Abstract

Industrialization and urbanization have increased the number of industries that utilize colors and their wastewater, contributing to the global pollution catastrophe. Recently, wastewater treatment has relied on expensive, energy-inefficient, and limited-flexibility physico-chemical processes. This study sought a low-cost, efficient method of removing crystal violet (CVD). We created a statistical approach to choose the best practice by immobilizing physically prepared Actinomucor elegans AUMC15946 biomass. The immobilized cells displayed an enhanced CVD removal (80.3%) than the free cells (66.2%). The Box-Behnken design (BBD) was utilized at three physical pretreatment parameters (heat, UV radiation, and gamma ray) for the first time to explore and maximize the positive impact of physical parameters on the immobilized fungus efficiency for potent crystal violet removal. The maximum CVD removal (96.4%) was achieved at the following optimum conditions (45 °C of heat treatment, 20 min of UV exposure, and 300 Gy of gamma irradiation). The toxicity of the treated CVD compared to the untreated one was also evaluated via three different protocols (phytotoxicity, microbial toxicity, and cytotoxicity). The treated CVD has no any adverse effect on seed germination. Similarly, the treated dye revitalized the growth of Escherichia coli cells and two normal cell lines, epithelial breast MCF-12F and fibroblast BJ-1, compared to the untreated dye. Thus, the physically pretreated and immobilized biomass of Actinomucor is a new and potent candidate that could be applied in dye bioremediation practices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Society’s top objectives are clean water and a non-toxic environment where a healthy life depends on clean water. Yet, extensive freshwater pollution and the dissemination of industrial waste into the ecosystem are already at an alarming level [1, 2]. One significant source of water pollution is the discharge of dyes in wastewater produced by several industries [3]. Many industrial activities, including cosmetics, leather, printing, textile, food, paper, pharmaceutical, and plastic, release dyes into the water [4, 5].

Dyes are generally hazardous and even fatal to humans and the environment due to their remarkable stability and a high potential for carcinogenicity, genotoxicity, mutation, and teratogenicity. It should be noted that cationic dyes, like crystal violet, are more toxic and damaging than ionic dyes [6]. Crystal violet dye (CVD), a member of the triphenylmethane family, is lethal when inhaled, ingested, or touched to the skin. Furthermore, it has been linked to severe eye irritation and human cancer [7].

A very minor concentration of CVD in water (10–50 mg/L) is extremely observable and obstructs light dispersion in water systems, negatively affecting photosynthesis [8]. Hence, one of the most pressing issues is the removal of dyes from contaminated water sources. Note that the most significant variable determining dye removal efficacy is the best choice of removal agents [9].

The remediation of dyes can be performed by many treatment approaches, including biological, chemical, or physical procedures. Unfortunately, chemical treatments increased the chemical load in water bodies, leading to issues with sludge disposal. Nowadays, intensive research is concentrating on finding low-cost, ideal, broad-spectrum, and highly effective microbial biomass for dye decolorization [10, 11]. Biological methods are the most promising water treatment protocols because they appear environmentally secure. The dye biotransformation may result in its complete mineralization or the production of less hazardous compounds [12].

Fungal biomass among microbes is used as a sorbent and/or enzyme producer in the adsorption and biodegradation of various substances [13]. How effectively a dye is removed depends on its particular structure, the strain used in the decolorization process, how biomass is applied, and the chemical composition of the dye effluents. However, there are some disadvantages to utilizing fungal free-cell practice because the mycelium may be more susceptible to harsh environmental conditions; immobilizing biomass on various carriers may be a potent alternative [14]. The immobilization process enhances fungal activity while conserving biomass and maintains the production of several enzymes [15]. Moreover, it improves the environmental stress resistance of fungal strains to stresses at levels higher than those attained from free fungal suspension or mycelial pellet forms [16, 17]. Fungal cell immobilization also reduces protease activity and contamination risk, more straightforward liquid–solid separation, easy biomass recycling, and fewer blockages in continuous-flow systems [18].

Biomass surface modification can significantly modify the biomass’ capability for biosorption because the biosorption process mainly occurs on the biomass’ surface [2]. Massive enhancements in biomass’ biosorption capacity can be achieved by subjecting it to chemical, physical, and other processes that change its functional groups, altering its surface properties. Several physical pretreatment techniques have been employed, including heating, boiling, autoclaving, and freeze-drying [19]. To increase the biosorption potential, amine, phosphonate, sulfonate, thiol, hydroxyl, and carboxyl groups (representing active binding sites for dyes and metals) can be created, or their levels can be elevated via pretreatment protocols [20]. Various initiation techniques have been employed for producing active sites (free radicals or ionic chemical groups) for initiating polymerization reactions, including photochemical grafting via UV light and high energy radiation using gamma rays. Another enhancement role of the pretreatment is eliminating some particular groups in raw biomass that obstruct the biosorption of a specified pollutant, leading to a superior biosorbent [21].

Numerous fungi can decolorize various toxic dyes in either living or inactive forms [22,23,24]. Majul Leonardo et al. [25] reported that the immobilized Peniophora laxitexta removed between 30 and 50% of the azoic dye Xylidine and more than 50% of the anthraquinonic dye RBBR in three successive cycles and nearly 90% of the triphenylmethane Malachite Green in 10 repeated cycles without any loss of efficiency.

Crystal violet dye is a significant contaminant in wastewater from the effluent of clinical pathology labs, microbiology research, identification labs, textile, and cosmetic industry. Thus, the main objectives of the current study are to (a) investigate the role of immobilized Actinomucor elegans for the first time in the crystal violet removal process, (b) employ Box-Behnken design for studying the interaction effect of the different physical pretreatment protocol (heat, UV, gamma irradiation) for enhancing the efficiency of CVD removal, and (c) explore the novel approach of employing collective physical pretreatment to enhance CDV removal from a real wastewater sample.

2 Materials and methods

2.1 Chemicals and media

Adsorption and degradation studies of CV dye were carried out using Mineral Salts Medium (MSM) containing g l−1: MgSO4 0.2, CaCl2 0.02, KH2PO4 1, K2HPO4 1, FeCl2 0.05, and NH4NO3 1. The pH of the medium was adjusted to 7.0 by applying 1 N HCl or NaOH.

Any chemicals and media used were of high analytical purity grade. Mineral Salts Medium (MSM) containing g/l: (MgSO4: 0.2), (CaCl2: 0.02), (KH2PO4: 1), (K2HPO4: 1), (FeCl2: 0.05), and (NH4NO3: 1) was used to conduct adsorption and degradation investigations on CVD. The medium was brought down to a 7.0 pH value by adding 1 N HCl or NaOH.

2.2 Dye used

Analytical grade dye, Crystal violet C25H30ClN3, was developed as a stock solution, and additional concentrations were obtained through dilution. The pH was adjusted to the required concentration using sodium hydroxide and hydrochloric acid solutions at various concentrations (0.1–2 N). Supplementary Table S1 illustrates the main characteristics of CVD.

2.3 Fungal strain

The fungal strain with the highest decolorization potential against CV dye was selected and taxonomically identified based on its morphological characteristics and molecular identification.

2.4 Fungal identification

The selected fungi were identified by morphological features and molecular characterization in the Mycological Center of Assiut University (AUMC), Assiut, Egypt. They were deposited in their culture collection as Actinomucor elegans AUMC 15946.

The fungal isolate was cultivated on potato sucrose agar (PSA) medium and incubated at 28 °C for 5 days for molecular identification [26]. At Assiut University’s Molecular Biology Research Centre, fungal DNA was isolated using a Patho-gene-spin DNA/RNA extraction kit (Intron Biotechnology Company, Korea). Sequencing and polymerase chain reaction (PCR) was performed at the SolGent Corporation in Daejeon, South Korea. To amplify the ITS region of the rRNA gene, the universal primers ITS1 (forward) and ITS4 were used (reverse). ITS1 (5′-TCCGTAGGTGAA CCTGCGG-3′) and ITS4 (5′-TCCTCCGCTTATTGATATGC-3′) are the chemical formulas of the primers. The purified PCR product was sequenced using the same primers and the addition of ddNTPs to the reaction mixture [27].

2.5 Biomass production

The fungal spore inocula were placed in 1-L conical flasks with one-third of their capacity of Sabouraud’s broth medium and then incubated for 3 days at 27 °C while shaken. Fungal biomass was filtered to remove it from the medium at the end of the incubation period, and it was afterward washed with bi-distilled water several times. The acquired fungal biomass was kept in the fridge to be used as living biomass.

2.6 Immobilization of fungal biomass

As a hydrocolloid gelling material, sodium alginate salt (NaC6H7O6) from Sigma Aldrich (Germany) was used. A calcium chloride solution (Sigma Aldrich, Germany) was used as the fixing solution. The desired amount of fungal biomass was ground and mixed well with 4% (w/v) Na-alginate gel (10 ml). Dropping the produced mixed solution drop-wise through a pipette tip into a solution of 0.1 M calcium chloride resulted in the formation of spherical beads. The beads were hardened by soaking them in a solution of 2% (w/v) calcium chloride for 1 h, washing them in deionized water while being stirred at 100 rpm for 30 min, discarding the solution, and repeating the procedure five times [28]. The produced beads were gradually dried to a consistent weight at room temperature after any remaining water was wiped away using paper towels, and they were then used for additional experiments. Five-hundred beads ranging in diameter from 2.5 to 3.0 mm are produced by 10 ml of alginate gel. The resulting beads were stored for usage in the refrigerator. Free Na alginate (4%) was dissolved in a 0.1 M CaCl2 solution to create control beads.

2.7 Dye removal procedures

The MSM liquid culture media was added to 100-mL flasks without adding agar, and then the dye solution was added to create the appropriate concentration and final volume (25 ml). The pH was then set at 5.5 before sterilization. After cooling, both free biomass and 80 beads of immobilized biomass were tested individually, and the desired weight of fungal biomass was inoculated in each flask. All flasks were incubated at 30 °C under shaking conditions. At the end of the incubation period, beads were discarded by filtration. In another experiment, different biomass weights loaded with alginate beads were tested for efficient dye removal. The attained CVD-treated samples were centrifuged in both experiments to estimate the remaining dye at 570 nm. The remaining dye concentrations were calculated from a standard curve created at the same pH (Supplementary Fig. S1). The CVD removal efficiency (R%) is defined as follows:

where Ci is the initial concentration of CVD and Ct is the concentration of CVD at time t.

2.8 Modeling of physical pretreatment for enhanced biomass efficiency

MINITAB software version 18.0 was used to obtain the design of the Box-Behnken model. Box-Behnken design (BBD) of the response surface modeling (RSM) with three physical treatment parameters (heat, UV, gamma ray) at three tested levels, − 1 (low), 0 (central point), and + 1 (high), were used in this study to investigate, optimize, and study the interacted effect between the three physical treatment parameters on the biomass of the immobilized fungi for a maximum CV removal efficiency. Each independent variable was coded at three levels, which were heat (0–40–80 °C), UV exposure (0–15–30 min.), and gamma ray (0–150–300 Gy).

2.9 Statistical analysis

The experimental data acquired from the design were subjected to analysis by the response surface regression process, employing a second-order polynomial equation as follows:

where Yi is the predicted response, XiXj are the independent variables, β0 is the offset term, βi is the linear coefficient, βii is the quadratic coefficient, and βij is the interaction coefficient. The statistical parameters were estimated using analysis of variance (ANOVA). The experimental data was fitted using a second-order polynomial equation. The F-test was used to assess the relevance of the model equation and model terms. The coefficient of determination (R2), adjusted, and acceptable precision were used to represent the quality of the polynomial equation fit. The fitted polynomial equation was displayed as three-dimensional surface plots to visualize the link between the responses and the experimental levels of each factor employed in the design.

2.10 Decolorization monitoring

Using a UV–Vis spectrophotometer (2401 PC, Shimadzu), decolorization was observed, and alterations in the absorption spectrum (400–800) were recorded to monitor the decolorization process.

2.11 FTIR analysis

FTIR analysis was performed using a Perkin Elmer 783 Spectrophotometer, and variations in transmission percentage at various wavelengths were noted. With a Perkin Elmer Spectrum One instrument, the FTIR analysis of the tested, treated dye was performed, and the results were compared to the control (untreated) dye in the mid-IR range of 500–4000 cm−1 with 16 scan speeds. The samples were combined at a ratio of 2:200 with spectroscopically pure KBr, fixed pellets, and analysis was performed.

2.12 Toxicity evaluation of the treated dye

2.12.1 Phytotoxicity assay

On Trigonella foenum-graecum and Vicia faba seed germination, the phytotoxicity of both treated (bioremediated) and untreated CVD solutions was noted. The examined seeds were sterilized for 50 s in a 0.1% HgCl2 solution and then washed 6–7 times in sterile distilled water to eliminate any remaining HgCl2 ions. Fifty numbers of viable and healthy seeds of Trigonella foenum-graecum and 25 numbers of Vicia faba seeds were taken, each separately, in plastic glass pots and soaked in 100 ml of 50 ppm CVD and optimum treated CVD; each was tested independently for a period of 24 h. Similar tested viable and healthy seedlings were taken in a different experiment and left in 100 ml of distilled water for 24 h as a negative control. Following soaking for 24 h, the swelled seeds were covered with a wet cotton cloth and left at room temperature for an additional 24 h for Trigonella foenum-graecum and 48 h for Vicia faba. The well-germinated seeds were counted, and the germination percentage was calculated when the incubation period ended.

2.12.2 Microbial toxicity studies

Toxicity of the bioremediated and untreated dye solution was also observed on bacterial growth by measuring the zone of inhibition [29]. Log phase cells of Escherichia coli, 0.1 ml of the prepared bacterial cell suspension (108 CFU/ml) were regularly spread on petri plates containing Mueller–Hinton agar medium. Then, agar well was formed by a sterilized cork-borer and then was filled with 50 µl of bioremediated and untreated dye solution; each was tested separately. The plates were kept in the refrigerator for 3 h to allow diffusion of the dye solution, at 37 °C incubator for 24 h. The development of the inhibition zone was searched and measured.

2.12.3 Cytotoxicity studies

The treated and untreated CVD solutions were tested for cytotoxicity against two normal cell lines, epithelial breast MCF-12F and fibroblast BJ-1. Cell lines were grown in DMEM media supplemented with 10% FBS, two mM L-glutamine, and 1% streptomycin/penicillin in cell culture flasks (Corning, NY, USA). When cultures had attained a confluence of 70–80%, Trypsin 0.05%/0.53 mM EDTA was added for trypsinization, and 105 cells were cultured at a volume of 100 µl media per well in 96-well plates holding various doses (5, 10, 25, 50 µl) of treated and untreated dye solution; each of which was examined individually. An MTT assay was employed to assess the viability of cells. Accordingly, 20 µl (5 mg/ml) of 0.5% MTT phosphate-buffered saline solution was added to each well after incubation for 1 day. During another 4 h of incubation, 130 µl of 0.04 M HCl/isopropanol was added to each well. A microplate reader (Bio-Rad, Richmond, CA) was used to evaluate the absorbance at 570 nm to determine the cells’ viability. Wells without cells were used as blanks. The following formula (Eq. 2) was used to express the cytotoxicity of test samples on the normal cells’ proliferation as a percentage of cell viability [30]:

2.13 Application of CVD decolorization on real wastewater

Real wastewater containing CVD was collected from the clinical pathology labs at Zagazig General Hospital, Egypt. Physically pretreated immobilized fungus with the optimum parameters from the response surface methodology was added to wastewater samples, and its effectiveness in CVD removal was evaluated for four subsequent days.

3 Results

3.1 Fungal morphological and molecular identification

The Actinomucor species belongs to the class of zygomycetes and is a member of the Mucorales (Mucoraceae division). The genus Actinomucor elegans is the representative species of the Actinomucor class fungi. It has long, slender, non-segmented, and poly-nucleated hyphae. This fungus group is distinguished by short sporophores under the sporangia, stolons, and rhizoids at their apex. Although morphologically similar to the Mucor family, the Actinomucor varies; in that, it has two stolons and one rhizoid, which derive from the rhizoids. According to the literature, this species can be cultivated in a broad temperature range between 18 and 40 °C, with optimum temperature at 30 °C, and pH range between 3.5 and 9.0, with optimum at pH 7.0. Shaking conditions are favored over stationary incubation. Figure 1a, b, c show the morphological features and microscopic image. The National Center of Biotechnology Information’s (NCBI) website’s Basic Local Alignment Search Tool (BLAST) was used to examine the obtained ITS sequences. MegAlign (DNA Star) software version 5.05 was used to create the phylogenetic tree (Fig. 1d).

3.2 Immobilization effect on CVD removal

The standard curve of CVD was achieved to determine the concentration of differently treated samples of dye, as shown in Fig. 2a. The removal and decolorization of crystal violet using free cells, immobilized cells, and control beads (sterile beads without immobilized Actinomucor elegans) was compared. As shown in Fig. 2a, the immobilized cells achieved the highest removal efficiency of crystal violet (80.3%), while 66.2% of crystal violet was remediated by free cells after 168-h contact time. After 72 h, contact time does not significantly affect CVD removal.

3.3 Effects of biomass dosage on dye removal

The impact of the biomass dosage was assessed for 3 days at 30 °C and a concentration of 50 ppm. As revealed in Fig. 2b, an initial dye concentration of 50 ppm for 72 h was decolorized up to 87.8% by preparation of 1 g biomass loaded with Na-alginate beads, up to 88.4% by preparation of 0.5 g biomass, up to 80% by preparation of 0.25 g biomass, and up to 63% by preparation control Na-alginate beads without biomass loaded. Results illustrate that the application of 0.5 and 1 g of biomass was sufficient to achieve a good decolorization efficiency with no conspicuous differences between them.

3.4 Response surface methodology

Various physical pretreatment parameters (heat, UV, and gamma) combinations on Actinomucor biomass were used and corresponding CVD removal efficiency (predicted and experimental data) was estimated (Table 1). Linear multiple regression analysis and graphical designing were attained using the Minitab version 18 software. The mathematical design incorporating the collaborative effect of the tested parameters was submitted for CVD removal % as shown in Eq. 3:

where A refers to heat dose, B to UV dose, and C to gamma radiation dose. ANOVA of the regression model verified that the design was highly significant (P value < 0.05) (Supplementary Table S2). AA, AB, CC, BC, and C are significant model terms. Significant terms were represented graphically in a Pareto chart (Fig. 3a), while positively affected terms were described in a normal effect plot (Fig. 3b). The coefficient of determination (R2) value determined the model’s goodness of fit. Here, the R2 value of this design equals 0.9732. Thus, it is accurate to apply the regression to investigate the obtained in the responses. The graphical illustration of the regression equation generated through data analysis was represented by 3D surface graphs shown in Fig. 4. The diagrams demonstrate the interactions between levels of most significant effectors on CVD removal %. From the response optimizer facility in Supplementary Fig. S2, the maximum predicted CVD removal value is 96.24% when the heat dose is 60 °C, the UV exposure dose is 30 min, and the gamma radiation dose is 300 Gy. A confirmation experiment was conducted with the optimum levels to verify the expected result, and the actual and expected data were compared. The expected CVD removal in the Box-Behnken model (96.24%) and actual result (96.4%) were in good agreement, which was higher than CVD removal in unoptimized conditions (63.8%), as shown in Fig. 5.

3.5 Characterization of decolorized CVD

Using an FTIR, scans were performed in the 4000–500-cm1 wave number range before and after the decolorization of CVD by immobilized pretreatment of Actinomucor elegans cells. According to earlier literature, peaks in the FTIR spectra of CVD were attributed to distinct groups and bonded in line with their corresponding wave numbers. The essential characteristics of CVD bioremediation and the process of biodegradation are the presence of different peaks before treatment, their absence after treatment, and the emergence of further new peaks that did not exist before treatment. Figure 6 displays the spectra demonstrating the band shift variations between the intervals before and after CVD biodegradation. One of the significant variations is that, in contrast to the band’s presence before treatment, the band at 2362.47 cm−1 corresponded to the symmetrical and asymmetrical stretching of tertiary amine salt after treatment. After treatment, the absence of the peak at 669.21 cm−1 suggests that the aromaticity or benzene ring has been lost. Moreover, new bands appeared at 1025, 1156, 16, 17, and 2854 cm−1. Another indication of biodegradation processes was the stretch vibrations of C–O–C and C–N, found at 25 cm−1.

A significant and vast band stretch, suggestive of − NH2 groups, was visible between 3200 cm−1 and 3600 cm−1. The light stretch at 2925.61 cm−1 revealed the asymmetric CH3 group’s C–H vibration. The vibrations of the C–N stretch of aromatic tertiary amine peaked at 1396.27 cm−1, while the COO, C = O, and C–N stretching vibrations peaked at 1630.27 cm−1. Possible phosphonate bands can be found at 1094.45 cm−1 (P–OH stretching). The vibrations of the benzene ring, which correlate to the band at 669 cm−1, indicate CVD’s aromatic character.

3.6 Toxicity evaluation of decolorized CVD

3.6.1 Phytotoxicity assay

Untreated dye effluents are discharged into water bodies, and this water can be used for agriculture even though they represent significant risks to the environment and human health. The soil fertility is directly impacted by using dyeing effluents in agriculture; hence, it was essential to evaluate CVD’s phytotoxicity before and after degradation. The effect of treated CVD on Trigonella foenumgraecum (Fenugreek) and Vicia faba (broad bean) germination was studied for any inhibitory effect. According to the results, the pigment has no significant harmful effect on the germination of the seeds, as represented in Fig. 7 and Supplementary Table S3.

According to these findings, the degradation product is less damaging to plants. Hence, research on phytotoxicity showed that the CVD’s detoxification was caused by biodegradation. As a result, treated wastewater can be applied for irrigation.

3.6.2 Microbial toxicity assay

Microbial bioassay research revealed that treated dye did not exhibit any zone of inhibition, but untreated CVD (50 ppm) inhibited the growth of Escherichia coli by generating a mean area of inhibition equal to 2.8 cm (Fig. 8). Our results demonstrate that the bioremediated CVD is non-toxic.

3.6.3 Cytotoxicity assay

Untreated CVD (at a concentration of 50 ppm) and treated samples were tested for their cytotoxic activity against two normal cell lines, MCF-12F and BJ-1, and recorded data were represented in Fig. 9. As illustrated, untreated CVD displayed potential toxic activity against the two tested cell lines. This activity increased by increasing the inoculated untreated dye volume from 5 to 50 µl. Since the untreated CVD recorded cytotoxicity% of 1.45, 7.23, 13.34, and 21.26% at different inoculated dye volumes of 5, 10, 25, and 50 µl, respectively. Meanwhile, the bioremediated dye shows very little cytotoxicity%, recording 0.15, 0.91, 1.78, and 2.67% at different inoculated dye volumes of 5, 10, 25, and 50 µl, respectively.

3.7 Real wastewater evaluation

Immobilized and pretreated Actinomucor elegans was examined through an actual wastewater system that contained CVD and other substances used to stain bacteria (iodine, carbol fuchsin, water, and 90% alcohol). The mixture was first spectrophotometrically assessed to confirm the presence of the crystal dye’s characteristic peak before treatment. Figure 10 demonstrates the 400–700-nm UV–visible spectra before and after the biodegradation process. The findings show that the real system had been decolored after 4 days of incubation with the immobilized pretreatment Acinomucor elegans cells. At first (0 h), the maximum peak at 570 nm (absorbance: 2.08 nm, concentration: 57 ppm) was seen. After 4 days of incubation, this peak was completely decolored. It is confirmed that the area under the curve significantly decreased, demonstrating the effectiveness of the fungal biomass in eliminating the color contained in the real wastewater. After 1, 2, 3, and 4 days of incubation with immobilized biomass, the removal percentage achieved in these test conditions was 69.4, 80.7, 87.8, and 89.8%. It is clear that the removal percentage of CVD through individual systems after the third day has reached 95.8%, but it decreased to 89.8% after the fourth day when removed in a real wastewater-colored system. During the bioremediation, other dyes (iodine and carbol fuchsin) were found to be competitive with CVD; this affected the process delays.

3.8 Comparison of the crystal violet decolorization efficiency with other studies

The decolorization of crystal violet dye investigated in this study was compared to that of other studies in Table 2. As demonstrated in Table 2, the crystal violet dye was bioremediated via adsorption or/and biodegradation. Compared to other experiments, this one’s crystal removal potential was obviously far more efficient, as seen by the removal percentage of 95.8% for a 50 ppm concentration after 3 days.

In this study, we demonstrated that the crystal was remediated through initial adsorption and biodegradation, resulting in the conversion of the dangerous material into a more avoidable, non-toxic form.

4 Discussion

Crystal violet can resist ecological damage and persist in sewage and soil for a long time. In addition to generating an intense color even in small quantities, crystal violet poses a severe risk to aquatic life, plants, and people [31].

Some microorganisms can biodegrade crystal violet, including bacteria such as Staphylococcus epidermidis [11] and fungi such as Aspergillus niger [32]. However, the new strain, Actinomucor elegans, used to biodegrade crystal violet in the current manuscript has not been reported. As a result, this study provides the first evidence that crystal violet can be efficiently remediated using biomass from the Actinomucor elegans AUMC15946 strain that has been immobilized and physically processed. It can be shown that immobilized cells on the alginate beads considerably increased the removal of crystal violet since their removal rate was higher than that of free cells. This result is consistent with other cells immobilized on alginate to degrade dyes [33, 34]. From our observations and results, the immobilization system offers many advantages, such as continuous utilization, higher cell density, and protection against harsh environments. This also aligns with Moreira [35], who reported that immobilized preparations have a higher biomass concentration per volume unit and higher operational stability. As a result, the decolorization process becomes more powerful and proceeds more quickly. Previous investigations have also noted the advantage of employing more biomass [36]. These studies generally attributed the benefit to having more binding sites and enzymes that lead to biosorption and biodegradation, respectively. Also, it was demonstrated that immobilizing substances can change cellular physiology and improve the permeability and stability of cell membranes [37]. These substances are a barrier to safeguard interior cells, along with the microcolonies’ surface-attached cells [38]. In summary, sodium alginate is one of the most widely utilized natural carriers for immobilizing entrapments because of its excellent biocompatibility, ease of gelatinization, mechanical stability, high porosity, high transparency, and tolerance to salts and chelating agents [39].

The results show that the percentage of CVD elimination increased to a specific point as loaded biomass concentrations increased. It is evident that when biomass concentration rises, the number of potential biosorption sites grows, raising the concentration of absorbed material. Further increment in loaded biomass concentration from 0.5 g did not cause improvement in CVD removal. This is because practically all the ions are bound to the biomass when the equilibrium between the dye molecules tied to the biomass and those still in the solution that have not been absorbed is reached. These findings are consistent with earlier investigations [40, 41].

According to research on aqueous dye solutions, decolorization can occur in two ways: either the dyes adsorb on microbial biomass or are biodegraded by the entire microbial cell [42,43,44]. This study used the IR spectroscopy analysis of the CVD before and after treatment to understand the mechanisms of CVD bioremediation. The shift in bands reveals that metabolites unique from the original substrate are formed.

Actinomucor elegans may decolorize dyes either through the activity of extracellular enzymes or through biosorption by the fungal biomass. Generally, biosorption of dyes happens by one of five different mechanisms: complexation, physical force-induced adsorption, precipitation, trapping in the interior spaces of fungi, ion exchange caused by surface ionization, or the formation of hydrogen bonds [45]. Fungi interact physically with their environment more because they have a higher cell-to-surface ratio. As a result, some fungi have shown dye adsorption potential that is better than activated charcoal [46]. Furthermore, certain species frequently exhibit enzyme-mediated degradation and biosorption during the decolorization of dyes [47]. It is therefore believed that the ability of the soil fungi to decolorize synthetic dyes is related to their capacity for biosorption in addition to the generation of extracellular enzymes [29].

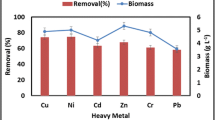

The physical pretreatment factors (heat, UV, and gamma treatment) were statistically adjusted using the Box-Behnken design. Consequently, they were employed collectively to attain the maximum dye decolorization capacity of immobilized Actinomucor. In literature [48,49,50], RSM proved its proficiency in optimizing different bioprocesses. In addition, gamma irradiation was applied to fungi to improve their heavy metal bioremediation potential [51].

In addition, bacterial growth, normal cell line, and seed germination bioassays in this investigation supported that detoxification of CVD had occurred.

In soil ecosystems, fungi are key players in lignocellulose decomposition due to their ligninolytic enzymes [52]. These lignin-degrading enzymes play a direct role in the breakdown of numerous xenobiotic chemicals, such as dyes, and the breakdown of lignin in its natural lignocellulosic substrates. Additionally, it has been demonstrated that ligninolytic enzymes may oxidize a wide range of resistant chemicals, including phenols, polycyclic aromatic hydrocarbons (PAHs), organophosphorus compounds, and chlorophenols [53].

5 Conclusion

The authors conclude in Fig. 11 that the immobilized and optimized-pretreated Actinomucor elegans can be effectively used for the bioremediation of toxic CVD. In this system, dye removal with outstanding results proved to be a complex process, which combined physical adsorption on immobilized fungal surface and biological degradation by viable fungal biomass.

The immobilized fungal cells were better at getting rid of CVD (80.3% vs. 66.2% for the free cells). In order to remove as much CVD as possible (96.4%), the most effective conditions for pretreating the fungal biomass were 45 °C for 20 minutes under UV light and 300 Gy of gamma radiation. The treated CVD does not hurt the growth of seeds in any way. In the same way, the CVD that had been treated allow the growth of E. coli cells and two normal cell lines, epithelial breast MCF-12F and fibroblast BJ-1.

6 Future perspectives

Future research on fungal dye degradation should focus on reducing the factors limiting fungal activity. Recent and early effective studies should be re-examined to improve fungal activities’ performance. Degradation pathways, environmental conditions, degradation rate, and degradation processes that affect the elimination of dye pollutants should all be considered in an effective biodegradation process. The degradation products must not be hazardous to aquatic life or vegetation. Integrating several dye pollution treatment technologies is desirable for effective translation to industries. Investigating methods and theories for fungal degradation of dye wastewater would aid in studying fungal degradation kinetics.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Efimov M, Vasilev A, Muratov D, Baranchikov A, Karpacheva G (2019) IR radiation assisted preparation of KOH-activated polymer-derived carbon for methylene blue adsorption Journal of Environmental. Chem Eng 7(6):103514. https://doi.org/10.1016/j.jece.2019.103514

Li Z, Chen Z, Zhu Q, Song J, Li S, Liu X (2020) Improved performance of immobilized laccase on Fe3O4@ C-Cu2+ nanoparticles and its application for biodegradation of dyes. J Hazard Mater 399:123088. https://doi.org/10.1016/j.jhazmat.2020.123088

Nouren S, Bhatti HN, Iqbal M, Bibi I, Nazar N, Iqbal DN, Kanwal Q, Kausar A, Hussain F (2017) Redox mediators assisted-degradation of direct yellow 4 Polish. J Environ Studies 26(6):2885–2890. https://doi.org/10.15244/pjoes/68564

Affat SS (2021) Classifications, advantages, disadvantages, toxicity effects of natural and synthetic dyes: a review. University Thi-Qar J Sci 8(1):130–135. https://doi.org/10.32792/utq/utjsci/v8/1/21

Sharifpour E, Haddadi H, Ghaedi M (2017) Optimization of simultaneous ultrasound assisted toxic dyes adsorption conditions from single and multi-components using central composite design: application of derivative spectrophotometry and evaluation of the kinetics and isotherms. Ultrason Sonochem 36:236–245. https://doi.org/10.1016/j.ultsonch.2016.11.011

Shayesteh H, Rahbar-Kelishami A, Norouzbeigi R (2016) Adsorption of malachite green and crystal violet cationic dyes from aqueous solution using pumice stone as a low-cost adsorbent: kinetic, equilibrium, and thermodynamic studies. Desalination Water Treat 57(27):12822–12831. https://doi.org/10.1080/19443994.2015.1054315

Gusmão KAG, Gurgel LVA, Melo TMS, Gil LF (2012) Application of succinylated sugarcane bagasse as adsorbent to remove methylene blue and gentian violet from aqueous solutions—kinetic and equilibrium studies. Dyes Pigments 92(3):967–974. https://doi.org/10.1016/j.dyepig.2011.09.005

Farooq S, Saeed A, Sharif M, Hussain J, Mabood F, Iftekhar M (2017) Process optimization studies of crystal violet dye adsorption onto novel, mixed metal Ni0.5Co0.5Fe2O4 ferrospinel nanoparticles using factorial design. Journal of water process engineering 16:132–141. https://doi.org/10.1016/j.jwpe.2017.01.001

Zhang L, Yao L, Ye L, Long B, Dai Y, Ding Y (2020) Benzimidazole-based hyper-cross-linked polymers for effective adsorption of chlortetracycline from aqueous solution Journal of Environmental. Chem Eng 8(6):104562. https://doi.org/10.1016/j.jece.2020.104562

Sreedharan V, Bhaskara Rao KV (2019) Biodegradation of textile azo dyes. Nanoscience and Biotechnology for Environmental Applications 22:115–139. https://doi.org/10.1007/978-3-319-97922-9_5

Ayed L, Chaieb K, Cheref A, Bakhrouf A (2010) Biodegradation and decolorization of triphenylmethane dyes by Staphylococcus epidermidis. Desalination 260(1–3):137–146. https://doi.org/10.1016/j.desal.2010.04.052

Yang P, Shi W, Wang H, Liu H (2016) Screening of freshwater fungi for decolorizing multiple synthetic dyes. Brazilian J Microbiol 47:828–834. https://doi.org/10.1016/j.bjm.2016.06.010

Liu W, Chao Y, Yang X, Bao H, Qian S (2004) Biodecolorization of azo, anthraquinonic and triphenylmethane dyes by white-rot fungi and a laccase-secreting engineered strain. J Ind Microbiol Biotechnol 31(3):127–132. https://doi.org/10.1007/s10295-004-0123-z

Velkova Z, Kirova G, Stoytcheva M, Kostadinova S, Todorova K, Gochev V (2018) Immobilized microbial biosorbents for heavy metals removal. Eng Life Sci 18(12):871–881. https://doi.org/10.1002/elsc.201800017

Couto SR (2009) Dye removal by immobilised fungi Biotechnology advances. Biotechnol Adv 27(3):227–235. https://doi.org/10.1016/j.biotechadv.2008.12.001

Nakamura Y, Sungusia MG, Sawada T, Kuwahara M (1999) Lignin-degrading enzyme production by Bjerkandera adusta immobilized on polyurethane foam. J Biosci Bioeng 88(1):41–47. https://doi.org/10.1016/S1389-1723(99)80173-X

Zabłocka-Godlewska E, Przystaś W, Grabińska-Sota E (2012) Decolourization of diazo Evans blue by two strains of Pseudomonas fluorescens isolated from different wastewater treatment plants Water. Air, & Soil Pollution 223:5259–5266. https://doi.org/10.1007/s11270-012-1276-4

Ting YP, Sun G (2000) Use of polyvinyl alcohol as a cell immobilization matrix for copper biosorption by yeast cells Journal of Chemical Technology & Biotechnology International Research in Process. Environ Clean Technol 75(7):541–546. https://doi.org/10.1002/1097-4660(200007)75:7%3c541::AID-JCTB247%3e3.0.CO;2-9

O’Connell DW, Birkinshaw C, O’Dwyer TF (2008) Heavy metal adsorbents prepared from the modification of cellulose: a review. Biores Technol 99(15):6709–6724. https://doi.org/10.1016/j.biortech.2008.01.036

Ngah WW, Hanafiah MM (2008) Removal of heavy metal ions from wastewater by chemically modified plant wastes as adsorbents: a review. Biores Technol 99(10):3935–3948. https://doi.org/10.1016/j.biortech.2007.06.011

Park D, Yun Y-S, Park JM (2010) The past, present, and future trends of biosorption. Biotechnol Bioprocess Eng 15:86–102. https://doi.org/10.1007/s12257-009-0199-4

Thao TTP, Nguyen-Thi M-L, Chung ND, Ooi CW, Park S-M, Lan TT, Quang HT, Khoo KS, Show PL, Huy ND (2023) Microbial biodegradation of recalcitrant synthetic dyes from textile-enriched wastewater by Fusarium oxysporum. Chemosphere 325:138392. https://doi.org/10.1016/j.chemosphere.2023.138392

Thoa LTK, Thao TTP, Hung NB, Khoo KS, Quang HT, Lan TT, Hoang VD, Park S-M, Ooi CW, Show PL (2022) Biodegradation and detoxification of malachite green dye by extracellular laccase expressed from Fusarium oxysporum. Waste Biomass Valorization 13(5):2511–2518. https://doi.org/10.1007/s12649-022-01692-2

Chuah LF, Chew KW, Bokhari A, Mubashir M, Show PL (2022) Biodegradation of crude oil in seawater by using a consortium of symbiotic bacteria. Environ Res 213:113721. https://doi.org/10.1016/j.envres.2022.113721

Majul L, Wirth S, Levin L (2022) High dye removal capacity of Peniophora laxitexta immobilized in a combined support based on polyurethane foam and lignocellulosic substrates. Environ Technol 43(5):684–695. https://doi.org/10.1080/09593330.2020.1801851

Pitt JI, Hocking AD (2022) Ecology of fungal food spoilage. In Fungi and food spoilage. Springer, pp 3–12. https://doi.org/10.1007/978-0-387-92207-2_2

White TJ, Bruns T, Lee S, Taylor J (1990) Amplification and direct sequencing of fungal ribosomal RNA genes for phylogenetics. PCR Protocols: a Guide Methods Appl 18(1):315–322

Tan WS, Ting ASY (2012) Efficacy and reusability of alginate-immobilized live and heat-inactivated Trichoderma asperellum cells for Cu (II) removal from aqueous solution. Bioresource Technology 123:290–295. https://doi.org/10.1016/j.biortech.2012.07.082

Rani B, Kumar V, Singh J, Bisht S, Teotia P, Sharma S, Kela R (2014) Bioremediation of dyes by fungi isolated from contaminated dye effluent sites for bio-usability. Braz J Microbiol 45:1055–1063. https://doi.org/10.1590/S1517-83822014000300039

Raj KG, Sambantham S, Manikanadan R, Arulvasu C, Pandi M (2014) Fungal taxol extracted from Cladosporium oxysporum induces apoptosis in T47D human breast cancer cell line. Asian Pac J Cancer Prev 15(16):6627–6632. https://doi.org/10.7314/APJCP.2014.15.16.6627

Wu J, Gao H, Yao S, Chen L, Gao Y, Zhang H (2015) Degradation of crystal violet by catalytic ozonation using Fe/activated carbon catalyst. Sep Purif Technol 147:179–185. https://doi.org/10.1016/j.seppur.2015.04.022

Ali H, Shehata S, Ramadan K (2016) Microbial decolorization and degradation of crystal violet dye by Aspergillus niger. Int J Environ Sci Technol 13:2917–2926. https://doi.org/10.1007/s13762-016-1117-x

Chen J-P, Lin Y-S (2007) Decolorization of azo dye by immobilized Pseudomonas luteola entrapped in alginate–silicate sol–gel beads. Process Biochemistry 42(6):934–942. https://doi.org/10.1016/j.procbio.2007.03.001

Munck C, Thierry E, Gräßle S, Chen SH, Ting ASY (2018) Biofilm formation of filamentous fungi Coriolopsis sp. on simple muslin cloth to enhance removal of triphenylmethane dyes. J Environ Manag 214:261–266. https://doi.org/10.1016/j.jenvman.2018.03.025

Wang N, Chu Y, Zhao Z, Xu X (2017) Decolorization and degradation of Congo red by a newly isolated white rot fungus, Ceriporia lacerata, from decayed mulberry branches. Int Biodeterior Biodegradation 117:236–244. https://doi.org/10.1016/j.ibiod.2016.12.015

Bankole PO, Adekunle AA, Govindwar SP (2018) Enhanced decolorization and biodegradation of acid red 88 dye by newly isolated fungus. Achaetomium Strumarium J Environ Chem Eng 6(2):1589–1600. https://doi.org/10.1016/j.jece.2018.01.069

Tao X-Q, Lu G-N, Liu J-P, Li T, Yang L-N (2009) Rapid degradation of phenanthrene by using Sphingomonas sp GY2B immobilized in calcium alginate gel beads. Int J Environ Res Publ Health 6(9):2470–2480. https://doi.org/10.3390/ijerph6092470

Cheng Y, Lin H, Chen Z, Megharaj M, Naidu R (2012) Biodegradation of crystal violet using Burkholderia vietnamiensis C09V immobilized on PVA–sodium alginate–kaolin gel beads. Ecotoxicol Environ Safety 83:108–114. https://doi.org/10.1016/j.ecoenv.2012.06.017

Serp D, Cantana E, Heinzen C, Von Stockar U, Marison I (2000) Characterization of an encapsulation device for the production of monodisperse alginate beads for cell immobilization. Biotechnol Bioeng 70(1):41–53. https://doi.org/10.1002/1097-0290(20001005)70:1%3c41::AID-BIT6%3e3.0.CO;2-U

Bayramoglu G, Yilmaz M (2018) Azo dye removal using free and immobilized fungal biomasses: isotherms, kinetics and thermodynamic studies. Fibers Polymers 19:877–886. https://doi.org/10.1007/s12221-018-7875-y

Khalaf MA (2008) Biosorption of reactive dye from textile wastewater by non-viable biomass of Aspergillus niger and Spirogyra sp. Biores Technol 99(14):6631–6634. https://doi.org/10.1016/j.biortech.2007.12.010

Khan R, Bhawana P, Fulekar M (2013) Microbial decolorization and degradation of synthetic dyes: a review. Rev Environ Sci Bio/Technol 12:75–97

Buntić AV, Pavlović MD, Antonović DG, Šiler-Marinković SS, Dimitrijević-Branković SI (2017) A treatment of wastewater containing basic dyes by the use of new strain Streptomyces microflavus CKS6. J Clean Prod 148:347–354. https://doi.org/10.1016/j.jclepro.2017.01.164

Mahmoud M (2016) Decolorization of certain reactive dye from aqueous solution using Baker’s Yeast (Saccharomyces cerevisiae) strain. HBRC journal 12(1):88–98. https://doi.org/10.1016/j.hbrcj.2014.07.005

Yeddou-Mezenner N (2010) Kinetics and mechanism of dye biosorption onto an untreated antibiotic waste. Desalination 262(1–3):251–259. https://doi.org/10.1016/j.desal.2010.06.023

Shahid A, Singh J, Bisht S, Teotia P, Kumar V (2013) Biodegradation of textile dyes by fungi isolated from North Indian field soil. Environment Asia 6(2):51–57. https://doi.org/10.14456/ea.2013.18

Sen SK, Raut S, Bandyopadhyay P, Raut S (2016) Fungal decolouration and degradation of azo dyes: a review. Fungal Biol Rev 30(3):112–133. https://doi.org/10.1016/j.fbr.2016.06.003

Garyali S, Kumar A, Reddy MS (2014) Enhancement of taxol production from endophytic fungus Fusarium redolens. Biotechnol Bioprocess Eng 19:908–915. https://doi.org/10.1007/s12257-014-0160-z

Colla LM, Primaz AL, Benedetti S, Loss RA, Lima MD, Reinehr CO, Bertolin TE, Costa JAV (2016) Surface response methodology for the optimization of lipase production under submerged fermentation by filamentous fungi. Brazilian Journal of Microbiology 47:461–467. https://doi.org/10.1016/j.bjm.2016.01.028

Abdel-Fattah YR, El Enshasy H, Anwar M, Omar H, Abolmagd E, Zahra R (2007) Application of factorial experimental designs for optimization of cyclosporin a production by Tolypocladium inflatum in submerged culture. J Microbiol Biotechnol 17(12):1930

Das D, Chakraborty A, Bhar S, Sudarshan M, Santra S (2013) Gamma irradiation in modulating cadmium bioremediation potential of Aspergillus sp IOSR. J Environ Sci Toxicol Food Technol 3:51–55 (https://api.semanticscholar.org/CorpusID:56398691)

Zheng H, Yang T, Bao Y, He P, Yang K, Mei X, Wei Z, Xu Y, Shen Q, Banerjee S (2021) Network analysis and subsequent culturing reveal keystone taxa involved in microbial litter decomposition dynamics. Soil Biol Biochem 157:108230. https://doi.org/10.1016/j.soilbio.2021.108230

Kumar A, Chandra R (2020) Ligninolytic enzymes and its mechanisms for degradation of lignocellulosic waste in environment. Heliyon 6 (2). https://doi.org/10.1016/j.heliyon.2020.e03170

Acknowledgements

The authors would like to express their appreciation and profound thanks to Dr. Mahmoud A. Mosleh at the Egyptian Atomic Energy Authority (EAEA) for his continuous help.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

Y. A. H. and A. G. Z. investigated the article; designed the experimental methodology; conducted a statistical optimization model, toxicity bioassay, and real wastewater analysis experiments; wrote the original draft; contributed to data analysis and data representation; and revised the manuscript. A. S. A. suggested the research point, designed the research methodology, conducted experiments in the fungal isolation and immobilization technique part, provided chemicals and devices, and participated in data analysis and manuscript revising. All authors reviewed the article.

Corresponding authors

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Research involving human participation and/or animals

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hasanien, Y.A., Zaki, A.G. & Abdel-Razek, A.S. Employment of collective physical pretreatment and immobilization of Actinomucor biomass for prospective crystal violet remediation efficiency. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04991-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04991-3