Abstract

Hydrothermal methods are commonly applied in pretreatment of lignocellulose for conversion to biofuels and chemicals. This pretreatment partially disassembles and solubilizes hemicelluloses and lignin, releasing sugars and phenolic compounds, which are potential inhibitors for the subsequent enzymatic saccharification step. In this work, the inhibitory effect of soluble phenolics in hydrothermal pretreatment liquor on canonical Trichoderma reesei enzymes was investigated, using purified cellobiohydrolases, endoglucanases, a xylanase, and a lytic polysaccharide monooxygenase, as well as commercial enzyme cocktails Cellic Ctec2 and Celluclast. The pretreatment liquor was fractionated to enrich the phenolics, and thoroughly analyzed. The most sensitive to phenolics inhibition were cellobiohydrolases, the major enzymes in crystalline cellulose degradation and the primary component in cellulolytic mixtures. These were inhibited by the oligophenolics and phenol-carbohydrate complexes (lignin-carbohydrate complex type of compounds), the latter of which could be mitigated by other enzymes, i.e., xylanases and endoglucanases. Addition of lytic polysaccharide monooxygenase to the hydrolysis reactions was found to relieve the negative effect of phenolics. Similarly, hydrolytic activity of a commercial enzyme cocktail Cellic Ctec2 was enhanced in the presence of low concentrations of phenolics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Background

Sustainable industrial processes utilizing renewable raw materials are needed in production of fuels and chemicals, in order to meet the demands of growing human population and resolve the global environmental challenges. The use of lignocellulose feedstocks for the production of biochemicals and biofuels typically requires hydrolysis of polysaccharides to monosaccharides, which in turn are converted to products of interest. Enzymatic hydrolysis is a preferred depolymerization method, due to high sugar yields under mild reaction conditions.

Prerequisite to an efficient enzymatic hydrolysis of lignocellulose is biomass pretreatment, which disrupts the plant tissues and cell walls and consequently improves the accessibility of the enzymes to their substrates. The most commonly applied pretreatment technologies involve heating of the wet biomass to, e.g., 180–210 °C with or without an added acid catalyst, leading to partial dissolution and degradation of hemicelluloses and modification of lignin [1]. A drawback in this type of technologies is the formation of pretreatment products that are inhibitory for enzymatic hydrolysis and/or for the fermenting microorganism, which impairs the process yield and cost efficiency [2]. The known pretreatment-derived inhibitors for microbes or enzymes include hemicellulose-derived mono- and oligo-saccharides, acetic acid, furfural, 5-hydroxymethyfurfural (HMF), and various phenolic compounds, including modified lignin or pseudolignin [1].

The enzyme mixtures used in a lignocellulose hydrolysis typically contain a number of hydrolytic enzymes, including cellobiohydrolases (CBHs), endoglucanases (EGs), a β-glucosidase (BGL), and different hemicellulases [3]. The state-of-the-art commercial enzyme products also contain lytic polysaccharide monooxygenases (LPMOs), which are oxidative enzymes with a capability to strongly boost overall saccharification of cellulose in the presence of suitable reducing agents and oxygen or hydrogen peroxide [4,5,6]. Xylan- or mannan-derived oligosaccharides arising from lignocellulose pretreatment can be strong inhibitors for cellulolytic enzyme cocktails [7, 8]. Lignin adsorbs many lignocellulolytic enzymes which can lead to irreversible deactivation via denaturation [9]. On the other hand, a vast number of studies were carried out to elucidate a positive role of high molecular weight lignin and its soluble low molecular weight fragments in the oxidative reactions of LPMO enzymes [10,11,12,13,14,15]. In the current study, we focus mainly on cellulases and their inhibition by soluble phenolic compounds, although synergistical behavior with LPMO was also investigated here in hydrolysis reactions.

The soluble phenolic fraction of the pretreatment liquors is typically very complex and contains compounds arising both from lignin and carbohydrate degradation [16, 17]. The pretreatment liquor phenolics have negative overall effect on hydrolysis by cellulolytic enzyme mixtures [18,19,20,21], but information about effects on individual enzymes is scarce and related mostly to xylanases [22]. The effect of soluble phenolics on purified cellulases has been studied so far mainly using commercial model compounds, such as vanillin or tannic acid [23, 24].

Wheat straw is an abundant residue from agriculture, widely explored as renewable raw material in biofuel production. In previous works, we have studied the inhibitory effects of hemicellulosic oligosaccharides [25] and isolated lignins [26] from the hydrothermally or steam pretreated wheat straw on purified cellulolytic enzymes. Here we have performed an optimized hydrothermal pretreatment of wheat straw, followed by fractionation of the pretreatment liquor (PL), comprehensive analysis of its composition, and identification of monomeric and dimeric phenolic structures. Inhibitory effects of the soluble phenolics on purified CBHs and EGs from archetypical Trichoderma reesei, as well as on commercial enzyme cocktails, were studied.

2 Methods

2.1 Enzymes and substrates

The following enzymes were used in the hydrolysis experiments with microcrystalline cellulose (Avicel) as substrate. Cellic Ctec2 (Lot # VCSI0006, protein concentration 257 g/L) was obtained from Novozymes A/S (Bagvaerd, Denmark). The enzymes TrCel7A (CBH1), TrCel6A (CBH2), TrCel7B (EG1), TrCel5A (EG2), TrXyn11 (XYN2) from Trichoderma reesei and Aspergillus niger β-glucosidase AnCel3A (BGL) were purified and assayed as described [26]. The enzymes TrCel12A (EG3) and TrCel45A (EG5) were purified from T. reesei culture supernatant according to a previously established protocol [27]. The T. reesei LPMO TrAA9A was produced and purified according to [28]. The protein concentrations of the purified enzymes were quantified by measuring absorbance at 280 nm and using corresponding molar extinction coefficients and masses (Supplementary information, Table S1).

Celluclast 1.5L (Lot # SLBB4803V) and Cellic CTec2 (Lot # SLBS6227) used in the experiments with radioactively labelled cellulose substrate was purchased from Sigma. The protein concentration of these blends was measured using a ninhydrin assay with acidic hydrolysis [29] and was 124 ± 10 g/L and 269 ± 7 g/L for Celluclast 1.5L and Cellic Ctec2, respectively. TrCel7A and TrCel6A used in the experiments with the radioactively labelled bacterial microcrystalline cellulose (14C-BMCC) substrate were purified from the culture filtrate of Tr QM 9414 as described [30].

14C-BMCC was prepared from 14C-labeled bacterial cellulose (14C-BC). Bacterial cellulose was produced by growing Gluconobacterium xylinum strain ATCC 53,582 in the medium supplied with 14C-glucose as described [31]. 14C-BC (2 g/L) was incubated with 1.0 M HCl at 100 °C for 3 h followed by extensive washing with water. The specific radioactivity of 14C-BMCC was 6.4 × 105 dpm mg−1. Avicel was purchased from Serva GmbH (Heidelberg, Germany).

2.2 Hydrothermal pretreatment of wheat straw

Chopped wheat straw from Finland was used as the feedstock for hydrothermal pretreatment using a 30-L pressure reactor. The composition of straw was determined according to a previously established protocol [32]. Batches of 1.71 kg (dry matter, DM) of chopped straw after pre-soaking with water to 50% DM were heated by direct steam injection and a heating jacket to 195 °C and the temperature was maintained for 15 min. The thermal severity factor Log(R0) of the reaction was 4.02, calculated from the reactor temperature curve accordingly [33], which was considered effective for wheat straw [34, 35]. After the reaction, the material was quickly cooled to 80 °C by jacket cooling with water and the soluble fraction was recovered by displacement washing, by feeding water at 80 °C from underneath and collecting the liquid from the top of the material bed in 1–2 L fractions. The hydrothermal pretreatment was repeated 6 times and the first 6 l from each reaction were pooled together, providing the original PL used as the source of phenolics in this study. The DM balance was determined by oven-drying of solid and liquid samples at 105 °C. The liquor was stored frozen (–20 °C).

2.3 Isolation of phenolic fraction from wheat straw pretreatment liquor

PL was fractionated on a glass column (250 mL column volume, CV) packed with water-rinsed Amberlite XAD-7 HP resin (Acros Organics, Germany). The column bed volume was 220 mL (XAD-7 pore volume 1.14 mL/g). PL (750 mL) containing 3.6 g of UV-phenolics (25 mg/g resin) was loaded into the column with flow rate of 5 mL/min (0.25 cm/min). The column was washed with 4–5 CV of water with flow rate of 10 mL/min (0.5 cm/min). Bound phenolic compounds were eluted with 100% ethanol at flow rate of 3 mL/min (0.15 cm/min). An ethanol-eluted phenolic fraction (250 mL) was collected and analyzed for soluble phenolic compounds and carbohydrates as described below. The purification run was repeated for 6 batches. The water eluates were stored frozen (–20 °C) and the combined phenolic fraction (Phe-Fr) was freeze-dried. Analytical fractionation of PL was performed as described above in a single XAD-7 column chromatography run with the ethanol gradient, applied stepwise by 10% increase of ethanol concentration (10–90% ethanol, 250 mL each step). All the eluate fractions including water fraction were collected and freeze-dried.

2.4 Preparation of Cellic Ctec2-treated pretreatment liquor

Cellic Ctec2-treated PL (Ctec-PL) was prepared by incubating 12 mL PL with 2 mg of Cellic Ctec2 (5 mg/g DM PL) in 50 mM sodium acetate buffer, pH 5.0 at 50 °C, for 18 h. After incubation the enzymes were inactivated by heating at 100 °C for 20 min. Heat-inactivated enzymes were pelleted by 2 min centrifugation (10,000 × g) and aliquots (1.5 mL) of supernatant were stored at –20 °C. Carbohydrates and phenolics in the Ctec-PL were analyzed as described below.

2.5 Spectrophotometric quantification of soluble phenolic compounds

The total concentration of the soluble phenolic compounds was determined with a UV-spectrophotometric assay based on the determination of acid soluble lignin in the biomass compositional analysis [32], using the absorptivities determined by method described previously [36]. UV-phenolics concentration was used further on in the paper, if not stated otherwise. Correlation factor between UV-phenolics and total solids for Phe-Fr was calculated to be 0.48 ± 0.07 (g UV-phenolics/g total solids) (Supplementary information, Figure S1).

2.6 Quantification of soluble carbohydrates and furaldehydes

Monosaccharides were analyzed by HPAEC-PAD, using CarboPac PA1 column on DIONEX ICS-5000 and 300 mM NaAc/NaOH gradient as described [37]. The linear xylooligosaccharides were analyzed using CarboPac PA1 column on DIONEX ICS-3000A as described [38]. The total amount of soluble carbohydrates was analyzed by hydrolyzing oligosaccharides with 3% H2SO4 at 120 °C for 1 h and analyzing the monosaccharides as described above. Furfural and 5-hydroxymethylfurfural were determined by HPLC using PerkinElmer Flexar equipment with Bio-Rad Aminex HPX-87 300 × 7.8 column.

2.7 Determination of phenolic fraction molecular weight distribution

The weight average molecular weight (MW) measurements were performed by size exclusion chromatography (SEC) and analyzed as described previously [39]. For the analysis, 2 mg of lyophilized Phe-Fr was dissolved in 0.1 M NaOH and filtered (filter pore size 0.45 μm). The SEC measurements were performed in 0.1 M NaOH eluent (pH 13, 0.5 ml/min, T = 25 °C) using PSS MCX 1000 and 100,000 Å columns with a pre-column. The elution curves were detected using Waters 2998 Photodiode Array detector at 280 nm. The molar mass distributions (MMD) were calculated against polystyrene sulphonate (10 × PSS, 1600–267,200 g/mol) standards, using Waters Empower 3 software.

2.8 GC/MS analysis of the phenols

The PL and Phe-Fr samples were analyzed for phenolic compounds by GC/MS after trimethylsilylation. For that, the PL in water (2 mL) was extracted twice with 5 mL of diethyl ether, after the addition of salicylic acid as the internal standard. The organic phases were combined and evaporated to dryness. The Phe-Fr in ethanol (0.3 mL) was readily evaporated to dryness, after the addition of the same salicylic acid standard. The evaporation residues were trimethylsilylated and analyzed by GC/MS as described previously [40]. Accordingly, the runs (at scanning range of 40–800 m/z) were performed with an Agilent 6890 series GC system, equipped with an Agilent 5973 mass selective detector and a DB-5 capillary column (30 m × 0.25 mm, film thickness 0.25 μm). The applied oven temperature program was 1 min at 70 °C, followed by 10 °C/min to 300 °C where kept for 9 min.

The peak areas were used for the indicative concentration calculations, without any corrections.

2.9 Hydrolysis assays with Avicel as substrate

The hydrolysis assays were carried out in 50 mM sodium acetate pH 5.0 at 45 °C with magnetic mixer stirring at 1000 rpm. Enzymes concentration was 0.1 g/L (10 mg/g Avicel) for Cellic Ctec2 and purified cellulases, when assayed alone. The mixture of T. reesei cellulases was composed of 58.4% w/v TrCel7A, 19.5% w/v TrCel6A, 9.8%w/v TrCel5A, and 2.6% w/v TrXyn11. The hydrolysis reactions with individual T. reesei cellulases and with the mixture were supplied with AnCel3A (500 nkat β-glucosidase/g Avicel). Avicel concentration in all the reactions was 10 g/L, Phe-Fr concentration in the assays with Cellic Ctec2 varied from 0.25 to 5 g/L, while the purified enzymes were assayed at 5 g/L Phe-Fr. In synergy experiments, TrAA9A enzyme was added at concentration 0.005 g/L (0.5 mg/g Avicel), while concentration of purified enzymes, their mixture, and Cellic Ctec2 was 0.1 g/L (10 mg/g Avicel). Synergy experiments were performed at 10 g/L Avicel and 5 g/L Phe-Fr in the reactions, as described above. Prior to hydrolysis, the freeze-dried Phe-Fr was dissolved in 0.1 M sodium acetate at pH 5.0 by heating at 40 °C for 20 min with stirring, and then incubated with Avicel for another 20 min. The hydrolysis reactions were initiated by addition of the enzyme, run in duplicates (purified enzymes) or triplicates (Cellic Ctec2) for 4 and 24 h for purified enzymes and 4, 24, 48 h for Cellic Ctec2. The reactions were stopped by addition of 10 μL of 10 M NaOH and the insoluble cellulose was removed by centrifugation (5 min at 3220 × g). Soluble reducing sugars were analyzed with 4-hydroxybenzoic acid hydrazide (PAHBAH) reagent and glucose standards [41]. The method was proved to be suitable for assays including Phe-Fr within concentrations range (Supplementary information, Figure S2). Control hydrolysis reactions lacking Phe-Fr (10 g/L Avicel) and control reactions for Phe-Fr background carbohydrates (0 g/L Avicel) were carried out in the same way as described above. To take into account background carbohydrate content in Cellic Ctec2 and pure cellulases, control hydrolysis reactions were performed including enzymes and buffer only. Tannic acid inhibition experiments were performed with purified cellulases, their mixture and Cellic Ctec2 at fixed tannic acid concentration 0.1 g/L, same way as described above for Phe-Fr. Inhibitory effects of PL analytical fractions from ethanol gradient elution were studied with Cellic CTec2 as described above, using total solids 10 g/L concentration of each fraction in Avicel hydrolysis. The released glucose was analyzed with HPLC, as described above.

2.10 Hydrolysis assays with radioactively labelled bacterial microcrystalline cellulose as substrate

All reactions were performed in 50 mM sodium acetate, pH 5 at 50 °C for 18 h without stirring. Concentration of 14C-BMCC was 0.6 g/L. The reactions were stopped by adding NaOH to a final concentration of 0.1 M (in inhibition experiments the reactions were stopped by centrifugation, 2 min at 104 × g). Cellulose was pelleted by centrifugation (2 min at 104 × g) and radioactivity in the supernatants was measured using scintillation counter. The degree of cellulose degradation was found as the ratio of radioactivity in the supernatant to the total radioactivity in the mixture. Inhibition studies were carried out using protein concentrations 1.0 µM (about 0.06 g/L) for CBHs and 0.01 g/L for Celluclast 1.5L and Cellic CTec2 and different volume fractions (v/v %) of the PL, Ctec-PL, and Phe-Fr. The freeze-dried Phe-Fr was dissolved for the experiments by heating at 40 °C for 20 min with stirring. The concentration of PL was expressed as its volume fraction (in %). Based on the concentration of UV-phenolics in Ctec-PL and Phe-Fr, their concentrations were expressed as the equivalent volume fraction of PL (100% volume fraction in the assay corresponds to UV-phenolic concentration of PL (4.55 g/L).

Inhibition data were analyzed according to Eq. 1:

In Eq. 1, the relative activity (%) is a ratio of the degree of cellulose conversion measured in the presence of inhibitor to that measured in the absence of inhibitor. [I] stands for the concentration of inhibitor (in v/v %) and IC50 is the inhibitor concentration that causes 50% decrease in the degree of cellulose conversion.

3 Results

3.1 Hydrothermal pretreatment of wheat straw

Wheat straw was pretreated using a bench-scale hydrothermal method to produce material for the inhibition studies. The yields of solids and soluble compounds were 71% (standard error 2%) and 18% of DM, respectively. The final PL contained 57% of the solubles. The major compounds of PL were carbohydrates (glucose and xylose as main sugars), phenolic compounds, acetate, and furfural (Table 1). The carbohydrate part was composed of both monosaccharides (22.8% of DM) and oligosaccharides or other sugar conjugates (31.3% of DM), of which 17.2% of DM were linear xylooligosaccharides with DP 2–6. The soluble sugar recovery corresponded to 15% of total carbohydrate in the initial straw biomass DM. Altogether, 66% of the C5 (hemicellulosic) sugars in straw were dissolved and 37% recovered, which is in line with [34] and [28]. The amount of soluble phenolics in PL was 4.55 g/L (13.2% of DM), quantified with the UV method, corresponding to 2.4% of original straw DM.

3.2 Column chromatography fractionation of pretreatment liquor

Column chromatography fractionation of PL was carried out using a polyacrylic Amberlite XAD-7 resin aiming at enrichment of phenolics for the inhibition studies. Most of the carbohydrates were eluted with water, while the most of phenolic compounds (Phe-Fr) was eluted with 100% ethanol (Fig. 1A). The recovered Phe-Fr contained 66% of the phenolics quantified from PL, while majority of the soluble sugars were removed successfully (Fig. 1A, Table 1). The phenolic compounds composed 60% of DM in the Phe-Fr (Table 1). The amount of free monosaccharides in Phe-Fr was less than 0.1% of the DM, but the total amount of monosaccharides, mostly xylose, released in mild acid hydrolysis of Phe-Fr contributed 23% of the DM. The amount of linear xylooligosaccharides with DP 2–6 was, however, found to be low (1.4% DM) (Table 1). This suggests that majority of sugar in Phe-Fr were bound to phenolics, resulting in their binding to XAD resin until eluted with ethanol. In addition, more thorough fractionation of the PL was carried out using increasing ethanol gradient and obtained fractions with different carbohydrate contents (Fig. 2) were further studied for inhibitory effect on Cellic Ctec2 in microcrystalline cellulose hydrolysis.

Isolation of Phe-Fr on a column packed with Amberlite XAD-7 resin. A Recovery of DM, carbohydrates, and phenolics in fractionations eluted with water and ethanol (Phe-Fr). B MW distribution in isolated Phe-Fr. The carbohydrates were analyzed after acid hydrolysis with HPAEC-PAD and phenolics were quantified with the UV-method. MW distribution was determined with SEC connected to UV detector

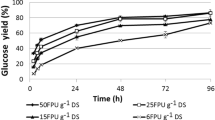

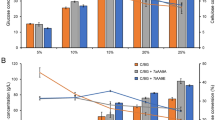

Screening for inhibitory effect of phenolic fraction (Phe-Fr). All hydrolysis reactions were performed at 45 °C in 50 mM sodium acetate pH 5.0 with Avicel concentration 10 g/L and enzyme dosage 0.1 g/L. The temperature of 45 °C was chosen to ensure thermal stability of the different enzymes used in the experiments. A Progress curves for Cellic CTec2 Avicel hydrolysis in the presence of Phe-Fr (0–5 g/L). Soluble reducing sugars were determined with PAHBAH. B Analytical fractionation of PL on Amberlite XAD-7 column with ethanol gradient (0–90%), showing phenolics/carbohydrate composition of different fractions, dosed at 10 g/L DM in Avicel hydrolysis by Cellic CTec2. The inhibitory effect of different analytical fractions is presented as activity remained in the presence of each fraction in comparison to a control (without phenolic fraction) at 24-h time point. Soluble sugars were determined with HPLC

3.3 Phenolic composition of pretreatment liquor and phenolic fraction

Molecular weight (MW) distribution of Phe-Fr was determined with SEC. An average MW was estimated to be 820 Da (Fig. 1B). Majority of the Phe-Fr compounds (60% w/w) fell into fractions with MW between 450 and 1700 Da, which corresponds to DP from 1–5 up to 8–18, as the MW of phenolic and carbohydrate units varies approximately between 90 and 250 Da.

Low molecular weight phenolic compounds (LMWs), with molar mass up to 450 Da in the original PL and Phe-Fr, were analyzed in detail using GC/MS (Table 2). The analysis revealed the presence of up to 130–150 different compounds (Supplementary information, Figure S3). Approximately 50% of them turned out to be monomeric phenolic (and related) compounds, and the rest were clearly dimeric compounds, composed either of two aromatic units or one aromatic unit and one sugar unit (Table 2). Most of the main monomeric and dimeric compounds were characterized, based on our numerous earlier studies on lignin degradation products [40, 42].

Majority of the identified monomeric phenolic compounds represented characteristic degradation products of lignin, i.e., 4-substituted phenols, guaiacols, and syringols. In line with recent studies by [16], many of them are related to the Hibbert’s ketones. Relatively high amounts of hydroquinones and catecholic compounds were also found among the monomeric compounds (Table 2). Catechols formation could arise from degradation-condensation reactions of carbohydrates, along with formation of other various phenolic compounds. It is thus possible that some simple catechols and certain unidentified phenols are at least partially also derived from such sources. A special type of phenolic compound, 3,8-dihydroxy-2-methylchromone, turned out to be one of the dominating constituents among the identified phenols. This compound belongs to the main aromatic compounds formed from xylose and hexuronic acids under mild acidic conditions [43]. A relatively abundant unknown phenolic compound with a molecular weight of 380 (as trimethylsilyl derivative) may also be derived from carbohydrates.

The main dimeric phenolic compounds could be identified [16] as different 4-hydroxycinnamic and ferulic acid esters with pentoses. Interestingly, the presence of several other hydroxycinnamic and ferulic acids esters was also recognized. One of the most characteristic features in the mass spectra of their trimethylsilylated derivatives was the presence of intense (typically 50–70%) ions corresponding to the molecular ion peaks of trimethylsilylated 4-hydroxycinnamic acid (m/z 308) and ferulic acid (338) (Supplementary information, Figure S3). Their more detailed identification is currently not possible, although in most cases their apparent molecular weights could also be established. Of the dilignols, only syringaresinol could be fully identified in the analysis. Most of the other dilignols are characterized by the intense benzylic ions in their mass spectra, representing both guaiacyl (m/z 209, 223, 297) and syringyl (239, 253, 327) structures (Supplementary information, Figure S3).

3.4 Screening for inhibitory effects of phenolic fraction

The effect of Phe-Fr on enzymatic saccharification was first studied with a commercial enzyme preparation Cellic Ctec2 and using microcrystalline cellulosic substrate (Avicel) as substrate. The hydrolysis tests were carried out using different Phe-Fr concentrations and fixed cellulose concentration, thus leading to varying cellulose-phenolic ratios in the reactions at fixed enzyme concentration. The hydrolysis of Avicel by Cellic Ctec2 was inhibited by Phe-Fr when phenolic concentration was above 1.25 g/L (12.5% DM of the cellulose concentration) (Fig. 2A). It was seen that the Cellic CTec2 also hydrolyzed carbohydrates in Phe-Fr and the background arising from Phe-Fr hydrolysis (Supplementary information, Figure S4) was subtracted from the progress curves. Interestingly, higher amount of reducing sugars was released by Cellic Ctec2 in the presence of the lowest phenolic concentrations (0.25–0.5 g/L) compared to the Avicel hydrolysis alone (Fig. 2A). However, this increase was detectable only in the final 48-h time point. The effect of the PL fractions obtained in elution from Amberlite XAD-7 column with ethanol gradient was also tested in hydrolysis, showing a clear dependence of phenolics-carbohydrate ratio in different fractions and their inhibitory effect on Cellic Ctec2 (Fig. 2B). Phenolic compounds eluted with higher concentration of ethanol contained less carbohydrates and were more inhibitory for the Cellic Ctec2.

Next, the inhibitory effect of Phe-Fr on individual enzymes was investigated, using fixed cellulose-phenolic ratio (10 g/L Avicel, 5 g/L Phe-Fr). Figure 3 A shows residual hydrolysis yield achieved with T. reesei cellulases (TrCel7A, TrCel6A, TrCel7B, TrCel5A, TrCel12A) and their mixture with xylanase TrXyn11 (all supplemented with β-glucosidase) in the presence of Phe-Fr (100% is the yield in the absence of Phe-Fr). The CBHs TrCel7A and TrCel6A were clearly inhibited by Phe-Fr: the hydrolysis yield dropped by 70–75% in comparison to the reference hydrolysis without Phe-Fr. EGs were also inhibited by Phe-Fr (Fig. 3A), but differently from CBHs, they were also able to release reducing sugars from Phe-Fr (Fig. 3B). In the latter context, the most efficient enzyme at 4 h was xylanase TrXyn11, followed by EGs TrCel7B and TrCel12A, while after 24-h, TrCel7B released the highest amount of reducing sugars among these enzymes (Fig. 3B). The mixture of purified T. reesei enzymes was inhibited by the Phe-Fr to similar extent as the individual CBHs, which is in line with the major role of CBHs in the hydrolysis of crystalline cellulose (Fig. 3A).

Inhibitory effect of phenolic fraction (Phe-Fr) on individual T.reesei enzymes and their synergistic behavior. All hydrolysis reactions were performed at 45 °C in 50 mM sodium acetate pH 5.0 with Avicel concentration 10 g/L and enzyme dosage 0.1 g/L. The temperature of 45 °C was chosen to ensure thermal stability of the different enzymes used in the experiments. Relative hydrolysis yields were calculated as ratio of soluble reducing sugars released from Avicel at certain time point in the presence of Phe-Fr (5 g/L) to soluble reducing sugars released from Avicel without Phe-Fr at the same time point. Soluble reducing sugars were determined with PAHBAH. Data on Cellic Ctec2 is presented as a reference. A Relative hydrolysis yields of purified T. reesei cellulases (TrCel7A, TrCe6A, TrCel5A, TrCel12A, TrCel45A) and their mixture with TrXyn11, all supplemented with AnCel3A (5000 nkat/L). B Hydrolysis of carbohydrates in Phe-Fr (5 g/L) by purified T. reesei cellulases and xylanase TrXyn11,and their mixture, all supplemented with AnCel3A (5000 nkat/L), except TrXyn11. C Synergistic behavior of T. reesei cellulases and LPMO TrAA9A in Avicel hydrolysis in the presence of Phe-Fr (5 g/L). Enzyme dosage was 0.1 g/L without LPMO (solid bars) and 0.005 g/L LPMO was added to 0.1 g/L enzymes to observe synergistic effect (pattern bars). All reactions were supplemented with AnCel3A (5000 nkat/L). D Hydrolysis of carbohydrates in Phe-Fr (5 g/L) by purified T. reesei cellulases and xylanase TrXyn11,and their mixture in the presence of 0.005 g/L LPMO, all supplemented with AnCel3A (5000 nkat/L), except TrXyn11. Solid bars represent soluble sugars released without LPMO, pattern bars represent soluble sugars released in the presence of LPMO

Lignocellulose-derived phenolic compounds have been frequently reported to support LPMO activity, by acting reductants necessary for the oxidative action and/or as according our earlier work, reacting with oxygen to produce hydrogen peroxide, which can act as co-substrate for these enzymes [10,11,12,13,14,15, 28]. Activation of LPMOs in turn is important for net hydrolysis [12]. To explore this, synergy studies were performed with T. reesei LPMO TrAA9A and the purified cellulases and cellulase mixtures. In the presence of TrAA9A, the negative effect of Phe-Fr on Avicel hydrolysis was clearly relieved in the beginning of hydrolysis (4 h), especially in the case for EGs TrCel7B and TrCel12A (45–50%), followed by CBHs TrCel7A and TrCel6A (10–15%), and resulted in 5–10% improvement for Cellic Ctec2 and enzyme mixture at 24-h time point (Fig. 3C). At the same time, TrAA9A did not affect degradation of Phe-Fr oligosaccharides (Fig. 3D), so the effect arose from improved cellulose (Avicel) hydrolysis.

To estimate the impact of high molecular weight phenolic compounds onto inhibition of purified enzymes, their mixture, and Cellic Ctec2, a model polyphenol tannic acid (MW 1701 Da) was used in Avicel hydrolysis at concentration mimicking the amount of high molecular weight phenolic s in the Phe-Fr (0.1 g/L, i.e., 10% of total phenolics, see Fig. 1B). The inhibitory effect of tannic acid at this concentration was negligible for EGs, about 20% decrease in hydrolytic activity was observed for CBHs, enzyme mixture, and Cellic Ctec2 at 24-h time point (Supplementary information, Figure S5). This implied CBHs inhibition to be governed mainly by oligophenols (Mw 450–1700 Da) in Phe-Fr.

3.5 Comparison of inhibitory effect of pretreatment liquor and its fractions on T. reesei cellobiohydrolases and commercial cellulase mixtures

The inhibition of T. reesei CBHs (TrCel7A and TrCel6A) and commercial cellulolytic enzyme mixtures CellicCtec2 and Celluclast by PL, Phe-Fr, and Ctec-PL was compared to evaluate the significance of carbohydrate and phenolic compounds in the overall inhibition. Composition of all three fractions is presented in Table 1. The difference between Phe-Fr and Ctec-PL was that the first one was separated from PL via column chromatography and the latter was enzymatically pretreated PL with high dosage of Cellic Ctec2 (16.5 mg protein/g non-monomeric xylan) in order to remove xyloligosaccharides well-known inhibitors for CBHs [7, 25]. Since Cellic Ctec2 was efficient in releasing reducing sugars from Phe-Fr (Fig. 3B), Cellic Ctec2 pretreatment was considered as an alternative strategy to remove oligosaccharides (both free and phenolics associated) from PL, retaining all the phenolic compounds. The drawback of this method was the presence of released monosaccharides in Ctec-PL. However, since inhibition of CBHs by monomeric xylose is negligible [7, 44], this was not expected to interfere with phenolics inhibition.

The comparison was carried out using 14C-labeled cellulose (BMCC) as substrate, because it enabled sensitive and robust detection of cellulose substrate degradation in a complex background of the compounds present in PL. In order to avoid well-known product inhibition of CBHs [45], low concentration of BMCC (0.6 g/L) was used. To ensure significant degree of cellulose conversion (around 50%) in inhibition experiments, BMCC was first incubated with enzymes at different concentrations (Fig. 4A). Based on these results, the protein concentration was chosen 0.01 g/L (16.7 mg/g cellulose) and 0.06 g/L (10 mg/g cellulose) for commercial enzyme mixtures and purified CBHs, respectively, for inhibition studies (Fig. 4B-D). PL, Phe-Fr, and CTec-PL were dozed into the reactions so that the phenolic concentrations (UV-phenolics) in volume fraction were comparable (0.05–3.3 g/L) and in range with phenolic concentration measured from PL (4.55 g/L). Consequently, the phenolic concentration was between 8 and 550% of the cellulose concentration in the reactions. For comparison, phenolic concentration was 7.5% (12.5% of dry matter) of the cellulose concentration in screening experiments with purified enzymes in Avicel hydrolysis. This allowed merely qualitative comparison of the results obtained for Phe-Fr in Avicel and BMCC hydrolysis.

Inhibition of cellulases studied with 14C-BMCC model substrate. All reactions were made in 50 mM sodium acetate pH 5.0 at 50 °C for 18 h with 14C-BMCC concentration of 0.6 g/L. A The effect of enzyme dosage on the degree of degradation of 14C-BMCC. Inhibition of cellulases by PL (B), Phe-Fr (C), and Ctec-PL (C). B–D The concentration of TrCel7A and TrCel6A was 1.0 µM (about 0.06 g/L) and the concentration of Celluclast 1.5 L and Cellic Ctec2 was 0.01 g/L. The concentration of inhibitors is expressed as their volume fraction in the reaction mixture (in %). The Phe-Fr and Ctec-PL were dosed based on their content of phenolics taking the concentration of phenolics in PL (4.55 g/L) equal to 100% volume fraction

The most sensitive enzymes towards inhibition by PL were CBHs followed by Celluclast 1.5L and Cellic Ctec2 (Fig. 4B). Ctec2-PL contained ca 44% less oligosaccharides than PL (Table 1), and as expected, the inhibitory effect of Ctec-PL on the enzymes was remarkably lower compared to PL (Fig. 4D, Table 3). The effect was most prominent with CBHs, inhibition of which was relieved by the factor of 50–100. In the case of CBHs, the residual activity also decreased nearly linearly with concentration of Ctec-PL (Fig. 4D). This is not consistent with Eq. 1 (the IC50 values in Table 3 were found using linear regression analysis), which suggests a different mechanism of inhibition compared to PL.

Inhibition of cellulases by Phe-Fr followed the same trends as with PL, being strongest for CBHs and weakest for Cellic Ctec2, but for all enzymes, the inhibition was about 3-–fourfold weaker than that by PL, and on the other hand essentially higher that Ctec2-PL (Fig. 4C, Table 3). The weaker inhibition by Phe-Fr was presumably caused by the removal of free oligosaccharides in XAD-7 fractionation (Fig. 1A, Table 1). As in the case of Ctec-PL, the significant amount of oligosaccharides (23% of dry matter) was still present in Phe-Fr, presumably bound to the phenolics (Fig. 1A, Table 1). However, due to enrichment of phenolics in the XAD-7 fractionation, the Phe-Fr reactions contained 3.5 or 8.3 times less oligosaccharides than PL and Ctec-PL containing reactions in the same phenolic concentrations. As such, the inhibitory effect of Phe-Fr could be expected to be caused by the phenolic compounds. Alternatively, the oligosaccharides bound to the phenolics in Phe-Fr were remarkably inhibitory towards the enzymes studied. Similar to PL, increasing concentration Phe-Fr caused non-linear regression of hydrolysis, suggesting similar inhibitory mechanisms.

Somewhat similar to the hydrolysis experiments with Avicel, there was a slight activating effect on hydrolysis of BMCC by Cellic Ctec2 at the lowest inhibitor concentration tested (Fig. 4B-D). Notably, similar activating effect was not observed in the case of individual CBHs and Celluclast 1.5 L.

4 Discussion

The composition of the soluble Phe-Fr in the wheat straw PL was found to be very complex. Numerous monomeric and dimeric compounds were detected using the GC–MS analysis, but their proportion of the total amount of phenolics was low (0.4 g/L of the 4.5 g/L). The effects of pure phenolic monomers on enzymes have been widely studied [24, 46]. The reported inhibitory/deactivating concentrations of the phenolic monomers are typically in the order of 1–10 g/L, which is much higher than the concentrations detected in the PL studied in present work. This suggests that the phenolic monomers may not necessarily be the major drivers of the inhibition of enzymes. Instead, the low molecular weight phenolics are prominent reductants for LPMOs, and such may have hydrolysis boosting effect by activation of the oxidative action [10,11,12,13,14,15].

Significance of phenolic compounds in the reduced hydrolysis yield was supported by our results, including the analytical fractionation of the PL, which showed that purer phenolic fractions, eluted with higher ethanol concentrations, were more inhibitory to the enzymatic cellulose hydrolysis, than carbohydrate containing fractions. A vast majority of the phenolic compounds in the PL of wheat straw had Mw characteristic to oligophenolic compounds (between 450 and 1700 Da). It has been proposed that wheat straw-derived oligophenolic compounds are responsible for phenolic inhibition of commercial enzyme cocktail Cellic Ctec3 via non-specific binding to the enzymes [20]. Tannic acid was used as model compound to evaluate the significance of higher molecular weight phenolics in the inhibition. Tannic acid has been reported to be a strong inhibitor for T. reesei CBHs (TrCel7A and TrCel6A) and EGs (TrCel7B and TrCel5A) [23]. However, here, the inhibition by tannic acid had only a moderate effect on purified enzymes and Cellic CTec2 in concentration mimicking the amount of high molecular weight phenols in the Phe-Fr, which indicated that primary inhibition arose from the major fraction with MW 450–1700 Da, representing oligophenolic compounds.

Comparison of different types of cellulases here showed that the CBHs in particular were sensitive to the inhibition by PL and its fractions. CBHs are key enzymes in the hydrolysis of crystalline cellulose [47], and thus their inhibition is expected to have major overall net effect on the cellulose saccharification by the cellulolytic enzyme mixtures. Strong inhibition of CBHs by hemicellulosic oligosaccharides is well known [25] and observed also in this study. This is caused by binding of the xylooligosaccharides the tunnel-shaped active site of CBHs [25]. However, this type of inhibition can be relieved by oligosaccharide-degrading enzymes present in cellulolytic cocktails. Interestingly, we observed that a substantial fraction of xylooligosaccharides was bound to the hydrophobic XAD resin, suggesting that they were interlinked with phenolics. These are expected to originate from lignin-carbohydrate complexes (LCCs), having molecular weight similar to oligophenols. The Phe-Fr fraction, containing phenolics and phenolics-associated oligosaccharides, was clearly more inhibitory to the CBHs than Ctec-PL fraction, where PL was pretreatead and partially hydrolyzed by Cellic Ctec 2 enzymes.

XAD resins have been previously used in binding of lignin-fragments and other aromatic compounds from lignocellulose extracts and hydrolysates [48, 49]. Fractions isolated with XAD resins from pretreated hardwood, softwood, and sugarcane baggase have also been reported to contain LCCs [48, 50]. On the other hand, wheat straw LCCs are known to contain lignin bound to glucan and xylan moieties via ferulic acid and phenyl glycosidic linkages, respectively [51], and feruloylated oligosaccharides have also previously been identified in wheat straw hydrothermal pretreatment liquor [20]. The LCC type of compounds can thus be the source of oligosaccharides in the XAD-bound fraction of wheat straw PL. This was supported by the GC–MS analysis, which showed that 4-hydroxycinnamic and ferulic acid esters with pentoses were present in the XAD bound Phe-Fr.

The effect of LCC type of compounds on cellulolytic enzymes is not well known, although the inhibition of cellulases by softwood LCCs has been proposed [52]. In that study, it was observed that ethanol organosolv dissolved lignin, containing LCCs, was essentially more inhibitory to cellulases, than enzymatically pretreated lignin where bound carbohydrates were removed [52]. The inhibition of cellulases by Phe-Fr may thus partially originate from LCC type of compounds. EGs and xylanases from T. reesei were also able to release sugars from the oligosaccharides in Phe-Fr, suggesting that they can contribute to relieving the inhibitory effect of LCCs. CBHs could poorly cleave off sugars in Phe-Fr (Fig. 3B), due to their high specificity to cellulose chain; similar low yields were observed for TrCel45A, known to be specific to cellulose and cereal β-glucans [27]. EG TrCel7B was reported to be able to hydrolyze a wide range of substrates, including celluloses, xyloglucan, arylated disaccharides, and xylans [54, 55]; TrCel12A also showed activity on xyloglucan [27, 55]. Ferulic acid derivatives have been reported to bind in xylanase active site [53]. One can speculate that the open-cleft architecture in the active site of EGs allows similar binding of these type of compounds. Despite high enzyme load, all the bound saccharides in PL were not hydrolyzed to monosaccharides during pretreatment by Cellic Ctec2. The inhibition of enzymes by Ctec-PL represents an inhibitory power of PL that cannot be mitigated by the enzymes present in this state-of-the-art enzyme cocktail. Combating with this remaining inhibitory power, may pave a way for mitigating the enzymes inhibition and improving their performance on lignocellulose degradation.

An activating effect of phenolic compounds was steadily observed with Cellic Ctec2 in hydrolysis of BMCC and Avicel, while not present with Celluclast 1.5L. The major difference between Celluclast 1.5L and Cellic Ctec2 is that the latter is rich in LPMOs [4]. Our recent study has revealed that the phenolic compounds in PL of wheat straw can support LPMOs with both electrons and H2O2 co-substrate [28]. The ability of LPMOs to use lignin and lignin-derived compounds as reductant has also been reported several times [10,11,12,13,14,15]. We also observed that including a LPMO (TrAA9A) in hydrolysis reaction with purified cellulases had apparent relieving effect on the inhibition, which may reflect the dual effect of Phe-Fr. The more pronounced effect of the LPMO in the beginning of hydrolysis can also be derived from a preservation of the LPMO activity over time and/or mixed nature of the phenolic fraction, and several inhibition mechanisms, which have different strengths over time. Thus, the net effect of soluble phenolic compounds on enzymatic hydrolysis is likely derived from balance between strong CBHs inhibition and activation of the hydrolysis boosting effect of LPMOs.

5 Conclusions

The soluble phenolics and phenol-carbohydrate complexes (or LCCs) in the hydrothermal PL of wheat straw have variable effects on commercial cellulolytic mixtures and purified cellulases. The results suggested the key enzymes of cellulolytic cocktails CBHs were sensitive to inhibition driven by phenolic oligomers and xylooligosaccharides interlinked to phenolics, having MW range of between 450 and 1700 Da. Supplementation of cellulolytic enzyme cocktails with LCC cleaving enzymes has thus potential in mitigating the inhibition. The high molecular weight phenolic compounds were also found to be inhibitory, but their relative amount in the pretreatment liquor was low. The development of oligophenol-tolerant CBHs could be a route to improve the overall hydrolysis.

References

Sannigrahi P, Kim DH, Jung S, Ragauskas A (2011) Pseudo-lignin and pretreatment chemistry. Energy Environ Sci 4(4):1306–1310. https://doi.org/10.1039/c0ee00378f

Jönsson LJ, Martín C (2016) Pretreatment of lignocellulose: Formation of inhibitory by-products and strategies for minimizing their effects. Biores Technol 199:103–112. https://doi.org/10.1016/j.biortech.2015.10.009

Van Dyk JS, Pletschke BI (2012) A review of lignocellulose bioconversion using enzymatic hydrolysis and synergistic cooperation between enzymes-Factors affecting enzymes, conversion and synergy. Biotechnol Adv 30(6):1458–1480. https://doi.org/10.1016/j.biotechadv.2012.03.002

Müller G, Várnai A, Johansen KS, Eijsink VGH, Horn SJ (2015) Harnessing the potential of LPMO-containing cellulase cocktails poses new demands on processing conditions. Biotechnology for Biofuels 8(1):1–9. https://doi.org/10.1186/s13068-015-0376-y

Bissaro B, Røhr ÅK, Müller G, Chylenski P, Skaugen M, Forsberg Z, Horn SJ, Vaaje-Kolstad G, Eijsink VGH (2017) Oxidative cleavage of polysaccharides by monocopper enzymes depends on H2O2. Nat Chem Biol 13(10):1123–1128. https://doi.org/10.1038/nchembio.2470

Kont R, Bissaro B, Eijsink VGH, Väljamäe P (2020) Kinetic insights into the peroxygenase activity of cellulose-active lytic polysaccharide monooxygenases (LPMOs). Nat Commun 11:5786. https://doi.org/10.1038/s41467-020-19561-8

Qing Q, Yang B, Wyman CE (2010) Xylooligomers are strong inhibitors of cellulose hydrolysis by enzymes. Biores Technol 101(24):9624–9630. https://doi.org/10.1016/j.biortech.2010.06.137

Kumar R, Wyman CE (2014) Strong cellulase inhibition by mannan polysaccharides in cellulose conversion to sugars. Biotechnol Bioeng 111(7):1341–1353. https://doi.org/10.1002/bit.25218

Rahikainen J, Mikander S, Marjamaa K, Tamminen T, Lappas A, Viikari L, Kruus K (2011) Inhibition of enzymatic hydrolysis by residual lignins from softwood-study of enzyme binding and inactivation on lignin-rich surface. Biotechnol Bioeng 108(12):2823–2834. https://doi.org/10.1002/bit.23242

Dimarogona M, Topakas E, Olsson L, Christakopoulos P (2012) Lignin boosts the cellulase performance of a GH-61 enzyme from Sporotrichum thermophile. Biores Technol 110:480–487

Westereng B, Cannella D, Agger JW, Jørgensen H, Andersen ML, Eijsink VG, Felby C (2015) Enzymatic cellulose oxidation is linked to lignin by long-range electron transfer. Sci Rep 5(1):1–9

Rodríguez-Zúñiga UF, Cannella D, de Campos Giordano R, Giordano RDLC, Jørgensen H, Felby C (2015) Lignocellulose pretreatment technologies affect the level of enzymatic cellulose oxidation by LPMO. Green Chem 17(5):2896–2903

Frommhagen M, Mutte SK, Westphal AH, Koetsier MJ, Hinz SW, Visser J, Kabel MA (2017) Boosting LPMO-driven lignocellulose degradation by polyphenol oxidase-activated lignin building blocks. Biotechnology for biofuels 10(1):1–16

Muraleedharan MN, Zouraris D, Karantonis A, Topakas E, Sandgren M, Rova U, Karnaouri A (2018) Effect of lignin fractions isolated from different biomass sources on cellulose oxidation by fungal lytic polysaccharide monooxygenases. Biotechnology for biofuels 11(1):1–15

Ni H, Li M, Li F, Wang L, Xie S, Zhang X, Yu H (2020) In-situ lignin drives lytic polysaccharide monooxygenases to enhance enzymatic saccharification. Int J Biol Macromol 161:308–314

Mitchell VD, Taylor CM, Bauer S (2014) Comprehensive analysis of monomeric phenolics in dilute acid plant hydrolysates. BioEnergy Research 7(2):654–669. https://doi.org/10.1007/s12155-013-9392-6

Rasmussen H, Sørensen HR, Meyer AS (2014) Formation of degradation compounds from lignocellulosic biomass in the biorefinery: sugar reaction mechanisms. Carbohyd Res 385:45–57. https://doi.org/10.1016/j.carres.2013.08.029

Djioleu A, Carrier DJ (2018) Statistical approach for the identification of cellulolytic enzyme inhibitors using switchgrass dilute acid prehydrolyzates as a model system. ACS Sustainable Chemistry & Engineering 6(3):3443–3452

Rasmussen H, Tanner D, Sørensen HR, Meyer AS (2017) New degradation compounds from lignocellulosic biomass pretreatment: routes for formation of potent oligophenolic enzyme inhibitors. Green Chem Royal Society of Chemistry 19(2):464–473. https://doi.org/10.1039/C6GC01809B

Rasmussen H, Sørensen HR, Tanner D, Meyer AS (2017) New pentose dimers with bicyclic moieties from pretreated biomass. RSC Adv Royal Society of Chemistry 7(9):5206–5213. https://doi.org/10.1039/C6RA25432B

Kim Y, Ximenes E, Mosier NS, Ladisch MR (2011) (2011) Soluble inhibitors/deactivators of cellulase enzymes from lignocellulosic biomass. Enzyme Microb Technol 48:408–415. https://doi.org/10.1016/j.enzmictec.2011.01.007

Mathibe, B.N., Malgas, S., Radosavljevic, L., Kumar, V., Shukla, P., Pletschke, B.I. Lignocellulosic pretreatment-mediated phenolic by-products generation and their effect on the inhibition of an endo-1,4-β-xylanase from Thermomyces lanuginosus VAPS-24. 3 Biotech. Springer International Publishing, 2020; 10(8):1–11. https://doi.org/10.1007/s13205-020-02343-w

Tejirian A, Xu F (2011) Inhibition of enzymatic cellulolysis by phenolic compounds. Enzyme Microb Technol 48(3):239–247. https://doi.org/10.1016/j.enzmictec.2010.11.004

Qin L, Li W-C, Liu L, Zhu J-Q, Li X, Li B-Z, Yuan Y-J (2016) Inhibition of lignin-derived phenolic compounds to cellulase. Biotechnology for Biofuels 9(1):70. https://doi.org/10.1186/s13068-016-0485-2

Kont R, Kurašin M, Teugjas H, Väljamäe P (2013) Strong cellulase inhibitors from the hydrothermal pretreatment of wheat straw. Biotechnol Biofuels 6(1):1–14. https://doi.org/10.1186/1754-6834-6-135

Kellock M, Rahikainen J, Marjamaa K, Kruus K (2017) Lignin-derived inhibition of monocomponent cellulases and a xylanase in the hydrolysis of lignocellulosics. Biores Technol 232:183–191. https://doi.org/10.1016/j.biortech.2017.01.072

Karlsson J, Siika-Aho M, Tenkanen M, Tjerneld F (2002) Enzymatic properties of the low molecular mass endoglucanases Cel12A (EG III) and Cel45A (EG V) of Trichoderma reesei. J Biotechnol 99(1):63–78. https://doi.org/10.1016/S0168-1656(02)00156-6

Kont R, Pihlajaniemi V, Borisova AS, Aro N, Marjamaa K, Loogen J, Büchs J, Eijsink VGH, Kruus K, Väljamaë P (2019) The liquid fraction from hydrothermal pretreatment of wheat straw provides lytic polysaccharide monooxygenases with both electrons and H2O2 co-substrate. Biotechnol Biofuels 12(1):235. https://doi.org/10.1186/s13068-019-1578-5

Haven MØ, Jørgensen H (2014) The challenging measurement of protein in complex biomass-derived samples. Appl Biochem Biotechnol 172(1):87–101. https://doi.org/10.1007/s12010-013-0466-x

Bhikhabhai R, Johansson G, Pettersson G (1984) Isolation of cellulolytic enzymes from Trichoderma reesei QM 9414. J Appl Biochem 6(5–6):336–345

Velleste R, Teugjas H, Väljamäe P (2010) Reducing end-specific fluorescence labeled celluloses for cellulase mode of action. Cellulose 17(1):125–138. https://doi.org/10.1007/s10570-009-9356-3

Sluiter, A., Hames, B., Ruiz, R.O., Scarlata, C., Sluiter, J., Templeton, D., Crocker, D. Determination of structural carbohydrates and lignin in biomass: laboratory analytical procedure (LAP), Technical Report NREL/TP-510–42618. National Renewable Energy Laboratory, U.S. Department of Energy, 2011.

Overend RP, Chornet E (1987) Fractionation of lignocellulosics by steam-aqueous pretreatments. Phil Trans R Soc Lond A 321:23–536

Carvalheiro F, Silva-Fernandes T, Duarte LC, Gírio FM (2009) Wheat straw autohydrolysis: process optimization and products characterization. Appl Biochem Biotechnol 153(1–3):84–93. https://doi.org/10.1007/s12010-008-8448-0

Petersen MØ, Larsen J, Thomsen MH (2009) Optimization of hydrothermal pretreatment of wheat straw for production of bioethanol at low water consumption without addition of chemicals. Biomass Bioenerg 33(5):834–840. https://doi.org/10.1016/j.biombioe.2009.01.004

Goldschmid O (1971) Ultraviolet spectra. In: Sarkanen KV, Ludwig CH (eds) Lignins: occurrence, formation, structure and reactions. John Wiley & Sons Inc., pp 241–298

Tenkanen M, Siika-aho M (2000) An α-glucuronidase of Schizophyllum commune acting on polymeric xylan. J Biotechnol 78(2):149–161. https://doi.org/10.1016/S0168-1656(99)00240-0

Tenkanen M, Makkonen M, Perttula M, Viikari L, Teleman A (1997) Action of Trichoderma reesei mannanase on galactoglucomannan in pine kraft pulp. J Biotechnol 57(1–3):191–204. https://doi.org/10.1016/S0168-1656(97)00099-0

Jääskeläinen AS, Liitiä T, Mikkelson A, Tamminen T (2017) Aqueous organic solvent fractionation as means to improve lignin homogeneity and purity. Ind Crops Prod 103:51–58. https://doi.org/10.1016/j.indcrop.2017.03.039

Borrega M, Niemelä K, Sixta H (2013) Effect of hydrothermal treatment intensity on the formation of degradation products from birchwood. Holzforschung 67(8):871–879. https://doi.org/10.1515/hf-2013-0019

Lever M (1972) A new reaction for colorimetric determination of carbohydrates. Anal Biochem 47(1):273–279. https://doi.org/10.1016/0003-2697(72)90301-6

Niemela K (1990) Low-molecular-weight organic compounds in birch kraft black liquor. Ann Acad Sci Fenn Ser A II Chemica 229:142

Popoff T, Theander O (1972) Formation of aromatic compounds from carbohydrates: part 1. Reaction of D-glucuronic acid, D-glacturonic acid, D-xylose, and L-arabinose in slightly acidic, aqueous solution. Carbohydr Res 21(1):135–149

Momeni MH, Ubhayasekera W, Sandgren M, Ståhlberg J, Hansson H (2015) Structural insights into the inhibition of cellobiohydrolase Cel7A by xylo-oligosaccharides. FEBS J 282(11):2167–2177

Teugjas H, Väljamäe P (2013) Product inhibition of cellulases studied with 14C-labeled cellulose substrates. Biotechnol Biofuels 6(1):1–14. https://doi.org/10.1186/1754-6834-6-104

Ximenes E, Kim Y, Mosier N, Dien B, Ladisch M (2010) Inhibition of cellulases by phenols. Enzyme Microb Technol 46(3–4):170–176. https://doi.org/10.1016/j.enzmictec.2009.11.001

Payne CM, Knott BC, Mayes HB, Hansson H, Himmel ME, Sandgren M, Ståhlberg J, Beckham GT (2015) Fungal cellulases. Chem Rev 115(3):1308–1448. https://doi.org/10.1021/cr500351c

Narron RH, Chang H-M, Jameel H, Park S (2017) Soluble lignin recovered from biorefinery pretreatment hydrolyzate characterized by lignin–carbohydrate complexes. ACS Sustainable Chemistry & Engineering 5(11):10763–10771. https://doi.org/10.1021/acssuschemeng.7b02716

Sumerskiy I, Pranovich A, Holmbom B, Willför S (2015) Lignin and other aromatic substances released from spruce wood during pressurized hot-water extraction, Part 1: Extraction Fractionation and Physico-Chemical Characterization. Journal of Wood Chemistry and Technology 35(6):387–397. https://doi.org/10.1080/02773813.2014.965331

Zhang Y, Wang S, Xu W, Cheng F, Pranovich A, Smeds A, Willför S, Xu C (2019) Valorization of lignin-carbohydrate complexes from hydrolysates of Norway spruce: efficient separation, structural characterization, and antioxidant activity. ACS Sustainable Chemistry and Engineering 7(1):1447–1456. https://doi.org/10.1021/acssuschemeng.8b05142

Tarasov D, Leitch M, Fatehi P (2018) Lignin-carbohydrate complexes: Properties, applications, analyses, and methods of extraction: A review. Biotechnol Biofuels 11(1):1–28. https://doi.org/10.1186/s13068-018-1262-1

Berlin A, Balakshin M, Gilkes N, Kadla J, Maximenko V, Kubo S, Saddler J (2006) Inhibition of cellulase, xylanase and β-glucosidase activities by softwood lignin preparations. J Biotechnol 125(2):198–209. https://doi.org/10.1016/j.jbiotec.2006.02.021

Vardakou M, Flint J, Christakopoulos P, Lewis RJ, Gilbert HJ, Murray JW (2005) A family 10 Thermoascus aurantiacus xylanase utilizes arabinose decorations of xylan as significant substrate specificity determinants. J Mol Biol 352(5):1060–1067. https://doi.org/10.1016/j.jmb.2005.07.051

Bailey M, Buchert J, Viikari L (1993) Effect of pH on production of xylanase by Trichoderma reesei on xylan- and cellulose-based media. Appl Microbiol Biotechnol 40(2–3):224–229. https://doi.org/10.1007/BF00170371

Nakazawa H, Okada K, Kobayashi R, Kubota T, Onodera T, Ochiai N, Omata N, Ogasawara W, Okada H, Morikawa Y (2008) Characterization of the catalytic domains of Trichoderma reesei endoglucanase I, II, and III, expressed in Escherichia coli. Appl Microbiol Biotechnol 81(4):681–689. https://doi.org/10.1007/s00253-008-1667-z

Acknowledgements

Riitta Alander is acknowledged for technical assistance in enzyme activity experiments, Ulla Vornamo and Marita Ikonen are thanked for technical assistance in carbohydrate analysis.

Funding

Open Access funding provided by Technical Research Centre of Finland (VTT). This work was funded by the INNO INDIGO Partnership Programme Biobased Energy (grant # 311971) and by the Estonian Research Council (grant, PRG1236). We are also grateful for the support by the FinnCERES Bioeconomy Ecosystem (Academy of Finland).

Author information

Authors and Affiliations

Contributions

KK and KM coordinated and supervised the research project. PV supervised and advised on kinetic studies. ASB, VP, RK, KN, PV, and KM designed experiments; ASB, VP, RK, KN, TK, and AM performed experiments and analyzed the data; ASB, PV, and KM wrote the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visithttp://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Borisova, A.S., Pihlajaniemi, V., Kont, R. et al. The effect of soluble phenolic compounds from hydrothermally pretreated wheat straw on Trichoderma reesei cellulases and commercial enzyme cocktails. Biomass Conv. Bioref. 14, 971–984 (2024). https://doi.org/10.1007/s13399-022-02674-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02674-z