Abstract

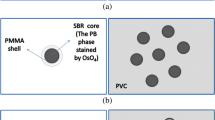

The improvement in toughness of rigid polymers like poly(vinyl chloride) (PVC) has been of great interest for developing their applications. This could be provided by designing impact modifiers which could be blended with the polymeric matrix. Here, core–shell type impact modifier particles with different glass transition temperatures of the shell and specifically, with nanometric shell thickness were prepared through seeded emulsion polymerization. The core consisted of polybutadiene particles and the shell was made of poly(methylmethacrylate-co-butyl acrylate) that was grafted onto the surface of the seed particles. The polymerization reaction was optimized and the resulting latex particles were well characterized by several techniques such as DSC, DLS, SEM, and TEM. It was found that the core–shell particles have diameters of about 350–360 nm, including the shell with thickness of almost 20–30 nm and glass transition temperatures ranging between 70 and 120 °C. The prepared particles were blended with PVC and the corresponding impact strengths of the moldings were measured by means of Izod impact test. The impact results revealed that by decreasing T g of the shell in impact modifier particles, the impact resistance of the molded sheets increased remarkably. Also the brittle–ductile transition temperatures (BDTT) of the prepared blends were studied and an increase in BDTT was found with lowering T g of the shell.

Similar content being viewed by others

References

Breuer H, Haaf F, Stabenow J (1997) Stress whitening and yielding mechanism of rubber-modified PVC. J Macromol Sci Part B Phys 14:387–417

Ahmadi M, Moghbeli MR, Shokrieh MM (2012) Shrinkage and mechanical properties of unsaturated polyester reinforced with clay and core–shell rubber. Iran Polym J 21:855–868

Zhou C, Chen M, Tan ZY, Sun SL, Ao YH, Zhang MY, Yang HD, Zhang HX (2006) The influence of arrangement of St in MBS on the properties of PVC/MBS blends. Eur Polym J 42:1811–1818

Chen X, Wang J, Shen J (2005) Effect of UV-irradiation on poly(vinyl chloride) modified by methyl methacrylate–butadiene–styrene copolymer. Polym Degrad Stab 87:527–533

Si QB, Zhou C, Yang HD, Zhang HX (2007) Toughening of polyvinylchloride by core–shell rubber particles: influence of the internal structure of core–shell particles. Eur Polym J 43:3060–3067

Scott G, Tahan M (1977) The photo-oxidation of PVC and impact modified PVC chemical changes. Eur Polym J 13:989–996

Rabinovic IS (1983) The all-acrylic weatherable impact modifier for PVC. J Vinyl Technol 5:179–182

Zhang Z, Chen S, Zhang J, Li B, Jin X (2010) Influence of chlorinated polyethylene on poly(vinyl chloride)/poly(α-methylstyrene–acrylonitrile) blends: mechanical properties, morphology and thermal properties. Polym Test 29:995–1001

Zhang Z, Chen S, Zhang J (2011) Synergistic toughening effect of chlorinated polyethylene and ethylene–vinyl acetate copolymer on the poly(vinyl chloride)/poly(α-methylstyrene–acrylonitrile) blends via compatibilization. Polym Test 30:534–542

Hardt D (1969) Elasticisation and plasticisation of PVC with ethylene–vinyl acetate copolymers. Brit Polym J 1:225–232

Liu Z, Zhu X, Wu L, Li Y, Qi Z, Choy C, Wang F (2001) Effects of interfacial adhesion on the rubber toughening of poly(vinyl chloride). Part 1. Impact tests. Polymer 42:737–746

Wang Q, Zhang X, Liu S, Gui H, Lai J, Liu Y, Gao J, Huang F, Song Z, Tan B, Qiao J (2005) Ultrafine full-vulcanized powdered rubbers/PVC compounds with higher toughness and higher heat resistance. Polymer 46:10614–10617

Liu ZH, Wu LX, Kwok KW, Zhu XG, Qi ZN, Choy CL, Wang FS (2001) Effects of interfacial adhesion on the rubber toughening of poly(vinyl chloride). Part 2. Low-speed tensile tests. Polymer 42:1719–1724

Wu G, Zhao J, Shi H, Zhang H (2004) The influence of core–shell structured modifiers on the toughness of poly(vinyl chloride). Eur Polym J 40:2451–2456

Wu G, Yang F, Tan Z, Ge H, Zhang H (2012) Synthesis of montmorillonite-modified acrylic impact modifiers and toughening of poly(vinyl chloride). Iran Polym J 21:793–798

Morgan LW (1982) Multifeed emulsion polymers: the effects of monomer feed sequence and the use of seed emulsion polymers. J Appl Polym Sci 27:2033–2042

Lee SM, Lee SJ, Kim JH, Cheong IW (2011) Synthesis of polystyrene/polythiophene core/shell nanoparticles by dual initiation. Polymer 52:4227–4234

Anderson CD, Daniels ES (2003) Emulsion polymerization and latex applications. Rapra Review Report, New York

Hirose M, Kadowaki F, Zhou J (1997) The structure and properties of core–shell type acrylic-polyurethane hybrid aqueous emulsions. Prog Org Coat 31:157–169

Khan AK, Ray BC, Dolui SK (2008) Preparation of core–shell emulsion polymer and optimization of shell composition with respect to opacity of paint film. Prog Org Coat 62:65–70

Cui X, Zhong S, Wang H (2007) Emulsifier-free core–shell polyacrylate latex nanoparticles containing fluorine and silicon in shell. Polymer 48:7241–7248

Mu Y, Qiu T, Li X (2009) Monodisperse and multilayer core–shell latex via surface cross-linking emulsion polymerization. Mater Lett 63:1614–1617

Zhao J, Yuan H, Pan Z (1994) Grafting mechanism in SBR–St–MMA core–shell emulsion copolymerization. J Appl Polym Sci 53:1447–1452

Todo M, Takahashi J, Watanabe H, Nakamoto J, Arakawa K (2006) Effect of loading-rate on fracture micromechanism of methylmethacrylate–butadiene–styrene polymer blend. Polymer 47:4824–4830

Smith LSA, Schmitz V (1988) The effect of water on the glass transition temperature of poly(methyl methacrylate). Polymer 29:1871–1878

Lu WL, Huang CY, Roan ML (2003) Effect of plasma treatment on the degree of AAm grafting for high-density polyethylene. Surf Coat Technol 172:251–261

White SR, Sottos NR, Geubelle PH, Moore JS, Kessler MR, Sriram SR, Brown EN, Viswanathan S (2001) Autonomic healing of polymer composites. Nature 409:794–797

Fu Y, Song H, Zhou C, Sun S, Zhang H (2013) Influence of core–shell particles structure on the morphology and brittle-ductile transition of PBT/ABS-g-GMA blends. Polym Compos 34:15–21

Acknowledgments

We wish to express our gratitude to Iran Polymer and Petrochemical Institute (IPPI) for financial support of this work (Grant # 24761156). We would like also to thank Mrs. Khosravi for taking SEM images.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gharieh, A., Mahdavian, A.R. & Salehi-Mobarakeh, H. Preparation of core–shell impact modifier particles for PVC with nanometric shell thickness through seeded emulsion polymerization. Iran Polym J 23, 27–35 (2014). https://doi.org/10.1007/s13726-013-0196-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-013-0196-5