Abstract

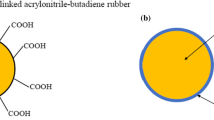

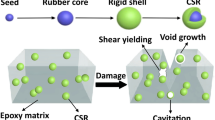

An epoxy resin, cured using an anhydride hardener, has been modified by the addition of preformed core–shell rubber (CSR) particles which were approximately 100 or 300 nm in diameter. The glass transition temperature, T g, of the cured epoxy polymer was 145 °C. Microscopy showed that the CSR particles were well dispersed through the epoxy matrix. The Young’s modulus and tensile strength were reduced, and the glass transition temperature of the epoxy was unchanged by the addition of the CSR particles. The fracture energy increased from 77 J/m2 for the unmodified epoxy to 840 J/m2 for the epoxy with 15 wt% of 100-nm diameter CSR particles. The measured fracture energies were compared to those using a similar amount of carboxyl-terminated butadiene-acrylonitrile (CTBN) rubber. The CTBN particles provided a larger toughening effect when compared to CSR particles, but reduced the glass transition temperature of the epoxy. For the CSR-modified epoxies, the toughening mechanisms were identified using scanning electron microscopy of the fracture surfaces. Debonding of the cores of the CSR particles from the shells was observed, accompanied by plastic void growth of the epoxy and shell. The observed mechanisms of shear band yielding and plastic void growth were modelled using the Hsieh et al. approach (J Mater Sci 45:1193–1210). Excellent agreement between the experimental and the predicted fracture energies was found. This analysis showed that the major toughening mechanism, responsible for 80–90% of the increase in fracture energy, was the plastic void growth.

Similar content being viewed by others

References

Drake RS, Siebert AR (1975) SAMPE Q 6:11

Kinloch AJ, Shaw SJ, Tod DA, Hunston DL (1983) Polymer 24:1341. doi:10.1016/0032-3861(83)90070-8

Kinloch AJ (2003) MRS Bull 28:445

Rowe EH, Siebert AR, Drake RS (1970) Mod Plast 47:110

Pearson RA, Yee AF (1986) J Mater Sci 21:2475. doi:10.1007/BF01114294

Pascault JP, Williams RJJ (1999) In: Paul DR, Bucknall CB (eds) Polymer blends, volume 1: formulation. Wiley, New York

Bucknall CB, Partridge IK (1983) Polymer 24:639. doi:10.1016/0032-3861(83)90120-9

Kinloch AJ, Yuen ML, Jenkins SD (1994) J Mater Sci 29:3781. doi:10.1007/BF00357349

Day RJ, Lovell PA, Pierre D (1997) Polym Int 44:288

Qian JY, Pearson RA, Dimonie VL, Elaasser MS (1995) J Appl Polym Sci 58:439

Shen J, Zhang Y, Qiu J, Kuang J (2004) J Mater Sci 39:6383. doi:10.1023/B:JMSC.0000043763.65417.4f

Pearson RA, Yee AF (1991) J Mater Sci 26:3828. doi:10.1007/BF01184979

Lin K-F, Shieh Y-D (1998) J Appl Polym Sci 70:2313

Becu-Longuet L, Bonnet A, Pichot C, Sautereau H, Maazouz A (1999) J Appl Polym Sci 72:849

Day RJ, Lovell PA, Wazzan AA (2001) Compos Sci Technol 61:41

Hayes BS, Seferis JC (2001) Polym Compos 22:451

Young RJ, Beaumont PWR (1975) J Mater Sci 10:1343. doi:10.1007/BF00540824

Spanoudakis J, Young RJ (1984) J Mater Sci 19:473. doi:10.1007/BF00553571

Amdouni N, Sautereau H, Gerard JF (1992) J Appl Polym Sci 46:1723

Lee J, Yee AF (2000) Polymer 41:8363

Kawaguchi T, Pearson RA (2003) Polymer 44:4239

Kitey R, Tippur HV (2005) Acta Mater 53:1167

Kinloch AJ, Lee JH, Taylor AC, Sprenger S, Eger C, Egan D (2003) J Adhes 79:867

Kinloch AJ, Mohammed RD, Taylor AC, Eger C, Sprenger S, Egan D (2005) J Mater Sci 40:5083. doi:10.1007/s10853-005-1716-2

Ragosta G, Abbate M, Musto P, Scarinzi G, Mascia L (2005) Polymer 46:10506

Zhang H, Zhang Z, Friedrich K, Eger C (2006) Acta Mater 54:1833

Kinloch AJ, Masania K, Taylor AC, Sprenger S, Egan D (2008) J Mater Sci 43:1151. doi:10.1007/s10853-007-2390-3

Sober DJ (2008) Personal Communication. Kaneka, Houston

ISO-527–1 (1993) Plastics—determination of tensile properties—part 1: general principles. ISO, Geneva

ISO-527–2 (1996) Plastics—determination of tensile properties—part 2: test conditions for moulding and extrusion plastics. ISO, Geneva

ISO-13586 (2000) Plastics—determination of fracture toughness (GIC and KIC)—linear elastic fracture mechanics (LEFM) approach. ISO, Geneva

Hsieh T-H, Kinloch AJ, Masania K, Sohn Lee J, Taylor AC, Sprenger S (2010) J Mater Sci 45:1193. doi:10.1007/s10853-009-4064-9

Fox TG (1956) Bull Am Phys Soc 1:123

Halpin JC, Pagano NJ (1969) J Compos Mater 3:720

Kerner EH (1956) Proc Phys Soc B 69:808

Nielsen LE (1966) J Appl Polym Sci 10:97

Ahmed S, Jones FR (1990) J Mater Sci 25:4933. doi:10.1007/BF00580110

Nielsen LE, Landel RF (1994) Mechanical properties of polymers and composites. Marcel Dekker, New York

Kinloch AJ, Taylor AC (2006) J Mater Sci 41:3271. doi:10.1007/s10853-005-5472-0

Fornes TD, Paul DR (2003) Polymer 44:4993

Luo J-J, Daniel IM (2003) Compos Sci Technol 63:1607

Halpin JC (1969) J Compos Mater 3:732

Halpin JC, Kardos JL (1976) Polym Eng Sci 16:344

Lewis TB, Nielsen LE (1970) J Appl Polym Sci 14:1449

McGee S, McCullough RL (1981) Polym Compos 2:149

Nielsen LE (1968) J Compos Mater 2:120

Kinloch AJ (1987) Adhesion and adhesives: science and technology. Chapman & Hall, London

Kunz SC, Beaumont PWR (1981) J Mater Sci 16:3141. doi:10.1007/BF00540323

Andrews EH (1968) Fracture in polymers. Oliver & Boyd, Edinburgh

Sue H-J (1991) Polym Eng Sci 31:275

Sue H-J (1991) Polym Eng Sci 31:270

Karger-Kocsis J, Friedrich K (1992) Colloid Polym Sci 270:549

Cheng C, Hiltner A, Baer E, Soskey PR, Mylonakis SG (1995) J Mater Sci 30:587. doi:10.1007/BF00356315

Azimi HR, Pearson RA, Hertzberg RW (1996) Polym Eng Sci 36:2352

Chen TK, Jan YH (1992) J Mater Sci 27:111. doi:10.1007/BF02403652

Guild FJ, Kinloch AJ, Taylor AC (2010) J Mater Sci 45:3882. doi:10.1007/s10853-010-4447-y

Huang Y, Kinloch AJ (1992) J Mater Sci 27:2763. doi:10.1007/BF00540703

Sultan JN, McGarry FJ (1973) Polym Eng Sci 13:29

Guild FJ, Young RJ (1989) J Mater Sci 24:298. doi:10.1007/BF00660971

Caddell RM (1980) Deformation and fracture of solids. Prentice-Hall, Englewood Ciffs

Guild FJ, Young RJ (1989) J Mater Sci 24:2454. doi:10.1007/BF01174511

Acknowledgements

The authors would like to thank Kaneka (D. Sober) and Nanoresins (S. Sprenger) for the supply of materials. They also acknowledge the EPSRC for a doctoral training award for K. Masania, and Becker Industrial Coatings for supporting G. Giannakopoulos. Some of the equipment used was provided by A.C. Taylor’s Royal Society Mercer Junior Award for Innovation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Giannakopoulos, G., Masania, K. & Taylor, A.C. Toughening of epoxy using core–shell particles. J Mater Sci 46, 327–338 (2011). https://doi.org/10.1007/s10853-010-4816-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4816-6