Abstract

The world population’s rapid growth has led to a surge in solid waste production, posing complex waste management challenges. This study explores the use of food waste for biogas production through anaerobic digestion, offering a sustainable solution. Anaerobic bacterial consortia were utilized to produce biogas from vegetable waste, banana peels, and cow dung. Proximate analysis revealed that a solid concentration exceeding 15% is crucial for effective anaerobic digestion. pH levels shifted from 4.2 to 6.9 post-digestion, indicating successful fermentation by methanogenic bacteria. Co-digestion of cattle dung with food waste yielded the highest cumulative biogas output of 1732 ml, surpassing mono-digestion at 1035 ml. Validation through a flame test confirmed biogas’s viability as a renewable energy source. Bacterial isolation highlighted their role in enhancing biogas output and process stability. Life cycle assessment (LCA) emphasized the environmental benefits of anaerobic digestion–based biogas production, underscoring its potential for sustainable waste management and bioenergy generation.

Similar content being viewed by others

Data Availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Bernard SS, Srinivasan T, Suresh G, Paul AI, Fowzan KM, Kishore VA (2020) Production of biogas from anaerobic digestion of vegetable waste and cow dung. Mater Today Proc 33:1104–1106

Zan F, Iqbal A, Lu X, Wu X, Chen G (2022) “Food waste-wastewater-energy/resource” nexus: integrating food waste management with wastewater treatment towards urban sustainability. Water Res 211:118089

Kaur G, Luo L, Chen G, Wong JW (2019) Integrated food waste and sewage treatment–a better approach than conventional food waste-sludge co-digestion for higher energy recovery via anaerobic digestion. Biores Technol 289:121698

Al-Wahaibi A, Osman AI, Al-Muhtaseb AA, Alqaisi O, Baawain M, Fawzy S, Rooney DW. (2020) Techno-economic evaluation of biogas production from food waste via anaerobic digestion. Sci Rep 10(1):1–16

Osman AI (2020) Catalytic hydrogen production from methane partial oxidation: mechanism and kinetic study. Chem Eng Technol 43:641–648

Chen H, Osman AI, Mangwandi C, Rooney D (2019) Upcycling food waste digestate for energy and heavy metal remediation applications. Resour Conserv Recycl 3:100015

Munaf AA, Premkumar P, Velmurugan A, Nalluri P, Kanna SR, Roy JNJ, & Suresh G 2021. Catalytic degradation of used plastics oil as liquid fuel for IC engines. In Journal of Physics: Conference Series (Vol. 2054, No. 1, p. 012072). IOP Publishing

Ouda OK, Raza SA, Nizami AS, Rehan M, Al-Waked R, Korres NE (2016) Waste to energy potential: a case study of Saudi Arabia. Renew Sust Energ Rev 61:328–340

Anwar A, Younis M, Ullah I (2020) Impact of urbanization and economic growth on CO2 emission: a case of far east Asian countries. Int J Environ Res Public Health 17(7):2531

Owusu PA, Asumadu-Sarkodie S (2016) A review of renewable energy sources, sustainability issues and climate change mitigation. Cogent Eng 3:1167990

Shahzad A, Ullah F, Irshad H, Ahmed S, Shakeela Q, Mian AH (2021) Molecular detection of Shiga toxin-producing Escherichia coli (STEC) O157 in sheep, goats, cows and buffaloes. Mol Biol Rep 48(8):6113–6121

Amir SM, Liu Y, Shah AA, Khayyam U, Mahmood Z (2020) Empirical study on influencing factors of biogas technology adoption in Khyber Pakhtunkhwa Pakistan. Energy Environ 31(2):308–329

Akor CI, Osman AI, Farrell C, McCallum CS, Doran WJ, Morgan K, Sheldrake GN (2021) Thermokinetic study of residual solid digestate from anaerobic digestion. Chem Eng J 406:127039

Sarikaya E, Demirer GN (2013) Biogas production from broiler manure, wastewater treatment plant sludge, and greenhouse waste by anaerobic co-digestion. J Renew Sustain Energy 5:043126

Wang K, Yin J, Shen D, Li N (2014) Anaerobic digestion of food waste for volatile fatty acids (VFAs) production with different types of inoculum: effect of pH. Bioresour Technol 161:395–401

Mata-Alvarez J, Mace S, Llabrés P (2000) Anaerobic digestion of organic solid wastes. An overview of research achievements and perspectives. Bioresour Technol 74(1):3–16

Weiland P (2010) Biogas production: current state and perspectives. Appl Microbiol Biotechnol 85(4):849–860

Wilawan W, Pholchan P, Aggarangsi P (2014) Biogas production from co-digestion of Pennisetum pururem cv. Pakchong 1 grass and layer chicken manure using completely stirred tank. Energy Procedia 52:216–222

Zhai N, Zhang T, Yin D, Yang G, Wang X, Ren G, Feng Y (2015) Effect of initial pH on anaerobic co-digestion of kitchen waste and cow manure. J Waste Manag 38:126–131

Rajagopal R, Masse DI, Singh G (2013) A critical review on inhibition of anaerobic digestion process by excess ammonia. Biores Technol 143:632–641

Guo M, Song W, Buhain J (2018) Bioenergy and biofuels: history, status, and perspective. Renew Sustain Energy Rev 82:1740–1760

El-Mashad HM, Zhang R (2010) Biogas production from co-digestion of dairy manure and food waste. Biores Technol 101(11):4021–4028

Horváth IS, Tabatabaei M, Karimi K, Kumar R (2016) Recent updates on biogas production-a review. Biofuel Res J 3:394

Asikong BE, Idire SO, Tiku DR (2016) Microorganisms associated with biogas production using vegetable (Telfairia occidentalis) wastes, banana peel and pig dung as substrates. Br Microbiol Res J 16:1–12

Obileke K, Nwokolo N, Makaka G, Mukumba P, Onyeaka H (2020) Anaerobic digestion: technology for biogas production as a source of renewable energy—a review. Energy Environ 32:191–225

Sunny SM, Joseph K (2018) Review on factors affecting biogas production. Int J Tec Res Eng 5:3693–3697

Tetteh EK, Amano KOA, Asante-Sackey D (2017) Biochemical methane potential of miscanthus fuscus for anaerobic digestion. Int J Sci Res Publ 7:434–439

Nizami AS, Rehan M, Waqas M, & Naqvi M (Eds.). 2017. Biogas production and utilization: status, challenges, and future directions. Springer

Paritosh K, Kushwaha SK, Yadav M, Pareek N, Chawade A, Vivekanand V, Kumar M (2019) Food waste to energy: an overview of sustainable approaches for food waste management and nutrient recycling. Biotechnol Rep 21:e00301

Deublein D, Steinhauser A (2010) Biogas from waste and renewable resources: an introduction. John Wiley & Sons

K Möller T Müller(2012) Effects of anaerobic digestion on digestate nutrient availability and crop growth: A review. Eng Life Sci 12:242

Kratzeisen MN, Starcevic M, Martinov C, Maurer, J, Müller (2010) Applicability of biogas digestate as solid fuel. Fuel 89:2544

Desloover J, Woldeyohannis AA, Verstraete WN, Boon N, K, Rabaey (2012) Electrochemical resource recovery from digestate to prevent ammonia toxicity during anaerobic digestion. Environmental science & technology. Environ Sci Technol 46:12209

(2016) Increased zinc and copper availability in organic waste amended soil potentially involving distinct release mechanisms. Environ Pollut 212:299

Mangwandi C, JiangTao L, Albadarin AB, Allen SJ, Walker GM (2013) Alternative method for producing organic fertiliser from anaerobic digestion liquor and limestone powder: High Shear wet granulation. Powder Technol 233:245

(2011) Life cycle assessment of biogas digestate processing technologies. Conserv Recycl 56:92

Cathcart A, Smyth BM, Lyons G, Murray ST, Rooney D, Johnston CR (2021) An economic analysis of anaerobic digestate fuel pellet production: can digestate fuel pellets add value to existing operations? Cleaner Eng Technol 3:100098

Yadav N, Kumar R, Rawat L, Gupta S (2014) Physico-chemical properties of before and after anaerobic digestion of Jatropha seed cake and mixed with pure cow dung. J Chem Eng Process Tech 5:1–5

Samun I, Saeed R, Abbas M, Rehan M, Nizami AS (2017) Assessment of bioenergy production from solid waste. Energy Proc 142:655–660

Liaquat R, Jamal A, Tauseef I, Qureshi Z, Farooq U, Imran M, Ali MI (2017) Characterizing bacterial consortia from an anaerobic digester treating organic waste for biogas production. Pol J Environ Stud 26(3):709–716

Ali JMA, Mohan S, Velayutham T, Sankaran S (2016) Comparative study of biogas production from municipal solid waste using different inoculum concentration on batch anaerobic digestion. Asian J Eng Technol Innov 4:59–65

Krishania M, Kumar V, Vijay VK, Malik A (2013) Analysis of different techniques used for improvement of biomethanation process: a review. Fuel 106:1–9

Elsayed M, Andres Y, Blel W, Gad A (2015) Methane production by anaerobic co-digestion of sewage sludge and wheat straw under mesophilic conditions. Int J Eng Sci Technol 4:1–6

APHA. 1998. 20th edition. Standard methods for the examination of water and wastewater. Washington, D.C, USA.

Baniya S (2019) Economical design of cold-resistant biogas digesters for degrading household waste in mountainous areas of developing countries. The University of Texas, Arlington Department of Microbiology

Jalil A, Karmaker S, Basar S, Hoque S (2019) Anaerobic digestion of vegetable wastes for biogas production in single chamber and double chamber reactors. Int J Waste Resour 9(1):1–6

Mian AH (2021) Isolation and characterization of biosurfactant producing bacteria from different environmental soil samples. J Toxicol Environ Sci 1(1):36–47

Mian AH, Qayyum S, Zeb S, Fatmia T, Jameel K, Rehman B (2024) Exploring indigenous fungal isolates for efficient dye degradation: a comprehensive study on sustainable bioremediation in the total environment. Environ Technol Innov 103615

Y, Ya’aba, AS, Ramalan (2020) Isolation, identification and characterization of some bacteria associated with biogas production from cow dung. Equity J Sci Technol 7:91–99

Osman AI, Mehta N, Elgarahy AM, Al-Hinai A, Al-Muhtaseb AAH, Rooney DW (2021) Conversion of biomass to biofuels and life cycle assessment: a review. Environ Chem Lett 19:4075–4118

Gopinath LR, Christy PM, Mahesh K, Bhuvaneswari R, Divya D (2014) Identification and evaluation of effective bacterial consortia for efficient biogas production. J Environ Sci Toxicol Food Technol 8:80–86

Li A, Chu YN, Wang X, Ren L, Yu J, Liu X, Yan J, Zhang L, Wu S, Li S (2013) A pyrosequencing-based metagenomic study of methane-producing microbial community in solid-state biogas reactor. Biotechnol Biofuels 6:1–17

Dhadse S, Kankal NC, Kumari B (2012) Study of diverse methanogenic and non-methanogenic bacteria used for the enhancement of biogas production. Int J Life Sci Biotechnol Pharma Res 1:176–191

Murunga SI, Mbuge DO, Gitau AN, Mutwiwa UN, Wekesa IN (2016) Isolation and characterization of methanogenic bacteria from brewery wastewater in Kenya. Afr J Biotechnol 15:2687–2697

Chojnacka K, Moustakas K (2024) Anaerobic digestate management for carbon neutrality and fertilizer use: a review of current practices and future opportunities. Biomass Bioenerg 180:106991

Aragaw T, Gessesse A (2013) Co-digestion of cattle manure with organic kitchen waste to increase biogas production using rumen fluid as inoculums. Phys Sci Int J 8:443–450

Batool N, Qazi JI, Aziz N, Hussain A, Shah SZH (2020) Bio-methane production potential assays of organic waste by anaerobic digestion and co-digestion. Pak J Zool 52(3):971

Deressa L, Libsu S, Chavan RB, Manaye D, Dabassa A (2015) Production of biogas from fruit and vegetable wastes mixed with different wastes. Environ Ecol Res 3(3):65–71

Shwetmala CH and TV Ramachandra 2014. Anaerobic degradation pattern of urban solid waste components. Waste Manag. Res U 332–336

Abubakar BSUI, Ismail N (2012) Anaerobic digestion of cow dung for biogas production. ARPN J Eng Appl Sci 7:169–172

Otun TF, Ojo OM, Ajibade FO, Babatola JO (2015) Evaluation of biogas production from the digestion and codigestion of animal waste, food waste and fruit waste. Int J Energy Environ Res 3:12

Maile II and E Muzenda 2014. Production of biogas from various substrates under anaerobic conditions. In Int. Conf. Innov Eng Technol., 78–80

Benali M, Hamad T, Hamad Y (2019) Experimental study of biogas production from cow dung as an alternative for fossil fuels. J Sustain Bioenergy Syst 9:91–97

F Manthia N Amalin HHA Matin S Sumardiono 2018 Production of biogas from organic fruit waste in anaerobic digester using ruminant as the inoculum In MATEC Web of Conferences 156 03053

Bernard SS, Srinivasan T, Suresh G, Paul AI, Fowzan KM, Kishore VA (2020) Production of biogas from anaerobic digestion of vegetable waste and cow dung. Mater Today Proc 33:1104–1106

Sitorus B, Sukandar S, Panjaitan SD (2013) Biogas recovery from anaerobic digestion process of mixed fruit–vegetable wastes. Energy Proced 32:176–182

Gao R, Li Z, Wang X, Cheng S, Yin F (2015) Study on anaerobic co-digestion of cow manure, maize straw and vegetable waste. Int J Res Sci Innov Appl Sci 3:357–363

Wang X, Yang G, Feng Y, Ren G, Han X (2012) Optimizing feeding composition and carbon–nitrogen ratios for improved methane yield during anaerobic co-digestion of dairy, chicken manure and wheat straw. Bioresour Technol 120:78–83

Zhang T, Liu L, Song Z, Ren G, Feng Y (2013) Biogas production by co-digestion of goat manure with three crop residues. PLoS ONE 8:0066845

Aremu MO, Agarry SE (2013) Enhanced biogas production from poultry droppings using corn-cob and waste paper as co-substrate. Int J Eng Sci Technol 5(2):247–253

Adeniran KA, Ahaneku IE, Itodo IN, Rohjy HA (2014) Relative effectiveness of biogas production using poultry wastes and cow dung. Int J Agric Eng 16:126–132

Syed WS, Nadeem M, Ikram-ul-Haq FA (2013) Production of biogas by mesophilic bacteria isolated from nature. S Asian J Life Sci 1:12–18

Gemechu FK (2020) Evaluating the potential of domestic animal manure for biogas production in ethiopia. J Energy 2020:1–4

Laskri N, Hamdaoui O, Nedjah N (2015) Anaerobic digestion of waste organic matter and biogas production. J Clean Energy Technol 3:181–184

Lewandowski I et al (2000) Miscanthus: European experience with a novel energy crop. Biomass Bioenergy 19:209–227

Mian AH, Fatima T, Qayyum S, Ali K, Shah R, Noorullah, M, Ali (2020) A study of bacterial profile and antibiotic susceptibility pattern found in drinking water at district Mansehra, Pakistan. Appl Nanosci 10:5435–5439

Rabah AB, AS Baki, LG Hassan, M Musa and AD Ibrahim 2010. Production of biogas using abattoir waste at different retention times Sci World J 5 4

Khalid A, Naz S (2013) Isolation and characterization of the microbial community in biogas production from different commercially active fermentors in various regions of Gujranwala. Int J Water Res Environ Eng 2:28–33

Onwuliri FC, Onyimba IA, Nwaukwu IA (2013) Generation of biogas from cow dung. J Bioremed Biodeg 2:1–3

Shahzad A, Mian AHI, Ul haq, MA, Khan, Matiullah, K, Ali, Hamid (2021) The emergence of different bacterial pathogens in hospital wastewater samples and their antibiotic resistance pattern. Mater Circular Economy 3:1–8

Author information

Authors and Affiliations

Contributions

The authors contributed to the study conception and design. The authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

This is a non-human subject research, and the need for informed consent is waived.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

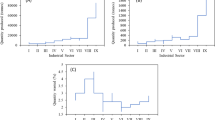

The regression analysis (Table 3) based on the stated inputs and cumulative outcomes showed that mono-digestion has a significant relationship with retention time. The outcomes show that each unit change causes 45.37 units of change in mono-digestion. The F-statistics confirm the stated outcomes.

The regression analysis (Table 4) based on the stated inputs and cumulative outcomes showed that co-digestion has a significant relationship with retention time. The outcomes show that each unit change causes a 69.96-unit change in co-digestion. The F-statistics significantly validated the stated outcomes. This study proved that co-digestion, i.e., (CD + VFW), is more effective than mono-digestion, i.e., (CD). And also, retention time has signification relationship with biogas yield.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qayyum, S., Tahir, A., Mian, A.H. et al. Optimizing biogas production through anaerobic digestion: transforming food waste and agricultural residues into renewable energy within a circular economy paradigm. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05651-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05651-w