Abstract

The anaerobic digestion of the invasive water hyacinth (Pontederia crassipes Mart.) from eutrophic water bodies could contribute to the sustainability of communities that have insecure energy sources. The optimization of critical process parameters, e.g., feed to inoculum ratio (F/I), temperature, supplementation, and inoculum acclimatization is important for large-scale applications. In the present work, water hyacinth was anaerobically digested at different F/I (1.0, 5.0, 10.0, and 30.0), mesophilic temperatures (30 and 40 °C), and supplementation settings using non-acclimatized and acclimatized inoculum to determine the process’s optimal conditions through kinetics (modified Gompertz, Chen and Hashimoto, and first-order) and energy analyses. The F/I ratio had a directly proportional effect on the methane yield [N mL·CH4/g·VS], which ranged from 416.8 ± 6.2 (F/I = 1.0) to 263.8 ± 26.9 (F/I = 30.0). The methane production rate [N mL·CH4/g·VS·day] was highest at 40 °C (9.0 ± 0.8) and lowest at F/I = 30 (5.6 ± 2.8). The biomethanation of water hyacinth followed the modified Gompertz and Chen and Hashimoto models when using the non-acclimatized and acclimatized inoculum, respectively. A 30-day pseudo-lag phase was observed at the highest F/I (30) and low temperature (30 °C) but was negligible at higher temperature (40 °C). For a 5.0 m3 biodigester, the highest estimated net energy occurred at F/I = 30 (370.5 ± 22.6 MJ). The doubling times at 40 °C (16.9 ± 0.3 days) were lower than that at 30 °C (49.6 ± 2.5 days). The anaerobic digestion of water hyacinth in batch mode was optimal at higher F/I ratio and high mesophilic temperatures.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Using the invasive water hyacinth (Pontederia crassipes Mart.) as a feedstock for bioconversion processes like anaerobic digestion can mitigate the costs associated with weed removal from eutrophic water bodies in developing communities. The energy produced during the anaerobic digestion of water hyacinth as a post weed management practice can be more than 10 times the energy consumed in mechanical harvesting [1]. The use of this weed as bioenergy feedstock would not only meet the energy needs but also mitigate environmental problems [2]. Parametric studies on the kinetics and energy balance could contribute to the scalability of this bioconversion process. Some of the main factors influencing the anaerobic digestion performance at large scale are related to process control (e.g., organic loading, temperature) and microbiology [3, 4]. However, the studies covering the main effect of these factors on the anaerobic digestion do not consider their economic impact at large scale.

During anaerobic digestion, the increase in organic load compared to the inoculum content has been reported to significantly reduce the methane percentage in biogas [5, 6]. For various substrates, the optimal feed to inoculum ratio (F/I) during anaerobic digestion has been reported to be between 0.3 and 1.5 on volatile solids (VS) basis [5, 7,8,9,10,11,12]. For the anaerobic digestion of water hyacinth, the optimal F/I was 2.0 over 4.0, 1.0, and 0.33 when using cow dung as inoculum on VS basis, and 0.05 among 0.04 to 0.16 when using poultry litter on total solids (TS) basis [13, 14]. Studies on anaerobic digestion of water hyacinth addressing an F/I ratio above 5 are scarce. Large-scale batch biodigesters operating at low F/I are not practical because most of the operating volume would be due to inoculum, and the total methane production per batch would be small. Therefore, evaluating the performance and energy implications of the anaerobic digestion of the invasive water hyacinth at high F/I is important for large-scale systems.

High F/I ratios of water hyacinth from contaminated water could inhibit the microbial consortium during anaerobic digestion. For easily degradable substrates, such as sugars, the acidogenic reactions are much faster than acetogenic and methanogenic ones, leading to the accumulation of VFA, H2, and CO2, and depressed pH [15]. Similarly, the use of feedstock with phytoremediation properties targeting metals could induce substrate inhibition. Water hyacinth is not only capable of uptaking nutrients but also heavy metals from contaminated waters [16,17,18,19]. The presence of high heavy metals in a soluble free form within anaerobic reactors leads to the accumulation of intermediate organic compounds and reduction in biogas production [20, 21]. However, the inhibitory effect of compounds within the anaerobic digesters can be minimized by inoculum acclimatization [22,23,24]. Accounting for inoculum acclimatization when determining the optimal F/I during the anaerobic digestion of water hyacinth is necessary for large-scale applications.

The use of single waste for anaerobic digestion has been associated with unbalanced nutrients [25]. Trace minerals such as selenium, molybdenum, manganese, aluminum, and boron stimulate methanogenic activity and are suggested to be added to anaerobic digesters to improve the process performance [25, 26]. Standard biochemical methane potential includes the addition of not only trace minerals but also vitamins to the assays [27]. High-performance scalability of the anaerobic digestion of the invasive water hyacinth needs to consider the need for additional nutrients through co-digestion. The effect of supplement addition on the biomethanation of water hyacinth would determine whether this macrophyte can be used as feedstock for large-scale systems without additional nutrients or co-substrates.

The energy required for keeping anaerobic digesters under steady temperatures is very important for the process’s performance and sustainability. In mesophilic biodigesters, the anaerobic consortia operate at 30–40 °C [28]. When assessing the effect of various temperatures (25 °C, 37 °C, 45 °C) on water hyacinth biomethanation, the best incubation temperature was 37 °C [29]. Similarly, studies on the anaerobic digestion of sludge showed that 38 °C was the optimal mesophilic temperature compared to 34 °C and 42 °C [30]. However, higher temperatures (i.e., 50 °C) are linked to higher organic matter degradation of fibrous materials, higher pH, and higher methane yield [31]. Agro-waste digestion at 40 °C had a higher cumulative gas yield than those at 25 °C, 30 °C, and 35 °C [32]. Costs related to operating temperature in anaerobic digestion are important for decision-makers during large-scale design. The effect of the lower (30 °C) and higher (40 °C) mesophilic limit range temperatures on the biomethanation performance and energy consumption in the anaerobic digestion of water hyacinth need to be determined.

Understanding the kinetics of methane production is important for designing and evaluating anaerobic digesters. The suitability of kinetic models on anaerobic digestion has been studied for different types of reactors, inoculums, and feedstocks [33,34,35]. The most popular kinetic models used for anaerobic digestion batch systems are first-order, Chen and Hashimoto, and modified Gompertz. The first-order model provides valuable information about hydrolysis kinetics but does not estimate the maximum methane potential and systems failure [33]. Chen and Hashimoto model predicts maximum biological activity and is reliable on predictions about high solid content anaerobic digestion systems [36]. The modified Gompertz model assumes that methane production follows the microbial growth pattern and predicts maximum methane potential, lag time, and methane production rate. This model has been effectively applied (R2 > 0.81) to batch anaerobic digestion of various feedstocks including water hyacinth [1, 14, 37]. The use of these three models on the biomethanation of feedstock gives a holistic picture of the process kinetics. However, studies assessing these kinetic models for the biomethanation of water hyacinth at high F/I under various mesophilic temperatures have not been conducted.

The goal of this paper is to determine the optimal conditions for the biomethanation of water hyacinth based on kinetics and energy analysis. The main and interaction effects of high F/I ratios, mesophilic temperature, media supplementation on the kinetics of the water hyacinth biomethanation, and their alteration by inoculum acclimatization were studied through factorial experiments. Also, the differences in kinetics and energy balance between the anaerobic digestion of water hyacinth at 30 °C and 40 °C were covered.

2 Materials and methods

2.1 Biomass

Water hyacinth was collected from the eutrophic freshwaters at El Naranjo (18°34′27.2″ N 69°47′09.9″ W) within Ozama River (Santo Domingo, Dominican Republic). Biomass sampling, preparation, and composition are detailed in previous work [1].

2.2 Inoculum

The microbial consortium was a mixture (1:2) of mesophilic anaerobic sludge from the North Davis Sewer District (NDSD) and Central Valley Water Reclamation Facility (CVWRF) collected in March 2019. The anaerobic sludge from NDSD (Syracuse, UT, USA) was provided by the Plant Superintendent, Mr. Myron Bachman. The CVWRF anaerobic sludge was obtained from the Sustainable Waste to Bioproducts Engineering Center (Dr. Ronald Sims, Co-Director) through a joint project and with permission of the Plant Manager, Dr. Phil Heck. The non-acclimatized sludge had a pH of 8.32, 2.58% TS, and 55% VS. The acclimatized inoculum is the residual sludge of the experimental units after sieving with a 250 μm mesh to get rid of the undigested water hyacinth. The acclimatized inoculum had pH = 7.97, 0.6 ± 0.05% TS, and 49.6 ± 0.7% VS. The non-acclimatized and acclimatized sludge was incubated at 40 °C for 72 h prior to use.

2.3 Experimental conditions

2.3.1 Non-acclimatized inoculum

The bio-reactions took place in 160-mL clear serum bottles at 100 mL working volume. The total solids for all the experimental units were 3.2 ± 0.6%. A 2 × 3 full factorial design was conducted for F/I at 1.0, 5.0, and 10 on VS basis; and supplemented vs non-supplemented anaerobic media. The supplemented media is a modification of the media used during standardized biochemical methane potential experiments without the addition of resazurin [38]. The non-supplemented media is the anaerobic media without vitamins and minerals. Each experimental unit was run in duplicate.

2.3.2 Acclimatized inoculum

The factors considered when using the adapted sludge were F/I at 5.0, and 10.0, and 30.0 on VS basis; the addition of anaerobic media (non-supplemented media and no media); and temperature at 30 °C and 40 °C; resulting in an un-replicated 3 × 2 × 2 factorial experiment. The average feed and total solids for the experimental units were 2.04 ± 0.12 g and 2.27 ± 0.05%, respectively.

2.3.3 Biomethane production

The produced gas was measured via volume displacement using a lubricated glass syringe every 2–6 days and analyzed using an Agilent 7890B Gas Chromatograph (Agilent Technologies, Santa Clara, CA, USA). The method used helium as the carrier gas, the thermo-conductivity detector (TCD) is heated to 250 °C, and the column is kept at 25 °C. The measured volume (V) was converted to normal volume (V0) using the ideal gas law (Eq. 1), where T0 = 273.15 K and P0 = 101,325 Pa. The barometric pressure (P) and temperature (T) during the gas measurements were recorded and were 86,400 ± 6.6 Pa and 294.3 ± 0.4 K in average. The volume of the accumulated methane was reported per mass of VS added (feedstock) to the experimental units.

2.4 Kinetic models

The first-order kinetic parameters for each experimental unit curve were modeled using Eq. (2), where W [N mL CH4/g VS feed] is the cumulative methane yield at digestion time t, K [day−1] is the first-order disintegration rate constant, and W0 [N mL CH4/g VS feed] represents the total yield of hydrolysable VS at the beginning of the test. In the modified Gompertz model (Eq. 3), A [N mL CH4/g VS feed] is the maximum methane produced, Kz [N L CH4/VS feed*day] is the maximum methane production rate, and Tlag [days] is the minimum time taken for bacteria to acclimatize to the environment. The doubling time (Td) was calculated from the model’s estimated A. The main kinetic parameters for Chen and Hashimoto model (Eq. 4) are ACH, KCH, and μm where KCH is the Chen and Hashimoto kinetic constant [dimensionless], and μm [day−1] is the maximum specific growth rate of microorganisms.

2.5 Energy analysis

The energy [MJ] produced (Ep) from the biomethanation units and the energy required for heating (Q) were calculated using Eq. 5 and Eq. 6, respectively. The energy analysis will assume a biodigester with a working capacity of 5 m3 (5000 L), which would require different loadings (m) of freshwater hyacinth depending on the F/I ratio (see Supplemental Material). The bulk density and water content of the fresh biomass were assumed to be 96 kg/m3 and 91% [39, 40]. The inoculum was assumed to be anaerobic sludge from a wastewater treatment plant, with 2.5% w/v solids and a dry density equal to 560 kg/m3 [41]. The overall heat capacity (Cp) was calculated using Eq. 7. The heat capacity of the fresh feedstock (plant leaves) and dry sludge was assumed to be 1.75 kJ/kg °C and 1.35 kJ/kg °C, respectively [42, 43]. The heat capacity of water is 4.19 kJ/kg °C. The initial temperature for the digestion was set to 20 °C, which is within the range for water hyacinth growth in tropical areas [44]. BMP [L CH4/kg] is the methane yield expressed on a dry biomass basis. The higher heating value (HHV) of methane is 0.0398 MJ/L. This analysis does not take into account the energy consumed in processes like harvesting and milling that are common to all the experimental units and are important at large scale.

2.6 Statistical analysis

All the measurement units were used for the assessment of the effects of F/I and media supplementation. The effect of anaerobic media was determined using all non-acclimatized and acclimatized experimental units, resulting in three levels for this independent variable (no media, non-supplemented media, and supplemented media). A subset of the experimental units was analyzed to determine the effect of inoculum acclimatization on the biomethanation of water hyacinth without the influence of confounding factors. The dataset consisted in the data at F/I equal to 5 and 10 for a total of 16 measurement units. Similarly, the effect of temperature was determined using only the measurement units that were digested with acclimatized inoculum.

The data collected from the factorial datasets were analyzed using the function ‘aov’ in R Studio (version 3.6.1). The differences between levels were determined using Tukey’s test (Tukey HSD), a post hoc analysis function in R. For single comparison between values, t test (www.graphpad.com) was used. The populations were assumed to be independent, normal distributed, and with equal variances.

3 Results and discussion

3.1 Media supplementation

After 105 days of digesting water hyacinth anaerobically, the methane yield [N mL CH4/g VS] was no statistically different (p = 0.697) when using supplemented media (356.4 ± 44.4), non-supplemented media (334.2 ± 48.3), and no media (301.9 ± 41.5). Also, the methane production rate and lag time between the experimental units digested under the studied media conditions were comparable (p > 0.317). These yield values [N mL CH4/g VS] are higher (p = 0.038) than those produced from sugar-rich wastes such as cranberry (231 ± 33) and ice-cream (125 ± 48) when co-digested with manure at a F/I below 5 [45]. Therefore, water hyacinth from eutrophic freshwater contains the minerals and vitamins required for the anaerobic consortia to efficiently produce biogas. The essential minerals required for the cultivation of methanogenic are Fe, Na, Se, Co, Mn, Mo, W, Zn, Ni, B, and Cu, which are present in the water hyacinth under study, with the exception of W and Se [1, 46]. Thus, water hyacinth can be used as feedstock for anaerobic digestion without additional supplementation or co-digestion.

3.2 Feed to inoculum ratio (F/I)

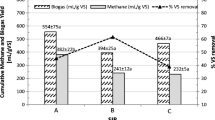

The methane yield and production rate for the biomethanation of water hyacinth were significantly affected by F/I. The yield [N mL CH4/g VS] for the anaerobic digestion at F/I = 1.0 (416.8 ± 6.2) was the highest (p < 0.001, Fig. 1) and at F/I = 30.0 (263.8 ± 26.9) the lowest (p < 0.001) among all the ratios under study. However, the methane produced [N mL CH4/g VS] at F/I = 5.0 (336.6 ± 13.2) was not quite different (p = 0.09) than that at F/I = 10.0 (318.2 ± 9.3). When using acclimatized inoculum at 30 °C, the methane production rate at F/I = 1.0, F/I = 5.0, and F/I = 10.0 was 8.4 ± 0.8 N mL CH4/g VS·day in average (p = 0.866, Table 1), which is higher (p < 0.008) than that at F/I = 30.0 (5.6 ± 2.8 N mL CH4/g VS·day). The effect of F/I on methane rate has been previously reported to be inversely proportional during the biogas production of sheep paunch manure at F/I between 0.25 and 0.75 [47]. The methane yield from the anaerobic digestion of wheat straw at F/I = 4.0 (287.3 N mL/g VS) and water hyacinth at F/I = 1.0 (262 N. mL/g VS) was comparable (p > 0.085) to our results at F/I = 30.0 [48]. Even though the performance of the water hyacinth biomethanation seemed to be compromised by an F/I above 10, the methane yield value under these conditions and the F/I effect on the methane rate are comparable to studies from other authors.

The effect of F/I on the lag phase of the water hyacinth biomethanation depended on the acclimatization of the inoculum. The effect of F/I on the length of the lag phase was negligible (p > 0.123) when using acclimatized inoculum. However, when the inoculum was non-acclimatized, the F/I ratio had a directly proportional effect (p < 0.006, Table 1) on the lag phase. At F/I = 1.0, the lag phase was more than four times than that at F/I = 5.0, and almost eight times higher than at F/I = 10.0. These results are in accordance with previous findings that indicated the lag phase depends on the concentration of bacteria during batch culture [49].

3.3 Inoculum acclimatization

The differences in methane yield and production rate between acclimatized and non-acclimatized anaerobic sludge were negligible (p > 0.641, Table 1). However, the biodigestion with non-acclimatized sludge had a longer (p < 0.0001) lag phase (6.2 ± 1.9 days) and doubling time (24.0 ± 2.8 days) than that with acclimatized inoculum (Tlag < 1 day, Tdoub 16.0 ± 1.4 days). As expected, acclimatizing the anaerobic consortia for the anaerobic digestion of water hyacinth eliminated the lag phase of the subsequential batch. This reduction might be due to the high content of calcium and magnesium in the feedstock, since the physiological need of bacteria for these nutrients is highest during lag phase, implying their important role in the transition from lag to exponential phase [1, 50]. The biomethanation of water hyacinth when using anaerobic sludge as inoculum would take less than 10 days for exponential production of biogas during the biodigester start-up and would continue on that stage when reloading the system.

3.4 Temperature

The methane yield for the anaerobic digestion of water hyacinth was not different (p > 0.176) at 30 °C and 40 °C. However, the methane production rate for the biomethanation of water hyacinth at 40 °C (9.0 ± 0.8 N mL CH4/g VS·day) was higher (p = 0.0002, Fig. 1) than that at 30 °C (6.4 ± 2.5 N mL CH4/g VS·day). The effect of temperature on methane production rate depends on the F/I in the system (p = 0.0138). When water hyacinth was digested at 30 °C using F/I = 30, the methane production rate (3.2 ± 0.2 N mL CH4/g VS·day) was lower (p < 0.002) than the other F/I ratios within the same temperature (7.9 ± 0.8 N mL CH4/g VS·day). As a result, in the anaerobic digestion of water hyacinth at 30 °C, doubling times increased by at least 3 days (p < 0.01, Table 1). However, there was no difference (p > 0.218) in the methane production rate between the digestions conducted at 40 °C. These results are partially in accordance with previous works. For the thermophilic anaerobic digestion of food waste, 10 °C reduction in temperature, from 65 °C to 55 °C, did not affect (p = 0.177) the production rate of methane [51]. When comparing anaerobic digestion of sludge at 34 °C, 38 °C, and 42 °C, the methane yield was higher at 38 °C but foaming formed at this and higher temperatures [30]. The biomethanation of water hyacinth at 40 °C would lead to higher methane production rates and shorter digestion times without compromising the stability of the process.

3.5 Kinetic models

The methane production per time curve was successfully fitted (R2 > 0.993, Fig. 2a) to the modified Gompertz model when non-acclimatized sludge was used as inoculum at 40 °C. However, the explanation of the data by this model decreased after inoculum acclimatization (R2 = 0.965 ± 0.02, Fig. 1b, c). The maximum methane potential of water hyacinth when digesting at 40 °C with acclimatized sludge is better explained (p = 0.0003) by Chen and Hashimoto model (R2 = 0.995 ± 0.01) than by the modified Gompertz model. After 105 days of digesting water hyacinth with acclimatized sludge at 40 °C, the stationary phase had not been reached (Fig. 1b), following an exponential pattern proper of Chen and Hashimoto model. The first-order kinetic model explained (R2 > 0.953) the hydrolysis stage through the disintegration rate constant (KH). The disintegration rate was larger (p < 0.01, Table 1) when the anaerobic digestion was conducted at 40 °C with acclimatized sludge, leading to a higher methane production rate (Table 1). These results differ from previous studies that evaluated the biomethanation kinetics of food waste and vegetable crop residues that concluded the modified Gompertz model was better fitted than the first-order and Chen and Hashimoto models [34, 52]. The inoculum acclimatization seems to have favored an exponential behavior in the biomethanation of water hyacinth.

Anaerobic digestion of water hyacinth at 30 °C and F/I = 30. a Kinetic profile of pseudo-lag and exponential phases that follow the modified Gompertz model. b Biogas production (N mL/g feed) and methane percentage per period (~ 4–10 days). During the inhibition phase (up to ~ 41 days), the biogas production was minimum and had less than 50% methane

When water hyacinth at F/I = 30 was digested at 30°, the biomethanation profile could not be explained by any of the models under study (Fig. 1c). The biomethanation kinetics under these conditions is different from the previously published works. The kinetic parameters included a period of time, named pseudo-lag phase, which took place after reaching an initial asymptote and before the exponential phase (Fig. 2a). The pseudo-lag phase lasted 36 days and its asymptote was 43.4 ± 2.5 N mL CH4/g VS. During this phase, the methane production followed the modified Gompertz model, which also governed the following exponential phase. The maximum methane potential for the exponential phase was 259.9 ± 16.9 N mL CH4/g VS, with a methane production rate of 3.9 N mL CH4/g VS. The anaerobic digestion of water hyacinth high F/I (30) and 30 °C could have been assumed to be terminated after 30 days due to low biogas generation and low %CH4 at that time (Fig. 2b). However, the consortia seem to have adapted to an F/I = 30, since the biogas produced after 45 days of digestion had a % CH4 above 65% (Fig. 2-B). Similarly, the production of biogas after more than 120 days of digestion did not seem to have ceased, which implies that the maximum methane potential is higher than the yield at that time (263.6 ± 23.0 N mL CH4/g VS, Fig. 2b).

3.6 Energy analysis

The conditions for the anaerobic digestion of water hyacinth that required the lowest heating energy were those at higher F/I and lower digestion temperature (Table 2). The difference between the produced and the heating energies was highest (p < 0.01, Table 2) for F/I = 10 at 30 °C, and F/I = 30 systems at 30 °C and 40 °C, and lowest (p < 0.05) for F/I = 5.0 at 30 °C. The anaerobic digestion at F/I = 30.0 resulted in the most energetically efficient system compared to those under study. The insignificant difference (p > 0.957) in the net energy Ep-Q between the biodigesters operating at 30° and 40 °C when F/I = 30 is due to the higher yield at 40 °C than at 30 °C.

The optimal conditions for the batch anaerobic digestion of water hyacinth would generate the highest amount of energy per time while having the minimum energy consumption per batch. The digestion of water hyacinth at F/I = 30 and 40 °C has the highest difference between the produced and the heating energies per batch (Table 2) while keeping low doubling times (16.9 ± 0.3 days). Even though the energy produced from the digestion of water hyacinth at F/I = 30 and 30 °C is more than 10 times the heating energy (Table 2), the doubling time (49.6 ± 2.5 days) is above 40% (p < 0.006) those of the rest of the experimental units. Also, the kinetics under these conditions includes a pseudo-lag phase where the production of methane is 20% of the methane yield and lasts more than 30 days. The anaerobic digestion of water hyacinth at high F/I should consider increasing the temperature of the system to overcome the deficiencies of the high substrate loading while keeping the energy efficiency of the large-scale systems.

4 Conclusion

The anaerobic digestion of water hyacinth at different F/I ratios, mesophilic temperatures, supplementation conditions, and inoculum acclimatization was conducted through factorial experiments. The study showed that using anaerobic media with and without vitamins and minerals did not improve the methane yield or rate in the batch systems. However, the F/I ratio affected the biomethanation performance. At F/I = 30, the methane yield (263.8 ± 26.9 N mL CH4/g VS) and rate (5.6 ± 2.8 N mL CH4/g VS·day) were lower than that at F/I = 1.0, F/I = 5.0, and F/I = 10.0. Digesting the biomass at higher temperatures did not affect the methane yield but increased the production rate [N mL CH4/g VS·day] from 6.4 ± 2.5 at 30 °C to 9.0 ± 0.8 at 40 °C, which leads to shorter digestion times. The highest difference between the energy produced and the heating energy consumed during the anaerobic digestion of water hyacinth occurred at F/I = 30 at 30° and 40 °C. However, the doubling times at 30 °C were almost three times that at 40 °C since 30 days pseudo-lag phase was observed during the biomethanation of water hyacinth at the lower temperature. The digestion of water hyacinth at high F/I (30) using high mesophilic temperature (40 °C) seems to be feasible.

Availability of data and materials

The data used for this manuscript are available upon request.

Code availability

The codes used for statistical analysis of the data are available upon request.

References

Castro YA, Agblevor FA (2020) Biomethanation of invasive water hyacinth from eutrophic waters as a post weed management practice in the Dominican Republic, a developing country. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-020-07927-w

Chandel AK, Garlapati VK, Jeevan Kumar SP, Hans M, Singh AK, Kumar S (2020) The role of renewable chemicals and biofuels in building a bioeconomy. Biofuels Bioprod Biorefining. https://doi.org/10.1002/bbb.2104

Holm-Nielsen JB, Oleskowicz-Popiel P (2013) Process control in biogas plants. In: Wellinger A, Murphy J, Baxter DBT-TBH (eds) Woodhead Publishing Series in Energy. Woodhead Publishing, Sawston, pp 228–247. https://doi.org/10.1533/9780857097415.2.228

Ward AJ, Hobbs PJ, Holliman PJ, Jones DL (2008) Optimisation of the anaerobic digestion of agricultural resources. Bioresour Technol 99:7928–7940. https://doi.org/10.1016/j.biortech.2008.02.044

Cheng X, Zhong C (2014) Effects of feed to inoculum ratio, co-digestion, and pretreatment on biogas production from anaerobic digestion of cotton stalk. Energy Fuels 28:3157–3166

Raposo F, Borja R, Martin MA, Martin A, de la Rubia MA, Rincón B (2009) Influence of inoculum-substrate ratio on the anaerobic digestion of sunflower oil cake in batch mode: process stability and kinetic evaluation. Chem Eng J 149:70–77. https://doi.org/10.1016/j.cej.2008.10.001

Braguglia CM, Mininni G, Tomei MC, Rolle E (2006) Effect of feed/inoculum ratio on anaerobic digestion of sonicated sludge. Water Sci Technol 54:77–84. https://doi.org/10.2166/wst.2006.549

Go B, Ko AA (2018) Effects of inoculum to feedstock ratio on anaerobic digestion for biogas production. Int. J. Hydrol. 2:567–571. https://doi.org/10.15406/ijh.2018.02.00027

Li Y, Jin Y, Borrion A, Li J (2018) Influence of feed/inoculum ratios and waste cooking oil content on the mesophilic anaerobic digestion of food waste. Waste Manag 73:156–164

Rashed M, Mamun A, Torii S (2017) Comparison effect of feedstock to inoculum ratios on biogas yields of cafeteria, vegetable, fruit wastes with cattle manure using co-digestion process vegetable, fruit wastes with cattle manure using co-digestion process. Int J Green Energy 14:665–673. https://doi.org/10.1080/15435075.2017.1318071

Zeng S, Yuan X, Shi X, Qiu Y (2010) Effect of inoculum/substrate ratio on methane yield and orthophosphate release from anaerobic digestion of Microcystis spp. J Hazard Mater 178:89–93

Zhou Y, Zhang Z, Nakamoto T, Yang Y, Utsumi M, Sugiura N (2010) Effect of substrate-to-inoculum ratio on methane production with a batch anaerobic digestion of bean curd residue. Jpn J Water Treat Biol 46(46):161–169

Bhui I, Matthew AK, Chaudhury S, Balachandran S (2018) Influence of volatile fatty acids in different inoculum to substrate ratio and enhancement of biogas production using water hyacinth and salvinia. Bioresour Technol 270:409–415

Patil JH, Raj MA, Muralidhara PL, Desai SM, Raju GKM (2012) Kinetics of anaerobic digestion of water hyacinth using poultry litter as inoculum. Int J Environ Sci Dev 3:94–98. https://doi.org/10.7763/IJESD.2012.V3.195

Bagley DM, Brodkorb TS (1999) Modeling microbial kinetics in an anaerobic sequencing batch reactor: model development and experimental validation. Water Environ Res 71:1320–1332

Gong Y, Zhou X, Ma X, Chen J (2018) Sustainable removal of formaldehyde using controllable water hyacinth. J Clean Prod 181:1–7. https://doi.org/10.1016/j.jclepro.2018.01.220

Mahmood T, Malik S, Hussain S (2010) Biosorption and recovery of heavy metals from aqueous solutions by Eichhornia crassipes (water hyacinth) ash. BioResources 5:1244–1256

Moyo P, Chapungu L, Mudzengi B (2013) Effectiveness of water Hyacinth (Eichhornia crassipes) in remediating polluted water: the case of Shagashe river in Masvingo. Zimbabwe Adv Appl Sci Res 4:55–62

Ting WHT, Tan IAW, Salleh SF, Wahab NA (2018) Application of water hyacinth (Eichhornia crassipes) for phytoremediation of ammoniacal nitrogen: a review. J Water Process Eng 22:239–249. https://doi.org/10.1016/j.jwpe.2018.02.011

Chen Y, Cheng JJ, Creamer KS (2007) Inhibition of anaerobic digestion process: a review. Bioresour Tehnol 99:4044–4064

Oleszkiewicz JA, Sharma VK (1990) Inhibition of anaerobic processes by heavy metals—a review. Biol Waters 31:45–67

Toreci I, Droste RL, Kennedy KJ (2011) Mesophilic anaerobic digestion with high-temperature microwave pretreatment and importance of inoculum acclimation. Water Environ Res 83:549–559. https://doi.org/10.2175/106143010X12780288628651

Wojcieszak M, Pyzik A, Poszytek K, Krawczyk PS (2017) Adaptation of Methanogenic Inocula to Anaerobic Digestion of Maize Silage. Front Microbiol 8:1–12. https://doi.org/10.3389/fmicb.2017.01881

Yangin-gomec C, Sapmaz T, Aydin S (2018) Impact of inoculum acclimation on energy recovery and investigation of microbial community changes during anaerobic digestion of the chicken manure. Environ Technol. https://doi.org/10.1080/09593330.2018.1551434

Rabii A, Aldin S, Dahman Y, Elbeshbishy E (2019) A review on anaerobic co-digestion with a focus on the microbial populations and the effect of multi-stage digester configuration. Energies 12:1–25. https://doi.org/10.3390/en12061106

Azbar N, Ursillo P, Speece RE (2001) Effect of process configuration and substratecomplexity on the performance of anaerobic processes. Water Res 35:817–829

Holliger C, Alves M, Andrade D, Angelidaki I, Astals S, Baier U, Bougrier C, Buffière P, Carballa M, De Wilde V, Ebertseder F, Fernández B, Ficara E, Fotidis I, Frigon JC, De Laclos HF, Ghasimi DSM, Hack G, Hartel M, Heerenklage J, Horvath IS, Jenicek P, Koch K, Krautwald J, Lizasoain J, Liu J, Mosberger L, Nistor M, Oechsner H, Oliveira JV, Paterson M, Pauss A, Pommier S, Porqueddu I, Raposo F, Ribeiro T, Pfund FR, Strömberg S, Torrijos M, Van Eekert M, Van Lier J, Wedwitschka H, Wierinck I (2016) Towards a standardization of biomethane potential tests. Water Sci Technol 74:2515–2522. https://doi.org/10.2166/wst.2016.336

Wellinger A, Murphy J, Baxter D (2013) The Biogas handbook: science, production and applications, 1st edn. Woodhead Publishing, Cambridge

El Amin HB, Dirar HA (1986) Biogas Production from Water Hyacinth [Eichhornia crassipes]: influence of temperature. In: El-Halwagi MM (ed) Biogas technology, transfer and diffusion. Springer, Dordrecht, pp 437–445. https://doi.org/10.1007/978-94-009-4313-1_52

Moestedt J, Rönnberg J, Nordell E (2017) The effect of different mesophilic temperatures during anaerobic digestion of sludge on the overall performance of a WWTP in Sweden. Water Sci Technol 76:3213–3219. https://doi.org/10.2166/wst.2017.367

Moset V, Poulsen M, Wahid R, Højberg O, Møller HB (2015) Mesophilic versus thermophilic anaerobic digestion of cattle manure: methane productivity and microbial ecology. Microb Biotechnol 8:787–800. https://doi.org/10.1111/1751-7915.12271

Uzodinma EOU, Ofoefule AU, Eze JI, Onwuka ND (2007) Optimum Mesophilic temperature of biogas production from blends of agro-based wastes. Trends Appl Sci Res 2:39–44. https://doi.org/10.3923/tasr.2007.39.44

Kafle GK, Chen L (2016) Comparison on batch anaerobic digestion of five different livestock manures and prediction of biochemical methane potential (BMP) using different statistical models. Waste Manag 48:492–502. https://doi.org/10.1016/j.wasman.2015.10.021

Li P, Li W, Sun M, Xu X, Zhang B, Sun Y (2019) Evaluation of biochemical methane potential and kinetics on the anaerobic digestion of vegetable crop residues. Energies 12:1–14. https://doi.org/10.3390/en12010026

Strömberg S, Nistor M, Liu J (2015) Early prediction of Biochemical Methane potential through statistical and kinetic modelling of initial gas production. Bioresour Technol 176:233–241. https://doi.org/10.1016/j.biortech.2014.11.033

Fongsatitkul P, Elefsiniotis P, Wareham DG (2012) Two-phase anaerobic digestion of the organic fraction of municipal solid waste: estimation of methane production. Waste Manag Res 30:720–726. https://doi.org/10.1177/0734242X11429987

Sarto S, Hildayati R, Syaichurrozi I (2019) Effect of chemical pretreatment using sulfuric acid on biogas production from water hyacinth and kinetics. Renew Energy 132:335–350. https://doi.org/10.1016/j.renene.2018.07.121

Angelidaki I, Alves M, Bolzonella D, Borzacconi L, Campos JL, Guwy AJ, Kalyuzhnyi S, Jenicek P, Van Lier JB (2009) Defining the biomethane potential (BMP) of solid organic wastes and energy crops: a proposed protocol for batch assays. Water Sci Technol. https://doi.org/10.2166/wst.2009.040

Akendo ICO, Gumbe LO, Gitau AN (2008) Dewatering and drying characteristics of water Hyacinth (Eichhornia crassipes) Petiole. Part II. Drying characteristics. Agric Eng Int CIGR E J X:1–11

Davies RM, Mohammed US (2011) Moisture-dependent engineering properties of water hyacinth parts. Singapore J Sci Res 1:253–263

O’Kelly BC (2005) Mechanical properties of dewatered sewage sludge. Waste Manag 25:47–52. https://doi.org/10.1016/j.wasman.2004.08.003

Jayalakshmy MS, Philip J (2010) Thermophysical properties of plant leaves and their influence on the environment temperature. Int J Thermophys 31:2295–2304. https://doi.org/10.1007/s10765-010-0877-7

Vaxelaire J, Puiggali JR (2002) Analysis of the drying of residual sludge: from the experiment to the simulation of a belt dryer. Dry Technol 20:989–1008. https://doi.org/10.1081/DRT-120003773

Duke JA (1983) Handbook of energy crops. Purdue University, Center for New Crops & Plants Products. OCLC 45954667

Lisboa MS, Lansing S (2013) Characterizing food waste substrates for co-digestion through biochemical methane potential (BMP) experiments. Waste Manag 33:2664–2669

Wolfe RS (2011) Chapter one—techniques for cultivating methanogens. In: Rosenzweig AC, Ragsdale SWBT-M (eds) Methods in methane metabolism, Part A. Academic Press, Cambridge, pp 1–2. https://doi.org/10.1016/B978-0-12-385112-3.00001-9

Lawal AA, Dzivama AU, Wasinda MK (2016) Effect of inoculum to substrate ratio on biogas production of sheep paunch manure. Res Agric Eng 62:8–14. https://doi.org/10.17221/30/2014-RAE

Shah FA, Rashid N, Mahmood Q, Ali A (2019) Effect of pretreatment and substrate ratios in biorefinery employing co-digestion of plant biomass and poultry waste. Front Energy Res 6:1–14. https://doi.org/10.3389/fenrg.2018.00143

Bertrand RL (2019) Lag phase is a dynamic, organized, adaptive, and evolvable period that prepares bacteria for cell division. J Bacteriol 201:1–21

Rolfe MD, Rice CJ, Lucchini S, Pin C, Thompson A, Cameron ADS, Alston M, Stringer MF, Betts RP, Baranyi J, Peck MW, Hinton JCD (2012) Lag phase is a distinct growth phase that prepares bacteria for exponential growth and involves transient metal accumulation. J Bacteriol 194:686–701. https://doi.org/10.1128/JB.06112-11

Gaby JC, Zamanzadeh M, Horn SJ (2017) The effect of temperature and retention time on methane production and microbial community composition in staged anaerobic digesters fed with food waste. Biotechnol Biofuels 10:302. https://doi.org/10.1186/s13068-017-0989-4

Pramanik SK, Suja FB, Porhemmat M, Pramanik BK (2019) Performance and kinetic model of a single-stage anaerobic digestion system operated at different successive operating stages for the treatment of food waste. Processes 7:600

Acknowledgements

This research was financially supported by the National Research Fund for Science, Technology, and Innovation (FONDOCYT 2015-2A3-123) of the Dominican Republic Ministry of Higher Education, Science and Technology (MESCYT).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Castro, Y.A., Agblevor, F.A. Interaction effect of high feed to inoculum ratio (F/I) and temperature on the biomethanation kinetics of water hyacinth. SN Appl. Sci. 2, 1818 (2020). https://doi.org/10.1007/s42452-020-03626-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-020-03626-w