Abstract

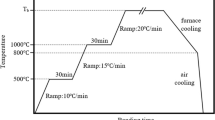

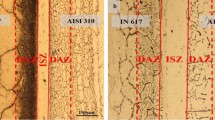

To enhance the joint’s properties for AISI 321 steel, due to the limitations of conventional joining methods, transient liquid phase bonding was investigated for this steel in order to achieve the optimum process parameters. In this way, the effects of bonding temperature (1050 to 1200 °C) and time (30 to 120 min) on microstructure and shear strength of the AISI 321/MBF-20/AISI 321 and AISI 321/MBF-30/AISI 321 joints were studied. Results showed that while incomplete isothermal solidification of the samples results in the formation of Fe–B, Cr–B, Ni–Si, and Ni–B phases at the centerline of the joints and diffusion-affected zone, more homogenous joints with higher shear strength values were obtained with the increase in bonding temperature and time. In addition, it was found that the presence of Fe and Cr in chemical composition of MBF-20 interlayer increased the amount of eutectic compounds at the centerline of joints and the amount of precipitates at heat-affected zone. Furthermore, it was found that regardless of the type of interlayer, the increase in bonding temperature from 1050 to 1150 °C increased the shear strength of the joints. The highest shear strength occurred in AISI 321/MBF-30/AISI 321 system bonded at 1150 °C for 60 min that was 99% of that of the base metal. Also, it was found that further increase in the bonding temperature beyond 1150 °C reduced drastically the shear strength of the bonds due to the occurrence of partial melting, especially at the grain boundaries of base metal. In addition, the study of the fracture surface of the joints showed that samples with high shear strength values were fractured by ductile mode. However, features of brittle fracture were observed in the fracture surface of the samples with lower shear strength values.

Similar content being viewed by others

References

M.A. Arafin, M. Medraj, D.P. Turner, P. Bocher, Effect of alloying elements on the isothermal solidification during TLP bonding of SS 410 and SS 321 using a BNi-2 interlayer. Mater. Chem. Phys. 106, 109–119 (2007)

M.M. Atabaki, Microstructural evolution in the partial transient liquid phase diffusion bonding of Zircaloy-4 to stainless steel 321 using active titanium filler metal. J. Nucl. Mater. 406, 330–344 (2010)

M.M. Atabaki, M. Bajgholi, E. Dehkordi, Partial transient liquid phase diffusion bonding of zirconium alloy (Zr–2.5 Nb) to stainless steel 321. Mater. Des. 42, 172–183 (2012)

M.M. Atabaki, A.T. Hanzaei, Partial transient liquid phase diffusion bonding of Zircaloy-4 to stabilized austenitic stainless steel 321. Mater. Charact. 61, 982–991 (2010)

R. Bakhtiari, A. Ekrami, The effect of gap size on the microstructure and mechanical properties of the transient liquid phase bonded FSX-414 superalloy. Mater. Des. 40, 130–137 (2012)

R. Bakhtiari, A. Ekrami, T.I. Khan, The effect of TLP bonding temperature on microstructural and mechanical property of joints made using FSX-414 superalloy. Mater. Sci. Eng. A 546, 291–300 (2012)

H. Chen, J.M. Gong, S.T. Tu, Numerical modeling and experimental investigation of diffusion brazing SS304/BNi-2/SS304 joint. Sci. Technol. Weld. Join. 14, 32–41 (2009)

A. Davoodi, A. Jamaloei, A. Khorram, A. Jafari, Characterization of microstructure and mechanical properties of dissimilar TLP bonding between IN718/IN600 with BNi-2 interlayer. J. Manuf. Process. 29, 447–457 (2017)

W.F. Gale, E.R. Wallach, Wettability of nickel alloys by boron-containing brazes. Weld. J. 70, 76s–79s (1991)

H. Hongjie, S. Guangmin, L. Mingcan, J. Yingjun, Microstructure and mechanical properties of transient liquid phase bonded joints of CB2 ferritic heat resistant steels with amorphous BNi-2 interlayer. Rare Met. Mater. Eng. 47, 2290–2297 (2018)

O. Idowu, N. Richards, M. Chaturvedi, Effect of bonding temperature on isothermal solidification rate during transient liquid phase bonding of Inconel 738LC superalloy. Mater. Sci. Eng. A 397, 98–112 (2005)

J. Jang, H. Shih, Evolution of microstructure of AISI 304 stainless steel joint brazed by mechanically alloyed nickel base filler with different silicon content. J. Mater. Sci. Lett. 22, 79–82 (2003)

M. Mosallaee, A. Ekrami, K. Ohsasa, K. Matsuura, Microstructural evolution in the transient-liquid-phase bonding area of IN-738LC/BNi-3/IN-738LC. Metall. Mater. Trans. A 39, 2389–2402 (2008)

D.C. Murray, S.F. Corbin, Determining the kinetics of transient liquid phase bonding (TLPB) of inconel 625/BNi-2 couples using differential scanning calorimetry. J. Mater. Process. Technol. 248, 92–102 (2017)

D.Y. Park, S.K. Lee, J.K. Kim, S.N. Lee, S.J. Park, Y.J. Oh, Image processing-based analysis of interfacial phases in brazed stainless steel with Ni-based filler metal. Mater. Charact. 130, 278–284 (2017)

M. Pouranvari, A. Ekrami, A. Kokabi, Transient liquid phase bonding of wrought IN718 nickel based superalloy using standard heat treatment cycles: microstructure and mechanical properties. Mater. Des. 50, 694–701 (2013)

M. Pouranvari, A. Ekrami, A. Kokabi, Microstructure–properties relationship of TLP-bonded GTD-111 nickel-base superalloy. Mater. Sci. Eng. A 490, 229–234 (2018)

S.J. Roh, C.H. Lee, Formation of secondary phases and their effect on the mechanical properties of joints formed by TLP bonding using Fe–B–Si insert metal in duplex stainless steel. Met. Mater. Int. 25, 425–438 (2019)

H.N.G. Wadley, K.P. Dharmasena, Y. Chen, P. Dudt, D. Knight, K. Kiddy, Compressive response of multilayered pyramidal lattices during underwater shock loading. Int. J. Impact Eng. 35, 1102–1114 (2008)

D. Wang, S. Xiu, Effect of bonding temperature on the interfacial micro-structure and performance of mild steel/austenite stainless steel diffusion-bonded joint. Acta Metall. Sin. 53, 567–574 (2017)

N.P. Wikstrom, A.T. Egbewande, O.A. Ojo, High temperature diffusion induced liquid phase joining of a heat resistant alloy. J. Alloys Compd. 460, 379–385 (2008)

A. Yarmou Shamsabadi, R. Bakhtiari, B.G. Eisaabadi, TLP bonding of IN738/MBF20/IN718 system. J. Alloys Compd. 685, 896–904 (2016)

W.D. Zhuang, T.W. Eagar, Transient liquid-phase bonding using coated metal powders. Weld. J. Res. Suppl. 76, 157s–162s (1997)

Acknowledgements

The authors would like to acknowledge Kermanshah Branch of Azad University for financial supports of this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bakhtiari, R., Misaghi, M., Eisaabadi B., G. et al. Optimizing the Process Parameters for TLP Bonding of AISI 321 Stainless Steel. Metallogr. Microstruct. Anal. 9, 239–251 (2020). https://doi.org/10.1007/s13632-020-00624-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-020-00624-7