 epoxy cyclohexylmethyl, 3′,4′-epoxycylohexane carboxylate and carboxyl terminated butadiene co-acrylonitrile (CTBN). Mater Sci Eng A 496:483–493

Bartlet P, Pascault JP, Sautereau H (1985) Relationships between structure and mechanical properties of rubber-modified epoxy networks cure with dicyanodiamide hardener. J Appl Polym Sci 30:2955–2966

Petrie EM (2006) Epoxy adhesive formulations. Mcgraw-Hill, New York

Parameswaranpillai J, Hameed N, Pionteck J, Woo EM (2017) Handbook of epoxy blends. Springer, Cham

Ning N, Liu W, Hu Q, Zhang L, Jiang Q, Qiu Y, Wei Y (2020) Impressive epoxy toughening by a structure-engineered core/shell polymer nanoparticle. Compos Sci Technol 199:108364

Wang J, Xue Z, Li Y, Wang Y, Zhong WH, Yang X (2018) Synergistically effects of copolymer and core-shell particles for toughening epoxy. Polymer 140:39–46

Jianwen Z, Yizhou H, Hong W, Yi H (2019) Practical technology of toughening epoxy resin: influence of toughening agents on mechanical and heat properties. Int J Ind Manuf Syst Eng 4:19

Thomas R, Durix S, Sinturel C, Omonov T, Goossens S, Groeninckx G, Moldenaers P, Thomas S (2007) Cure kinetics, morphology and miscibility of modified DGEBA-based epoxy resin:effects of a liquid rubber inclusion. Polymer 48:1695–1710

Siebert AR (1984). In: Riew CK, Gillham JK (eds) Rubber-modified thermoset resins. American Chemical Society, Washington

Jingqiang S, Yafeng Z, Jindong Q, Jianzheng K (2004) Core-shell particles with an acrylate polyurethane core as tougheners for epoxy resins. J Mater Sci 39:6383–6384

da Silva LFM, Rodrigues TNSS, Figueiredo MAV, de Moura MFSF, Chousal JAG (2006) Effect of adhesive type and thickness on the lap shear strength. J Adhes 82:1091–1115

da Silva LFM, Öchsner A, Adams R (2011) Handbook of Adhesion technology. Springer, Berlin

Da Silva LFM, Adams RD (2005) Measurement of the mechanical properties of structural adhesives in tension and shear over a wide range of temperatures. J Adhes Sci Technol 19:109–141

Dos Santos DJ, Batalha GF (2014) Failure criterion for adhesively bonded joints using Arcan’s experimental method. Polimeros 24:441–445

Possart W (2006) Adhesion: current research and applications. Wiley-VCH, Weinheim

Keith Kiew C, Siebert AR, Smith RW, Fernando M, Kinloch AJ (1996) Toughened epoxy resins: preformed particles as tougheners for adhesives and matrices. Adv Chem Ser 252:33–44

Gouri C, Ramaswamy R, Ninan KN (2000) Studies on the adhesive properties of solid elastomer-modified novolac epoxy resin. Int J Adhes Adhes 20:305–314

Awang Ngah S, Taylor AC (2016) Toughening performance of glass fibre composites with core-shell rubber and silica nanoparticle modified matrices. Compos Part A Appl Sci Manuf 80:292–303

Dadian A, Rahnama S, Zolfaghari A (2020) Experimental study of the CTBN effect on mechanical properties and mode I and II fracture toughness of a new epoxy resin. J Adhes Sci Technol 34:2389–2404

Ochi M, Mimura K, Motobe H (1994) Toughening mechanism of epoxy modified with CTBN elastomer adhesive joints. J Adhes Sci Technol 8:223–233

Ratna D, Banthia AK (2000) Toughened epoxy adhesive modified with acrylate based liquid rubber. Polym Int 49:281–287

Acknowledgements

This work was supported by UFABC’s Material Science and Engineering and Nanoscience and Advanced Materials Programs and funded by the Sao Paulo Research Foundation–FAPESP (grant number 2019/05460-6) and by Conselho Nacional de Desenvolvimento Cientifico e Tecnologico–CNPq. The authors also would like to thank the Multiuser Central Facilities (UFABC) for the experimental support.

Funding

This work was supported by the Fundação de Amparo à Pesquisa do Estado de São Paulo [2019/05460-6] and by the Conselho Nacional de Desenvolvimento Científico e Tecnológico CNPq (grant number 140216/2020-0).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Antonino, L.D., Garcia, G.E.S., de Oliveira Viani, C. et al. Effects of core–shell and reactive liquid rubbers incorporation on practical adhesion and fracture energy of epoxy adhesives. Iran Polym J 30, 1329–1338 (2021). https://doi.org/10.1007/s13726-021-00976-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-021-00976-z