Abstract

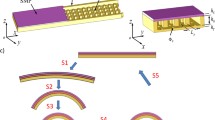

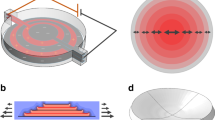

Carefully designed geometries and materials can program desired shapes. In this review, we introduce shape-transformable materials and their recent applications in electronic devices and robots. Strain-guiding shape transformation can be achieved by geometry design or materials design, which can program the magnitude and direction of strain to develop desired shapes. For the geometry design, we discuss origami and kirigami, which transform 2D sheet materials into desired 3D shapes via local deformations caused by fold creases and cut openings. The desired shape can be programmed by controlling the length and alignment of folds or cuts. For the material design, heterogeneities in materials can develop strain driven shape transformation. Heterogeneities in materials include those in anisotropic materials, graded materials, or mixtures of different materials. Shape-transformable materials can be prepared by introducing heterogeneities into stimuli-responsive materials, including inflatable materials, shape memory polymers, liquid crystal elastomers, and hydrogels. The development of shape-transformable materials has led to innovations in energy storage devices, displays, sensors, epidermal electronics, actuators, and robots.

Graphical abstract

Similar content being viewed by others

References

Liu, K., Paulino, G.H.: Non-linear mechanics of non-rigid origami: an efficient computational approach. Proc. R. Soc. Math. Phys. Eng. Sci. 473, 20170348 (2017)

Meloni, M. et al.: Engineering origami: A comprehensive review of recent applications, design methods, and tools. Adv. Sci. 8, 2000636 (2021)

Zhang, Z., Tian, Z., Mei, Y., Di, Z.: Shaping and structuring 2D materials via kirigami and origami. Mater. Sci. Eng. R: Rep. 145, 100621 (2021)

Park, J.J., Won, P., Ko, S.H.: A review on hierarchical origami and kirigami structure for engineering applications. Int. J. Precision Eng. Manuf. Green Technol. 6, 147–161 (2019)

Bertoldi, K., Vitelli, V., Christensen, J., van Hecke, M.: Flexible mechanical metamaterials. Nature Rev. Mater. 2.11, 1-11 (2017)

Ning, X et al., Assembly of advanced materials into 3D functional structures by methods inspired by origami and kirigami: a review. Adv. Mater. Interfaces 5.13, 1800284 (2018)

Rus, D., Tolley, M.T.: Design, fabrication and control of origami robots. Nat. Rev. Mater. 3, 101–112 (2018)

Erol, O., et al.: Transformer hydrogels: a review. Adv. Mater. Technol. 4, 1900043 (2019)

Skrzypek, J.J., Ganczarski, A.W.: Mechanics of Anisotropic Materials. Springer International Publishing, Cham, Switzerland (2015)

Ryan, K.R., Down, M.P., Banks, C.E.: Future of additive manufacturing: Overview of 4D and 3D printed smart and advanced materials and their applications. Chem. Eng. J. 403, 126162 (2021)

Budinski, Natalija, Mathematics and Origami: The Art and Science of Folds. Handbook of the Mathematics of the Arts and Sciences. 317–348 (2021)

Hull, T.: On the mathematics of flat origamis. Congressus Numerant. 100, 215–224 (1994)

Demaine, E.D., and Martin L. Demaine. Recent results in computational origami. In: Origami3: Third International Meeting of Origami Science, Mathematics and Education. (2002)

Bateman, A., Computer tools and algorithms for origami tessellation design. Origami3: Proc. the 3rd International Meeting of Origami Mathematics, Science, and Education (2002)

Wu, S.R., Chen, T.H., Tsai, H.Y.: A review of actuation force in origami applications. J. Mech. 35, 627–639 (2019)

Arun, S. B., B. H. Anveeth, and A. Majumder. Advancements in Origami Inspired Robots, a Review. In: 2019 2nd International Conference on Intelligent Computing, Instrumentation and Control Technologies (ICICICT) 1. (2019)

Liu, H., Plucinsky, P., Feng, F., James, R.D.: Origami and materials science. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 379, 20200113 (2021)

Iwata, Y., and E., Iwase. Stress-free stretchable electronic device using folding deformation. In: 2017 IEEE 30th International Conference on Micro Electro Mechanical Systems (MEMS). (2017)

Liu, S., Lu, G., Chen, Y., Leong, Y.W.: Deformation of the Miura-ori patterned sheet. Int. J. Mech. Sci. 99, 130–142 (2015)

Dudte, L.H., Vouga, E., Tachi, T., Mahadevan, L.: Programming curvature using origami tessellations. Nat. Mater. 15, 583–588 (2016)

Lang, Robert J, A computational algorithm for origami design. In: Proceedings of the twelfth annual symposium on Computational geometry (1996)

Tachi, T.: Origamizing polyhedral surfaces. IEEE Trans. Visual Comput. Graphics 16, 298–311 (2010)

Takahashi, S., Wu, H.-Y., Saw, S.H., Lin, C.-C., Yen, H.-C.: Optimized topological surgery for unfolding 3D meshes. Computer Graphics Forum 30, 2077–2086 (2011)

Xi, Z., Kim, Y.-H., Kim, Y.J., Lien, J.-M.: Learning to segment and unfold polyhedral mesh from failures. Comput. Graph. 58, 139–149 (2016)

Xi, Zhonghua, and Jyh-Ming Lien. Continuous unfolding of polyhedra-a motion planning approach. In: 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS). (2015)

Y. Hao, Y.-h. Kim, J.-M. Lien. Synthesis of fast and collision-free folding of polyhedral nets. In: Proceedings of the 2nd ACM Symposium on Computational Fabrication. pp 1–10 (2018)

Hao, Y., et al. "Creating Foldable Polyhedral Nets Using Evolution Control." Robotics: Science and Systems. (2018)

Overvelde, J.T., Weaver, J.C., Hoberman, C., Bertoldi, K.: Rational design of reconfigurable prismatic architected materials. Nature 541, 347–352 (2017)

Overvelde, J.T., et al.: A three-dimensional actuated origami-inspired transformable metamaterial with multiple degrees of freedom. Nature Commun. 7, 10929 (2016)

Xi, Z, and JM Lien, Folding rigid origami with closure constraints. In: International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. 46377 (2014)

Chen, B.G., et al.: Topological mechanics of origami and kirigami. Phys. Rev. Lett. 116, 135501 (2016)

Sadik, S., Dias, M.A.: On local kirigami mechanics I: Isometric conical solutions. J. Mech. Phys. Solids 151, 104370 (2021)

Lee, Y et al., Auxetic elastomers: mechanically programmable meta-elastomers with an unusual Poisson’s ratio overcome the gauge limit of a capacitive type strain sensor. Extreme Mech. Lett. 31, 100516 (2019)

Chen, B., et al.: Topological mechanics of origami and kirigami. Phys. Rev. Lett. 116, 13 (2016)

Cho, Y., et al.: Engineering the shape and structure of materials by fractal cut. Proc. Natl. Acad. Sci. U.S.A. 111, 17390–17395 (2014)

Celli, P., et al.: Shape-morphing architected sheets with non-periodic cut patterns. Soft Matter 14, 9744–9749 (2018)

Konaković, M., et al.: Beyond developable. ACM Trana. Graphics 35, 1–11 (2016)

Konaković-Luković, M., Panetta, J., Crane, K., Pauly, M.: Rapid deployment of curved surfaces via programmable auxetics. ACM Trans. Graphics 37, 1–13 (2018)

Jin, L., Forte, A.E., Deng, B., Rafsanjani, A., Bertoldi, K.: Kirigami-inspired inflatables with programmable shapes. Adv. Mater. 32, 2001863 (2020)

Choi, G.P.T., Dudte, L.H., Mahadevan, L.: Programming shape using kirigami tessellations. Nat. Mater. 18, 999–1004 (2019)

Sussman, D.M., et al.: Algorithmic lattice kirigami: a route to pluripotent materials. Proc. Natl. Acad. Sci. U.S.A. 112, 7449–7453 (2015)

Yang, S., Choi, I.-S., Kamien, R.D.: Design of super-conformable, foldable materials via fractal cuts and lattice kirigami. MRS Bull. 41, 130–138 (2016)

Wang, F., Guo, X., Xu, J., Zhang, Y., Chen, C. Q.: Patterning curved three-dimensional structures with programmable kirigami designs. J. Appl. Mech. 84.6, 061007 (2017)

Tang, Y et al., Programmable Kiri-Kirigami metamaterials. Adv. Mat. 29.10, 1604262 (2017)

An, N., Domel, A.G., Zhou, J., Rafsanjani, A., Bertoldi, K.: Programmable hierarchical Kirigami. Adv. Funct. Mat. 30.6, 1906711 (2019)

Liu, J., et al.: Responsive and foldable soft materials. Trends Chem. 2, 107–122 (2020)

Kuang, X., et al.: Materials, design, and fabrication of shape programmable polymers. Multifunct. Mater. 3, 032002 (2020)

Barnes, M., Rafael, V.: Direct shape programming of liquid crystal elastomers. Soft Matter. 155, 870-879 (2019)

Pikul, J.H., et al.: Stretchable surfaces with programmable 3D texture morphing for synthetic camouflaging skins. Science 358(6360), 210–214 (2017)

Ma, L.-K., Zhang, Y., Liu, Y., Zhou, K., Tong, X.: Computational design and fabrication of soft pneumatic objects with desired deformations. ACM Trans. Graphics 36, 1–12 (2017)

Siefert, E., Reyssat, E., Bico, J., Roman, B.: Bio-inspired pneumatic shape-morphing elastomers. Nat. Mater. 18, 24–28 (2019)

Siefert, E., Reyssat, E., Bico, J., Roman, B.: Programming curvilinear paths of flat inflatables. Proc. Natl. Acad. Sci. U.S.A. 116, 16692–16696 (2019)

Park, H., et al.: Three-dimensional constitutive model for shape memory polymers using multiplicative decomposition of the deformation gradient and shape memory strains. Mech. Mater. 93, 43–62 (2016)

van Manen, T., Janbaz, S., Zadpoor, A.A.: Programming 2D/3D shape-shifting with hobbyist 3D printers. Mater. Horiz. 4, 1064–1069 (2017)

Ahn, S.J., et al.: 4D printing of continuous shape representation. Adv. Mater. Technol. 6.6, 210133 (2021)

Wermter, H., Finkelmann, H.: Liquid crystalline elastomers as artificial muscles. e-Polymers 1.1, 013 (2001)

Aharoni, H., Xia, Y., Zhang, X., Kamien, R.D., Yang, S.: Universal inverse design of surfaces with thin nematic elastomer sheets. Proc. Natl. Acad. Sci. U.S.A. 115, 7206–7211 (2018)

Kotikian, A., Truby, R.L., Boley, J.W., White, T.J., Lewis, J.A.: 3D printing of liquid crystal elastomeric actuators with spatially programed nematic order. Adv. Mater. 30.10, 1706164 (2018)

Gladman, A.S., Matsumoto, E.A., Nuzzo, R.G., Mahadevan, L., Lewis, J.A.: Biomimetic 4D printing. Nat. Mater. 15, 413–418 (2016)

Nojoomi, A., Jeon, J., Yum, K.: 2D material programming for 3D shaping. Nature Commun. 12, 603 (2021)

Blees, M.K., et al.: Graphene kirigami. Nature 524, 204–207 (2015)

Shyu, T.C., et al.: A kirigami approach to engineering elasticity in nanocomposites through patterned defects. Nature Materia6els 14, 785–789 (2015)

Phillip, Won et al.: Stretchable and transparent kirigami conductor of nanowire percolation network for electronic skin applications. Nano Lett. 19.9, 6087–6096 (2019)

Hu, G., Zhao, C., Yang, Y., Li, X., Liang, J.: Triboelectric energy harvesting using an origami-inspired structure. Appl. Energy 306, 118037 (2022)

Wang, L.C., Song, W.L., Fang, D.: Twistable origami and kirigami: from structure-guided smartness to mechanical energy storage. ACS Appl. Mater. Interfaces. 11, 3450–3458 (2019)

Lin, C.H., et al.: Highly deformable origami paper Photodetector arrays. ACS Nano 11, 10230–10235 (2017)

Choi, C., et al.: Human eye-inspired soft optoelectronic device using high-density MoS2-graphene curved image sensor array. Nature Commun. 8, 1664 (2017)

Y. Kinoshita, K. Go, R. Kozono, K. Kaneko 2014 Origami tessellation display. In: CHI '14 Extended Abstracts on Human Factors in Computing Systems. pp 1837–1842

Irmler, C., et al.: Origami chip-on-sensor design: progress and new developments. J. Instrum. 8, C01014–C01014 (2013)

Xu, K., et al.: Highly stable kirigami-structured stretchable strain sensors for perdurable wearable electronics. J. Mater. Chem. C 7(31), 9609–9617 (2019)

Miyashita, S., et al. An untethered miniature origami robot that self-folds, walks, swims, and degrades. In: 2015 IEEE International Conference on Robotics and Automation (ICRA). IEEE (2015)

Zhang, H., et al. Origami-tessellation-based triboelectric nanogenerator for energy harvesting with application in road pavement. Nano Energy 78, 105177 (2020)

Tao, K., et al.: Miura-origami-inspired electret/triboelectric power generator for wearable energy harvesting with water-proof capability. Microsyst. Nanoeng. 6, 56 (2020)

Hong, S., et al.: Nature-inspired, 3D origami solar steam generator toward near full utilization of solar energy. ACS Appl. Mater. Interfaces. 10(34), 28517–28524 (2018)

Lee, K., et al.: Origami solar-tracking concentrator array for planar photovoltaics. ACS Photonics 3, 2134–2140 (2016)

Evke, E.E., et al.: Kirigami-based compliant mechanism for multiaxis optical tracking and energy-harvesting applications. Adv. Eng. Mater. 23, 2001079 (2021)

Kim, M.H., et al.: Bioinspired shape-morphing scale battery for untethered soft robots. Soft Robot (2021). https://doi.org/10.1089/soro.2020.0175

Kim, K.B., et al.: Extremely versatile deformability beyond materiality: A new material platform through simple cutting for rugged batteries. Adv. Eng. Mater. 21.7, 1900206 (2019)

Kim, G.G., Kim, Y., Yoo, S., Jang, H.S., Ko, H.C.: Hexahedral LED arrays with row and column control lines formed by selective liquid‐phase plasticization and nondisruptive tucking‐based origami. Adv. Mater. Technol. 5.6, 2000010 (2020)

Lee, Y.K., et al.: Computational wrapping: a universal method to wrap 3D-curved surfaces with non-stretchable materials for conformal devices. Sci. Adv. 6(15), eaax6212 (2020)

Zhang, K., et al.: Origami silicon optoelectronics for hemispherical electronic eye systems. Nature Commun. 8, 1782 (2017)

Yihui, Zhang et al., A mechanically driven form of Kirigami as a route to 3D mesostructures in micro/nanomembranes. In: Proceedings of the National Academy of Sciences 112.38. 11757–11764 (2015)

Liu, Z., et al.: Nano-kirigami with giant optical chirality. Sci. Adv. 4(7), eaat4436 (2018)

Evke, E.E., Meli, D., Shtein, M.: Developable rotationally symmetric kirigami‐based structures as sensor platforms. Adv. Mater. Technol. 4.12, 1900563 (2019)

Yeon, H., et al.: Long-term reliable physical health monitoring by sweat pore–inspired perforated electronic skins. Sci. Adv. 7(27), eabg78459 (2021)

Lee, D., et al.: High–load capacity origami transformable wheel. Sci. Robot. 6.53, eabe0201 (2021)

S. Miyashita et al., Ingestible, controllable, and degradable origami robot for patching stomach wounds. In: IEEE international conference on robotics and automation (ICRA). IEEE, (2016)

A. Rafsanjani et al., Kirigami skins make a simple soft actuator crawl. Science Robotics 3.15 (2018)

Chen, S., et al.: Simple triple-state polymer actuators with controllable folding characteristics. Appl. Phys. Lett. 110.13, 133506 (2017)

Lee, Y., Song, W.J., Sun. J-Y.: Hydrogel soft robotics. Mater. Today Phys. 15, 100258 (2020)

Martinez, R.V., et al.: Elastomeric origami: programmable paper-elastomer composites as pneumatic actuators. Adv. Func. Mater. 22(7), 1376–1384 (2012)

Jin, B., et al.: Programming a crystalline shape memory polymer network with thermo-and photo-reversible bonds toward a single-component soft robot. Sci. Adv. 4.1, eaao3865 (2018)

Ge, F., et al.: A new function for thermal phase transition-based polymer actuators: autonomous motion on a surface of constant temperature. Chem. Sci 8.9, 6307–6312 (2017)

Kularatne, R.S., et al.: Liquid crystal elastomer actuators: Synthesis, alignment, and applications. J. Polym. Sci., Part B: Polym. Phys. 55(5), 395–411 (2017)

Wani, O.M., et al.: A light-driven artificial flytrap. Nature Commun. 8, 1 (2017)

Zhang, Y., et al.: Seamless multimaterial 3D liquid-crystalline elastomer actuators for next-generation entirely soft robots. Sci. Adv. 6.9, eaay8606 (2020)

Liu, J., et al.: Shaping and locomotion of soft robots using filament actuators made from liquid crystal elastomer–carbon nanotube composites. Adv. Intell. Syst. 2.6, 1900163 (2020)

Li, X., et al.: Reversible bidirectional bending of hydrogel-based bilayer actuators. J. Mater. Chem. B. 5, 2804–2812 (2017)

Zheng, J., et al.: Mimosa inspired bilayer hydrogel actuator functioning in multi-environments. J. Mater. Chem. C 6(6), 1320–1327 (2018)

E. Palleau et al., Reversible patterning and actuation of hydrogels by electrically assisted ionoprinting. Nature Commun. 4.1 (2013)

Islam, M.R., et al.: Modeling swelling behavior of hydrogels in aqueous organic solvents. Chem. Eng. Sci. 242, 116744 (2021)

Funding

This work was supported by the National Research Foundation of Korea (NRF) (Grant numbers 2019R1A2C2003430, 2019R1A6A3A13097110, 2018M3A7B4089670, 2016R1A5A1938472), the Creative-Pioneering Researchers Program through Seoul National University, and LG Display under the LGD–Seoul National University Incubation Program

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lee, YK., Kim, J., Lien, JM. et al. Recent Progress in Shape-Transformable Materials and Their Applications. Electron. Mater. Lett. 18, 215–231 (2022). https://doi.org/10.1007/s13391-021-00330-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-021-00330-8