Abstract

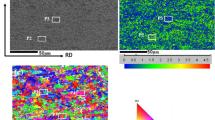

4340 steel was quenched to form lath martensite and then tempered at 200 °C for 1 h. Microstructural features of a large lath were examined in detail via transmission electron microscopy, including bright-field imaging, centered-dark-field imaging, and electron diffraction. Linear arrays of transition-iron-carbide precipitate were characterized. Rodlike arrays measured about 100 nm in length and were aligned predominantly along <100> martensite directions. The rodlike arrays consisted of small, closely spaced, nearly equiaxed transition-iron-carbide precipitates of less than 10 nm in diameter. Kinks in the rodlike arrays resulted is deviations from <100> directions by about 20°–30°. A less-common type of linear array measured 500 nm in length. These longer features were aggregates of kinked rodlike arrays that seemed to be “attached” by kinked segments, again at 20°–30° from <100> martensite directions. Transition-iron-carbide precipitates showed little if any association with martensite matrix dislocations that were aligned predominantly along <111> directions. A hypothesis was offered in which precipitates aligned along <100> martensite directions are a remnant of spinodal decomposition that develops planar modulations of high- and low-carbon regions prior to the first stage of tempering.

Similar content being viewed by others

Notes

4340 steel is a Society of Automotive Engineers (SAE) designation. It refers to a nickel–chromium–molybdenum steel with nominally 0.40 wt. pct. carbon.

In high-carbon steels (0.8 wt. pct. C), martensite in the early stages of aging or tempering shows measurable differences in the two lattice parameters, a and c, for this well-known tetragonal phase. In 4340 steel (with 0.4 wt. pct. C), and after tempering at 200 °C, little if any tetragonality remains. Nonetheless, there may be some remnant of the original tetragonality. This issue is addressed in the paper.

In the previous work on this same alloy, these features were rodlike in nature; therefore, the source of the lenslike or lenticular appearance is uncertain. Later in this paper, it will be shown that in fact these lenslike features are aggregates of much smaller precipitates, and the array of dots directly beneath the lens at “D” in Fig. 2b is a reasonably good representation of this aggregate.

References

S.W. Thompson, A two-tilt analysis of electron diffraction patterns from transition-iron-carbide precipitates formed during tempering of 4340 steel. Metallogr. Microstruct. Anal. 5, 367–383 (2016)

S.W. Thompson, Structural characteristics of transition-iron-carbide precipitates formed during the first stage of tempering in 4340 steel. Mater. Charact. 106, 452–462 (2015)

G.Y. Lai, On the precipitation of epsilon-carbide in lower bainite. Metall. Trans. 6A, 1469–1471 (1975)

A.J. Clarke, M.K. Miller, R.D. Field, D.R. Coughlin, P.J. Gibbs, K.D. Clarke, D.J. Alexander, P.A. Powers, P.A. Papin, G. Krauss, Atomic and nanoscale chemical and structural changes in quenched and tempered 4340 steel. Acta Mater. 77, 17–27 (2014)

E. Tekin, P.M. Kelly, A study of the tempering of steel using transmission electron microscopy, in Precipitation from iron-base alloys, ed. by G.R. Speich, J.B. Clark (Gordon and Breach, New York, 1965), pp. 173–221

C.J. Barton, The tempering of a low-carbon internally twinned martensite. Acta Metall. 17, 1085–1093 (1969)

S. Murphy, J.A. Whiteman, The precipitation of epsilon-carbide in twinned martensite. Metall. Trans. 1, 843–848 (1970)

Y. Hirotsu, S. Nagakura, Crystal structure and morphology of the carbide precipitated from martensitic high carbon steel during the first stage of tempering. Acta Metall. 20, 645–655 (1972)

K. Shimizu, H. Okamoto, High voltage electron microscopy study of the metastable iron carbide in a eutectoid Fe–C alloy. Trans. JIM 15, 193–199 (1974)

Y. Hirotsu, Y. Itakura, K.C. Su, S. Nagakura, Electron microscopy and diffraction study of the carbide precipitated from martensitic low and high nickel steels at the first stage of tempering. Trans. JIM 17, 503–513 (1976)

D.L. Williamson, K. Nakazawa, G. Krauss, A study of the early stages of tempering of an Fe-1.2 pct alloy. Metall. Trans. A 10A, 1351–1363 (1979)

Y. Tanaka, K. Shimizu, Carbide formation upon tempering at low temperatures in Fe–Mn–C alloys. Trans. Jpn. Inst. Metals 22, 779–788 (1981)

K.A. Taylor, G.B. Olson, M. Cohen, J.B. Vander Sande, Carbide precipitation during stage I tempering of Fe–Ni–C martensites. Metall. Trans. 20A, 2749–2765 (1989)

O.N.C. Uwakweh, J.-M.R. Génin, J.-F. Silvain, Electron microscopy study of the aging and first stage of tempering of high-carbon Fe–C martensite. Metall. Trans. 22A, 797–806 (1991)

Y. Ohmori, I. Tamura, Epsilon carbide precipitation during tempering of plain carbon martensite. Metall. Trans. A 23A, 2737–2751 (1992)

S.S. Babu, K. Hono, T. Sakurai, Atom probe field ion microscopy study of the partitioning of substitutional elements during tempering of a low-alloy steel martensite. Metall. Trans. A 25A, 499–508 (1994)

A.T.W. Barrow, J.-H. Kang, Rivera-Díaz-del-Castillo,: the ε → η → θ transition in 100Cr6 and its effect on mechanical properties. Acta Mater. 60, 2805–2815 (2012)

W.S. Choi, J. Lee, B.C. De Cooman, Internal-friction analysis of dislocation-interstitial carbon interactions in press-hardened 22MnB5 steel. Mater. Sci. Eng. A 639, 439–447 (2015)

D.T. Pierce, D.R. Coughlin, D.L. Williamson, K.D. Clarke, A.J. Clarke, J.G. Speer, E. De Moor, Characterization of transition carbides in quench and partitioned steel microstructures by Mössbauer spectroscopy and complementary techniques. Acta Mater. 90, 417–430 (2015)

K.A. Taylor, J.B. Vander Sande, M. Cohen, Discussion of “An interpretation of the carbon redistribution process during aging of high-carbon martensite”. Metall. Trans. 24A, 2585–2588 (1993)

G. Krauss, Principles of Heat Treatment of Steel (American Society for Metals, Metals Park, OH, 1980), pp. 200–209

K.A. Taylor, L. Chang, G.B. Olson, G.D.W. Smith, M. Cohen, J.B. Vander Sande, Spinodal decomposition during aging of Fe–Ni–C martensites. Metall. Trans. 20A, 2717–2737 (1989)

G.C. Capitani, P. Oleynikov, S. Hovmöller, M. Mellini, A practical method to detect and correct for lens distortion in the TEM. Ultramicroscopy 106, 66–74 (2006)

C.M. Wayman, Introduction to the Crystallography of Martensitic Transformations (The Macmillan Company, New York, 1964), p. 166

Z. Nishiyama, Martensitic Transformation (Academic Press, New York, 1978), p. 7

C.A. Apple, R.N. Caron, G. Krauss, Packet microstructure in Fe-0.2 pct C martensite. Metall. Trans. 5, 593–599 (1974)

L. Morsdorf, C.C. Tasan, D. Ponge, D. Raabe, 3D structural and atomic-scale analysis of lath martensite: effect of the transformation sequence. Acta Mater. 95, 366–377 (2015)

K.W. Andrews, Empirical formulae for the calculation of some transformation temperatures. JISI 203, 721–727 (1965)

B.P.J. Sandvik, C.M. Wayman, Characteristics of lath martensite: Part I. Crystallographic and substructural features. Metall. Trans. 14A, 809–822 (1983)

S.H. Wen, A.G. Khatchaturyan, J.W. Morris, Computer simulation of a tweed-transformation in an idealized elastic crystal. Metall. Trans. 12A, 581–587 (1981)

Acknowledgments

Support from the Advanced Steel Processing and Products Research Center is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thompson, S. Further Observations of Linear Arrays of Transition-Iron-Carbide Precipitates in Tempered 4340 Steel. Metallogr. Microstruct. Anal. 7, 680–691 (2018). https://doi.org/10.1007/s13632-018-0492-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-018-0492-8