Abstract

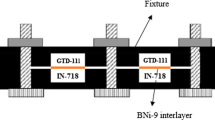

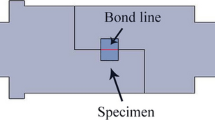

Transient-liquid-phase (TLP) bonding of the IN-738LC base alloy with BNi-3 interlayer was investigated in this article. Effects of the TLP bonding thermal cycle on the base alloy were studied microstructurally and macrostructurally. Microscopic investigation revealed that the microstructural evolution in the TLP bonding area was affected substantially by the bonding temperature. Therefore, a critical bonding temperature (T cr ) was defined for TLP bonding of IN-738LC/BNi-3/IN-738LC samples. Unlike bonding below T cr , TLP bonding at temperatures higher than T cr resulted in formation of individual γ-γ′ colonies in the adjacent base alloy to TLP bonding zone and caused significant reduction in the isothermal solidification kinetic. During TLP bonding at temperatures less than T cr , B-rich precipitates with two different morphologies, blocky and acicular, were formed in the adjacent base alloy to the TLP bonding zone. Microhardness and three-point bending tests were carried out in order to determine the effect of these formed constituents in the TLP bonding area on the mechanical properties of bonded samples.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

PHILIPS is a trademark of Philips Electronic Instruments Corp., Mahwah, NJ.

The fraction of area of TLP zone intermetallics to the area of the TLP zone was selected as AF TLP zoneI .

The fraction of the boride area to the DAZ area was selected as AF DAZI .

The maximum formation depth of boride in the base alloy from the L/S interface was selected as FD DAZI .

F.C.: Furnace cooled (cooling rate ∼10 °C/min).

The fraction of the DAZ constituent area to the DAZ area was selected as the area fraction of the DAZ constituent.

References

D.F. Paulonis, D.S. Duvall, and W.A. Owczarski: U.S. Patent 3,678,570, 1972

W.D. MacDonald, T.W. Eagar: Metal Science of Joining Conf., TMS, Warrendale, PA, 1992, pp. 93–100

C.G. Bieber, Suffern, and J.J. Galka: U.S. Patent 3,459,545, 1969

IN-738: Technical Data, The International Nickel Company Inc., New York, NY, 1981, pp. 1–11

R. Kayacana, R. Varola, O. Kimilli: Mater. Res. Bull., 2004, vol. 39, pp. 2171–86

M.H. Haafkens, G.H. Matthey: Weld. J., 1982, vol. 61 (11), pp. 25–30

T.J. Moore, K.H. Holko: Weld. J., 1970, vol. 49 (9), pp. 395s–409s

J.H.G. Mattheij: Mater. Sci. Technol., 1985, vol. 1 (8), pp. 608–12

O.A. Idowu, N.L. Richards, M.V. Chaturvedi: Mater. Sci. Eng. A, 2005, vol. 397 (1–2), pp. 98–112

N.P. Wikstrom, O.A. Ojo, M.V. Chaturvedi: Mater. Sci. Eng. A, 2006, vol. 417 (1–2), pp. 299–306

O.A. Ojo, N.L. Richards, M.C. Chaturvedi: Sci. Technol. Weld. Join., 2004, vol. 9 (6), pp. 532–40

O.A. Idowu, O.A. Ojo, M.V. Chaturvedi: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 2787–96

A. Rabinkin: Sci. Technol. Weld. Join., 2004, vol. 9 (3), pp. 181–99

W.E. Gale, E.R. Wallach: J. Mater. Sci., 1992, vol. 27, pp. 5653–60

Metals Handbook, vol. 10, Material Characterization, 9th ed., ASM, Metals Park, OH, 1986, p. 460

A.K. Koul, R. Thamburaj: Metall. Trans. A, 1985, vol. 16A, pp. 17–26

A.K. Koul, D. Morphy: Microstruct. Sci., 1982, vol. 11, pp. 79–88

J.C. Beddoes, W. Wallace: Metallography, 1980, vol. 13 (2), pp. 185–94

R.A. Steven, P.E.J. Flewitt: J. Mater. Sci., 1978, vol. 13 (2), pp. 367–76

R. Rosenthal, D.R.F. West: Mater. Sci. Technol., 1999, vol. 15 (12), pp. 1387–94

A.K. Koul, R. Castillo: Metall. Trans. A, 1988, vol. 19A, pp. 2049–66

D.S. Duvall and W.A. Owczarski: Weld. J., 1971, pp. 401s–409s

W. Hoffelner, E. Kny, R. Stickler, W.J. McCall: Z. Werkstofftech., 1979, vol. 10, pp. 84–92

J.M. Vitek, D.W. Gandy, S.S. Babu, and G.J. Frederick: www.ornl.gov/~webworks/cppr/y2001/pres/120433.pdf

W.D. MacDonald, T.W. Eagar: Ann. Rev. Mater. Sci., 1992, vol. 22, pp. 23–46

S. Lebaili, S. Hamar-Thibault: Acta Metall., 1987, vol. 35 (3), pp. 701–10

S.K. Tung, L.C. Lim, M.O. Lai: Scripta Mater., 1996, vol. 34 (5), pp. 763–69

A. Taylor: Trans. AIME, 1956, Oct., pp. 1356–62

P. Willemin, M. Durand-Charre: J. Mater. Sci., 1990, vol. 25 (1A), pp. 168–74

O. Kubaschewski, C.B. Alcock, P.J. Spencer: Materials Thermochemistry, 6th ed., Pergamon, Oxford, United Kingdom, 1993

M. Mosallaee, A. Ekrami, K. Ohsasa, K. Matsuura: Mater. Sci. Technol., 2008, vol. 24, pp. 449–56

C.W. Sinclair, G.R. Purdy, J.E. Morral: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 1187–92

C.W. Sinclair: J. Phase Equilibria, 1999, vol. 20 (4), pp. 361–69

J.D. Liu, T. Jin, N.R. Zhao, Z.H. Wang, X.F. Sun, H.R. Guan, Z.Q. Hu: Mater. Sci. Forum, 2007, vols. 546–549, pp. 1245–48

B. Jahnke, J. Demny: Thin Solid Films, 1983, vol. 110, pp. 225–35

S.K. Tung, L.C. Lim, O.M. Lai, H. Wu: Mater. Sci. Technol., 1997, vol. 13 (12), pp. 1051–56

R.B. Scarlin: Scripta Metall., 1976, vol. 10, pp. 711–15

R. Rosenthal and D.R.F. West: Mater. Sci. Technol., 1986, vol. 2, Feb., pp. 169–74

Acknowledgments

The authors are grateful to the Advanced High-Temperature Material Laboratory, Hokkaido University (Japan), for the use of their vacuum furnace. One of the authors (MM) is also thankful to Yazd University (Iran) for the doctoral scholarship award and the Laboratory of Microstructural Control, Hokkaido University (Japan), for the internship award to carry out this research at their laboratory.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 15, 2007.

Rights and permissions

About this article

Cite this article

Mosallaee, M., Ekrami, A., Ohsasa, K. et al. Microstructural Evolution in the Transient-Liquid-Phase Bonding Area of IN-738LC/BNi-3/IN-738LC. Metall Mater Trans A 39, 2389–2402 (2008). https://doi.org/10.1007/s11661-008-9588-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-008-9588-0