Abstract

The conversion of Eucalyptus biomass to ethanol via fermentation is beset with challenges including efficient sugar utilisation, the presence of inhibitors, expensive nutrients, and low yields. To address some of these challenges, this study evaluated Thermosacc Dry® and GSF335 xylose recombinant yeast in fermentations using acid pretreated Eucalyptus grandis fibre and hydrolysates. These fermentations were supplemented with novel and low-cost nutrients. Contrary to previous reports, the inclusion of trace metals in saccharification and hydrolysis fermentations of whole slurries did not eliminate the inhibitory effects of acetic acid. Elevated levels of xylitol and acetic acid suggested a redirection of carbon flux to redress redox imbalances in both yeast types. Using GSF335 propagated in xylose-enriched liquors, and Nutri-Plex Plus™, diammonium phosphate, or crude dried spent yeast as nitrogen sources, saccharification and hydrolysis fermentations produced ethanol yields ranging from 141.4 to 145.6 kg t−1 dry weight E.grandis. Inclusion of yeast hulls and trace metals in simultaneous saccharification and fermentations yielded 175.6 kg ethanol t−1 dry weight E.grandis, corresponding to a 64.4% conversion efficiency. Results from this study support the use of novel low-cost waste by-products as nutrient supplements in bioethanol production from Eucalyptus biomass. Furthermore, they have implications for the production of bioethanol from other lignocellulosic materials and warrant further investigation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Concerns about the availability and escalating demand for conventional fossil fuels, and their contribution to global warming, are driving research in commercial scale development of alternative transportation fuels. Lignocellulosic materials are an attractive raw feedstock for biofuel and bio-based chemical production due to their availability, low cost, and potential for mitigating greenhouse gas emissions [1]. Despite the attractiveness of lignocellulose as a low-cost feedstock for ethanol production, commercial exploitation at an industrial scale has yet to be realised. Efficient conversion of lignocellulose to bioethanol via bioprocessing generally involves three main stages: chemical pretreatment, enzymatic hydrolysis, and fermentation. The pretreatment step is crucial in exposing holocellulose for subsequent production of hydrolysates containing liberated sugars to support fermentation [2].

However, producing bioethanol and commodity chemicals using hydrolysates sourced from lignocellulosics presents a number of challenges. Hydrolysates produced from lignocellulosic biomass are nutrient deficient and contain a complex mixture of inhibitors, which adversely affect the growth and fermentation capabilities of yeast [3, 4]. For example, hydrolysates from Eucalyptus species typically contain less than 0.1% total nitrogen, which is more than tenfold less than grain mashes used in conventional ethanol fermentations [5]. Given that nitrogen is vital for both active cell growth and ethanol production, it is crucial that lignocellulosic fermentations are supplemented with assimilable nitrogen [6]. Materials abundant in free amino nitrogen provide an excellent source of assimilable nitrogen to support growth of Saccharomyces cerevisiae yeast during fermentation [6, 7].

In addition to supplying free amino nitrogen, proprietary yeast extracts and nutrient mixtures provide essential vitamins, trace elements, sterols, and unsaturated fatty acids for membrane synthesis during fermentation [7]. However, use of proprietary yeast extracts and nutrient mixtures is prohibitively expensive under industrial settings. Low-cost agro-industrial discards potentially provide a viable alternative source of free amino nitrogen and crucial nutrients. Several studies demonstrate greater yeast activity under high gravity fermentation conditions by using low-cost industry by-products such as corn steep liquor, spent sulphite liquor, cheese whey, and brewer’s spent yeast [7,8,9]. The latter is noteworthy owing to its similarity to proprietary yeast extract nutrient mixtures. Further to this, while significant improvements in ethanol yields from addition of brewer’s spent yeast to fermentation of maize and cassava mashes have been reported [9], prospects for using brewer’s spent yeast to improve ethanol yields from lignocellulosic hydrolysates have not been investigated.

As advocated by several authors [10,11,12], low-cost agro-industrial discards may also have potential to mitigate the effects of inhibitors found in lignocellulosic hydrolysates. Inhibitors frequently found in lignocellulosic hydrolysates include furan aldehydes and phenolics, which originate from the breakdown of sugar and lignin, and acetic acid released during hemicellulose deacetylation [13]. Kelbert et al. [10] demonstrated that addition of cheese whey and potassium metabisulfite to Eucalyptus globulus hydrolysates enhanced the tolerance of yeast to inhibitors during fermentation. When compared with unamended hydrolysates, saccharification and hydrolysis fermentations (SHF) and simultaneous saccharification and fermentations (SSF) yielded up to 2.3- and 7.4-times greater ethanol titres, respectively. The reasons for this were not clear; however, the introduction of trace metals contained within the two amendments may have played a role.

Trace metals such as magnesium, zinc, and calcium have previously been reported to counteract weak carboxylic acid inhibitory effects on yeast in lignocellulosic fermentations [14, 15]. This is significant because lignocellulosic hydrolysates can contain relatively high levels of acetic and other carboxylic acids. Supplied at low concentrations, these trace metals are critical co-factors for S. cerevisiae growth, glycolytic/ethanol metabolic pathway enzyme functioning and have been associated with protecting yeast from ethanol toxicity and thermal stress [7, 16]. For example, Xu et al. [16] reported that adding zinc to culture medium with high acetic acid content increased ethanol yield and productivity by 28% and 67%, respectively. Similarly, inclusion of calcium was found to mitigate acetic acid effects leading to shorter fermentation times with significantly higher yeast viabilities [17]. Ismail et al. [11] likewise found that augmenting xylose-enriched medium with Zn, Mg, and Ca trace metals appreciably improved resilience of S. cerevisiae to acetic acid.

Challenges associated with producing bioethanol from lignocellulosic materials are further compounded by the fact that lignocellulose sugar streams contain up to 20% pentose sugars, which are resistant to fermentation by industrial S. cerevisiae [18, 19]. Since economic production of lignocellulosic ethanol is reliant on utilising hydrolysates containing both C6 hexose and C5 pentose sugars, research efforts have predominantly focused on engineering heterologous pathways for efficient fermentation of C5 sugars, especially xylose [20]. Most metabolic engineering work has focused on S. cerevisiae, owing in part to its tolerance to lignocellulosic inhibitors, ethanol, and high sugar concentrations, and because S. cerevisiae consistently performs under industrial settings [19]. However, recombinant xylose-fermenting yeast are seldom reported to concomitantly ferment C5 and C6 sugars economically, with ethanol yields typically falling short of those required for viable commercial production [19, 20]. Accounts which approach viable targets are generally restricted to cellulose-enriched hydrolysate liquors derived from solid materials devoid of C5 sugars [21]. This raises uncertainty concerning the merits of using lignocellulosic-derived C5 sugar-enriched liquors to produce ethanol. As an alternative to this approach, Vancov et al. [22, 23] demonstrated that utilising C5 sugar-enriched liquors for propagation of recombinant yeast introduced efficiencies into processing, thus improving the viability of using recombinant xylose-fermenting yeast to produce ethanol from lignocellulosic materials.

Despite significant progress toward developing technologies for viable commercial production of ethanol from lignocellulosic materials, there remains a need to improve procedures for conversion of materials such as eucalyptus biomass to ethanol to overcome poor ethanol yields and high processing costs [24]. Consequently, this study investigated inclusion of novel low-cost nutrient supplements in fermentations of hydrolysates derived from Eucalyptus grandis to improve ethanol yields and is the first to report utilisation of spent brewer’s yeast with the aim of improving ethanol yields from fermentation of lignocellulosic hydrolysates. The performance of the industrial Thermosacc Dry® and the recombinant xylose-fermenting “GSF335” [25] S. cerevisiae strains were also compared using previously unreported fermentation parameter combinations.

2 Materials and methods

2.1 Materials

Unless otherwise stated in the text, all chemicals were acquired from Sigma Chemical Co. (St. Louis, MO) and were of reagent grade or above, including acid and bases, antibiotics, antifoam, salts, solvents, and analytical standards. Novozymes (Denmark) provided the enzyme blend Cellic® CTec 2 (CTec 2). Thermosacc Dry® (Thermosacc) yeast was supplied by Lallemand (USA), and the recombinant GSF335 strain was kindly provided by VIB (Belgium) for use in ethanol fermentations. The GSF335 strain is derived from Ethanol Red® and is a xylose fermenting yeast selected for its tolerance to lignocellulosic inhibitors [25]. Yeast extract and peptone were obtained from AMYL Media (VIC, Australia), and Nutri-Plex Plus™ (NPP) was supplied by Lallemand Biofuels & Distilled Spirits (GA, USA) and used as per the manufacturer’s instructions. NPP is a patented yeast nutrient mixture that stimulates yeast cell proliferation and viability, promoting efficient ethanol fermentations. Diammonium phosphate was acquired from EnolTech (Vic, Australia).

Brewer’s spent yeast was sourced from the Stone & Wood Brewing Company (Byron Bay, NSW Australia) and used in preparation of dried spent yeast (DSY) and yeast hull (YH) additives. These additives were prepared by suspending brewer’s spent yeast (10% w/v) in milli-Q water and mixing at 50 °C at 100 rpms in a glass vessel for 24 h. The resulting yeast autolysate was centrifuged for 20 min at 10,000 g to separate the DSY into a supernatant fraction and the YH into a pelletised fraction with each fraction subsequently freeze dried (Telstar Cryodos 50 freeze dryer, Spain) prior to storage. Subsamples of each fraction were also sent to Vintessential Laboratories (Victoria, Australia) for determination of free amino nitrogen levels using the NOPA assay.

E. grandis material was sourced and prepared as described by McIntosh et al. [24]. Briefly, powdered E. grandis was pre-treated in a 2-L Parr reactor (Parr Instruments, USA) with dilute H2SO4 at a concentration 4.8 wt% on solids and at a biomass to liquid ratio of 1:6 (wt/wt) and the Parr reactor temperature was set to 190 °C held for 15 min. National Renewable Energy Laboratory procedures [26] were used to determine the composition of pre- and post-treated fibres which corresponded to 100% and 70.7% recovery, 38.3% and 47.8% glucan, 9.6% and 2.9% xylan, and 26.0% and 38.3% lignin, respectively.

2.2 Hydrolysate preparation

Separate enzyme hydrolysis was carried out in 1-L glass reactor vessels (Duran GLS80) equipped with an overhead stirrer (RZR 2020 Heidolph, Germany). Reactor vessels contained 700-g total mass reaction material consisting of unwashed pretreated fibre (10% dry weight equivalent), 10 filter paper units (FPU) CTec 2 g−1 dry weight pretreated fibre, and the remainder made up with 20 mM citrate buffer (pH 5.0). Whole slurry hydrolysates (WS) were similarly prepared except that whole pre-treated slurries, consisting of pre-treated solids and liquors adjusted to pH 5.0, were used. Enzyme saccharification was undertaken in the reactor vessels at 50 °C with a constant stirring speed of 100 rpm for 72 h. The recovered hydrolysates were filtered through a 1.2-µm glass micro-fibre filter and, if needed, were adjusted to pH 5.0 using KOH. The resulting solution was chilled for 12 h to allow fine particles to settle, vacuum filtered through a 0.45-µm cellulose nitrate membrane filter, and kept in a sterile container at 4 °C for up to 24 h.

2.3 Yeast inoculum preparation

Routine culturing of Thermosacc and GSF335 yeasts was performed in 1-L baffled Erlenmeyer flasks with a YPG broth comprising 10 g L−1 yeast extract and 20 g L−1 peptone (YEP) and 20 g L−1 glucose. Both yeasts were grown overnight (up to 12 h) at 30 °C on an orbital shaker at 250 rpm. After growth, cells were harvested by centrifugation, washed twice, and resuspended in 0.9% sterile saline prior to optical density measurements at 600 nm (OD600). Dry weight yeast biomass was calculated using OD600 readings against predetermined growth curves adjusted to dry weight equivalents according to the equation below:

where x is cell biomass in g L−1 and OD600 is optical density at 600 nm.

Preparation of GSF335 inoculum specifically for use in fermentations was similarly undertaken except that glucose was substituted with xylose-enriched pre-treatment hydrolysate liquors to provide the primary sugar source. Cultures were prepared in Erlenmeyer flasks containing 200-mL filter-sterilised pre-treatment hydrolysate liquors, YEP, and 10 mg L−1 tetracycline. Flasks were seeded with GSF335 at a rate of 1 g L−1 and incubated at 30 °C on an orbital shaker set to 200 rpm. At time intervals specified in the text, 1-mL aliquots were withdrawn for analysis of sugars, by-products, and ethanol. Yeast cell biomass was determined as described above.

2.4 Separate hydrolysis fermentations

Preliminary SHF experiments were carried out in 120-mL serum bottles with silicone crimp-tops, fitted with a water trap to release gases and exclude oxygen. The fermentation media contained enzyme saccharified water insoluble solids (WIS) or WS with YEP and 10 μg mL−1 tetracycline to a total volume of 60 mL. Fermentation media were adjusted to pH 5.0 with KOH prior to filtration. Yeast strains were also fermented with YPGX synthetic media comprising of 10 g L−1 yeast extract, 20 g L−1 peptone, 40 g L−1 glucose, and 20 g L−1 xylose. Fermentations with YPGX functioned as the control treatment for the purpose of providing a comparative benchmark for fermentations with WIS and WS treatments. A fourth “WSM” treatment was also included which involved adding trace metal supplements to WS hydrolysates at the following rates: 0.86 g L−1 MgSO4, 0.052 g L−1 ZnSO4, 0.294 g L−1 CaCl2. These levels correspond to upper cofactor limits and are recognised for improving fermentation performance [6, 7, 11, 27]. Batch SHF were initiated by inoculating yeast cells at a rate of 4.0 g L−1, followed by sparging with nitrogen for 10 min to provide anoxic conditions. The serum bottles were quickly sealed with silicon septa crimp tops. Up to four serum bottles were coupled to a water trap and incubated at 35 °C on an orbital shaker set to 50 rpm. At times denoted in the text, 0.5-mL volume samples were withdrawn through the silicon septa tops using sterile syringes for quantification of sugars, by-products, and ethanol. SHF experiments were carried out in triplicate and repeated twice.

For nutrient supplement assessments, SHF were undertaken in Bioflo 110 2.0-L benchtop bioreactors (New Brunswick Scientific, USA). The fermentation medium consisted of enzyme digested WIS supplemented with the following: YEP and 10 μg mL−1 tetracycline, 0.55 g L−1 NPP, 10 g L−1 DSY, and 300 mg L−1 YH with trace metals (YHM) at rates specified above. To minimise slow or “stuck” fermentations, yeast assimilable nitrogen levels in hydrolysates were adjusted to approximately 400 ppm with diammonium phosphate prior to inoculation for SHF with YHM. Fermentations were inoculated with GSF335 at a rate of 4.0 g L−1 and sparged with nitrogen to expel oxygen and establish anoxic conditions. Fermentation mixes were adjusted and maintained at pH 5.0 with5 M KOH before and during fermentation. The temperature of the bioreactor was kept constant at 35 °C while agitation was maintained by setting the overhead stirrer speed to 100 rpm. A condenser was fitted to the bioreactor head plate to decrease evaporation of fermentation broth. To avoid excessive foaming and clogging of the exhaust filter, a foam probe and antifoam 204 were employed. For determination of yeast biomass, sugars, by-products, and ethanol concentrations, 0.5-mL samples were taken at times denoted in the text, centrifuged at 8000 g for 5 min, and syringe filtered (Sartorius 0.45 μm Minisart®, Germany) prior to analysis.

2.5 Simultaneous saccharification and fermentation

Unwashed fibre was used in all SSF. SSF and pre-hydrolysis SSF (PSSF) were carried out in sterile 1-L Duran GLS 80® glass reactors with a mounted overhead stirrer (RZR 2020 Heidolph, Germany). The fermentation reaction contained wet pretreated fibre (10% dry weight equivalent), 1.6 g L−1 diammonium phosphate, and 300 mg L−1 YHM with sterile milli-Q water added to achieve a final weight of 700 g. The slurry was adjusted to pH 5.0 with 10 M KOH before adding 15 mg L−1 tetracycline and 10 FPU CTec 2 g−1 dry weight unwashed fibre. Immediately after inoculation with GSF335, the reactor was sparged with nitrogen and immersed in a water bath held at 35 °C. The overhead stirrer speed was set at 100 rpm to maintain agitation of the fermentation mix. For sugar, by-product, and ethanol determinations, 0.5-mL samples were collected at times denoted in the text, centrifuged at 8000 g for 5 min, syringe filtered, and analysed. PSSF were performed in a similar manner to SSF, except that pre-hydrolysis was performed for 24 h at 50 °C, and fermentation was initiated by adding GSF335 after cooling to 35 °C. GSF335 was added to all fermentations at a rate of 4 g L−1 and SSF and PSSF experiments were carried out in duplicate and repeated twice.

2.6 Fermentation parameter calculations

Maximum specific growth rates were estimated during the exponential growth phase, as defined by Jeon et al. [28].

The maximum specific glucose and xylose uptake rates (qsmax,) and maximum specific ethanol production rates (qpmax,) were analysed during the exponential growth phase, and estimated using the following equations:

where Δs and Δe represent changes in substrate (glucose or xylose) and ethanol concentrations across time (Δt), respectively, and xav represents the average biomass concentration across time. Biomass, substrate (glucose and xylose), and ethanol concentrations are denoted by x, s, and p, respectively.

Ethanol product yield was calculated using total sugar consumption and determined as follows:

where ei and ef are the initial and final ethanol concentrations, and si and sf are the initial and final total fermentable sugars (glucose and or xylose) concentrations.

Yeast cell biomass product yield was determined as follows:

where xi and xf are the initial and final yeast cell mass, and si and sf are the initial and final total usable carbon (glucose, xylose, and or acetic acid) concentrations.

Xylitol product yield is defined as the average of the sum of produced xylitol relative to cell biomass at sampling and is calculated according to the following equation:

where xylitol is the amount of accumulated xylitol, x is biomass at specified sampling time point (t0, t2, t4 …. t48), and n is the number of sampling points.

Glycerol product yield is defined as the average of the sum of produced glycerol relative to cell biomass at sampling time and is calculated according to the following equation:

where glycerol is the amount of accumulated glycerol, x is the biomass at the specified sampling time point (t0, t2, t4 …. t48), and n is the number of sampling points.

Acetate product yield is defined as the average of the sum of produced acetate relative to cell biomass at sampling time and was calculated according to the following equation:

where acetate is the amount of accumulated acetate, x is biomass at specified sampling time point (t0, t2, t4 …. t48), and n is the number of sampling points.

The ethanol volumetric productivity (EVP) was based on the following equation:

where Δe represents the change in ethanol concentrations throughout time period Δt.

Ethanol conversion efficiency (%) measures the fermentation’s efficiency in relation to the starting material and was calculated as follows:

where 0.51 is the theoretical yield of ethanol per sugar quantity.

2.7 Analytical methods

The composition of fermentation and hydrolysate sample were analysed and identified using high performance liquid chromatography (HPLC). The Waters Empower® software was used to operate the HPLC system, which included a solvent supply system (Controller 600 Waters, Milford, MA), an auto sampler (717, Waters), and a differential refractometer (410, Waters). Sugars were detected and measured using a Carbo-H guard cartridge (Rezex™) pre-column and an RHM-Monosaccharide (7.8 mm × 300 mm, Rezex™) column. The RHM column was maintained at 60 °C while sugars, acetic acid, furfural, 4-hydroxymethylfurfural, and ethanol were eluted using a mobile phase made up of degassed milli-Q filtered water containing 0.005 M H2SO4 at a constant flow rate of 0.6 mL min−1. Retention times (RT) of analytical grade standards were used to identify and quantify peaks in test samples.

2.8 Statistical analysis

To identify significant variations between means, the data were analysed using one-way analysis of variance (ANOVA) with the real statistics data analysis tool in Microsoft Excel (365 ProPlus). A Tukey HSD post hoc analysis (α = 0.05) was conducted using the rapid publication-ready MS word table for one-way ANOVA [29] to determine the significance of differences between the groups.

3 Results and discussion

3.1 Saccharification and hydrolysis fermentation with Thermosacc

Substrate utilisation and product profiles of Thermosacc in SHF with YPGX, WIS, WS, and WSM are shown in Fig. 1a–d and kinetic parameter results are summarised in Table 1. The analysis provides information on the maximum specific rates of growth, sugar uptake, and includes ethanol titres.

Fermentation profiles of Thermosacc in (a) YPGX, (b) WIS, (c) WS, and (d) WSM and GSF335 in (e) YPGX, (f) WIS, (g) WS, and (h) WSM sugar hydrolysates at 35 °C for 48 h. WSM hydrolysate supplemented with trace metals (MgSO4·7H2O, ZnSO4, and CaCl2) as specified in Sect. 2. YPGX, yeast peptone media + glucose + xylose; WIS, water insoluble solids; WS, whole slurries. Error bars denote standard error (n = 6)

Thermosacc readily metabolised glucose in SHF with WIS and WS hydrolysates (Fig. 1a–d). During SHF with WIS, glucose was completely consumed within 10 h to produce 19.6 g ethanol L−1. This equates to an ethanol yield of approximately 91% which is similar to results reported for saccharification and hydrolysis fermentations with hydrolysates produced from other eucalyptus species [13, 24]. Apart from initial glucose uptake and ethanol production rates, the kinetic profile of Thermosacc in SHF with WIS was statistically similar to SHF with YPGX (Table 1), implying that the WIS hydrolysate was relatively free from fermentation inhibitors.

Slight differences in final ethanol yields between SHF with WIS and SHF with YPGX indicate that sugars in the WIS hydrolysate were channelled to unidentified metabolites other than glycerol, xylitol, or acetate. The latter three by-product yields per cell biomass were statistically similar in both SHF with WIS hydrolysates and SHF with YPGX media. Glycerol product yields (Table 1) were significantly (p < 0.05) greater in SHF with YPGX and SHF with WIS compared with SHF containing WS, and probably signify the yeast’s efforts to rectify oxidation–reduction imbalances arising from rapid ethanol production (i.e. higher qpmax; Table 1) [30]. The apparent co-elution of other fermentable monosaccharides on the HPLC column falsely implies that Thermosacc readily metabolised xylose in both SHF with WIS and SHF with WS (Fig. 1b, c, and d).

Compared to SHF with YPGX and SHF with WIS, μmax, qpmax, and ethanol yields were significantly (p < 0.05) lower in fermentation with WS and WSM (Table 1), inferring that carryover inhibitors in the pre-treatment liquor impacted yeast growth and ethanol production, regardless of the addition of trace metals. Dilute acid pre-treatment is known to release chemicals that deleteriously influence downstream processes such as enzyme hydrolysis and fermentation [31, 32]. These inhibitors are formed during the release and breakdown of sugars and lignin, namely furans, phenolic compounds, and organic acids. However, the relatively low level of furan aldehydes in WS hydrolysates, and their lack of detection beyond time zero, indicates that they were not a factor involved in Thermosacc’s poor performance.

Acetic acid is known to limit yeast growth and ethanol production at and above 3 g L−1 [31]. At pH 5, undissociated acetic acid (approximately 2 g L−1 at pH 5.0 according to the Henderson-Hasselbach equation) lowers intracellular pH levels in yeast [33]. To maintain intracellular pH for optimal metabolic functioning, yeast cells consume ATP to expel H+ ions. Consequently, the diversion of metabolic energy significantly lowers specific growth rates, the rate of ethanol production, and yield per gram of substrate. In the present study, acetic acid concentrations were measured at 5.9 g L−1, which indicates that acetic acid was the inhibitory compound that most likely affected the performance of Thermosacc during SHF (Fig. 1, Table S1).

Interestingly, SHF with WSM accumulated more xylitol (up to 1.1 g L−1) toward the end of the fermentation. Presumably this was in response to incomplete xylose metabolism. However, as indicated by the results presented in Table 1, xylitol and acetate accumulation per cell mass were significantly (p < 0.05) greater than in SHF with YPGX, WIS, and WS. Acetate is normally produced under fermentative conditions when S. cerevisiae generates excess NAD+ during glycerol biosynthesis. The latter is required to maintain redox flux owing to divergent (anabolic) reactions [33, 34]. Acetaldehyde is oxidised to acetate under these circumstances by NAD+ aldehyde dehydrogenase encoded by ALD3, which is primarily activated by salt stress [35]. However, the relatively low glycerol product yield observed for SHF with WSM (Table 1) indicates that addition of trace metals explicitly re-routed carbon flux to sustain redox equilibria.

S. cerevisiae contains additional aldehyde dehydrogenases which are not only capable of oxidising acetaldehydes but function to detoxify inhibitory furans [35, 36]. The ALD6 gene of S. cerevisiae encodes for the NADP+ dependant cytosolic acetaldehyde dehydrogenase. Expression of the ALD6 gene is known to be induced by 5-hydroxymethyl furaldehyde and the activity of cytosolic acetaldehyde dehydrogenase is known to increase by up to 100-fold in the presence of Mg2+ [37, 38]. Thus, in SHF with WSM, an apparent redox imbalance may have been triggered by ALD6 activation and subsequent oxidation of acetaldehyde to acetate to produce excess NADPH. This excess NADPH was then likely balanced by xylose reduction to xylitol via aldose reductase, a reaction that effectively acts as a redox sink but embodies a futile carbon flux. Other than accumulation of xylitol and acetate, the net effect of this was significantly less ethanol (Table 1).

Contrary to studies reporting that fermentation media supplemented with zinc negates acetic acid inhibition and improves carbon flux to ethanol [11, 27], during this study addition of zinc to SHF with acetic acid laden hydrolysates did not improve the performance of Thermosacc yeast. Presumably, anticipated benefits of trace metal additions to SHF with WS were dominated and masked by factors as discussed above which led to high levels of xylitol and acetate.

3.2 Saccharification and hydrolysis fermentation with GSF335

Fermentation profiles for GSF335 in SHF with YPGX synthetic media and WIS, WS, and WSM hydrolysates are shown in Fig. 1e–g and an analysis of kinetic parameters measured during fermentation is summarised in Table 1. Consistent with Thermosacc SHF, glucose in WIS was rapidly fermented by GSF335 within 10 h, producing 21.1 g ethanol L−1, equivalent to an ethanol yield of 90.3%. Despite significant differences in growth rates observed between SHF with YPGX and SHF with WIS, the kinetic characteristics of GSF335 were similar to Thermosacc (Table 1). Although xylitol and acetate were continuously detected after 8 h, their concentrations in SHF with WIS were significantly lower than Thermosacc at the same time point (Fig. 1), confirming that GSF335 fermented xylose to ethanol.

Growth of GSF335 in SHF with WS and SHF with WSM was considerably slower than in SHF with YPGX, with up to three to four times lower μmax in SHF with WSM. As was the case for Thermosacc, high acetic acid levels of up to 5.9 g L−1 (Table S1) in SHF with WS most likely had an adverse effect on growth of GSF335 and consequently, ethanol yields. In SHF without trace metal addition, glucose was exhausted by 10 h to produce ethanol titres of 17.2 g L−1, which is equivalent to an ethanol yield of 86.8%. Likewise, in SHF with WSM, glucose was mostly consumed within 10 h and ethanol titres averaged 17.4 g L−1, representing an ethanol yield of 83.5%. While ethanol yields were not significantly different to those for SHF with Thermosacc, glucose utilisation and ethanol production rates (qpmax) were notably higher in all SHF with GSF335 (Table 1), as indicated by more rapid declines in glucose levels and production of ethanol within the first 8 h (Fig. 1c, d, g, and h). These results support the notion that recombinant GSF335 is better suited to fermenting biomass hydrolysates than non-recombinant S. cerevisiae, owing to its xylose to ethanol metabolic flux capacity and also possibly its tolerance to inhibitors. This is further supported by significantly lower xylitol and acetate product yields (Table 1) observed for SHF with GSF335relative to SHF with Thermosacc. However, incomplete xylose utilisation and lower ethanol yields in SHF with WS and SHF with WSM were also observed. This might be explained by previous findings indicating that high acetic acid levels diminish the xylose fermentation performance of recombinant yeast [39, 40].

Ismail et al. [11] reported that ethanol yields and acetic acid tolerance of recombinant xylose fermenting S.cerevisiae increased with the addition of trace metals to xylose-enriched synthetic media. However, this was not observed during the present study. In fact, the addition of trace metals in the SHF with WSM treatment negatively affected the performance of GSF335, resulting in lower ethanol titres compared to SHF with WIS and SHF with WS. This may have been due to a persistence of futile xylose carbon flux in GSF335, which was unexpected. An apparent accumulation of xylitol also indicates that the ability of GSF335 to metabolise xylose to ethanol under high acetic acid levels may have been impaired despite trace metals being present. Supplementation with Mg2+ may be double-edged, in so far as Mg2+ being a requisite for Lachnoclostridium phytofermentans recombinant xylose isomerase (XI) activity in GSF335 [41] and its native ALD6 aldehyde dehydrogenase. Although xylitol marginally inhibits the recombinant XI in GSF335 [41], the possibility of protracted low-level suppression of XI as xylitol accrues cannot be ruled out. Coupled with the effects of high acetate levels, xylose flux may have shifted away from ethanol in favour of xylitol and acetate production in SHF with WSM. Although supplementary trace metal addition to lignocellulosic hydrolysates does not appear to benefit ethanol productivity and/or yields from recombinant xylose fermenting yeast such as GSF335, there is some evidence to indicate value (e.g. high initial glucose uptake and ethanol production) in trace metal addition which warrants further investigation.

3.3 Propagation of GSF335 in xylose-enriched prehydrolysate

GSF335 recombinant yeast was propagated in xylose-enriched prehydrolysate liquors as outlined in Sect. 2.3. The intent of cultivating inoculum in prehydrolysates is to pre-adapt yeast and hasten lignocellulosic fermentation [42], thus providing cost savings.

The proficiency of GSF335 to propagate under aerobic batch culture conditions in undiluted prehydrolysate E. grandis liquor is shown in Fig. 2. Almost all sugars and acetic acid were consumed within 24 h, representing about 98% of the total usable carbon (TUC), to produce approx. 9.9 g L−1yeast biomass. This corresponds to a yield (Yx/s) of 0.42 g yeast g−1 TUC, equating to a productivity of 0.41 g L−1 h−1. The observed biomass yield was also equivalent to 45.4 kg t−1 dry weight E. grandis. Extending growth beyond 24 h did not significantly increase yeast biomass. Although xylitol was not detected, significant ethanol and trace amounts of glycerol were produced during the initial stages, with the former exceeding expectations.

Yeast produced ethanol rather than biomass under aerobic conditions when glucose concentrations are > 1.0 g L−1. This phenomenon is known as the “Crabtree effect” [6]. As indicted in Fig. 2, initial prehydrolysate liquor glucose and xylose concentrations were 5.8 g L−1 and 14.7 g L−1, respectively. At the 10-h measurement point, glucose and xylose (5.7 and 14.2 g L−1, respectively) were completely consumed to produce 7.4 g L−1 ethanol and 2.9 g L−1 yeast biomass (Fig. 2). The theoretical ethanol yield from the 5.8 g L−1 glucose is only 3.0 g L−1 (0.51 conversion factor); thus, ethanol yields above this amount can be attributed to conversion of xylose to ethanol by GSF335. This apparent redirection of xylose away from yeast growth and toward production of ethanol is consistent with previous observations of GSF335 propagation in prehydrolysate liquors from cotton gin trash [22, 23]. With the exhaustion of sugars by 10 h, GSF335 began to assimilate and deplete accrued ethanol and acetic acid. Given the inefficiency of ethanol re-assimilation (a loss of 1 ATP molecule) [43], the relatively low yield of yeast biomass was not entirely unexpected.

Moderating input sugar concentration, or the specific growth rate of GSF335 below a certain critical value, by using a fed-batch fermentation approach could potentially mitigate the Crabtree effect to improve yeast biomass production. However, this requires further study. Judicious addition of cellulases and xylanases, to increase monomeric sugar levels in prehydrolysate liquors used to propagate yeast, may also improve production of yeast biomass.

3.4 Saccharification and hydrolysis fermentation with nutrient supplements

Based on its ethanol fermentation performance, GSF335 was selected for further assessment of nutrient supplements in SHF with WIS. Diammonium phosphate was used as a nitrogen source in SHF supplemented with yeast hulls and trace metal supplements were added or omitted for comparison. Fermentations were pitched with GSF335 inoculum cultured in xylose-enriched pretreatment liquors. A summary of the main fermentation kinetic analyses and SHF profiles is presented in Table 2 and Fig. 3, respectively.

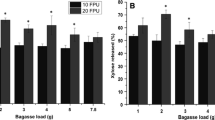

Bio-flow 110 fermentation profiles of GSF335 in WIS hydrolysates at 35 °C for 48 h supplemented with (a) yeast extract plus peptone (YEP), (b) nutri-plex plus™ (NPP), (c) trace metals (M), (d) dried spent yeast (DSY), (e) yeast hulls (YH), and (f) yeast hulls + trace metals (YHM). Trace metals (MgSO4·7H2O, ZnSO4, and CaCl2) at concentration specified in Sect. 2. Error bars denote standard error (n = 4)

Generally, GSF335 fermentation profiles in WIS hydrolysates augmented with different nutrient supplements appeared to be similar (Fig. 3). Excluding NPP and M, most SHF displayed rapid consumption of glucose within 6 h with concomitant xylose use after 4 h, leading to rapid increases in ethanol titres. Fermentation kinetics (Table 2) reinforces these observations with significantly higher initial sugar uptake (qsmax) and ethanol production (qpmax) rates noted in YEP, DSY, YH, and YHM treatments. Although the reasons for this are not clear, it appears that during the latter three nutrient amended SHF sugar flux may have been redirected toward co-metabolite and biomass production. Indeed, significantly higher biomass and glycerol product yields were observed in DSY supplemented fermentations (Table 2). In this instance, DSY induced faster cell growth (μmax) and likely altered the NAD+/NADH redox status. As mentioned above, yeast typically restores redox equilibria via glycerol production [34, 44]. Fermentations with yeast hulls with or without trace metals likewise generated significantly higher glycerol product yields than SHF with YEP. Fermentations with YEP yielded marginally higher ethanol titres (21.1 g L−1) and yields (93.2%) compared to other nutrient augmented SHF.

Unlike SHF described in Sect. 3.2, addition of trace metals did not increase xylitol or acetate levels. In fact, only trace amounts of xylitol were detected, while acetic acid concentrations were comparatively low and similar across all nutrient augmented fermentations (Fig. 3). Presumably, initial acetic acid and xylose levels in the hydrolysate fermentation media were too dilute to trigger futile xylose cycling. Fermentations supplemented with trace metals alone did, however, show significantly lower initial sugar uptake and ethanol production rates. The reasons for this are not clear but may be related to suboptimal growth factor (viz. vitamin cofactors, ergosterol, and fatty acids) concentrations in the media. The metabolic implications for yeast cells having to synthesise these de novo are the diversion of energy and metabolites away from cell biomass and ethanol production [45].Though small in magnitude, the impact of this was evident in the results which indicated significantly lower ethanol yields and cell productivities (Table 2). This scenario could equally apply to other nutrient supplemented SHF because they are not as nutritiously inclusive as YEP [12, 46].

The fermentation performance of GSF335 in SHF containing YEP was notably better than SHF with other nutrient adjuncts. This is consistent with studies which have found that higher levels of free amino acid and amino acid type in yeast extracts facilitate rapid protein synthesis owing to direct assimilation instead of deamination and resynthesis [3, 47]. Despite significant differences in kinetic parameters (Table 2), diammonium phosphate, NPP, and DSY amended SHF had similar ethanol yields. If the entire pretreatment and fermentation process is considered inclusively, differences in ethanol efficiencies and titres may diminish and become irrelevant under industrial conditions owing to scale-up and handling losses.

Accounting for monomeric sugar loss during pretreatment and enzyme saccharification, estimated ethanol titres per tonne of dry E. grandis for SHF with YEP, NPP, trace metal only, DSY, YH, and YHM supplements were 149.5 kg, 145.6 kg, 141.4 kg, 141.4 kg, 142.6 kg, and 141.4 kg, respectively. These yields equate to conversion efficiencies of between 51.9 and 54.8% t−1 dry weight E. grandis, or 69.5% and 73.5% based on recovered pretreated fibre. These results are comparable to reported studies examining the use of other low-cost nutrients in eucalyptus-based fermentations. For example, supplementation with an optimised nutritional mixture comprising of corn steep liquor, cheese why powder, yeast extract, urea, and K2O5S2 in SHF with hydrothermally pretreated E.globulus yielded ethanol titres of 39.6 g L−1 and 39.7 g L−1 after 120-h and 72-h fermentations [10, 47]. Although these ethanol titres are notably better than those attained in this study, the former benefited from greater fibre and cellulase/xylanase loads during SHF media preparation and included intrinsic fermentable sugars in the nutrient mixture. Even so, the theoretical conversion efficiencies of 52.5% and 54.2%, based on holocellulose content per tonne dry weight raw eucalypt, were less than observed for SHF during the present study.

3.5 Simultaneous saccharification and fermentation with pretreated fibre

SSF and PSSF were conducted with WIS to evaluate the value of YHM supplements under simulated industrial fermentation conditions. The YHM combination was selected for further study based on its low cost, reported ability to mitigate inhibitors [15,16,17], and potential for fast fermentation (high glucose uptake and qpmax; Table 2).

Fermentation profiles for the SSF and PSSF with GSF335 are shown in Fig. 4. During SSF, GSF335 rapidly metabolised residual glucose and xylose to produce 11.6 g L−1 ethanol within 12 h. Continuous fermentation of glucose and xylose by GSF335 prevented cellulase substrate inhibition, and ethanol production extended up to 144 h, peaking at 25.1 g L−1. In PSSF, initial prehydrolysis (24 h) produced 29.6 g L−1 glucose (Fig. 4b) which was promptly consumed within 12 h (at 36 h). Thereafter, GSF335 incrementally fermented xylose. The ethanol volumetric productivity for PSSF 12 h after inoculation achieved 1.68 g L−1 h−1 while SSF produced only 0.97 L−1 h−1 within the same period. The slow rate of ethanol production during SSF was probably due to a lower concentration of free glucose and xylose resulting from inadequate cellulase hydrolysis at 35 °C. Nonetheless, despite similar final volumetric productivities of 0.17 g L−1 h−1 for SSF and PSSF, SSF achieved a higher ethanol titre and theoretical yield of 74.0%, whereas PSSF produced ethanol titres and yields of 24.3 g L−1 and 71.8%, respectively.

Fermentation profiles of GSF335 in (a) SSF and (b) PSSF configurations with 10% (dry weight equivalent) unwashed pretreated fibre, 10 FPU CTec 2 g DW.−1, at 35 °C for 144 h. For PSSF, the initial 24-h hydrolysis was conducted at 50 °C. Dashed vertical lines (b) correspond to GSF335 inoculation and commencement of fermentation at 35 °C. Each data point indicates the mean of two independent runs with duplicates included within reach run. Error bars in represent standard error (n = 4)

Based on mass data, ethanol yields for SSF and PSSF configurations were estimated at 175.6 and 170.4 kg t−1 dry weight raw E. grandis, respectively. The ethanol conversion efficiency per tonne dry weight E. grandis for SSF and PSSF was 64.4% and 62.5%, respectively, and was calculated relative to fermentable holocellulose sugar content. The lower than anticipated conversion and ethanol yields for the PSSF can be attributed to sugar losses during pretreatment. Suboptimal conditions created by compromising temperature to 35 °C and ethanol accrual during fermentation may also have diminished cellulase and yeast activity [48, 49]. Nonetheless, ethanol titres and conversion efficiency were notably higher than for SHF (Fig. 3), but slightly lower than reported for previous studies of SSF using eucalyptus hydrolysates supplemented with low-cost nutrients.

Kelbert et al. [10, 47] described ethanol titres of 50.4 and 54.0 g L−1 in SSF with hydrothermally treated E. globulus supplemented with a nutrient mixture containing an undefined level of fermentable sugars. The latter, coupled with higher fibre and cellulase/xylanase loads in the SSF, would have greatly influenced final ethanol titres. Estimated ethanol yields were 231.1 and 242 kg t−1 dry weight E. globus, equating to cellulose and holocellulose conversion efficiencies of 91.2% and 66.8% [10] and 85.0% and 70.0% [47], respectively.

Cunha et al. [50] reported an ethanol titre of 93 g L−1, equating to an ethanol yield of 94% in SSF containing 25% pretreated E. globulus mixed with cheese whey powder and high enzyme loads (cellulase and β-galactosidase). Besides serving as a low-cost nitrogen source, high lactose levels (60%) in the cheese weigh powder boosted ethanol production. If considered on a dry tonne basis, the mixture (comprising 10.6% cheese weigh powder) would yield a final ethanol titre of 346 kg with a theoretical conversion of 65.3%.

In all reported E. globulus studies, use of high cellulase and auxiliary enzymes during SSF coupled with added fermentable sugars resulted in ethanol titres beyond yields anticipated from eucalyptus fibre alone. This raises the question as to whether these additives increase processing costs and potentially negate gains in ethanol yield.

4 Conclusion

The findings of this study demonstrate the potential for using low-cost nutrient supplements sourced from agro-industrial discards in place of more expensive proprietary yeast extracts and nutrient mixtures for producing ethanol from lignocellulosic materials. Dried spent brewer’s yeast and yeast hull with trace metals performed as well as other additives during saccharification and hydrolysis fermentations. However, the combination of simultaneous saccharification fermentations with the yeast hull and trace metal combination delivered the best result, producing 175.6 kg ethanol equivalent to a conversion efficiency of 64.2% t−1 dry weight E.grandis.

Additionally, the study supports previous research which highlights the potential for utilising xylose-enriched pre-treatment hydrolysates to cultivate xylose fermenting recombinant yeast strains to improve efficiencies in ethanol production. However, the study also found that supplementing xylose- and acetic acid-enriched hydrolysates with trace metals may alter the yeast’s redox balance during fermentation, consequently redirecting carbon flux from ethanol to production of other metabolites.

To progress on the work undertaken during this study, future research should focus on evaluating the dried spent brewer’s yeast and yeast hull with trace metals combinations in pilot scale fermentations to assess commercial viability. Future research should also focus on improving understanding of how trace metal additions affect the metabolic functions of xylose fermenting recombinant yeast propagated in crude pretreatment hydrolysate liquors.

Data availability

Not applicable.

Abbreviations

- CTec 2:

-

Cellic® CTec 2 cellulase mixture

- DSY:

-

Dried spent yeast

- FPU:

-

Filter paper units

- NPP:

-

Nutri-Plex Plus™

- PSSF:

-

Prehydrolysis and simultaneous saccharification and fermentation

- SHF:

-

Saccharification and hydrolysis fermentation

- SSF:

-

Simultaneous saccharification and fermentation

- WIS:

-

Water insoluble solids

- WS:

-

Whole slurries

- WSM:

-

Whole slurries with trace metal additives

- YEP:

-

Media comprising yeast extract and peptone

- YH:

-

Yeast hull

- YHM:

-

Yeast hull with trace metal additives

- YPG:

-

Media comprising yeast extract, peptone, and glucose

- YPGX:

-

Media comprising yeast extract, peptone, glucose, and xylose

References

Morales M, Quintero J, Conejeros R, Aroca G (2015) Life cycle assessment of lignocellulosic bioethanol: environmental impacts and energy balance. Renew Sustain Energy Rev 42:1349–1361. https://doi.org/10.1016/j.rser.2014.10.097

Mankar AR, Pandey A, Modak A, Pant KK (2021) Pretreatment of lignocellulosic biomass: a review on recent advances. Biores Technol 334:125235–125246. https://doi.org/10.1016/j.biortech.2021.125235

Persson M, Galbe M, Wallberg O (2021) Mitigation of pretreatment-derived inhibitors during lignocellulosic ethanol fermentation using spent grain as a nitrogen source. Biomass Convers Bioref. https://doi.org/10.1007/s13399-021-01454-5

Zheng J, Tashiro Y, Zhao T, Wang QH, Sakai K, Sonomoto K (2017) Enhancement of acetone-butanol-ethanol fermentation from eucalyptus hydrolysate with optimized nutrient supplementation through statistical experimental designs. Renew Energy 113:580–586. https://doi.org/10.1016/j.renene.2017.05.097

Tomás-Pejó E, Negro MJ, Sáez F, Ballesteros M (2012) Effect of nutrient addition on preinoculum growth of S. cerevisiae for application in SSF processes. Biomass Bioenerg 45:168–174. https://doi.org/10.1016/j.biombioe.2012.06.002

Ingledew WM (2009) Yeasts: physiology, nutrition and ethanol production. In: Ingledew WM, Kelsall DR, Austin GD, Kluhspies C (eds) The alcohol textbook : a reference for the beverage, fuel and industrial alcohol industries, 5th edn. Nottingham University Press, Nottingham, U.K, 101–113

Gibson BR (2011) 125th anniversary review: improvement of higher gravity brewery fermentation via wort enrichment and supplementation. J Inst Brew 117(3):268–284

Pereira FB, Guimaraes PMR, Teixeira JA, Domingues L (2010) Optimization of low-cost medium for very high gravity ethanol fermentations by Saccharomyces cerevisiae using statistical experimental designs. Biores Technol 101(20):7856–7863. https://doi.org/10.1016/j.biortech.2010.04.082

Puligundla P, Mok C, Park S (2020) Advances in the valorization of spent brewer’s yeast. Innov Food Sci Emerg Technol 62:8. https://doi.org/10.1016/j.ifset.2020.102350

Kelbert M, Romani A, Coelho E, Pereira FB, Teixeira JA, Domingues L (2015) Lignocellulosic bioethanol production with revalorization of low-cost agroindustrial by-products as nutritional supplements. Ind Crops Prod 64:16–24. https://doi.org/10.1016/j.indcrop.2014.10.056

Ismail KS, Sakamoto T, Hasunuma T, Zhao XQ, Kondo A (2014) Zinc, magnesium, and calcium ion supplementation confers tolerance to acetic acid stress in industrial Saccharomyces cerevisiae utilizing xylose. Biotechnol J 9(12):1519–1525. https://doi.org/10.1002/biot.201300553

Xiros C, Olsson L (2014) Comparison of strategies to overcome the inhibitory effects in high-gravity fermentation of lignocellulosic hydrolysates. Biomass Bioenerg 65:79–90. https://doi.org/10.1016/j.biombioe.2014.03.060

McIntosh S, Vancov T, Palmer J, Spain M (2012) Ethanol production from Eucalyptus plantation thinnings. Biores Technol 110:264–272. https://doi.org/10.1016/j.biortech.2012.01.114

Huang H, Guo X, Li D, Liu M, Wu J, Ren H (2011) Identification of crucial yeast inhibitors in bio-ethanol and improvement of fermentation at high pH and high total solids. Bioresour Technol 102(16):7486–7493. https://doi.org/10.1016/j.biortech.2011.05.008

Almeida JRM, Runquist D, Nogue VSI, Liden G, Gorwa-Grauslund MF (2011) Stress-related challenges in pentose fermentation to ethanol by the yeast Saccharomyces cerevisiae. Biotechnol J 6(3):286–299. https://doi.org/10.1002/biot.201000301

Xu GH, Zhao XQ, Li N, Bai FW (2012) Improvement of acetic acid tolerance of self-flocculating yeast by zinc supplementation. CIESC Journal 63(6):1823–1829. https://doi.org/10.3969/j.issn.0438-1157.2012.06.024

Zhao HW, Li JY, Wang JM, Xu X, Xian M, Liu HZ, Zhang HB (2017) Calcium supplementation abates the inhibition effects of acetic acid on Saccharomyces cerevisiae. Appl Biochem Biotechnol 181(4):1573–1589. https://doi.org/10.1007/s12010-016-2303-5

Nogue VS, Karhumaa K (2015) Xylose fermentation as a challenge for commercialization of lignocellulosic fuels and chemicals. Biotech Lett 37(4):761–772. https://doi.org/10.1007/s10529-014-1756-2

Park H, Jeong D, Shin M, Kwak S, Oh EJ, Ko JK, Kim SR (2020) Xylose utilization in Saccharomyces cerevisiae during conversion of hydrothermally pretreated lignocellulosic biomass to ethanol. Appl Microbiol Biotechnol 104(8):3245–3252. https://doi.org/10.1007/s00253-020-10427-z

Cunha JT, Soares PO, Baptista SL, Costa CE, Domingues L (2020) Engineered Saccharomyces cerevisiae for lignocellulosic valorization: a review and perspectives on bioethanol production. Bioengineered 11(1):883–903. https://doi.org/10.1080/21655979.2020.1801178

Paulova L, Patakova P, Branska B, Rychtera M, Melzoch K (2015) Lignocellulosic ethanol: technology design and its impact on process efficiency. Biotechnol Adv 33(6):1091–1107. https://doi.org/10.1016/j.biotechadv2014.12.002

Vancov T, Palmer J, Keen B (2018) A two stage pretreatment process to maximise recovery of sugars from cotton gin trash. Bioresource Technol Rep 4:114–122. https://doi.org/10.1016/j.biteb.2018.09.010

Vancov T, Palmer J, Keen B (2019) Two-stage pretreatment process validation for production of ethanol from cotton gin trash. Bioenerg Res 12:593–604. https://doi.org/10.1007/s12155-019-09989-2

McIntosh S, Zhang Z, Palmer J, Wong H-H, Doherty WOS, Vancov T (2016) Pilot-scale cellulosic ethanol production using eucalyptus biomass pre-treated by dilute acid and steam explosion. Biofuels Bioprod Biorefin 10(4):346–358. https://doi.org/10.1002/bbb.1651

Demeke MM, Dumortier F, Li Y, Broeckx T, Foulquie-Moreno MR, Thevelein JM (2013) Combining inhibitor tolerance and D-xylose fermentation in industrial Saccharomyces cerevisiae for efficient lignocellulose-based bioethanol production. Biotechnol Biofuels 6(1):120–136. https://doi.org/10.1186/1754-6834-6-120

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. National Renewable Energy Laboratory. NREL Technical Report NREL/TP-510-42618

Zhao XQ, Bai FW (2012) Zinc and yeast stress tolerance: micronutrient plays a big role. J Biotechnol 158(4):176–183. https://doi.org/10.1016/j.jbiotec.2011.06.038

Jeon YJ, Xun Z, Rogers PL (2010) Comparative evaluations of cellulosic raw materials for second generation bioethanol production. Lett Appl Microbiol 51(5):518–524. https://doi.org/10.1111/j.1472-765X.2010.02923.x

Assaad HI, Zhou L, Carroll RJ, Wu G (2014) Rapid publication-ready MS-Word tables for one-way ANOVA. Springerplus 3(1):474–481. https://doi.org/10.1186/2193-1801-3-474

Bakker BM, Overkamp KM, van Maris AJA, Kötter P, Luttik MAH, van Dijken JP, Pronk JT (2001) Stoichiometry and compartmentation of NADH metabolism in Saccharomyces cerevisiae. FEMS Microbiol Rev 25(1):15–37. https://doi.org/10.1111/j.1574-6976.2001.tb00570.x

Wang LQ, Cai LY, Ma YL (2020) Study on inhibitors from acid pretreatment of corn stalk on ethanol fermentation by alcohol yeast. RSC Adv 10(63):38409–38415. https://doi.org/10.1039/d0ra04965d

Kim Y, Ximenes E, Mosier NS, Ladisch MR (2011) Soluble inhibitors/deactivators of cellulase enzymes from lignocellulosic biomass. Enzyme Microb Tech 48(4–5):408–415. https://doi.org/10.1016/j.enzmictec.2011.01.007

Jönsson LJ, Alriksson B, Nilvebrant N-O (2013) Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol Biofuels 6(1):1–10. https://doi.org/10.1186/1754-6834-6-16

Erasmus DJ, van der Merwe GK, van Vuuren HJ (2003) Genome-wide expression analyses: metabolic adaptation of Saccharomyces cerevisiae to high sugar stress. FEMS Yeast Res 3(4):375–399. https://doi.org/10.1016/s1567-1356(02)00203-9

Navarro-Avino JP, Prasad R, Miralles VJ, Benito RM, Serrano R (1999) A proposal for nomenclature of aldehyde dehydrogenases in Saccharomyces cerevisiae and characterization of the stress-inducible ALD2 and ALD3 genes. Yeast 15(10A):829–842. https://doi.org/10.1002/(sici)1097-0061(199907)15:10a%3c829::Aid-yea423%3e3.0.Co;2-9

Saint-Prix F, Bönquist L, Dequin S (2004) Functional analysis of the ALD gene family of Saccharomyces cerevisiae during anaerobic growth on glucose: the NADP+-dependent Ald6p and Ald5p isoforms play a major role in acetate formation. Microbiology (Reading) 150(Pt 7):2209–2220. https://doi.org/10.1099/mic.0.26999-0

Dickinson FM (1996) The purification and some properties of the Mg(2+)-activated cytosolic aldehyde dehydrogenase of Saccharomyces cerevisiae. Biochem J 315(Pt 2):393–399. https://doi.org/10.1042/bj3150393

Petersson A, Almeida JR, Modig T, Karhumaa K, Hahn-Hägerdal B, Gorwa-Grauslund MF, Lidén G (2006) A 5-hydroxymethyl furfural reducing enzyme encoded by the Saccharomyces cerevisiae ADH6 gene conveys HMF tolerance. Yeast 23(6):455–464. https://doi.org/10.1002/yea.1370

Ko JK, Um Y, Lee SM (2016) Effect of manganese ions on ethanol fermentation by xylose isomerase expressing Saccharomyces cerevisiae under acetic acid stress. Bioresource Technol 222:422–430. https://doi.org/10.1016/j.biortech.2016.09.130

Bellissimi E, van Dijken JP, Pronk JT, van Maris AJA (2009) Effects of acetic acid on the kinetics of xylose fermentation by an engineered, xylose-isomerase-based Saccharomyces cerevisiae strain. FEMS Yeast Res 9(3):358–364. https://doi.org/10.1111/j.1567-1364.2009.00487.x

Brat D, Boles E, Wiedemann B (2009) Functional expression of a bacterial xylose isomerase in Saccharomyces cerevisiae. Appl Environ Microbiol 75(8):2304–2311. https://doi.org/10.1128/AEM.02522-08

van Dijk M, Erdei B, Galbe M, Nygård Y, Olsson L (2019) Strain-dependent variance in short-term adaptation effects of two xylose-fermenting strains of Saccharomyces cerevisiae. Biores Technol 292:121922–121930. https://doi.org/10.1016/j.biortech.2019.12192244

Pfeiffer T, Morley A (2014) An evolutionary perspective on the Crabtree effect. Front Mol Biosci 1:17. https://doi.org/10.3389/fmolb.2014.000145

Remize F, Andrieu E, Dequin S (2000) Engineering of the pyruvate dehydrogenase bypass in Saccharomyces cerevisiae: role of the cytosolic Mg(2+) and mitochondrial K(+) acetaldehyde dehydrogenases Ald6p and Ald4p in acetate formation during alcoholic fermentation. Appl Environ Microbiol 66(8):3151–3159. https://doi.org/10.1128/aem.66.8.3151-3159.2000

Perli T, Wronska AK, Ortiz-Merino RA, Pronk JT, Daran J-M (2020) Vitamin requirements and biosynthesis in Saccharomyces cerevisiae. Yeast 37(4):283–304. https://doi.org/10.1002/yea.3461

Jørgensen H (2009) Effect of nutrients on fermentation of pretreated wheat straw at very high dry matter content by Saccharomyces cerevisiae. Appl Biochem Biotechnol 153(1–3):44–57. https://doi.org/10.1007/s12010-008-8456-0

Kelbert M, Romani A, Coelho E, Pereira FB, Teixeira JA, Domingues L (2016) Simultaneous saccharification and fermentation of hydrothermal pretreated lignocellulosic biomass: evaluation of process performance under multiple stress conditions. Bioenergy Res 9(3):750–762. https://doi.org/10.1007/s12155-016-9722-6

Bezerra RM, Dias AA (2005) Enzymatic kinetic of cellulose hydrolysis: inhibition by ethanol and cellobiose. Appl Biochem Biotechnol 126(1):49–59. https://doi.org/10.1007/s12010-005-0005-5

Olofsson K, Bertilsson M, Liden G (2008) A short review on SSF - an interesting process option for ethanol production from lignocellulosic feedstocks. Biotechnol Biofuels 1:7–20. https://doi.org/10.1186/1754-6834-1-7

Cunha M, Romaní A, Carvalho M, Domingues L (2018) Boosting bioethanol production from Eucalyptus wood by whey incorporation. Biores Technol 250:256–264. https://doi.org/10.1016/j.biortech.2017.11.023

Acknowledgements

We gratefully acknowledge the support of NSW Department of Primary Industries and the Queensland University of Technology, Australia.

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions We gratefully acknowledge the financial support provided by Australia-India Strategic Research Fund (AISRF) for this work.

Author information

Authors and Affiliations

Contributions

Tony Vancov: conceptualisation, methodology, formal analysis, investigation, resources, writing — original draft, writing — review and editing, supervision, project administration, funding acquisition. Janice Palmer: methodology, validation, investigation, data curation. Brad Keen: methodology, validation, writing — review and editing.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Vancov, T., Palmer, J. & Keen, B. Bioethanol production from Eucalyptus grandis using novel low-cost nutrient supplements in fermentation. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04555-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04555-5