Abstract

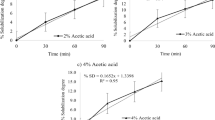

Pretreating water hyacinth (Pontederia crassipes Mart) with alkaline wet air oxidation (AWAO) increases the methane production rate when the feed to inoculum ratio (F/I) is equal to 1. Using higher F/I is more practical at large scale, but substrate inhibition occurs. The optimal conditions for the biomethanation of AWAO water hyacinth using high F/I (15) and the effect of biochar on the system were studied. Kinetic studies were conducted on the biomethanation of water hyacinth pretreated at 80 °C, 100 °C, 170 °C with 0.07, and 0.14 g Na2CO3/g feed and digested with 0 g, 0.05 g, and 0.10 g of biochar per g of feed. After 21 days of digestion, the methane rates for the untreated biomass and the water hyacinth pretreated at high temperature and alkali concentration (170 °C, 0.07 g Na2CO3/g) were 5.4 ± 0.1 and 3.6 ± 2.0 N. mL CH4/g feed *day, respectively. Higher methane rates (10.0 ± 0.7 N. mL CH4/g feed *day) were attained for the water hyacinth pretreated at lower temperature (80 °C) and lower alkali concentration (0.07 g Na2CO3/g). Also, the methane yield for the biomass pretreated at 80 °C was twice than that for the pretreated at 170 °C. The biomethanation of the water hyacinth pretreated at higher temperatures and low alkaline concentration showed a 20-day pseudo lag phase that was reduced by adding poultry litter biochar. The use of biochar on high F/I anaerobic digestion from pretreated water hyacinth is promising.

Similar content being viewed by others

Data availability

The data used for this manuscript is available upon request.

Code availability

The codes used for statistical analysis of the data are available upon request.

References

Wellinger A, Murphy J, Baxter D (2013) The biogas handbook: science, production and applications, 1st edn. Woodhead Publishing, Sawston

Kleerebezem R (2014) Biochemical conversion. Biomass as a sustain. Energy Source Futur 441–468

Masebinu SO, Akinlabi ET, Muzenda E, Aboyade AO (2019) A review of biochar properties and their roles in mitigating challenges with anaerobic digestion. Renew Sust Energ Rev 103:291–307

Wang S, Luo Z (2016) Pyrolysis of biomass. Berlin, De Gruyter. https://doi.org/10.1515/9783110369632

Zaman CZ, Pal K, Yehye WA, Sagadevan S, Shah ST, Adebisi GA, Marliana ER, Rahman FJ, Rafie B (2017) Pyrolysis: a sustainable way to generate energy from waste. In: Samer M (ed) Pyrolysis. Books on demand, p 350

Moldoveanu SC (2019) Chapter 1 - general information about pyrolysis. In: Moldoveanu SCBT-P of OM (Second ed). Elsevier, pp 1–33

Wang K, Brown R (2017) Prospects for fast pyrolysis of biomass. In: Fast pyrolysis of biomass: advances in science and technology. Royal Society of Chemistry, p 276. https://doi.org/10.1039/9781788010245-00001

Lehmann J, Joseph S (2009) Biochar for enviromental management: science and technology. Earthscan, London

Sikder S, Joardar JC (2019) Biochar production from poultry litter as management approach and effects on plant growth. Int J Recycl Org Waste Agric 8:47–58

Romdhane L, Awad YM, Radhouane L et al (2019) Wood biochar produces different rates of root growth and transpiration in two maize hybrids ( Zea mays L .) under drought stress. Arch Agron Soil Sci 65:846–866. https://doi.org/10.1080/03650340.2018.1532567

Revell KT, Maguire RO, Agblevor FA (2012) Influence of poultry litter biochar on soil properties and plant growth. Soil Sci 177:402–408. https://doi.org/10.1097/SS.0b013e3182564202

Revell KT, Maguire RO, Agblevor FA, Sites F (2012) Field trials with poultry litter biochar and its effect on forages, green peppers, and soil properties. Soil Sci 177:573–579. https://doi.org/10.1097/SS.0b013e3182741050

Jatav HS, Jayant H, Kumar S et al (2017) Role of biochar : in agriculture sector its implication and perspective. Int J Chem Stud 5:14–18

Akachukwu D, Gbadegesin MA, Ojimelukwe PC, Atkinson CJ (2018) Biochar remediation improves the leaf mineral composition of Telfairia occidentalis grown on gas flared soil. Plants 7:1–10. https://doi.org/10.3390/plants7030057

Perez-mercado LF, Lalander C, Berger C, Dalahmeh SS (2018) Potential of biochar filters for onsite wastewater treatment : effects of biochar type, physical properties and operating conditions. Water 10:1–18. https://doi.org/10.3390/w10121835

Sana S, Khatoon M (2017) To evaluate the efficiency of char and biochar for waste water treatment. J waste Recycl 2:1–6

Gwenzi W, Chaukura N, Noubactep C, Mukome FND (2017) Biochar-based water treatment systems as a potential low-cost and sustainable technology for clean water provision. J Environ Manag 197:732–749. https://doi.org/10.1016/j.jenvman.2017.03.087

Diallo O (2014) Effect of poultry litter biochar on Saccharomyces cerevisiae growth and ethanol production from steam-exploded poplar and corn Stover. Utah State University, Logan

Pan J, Ma J, Xiaxia L et al (2019) Effects of different types of biochar on the anaerobic digestion of chicken manure. Bioresour Technol 275:258–265

Capson-tojo G, Girard C, Rouez M et al (2018) Addition of biochar and trace elements in the form of industrial FeCl 3 to stabilize anaerobic digestion of food waste : dosage optimization and long-term study. J Chem Technol Biotechnol 94:505–515. https://doi.org/10.1002/jctb.5797

Linville JL, Shen Y, Leon PAI et al (2017) In-situ biogas upgrading during anaerobic digestion of food waste amended with walnut shell biochar at bench scale. Waste Manag Res 35:669–679. https://doi.org/10.1177/0734242X17704716

Shen Y, Linville J, Urgun-Dermitas M et al (2015) Producing pipeline-quality biomethane via anaerobic digestion of sludge amended with corn Stover biochar with in-situ CO2 removal. Appl Energy 158:300–309

Pellegrini MOO, Horn CN, Almeida RF (2018) Total evidence phylogeny of Pontederiaceae ( Commelinales ) sheds light on the necessity of its recircumscription and synopsis of Pontederia L. PhytoKeys 83:25–83. https://doi.org/10.3897/phytokeys.108.27652

Chandel AK, Garlapati VK, Jeevan Kumar SP et al (2020) The role of renewable chemicals and biofuels in building a bioeconomy. Biofuels Bioprod Biorefin. https://doi.org/10.1002/bbb.2104

Castro YA, Agblevor FA (2020) Biomethanation of invasive water hyacinth from eutrophic waters as a post weed management practice in the Dominican Republic, a developing country. Environ Sci Pollut Res 27:14138–14149. https://doi.org/10.1007/s11356-020-07927-w

Gupta GC (1980) Use of water hyacinths in wastewater treatment (a brief literature review). J Environ Health 43:80–82

Wilson JR, Rees M, Holst N et al (2001) Water hyacinth population dynamics. Proc ACIAR Biol Integr Control Water Hyacinth Eichhornia crassipes 102:96–104

Duke JA (1983) Handbook of energy crops. Purdue University. Center for New Crops and Plant Products

Castro YA, Agblevor FA (2020) Effect of wet air oxidation on the composition and biomethanation of water hyacinth. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-020-00825-8

Barakat A, Monlau F, Steyer J-P, Carrere H (2012) Effect of lignin-derived and furan compounds found in lignocellulosic hydrolysates on biomethane production. Bioresour Technol 104:90–99

Rivard C, Grohmann K (1991) Degradation of furfural (2-furaldehyde) to methane and carbon dioxide by an anaerobic consortium. Appl Biochem Biotechnol 28–29:285–295

Khanal SK, Huang J (2005) Effect of high influent sulfate on anaerobic wastewater treatment. Water Environ Res 77:3037–3046. https://doi.org/10.2175/106143005X73929

Zhao B, Xu H, Ma F et al (2019) Effects of dairy manure biochar on adsorption of sulfate onto light sierozem and its mechanisms. RSC Adv 9:5218–5223. https://doi.org/10.1039/C8RA08916G

Shen Y, Linville JL, Leon PAI et al (2016) Towards a sustainable paradigm of waste-to-energy process_ enhanced anaerobic digestion of sludge with woody biochar. J Clean Prod 135:1054–1064

Wyman CE (2013) Aqueous pretreatment of plant biomass for biological and chemical conversion to fuels and chemicals. Wiley, Noida

Shawky BT, Mahmoud MG, Ghazy EA et al (2011) Enzymatic hydrolysis of rice straw and corn stalks for monosugars production. J Genet Eng Biotechnol 9:59–63. https://doi.org/10.1016/j.jgeb.2011.05.001

Castro YA, Agblevor FA (2020) Interaction effect of high feed to inoculum ratio (F/I) and temperature on the biomethanation kinetics of water hyacinth. SN Appl Sci 2:1–9. https://doi.org/10.1007/s42452-020-03626-w

Sierra-Ramirez R, Holtzapple M, Piamonte N (2013) Fundamentals of biomass pretreatment at high pH. In: Stevens CV, Wyman CE (eds) Aqueous pretreatment of plant biomass for biological and chemical conversion to fuels and chemicals. https://doi.org/10.1002/9780470975831.ch8

Wijitkosum S, Jiwnok P (2019) Elemental composition of biochar obtained from agriculturalwaste for soil amendment and carbon sequestration. Appl Sci 9:. https://doi.org/10.3390/app9193980

Chiappero M, Norouzi O, Hu M et al (2020) Review of biochar role as additive in anaerobic digestion processes. Renew Sust Energ Rev 131. https://doi.org/10.1016/j.rser.2020.110037

Sg L, Jjo O, R A, St M (2021) The potential of biochar to enhance concentration and utilization of selected macro and micro nutrients for chickpea (Cicer arietinum) grown in three contrasting soils. Rhizosphere 17:100289. https://doi.org/10.1016/j.rhisph.2020.100289

Ballesteros LF, Michelin M, Vicente AA et al (2018) Lignocellulosic materials and their use in bio-based packaging. Springer International Publishing, Berlin

Pola L, Collado S, Oulego P, Díaz M (2019) Production of carboxylic acids from the non-lignin residue of black liquor by hydrothermal treatments. Bioresour Technol 284:105–114. https://doi.org/10.1016/j.biortech.2019.03.066

Issah A-A, Kabera T, Kemausuor F (2020) Biogas optimisation processes and effluent quality: a review. Biomass Bioenergy 133:105449. https://doi.org/10.1016/j.biombioe.2019.105449

Chen Y, Cheng JJ, Creamer KS (2007) Inhibition of anaerobic digestion process: a review. Bioresour Tehnol 99:4044–4064

Carlini M, Castellucci S, Mennuni A (2018) Water hyacinth biomass: chemical and thermal pre-treatment for energetic utilization in anaerobic digestion process. Energy Procedia 148:431–438. https://doi.org/10.1016/j.egypro.2018.08.106

Li W, Khalid H, Zhu Z et al (2018) Methane production through anaerobic digestion: participation and digestion characteristics of cellulose, hemicellulose and lignin. Appl Energy 226:1219–1228. https://doi.org/10.1016/j.apenergy.2018.05.055

Apedaile E (2001) A perspective on biosolids management. Can J Infect Dis 12:202–204. https://doi.org/10.1155/2001/801432

Funding

This research was financially supported by the National Research Fund for Science, Technology, and Innovation (FONDOCYT 2015-2A3–123) of the Dominican Republic Ministry of Higher Education, Science and Technology (MESCYT).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Article highlights

• AWAO biomass at 80 °C had higher methane rate than at 100 °C and 170 °C

• AWAO at 80 °C and low alkali (0.07 g Na2CO3/g) had highest methane rate

• Low alkali and high temperature produced a 20-day lag phase in biomethanation

• Biochar reduced a 20-day lag phase in high temperature and low alkali AWAO

Rights and permissions

About this article

Cite this article

Castro, Y.A., Agblevor, F.A. Effect of poultry litter biochar on the biomethanation of alkaline wet air-oxidized water hyacinth at high feed to inoculum (F/I) ratio. Biomass Conv. Bioref. 13, 5165–5174 (2023). https://doi.org/10.1007/s13399-021-01724-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01724-2