Abstract

This report describes the approach to create permanently updated 3D models of research aircraft and laboratory facilities. Therefore, optical metrology scans the research environment in its raw or as-delivered condition. The result is a virtual model of the actual geometry and, in comparison to reference data (e.g. CAD-data), the smallest inaccuracies can be identified and analyzed. The exact position of non-rigid components, like riser ducts, electronics or isolation, can be determined in the models. Further changes to the layout of these facilities are permanently digitized and added to the virtual model of the environment. This can be a new recording of the entire facility or of individual areas that are affected by the changes. The individual, newly recorded models are then integrated into the existing model. This creates an always up-to-date 3D model of the research environment, which is added to its digital twin and can be observed there. In combination with CAD data, future conversion and installation measures are planned in advance and analyzed virtually in relation to the up-to-date geometry and installation space data. In addition, the virtual models of the aircraft cabins can be used to support the lengthy approval and certification process at an early stage.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

An essential goal in the aviation research of the German Aerospace Center (DLR) is the end-to-end digitization of aviation, starting with product development and extending to the certification, manufacturing, and maintenance of new aircraft [1]. As environmental aspects become increasingly important to people, it is essential to make aviation more sustainable. Digitization can be used to identify unused potentials and accelerate the entire development process of new aircraft, as well as the approval and certification process.

In addition to the largest civil fleet of research aircraft within Europe, DLR operates a variety of laboratory and research facilities [2]. For most experiments in the cabins of research aircraft or laboratories, such as physical mock-ups, conversions must be performed at regular intervals. This can be seen as an example in Fig. 1. To accelerate the entire development process of new conversion, permanently updated virtual 3D models of the existing facilities are required. With this information, a constant reconciliation of the actual geometry in regard to reference data can be carried out. Especially in areas of frequent conversions, DMUFootnote 1 data, if existing, do not correspond to the actual state of the research environment. Therefore, planning and designs of new conversions and installations on the cabins of research aircraft or laboratory facilities are to be made on the basis of the actual geometry data. For this purpose, a digital model of the cabin is constantly created by high-resolution optical metrology. The results are 3D measurement data in the form of points clouds or triangulated surface models. The post-processed measurement data is added to the digital thread of the research environment and linked to its corresponding digital twin. The digital twin, a clearly identifiable digital image of the actual product, stores all information centrally and is thus available to all stakeholders at any time.

In the DLR guiding concept Virtual Product, the focus is on the mathematical–numerical representation of the aircraft with all its properties. This requires a consistent description of the realistic image of the aircraft [3]. For the realistic representation of the geometric dimensions and shapes, optical metrology provides high-resolution, three-dimensional data of the captured objects. This allows to digitize physical objects and systems with all their details, like production-related uncertainties. Optical metrology makes it possible to establish a continuous data flow of information of dimension and installation space from the design phase to production and back. Due to the design of new conversions and installations based on the permanently updated virtual image of the research environment, limitations of installation space can be recognized at an early stage and prevented, even if the physical infrastructure is at another site. Furthermore, all details such as the exact position of brackets, cables or other non-rigid materials, can be identified in the 3D recordings.

First, the terms digital twin (section “Digital twin”) and digital thread (section “Digital thread”) are explained, followed by the presentation of the central data model CPACS (Common Parametric Aircraft Configuration Schema) in section “CPACS: a central data model”, needed to create data models of the real geometries. The integration of the geometry data in CPACS is described in section “Linking external geometry data”. The process for digitizing physical objects is presented in section “Digitization of physical objects”. Subsequently, a classification of geometric models in digital twins (section “Geometric models within the digital twin”), with the description of a possible identification of components in triangulated surface meshes (section “Identification of components”) is described. Section Actual geometry data for assembly and manufacturing planning” shows applications for actual geometry data in manufacturing and assembly, as well as the use for assembly simulations in section “Actual geometry data for assembly simulation”.

2 Digital consistency in aviation

DLR research on virtual products anticipates the digitization of aviation, which basically consists of two areas, the digital twin, a highly accurate digital description of a physical product (section “Digital twin”), and the digital thread, which enables the consistency of data and information (section “Digital thread”).

2.1 Digital twin

The idea of a twin is to build an identical copy of the product or system to mirror operating cases, simulations, or optimizations. In the case of the digital twin, the above-mentioned copy is to be created in the digital respectively virtual space. Its development is driven by the rapid progress in computer technologies over the last decades, such as virtual simulation and data acquisition technology [4, 5]. In addition, there is constant development in the field of microchip, sensor, and IT technologies, which enable the communication and transmission of operating states between the physical and digital twin. Together with modern measurement methods, they all supply the digital counterpart with data [4]. This enables identification of problems and increases the efficiency of products and systems [6].

The term digital twin was first mentioned in NASA’sFootnote 2 technology objectives (area 11: modeling, simulation, information technology, and processing) [4, 7] and is defined as: “(...) multi-physical, multi-scale, probabilistic simulation of a vehicle or system that uses the best available physical models, sensor updates, fleet history, etc. to mirror the life of its flying twin” [8]. The virtual product should describe its physical counterpart “completely from the micro-atomic to the macro-geometric level” [4].

Digital twin over the entire product life cycle (PLC), acc. to [8], (pictures by DLR-SL)

According to Grieves [9], the digital twin consists of three parts, as shown in Fig. 2:

-

(1)

the physical product,

-

(2)

the virtual product, and

-

(3)

the bi-directional connection for data exchange between physical and virtual product.

These three parts cannot be considered as isolated, as they are in constant exchange with one another [6].

With this description, the digital twin provides a set of linked data and models from operating states and simulations that enhance over the products life cycle [4]. It is an integrated system that simulates, monitors, computes, regulates, and controls the various system states and processes. The digital twin always reflects the current state of its physical counterpart, which is in operation. Its behavior can be simulated and analyzed with the digital twin [5]. From a product life cycle management perspective, the digital twin integrates all data artifacts, such as data on performance information, predictions about the physical product, as well as design and production optimization, which can be viewed by various stakeholders. Therefore, it is not only suitable for virtual representation of the product, but also for predicting the expected product behavior under certain loads. The bi-directional linking of physical and digital twin, shown in Fig. 2, enables more effective product design, manufacturing, maintenance, and various other activities throughout the entire product life cycle [4].

Zheng et al. consider the concept of the digital twin as the best way to achieve communication and interaction between the physical and virtual space [5]. Qi et al. [6] emphasize, however, that in order to create high-resolution models and simulations, the physical world must be known, or clearly recognizable from the recorded data. As the first step, the parameters of the physical world, such as size, shape, structure, etc., should be measured using existing technologies and sensors. Figure 3 shows a selection of data that impacts the digital twin. This work focuses on the influence and acquisition of up-to-date geometric data in order to create a virtual image of the actual geometric shapes of the physical counterpart.

The concept of the digital twin offers the advantage of representing the physical product in the virtual world, in all its details, such as shape, position, material, status, and movement. In addition, Qi et al. describe that by monitoring, forecasting, and optimizing through the addition of sensor data, big data analyzes as well as artificial intelligence and machine learning, future trends can be predicted and comprehensive decision-making aids can be offered, over all phases of the product life cycle. By integrating environments, facilities, and people to the 3D representation of the digital twin and using virtual reality, training and inspections can be conducted on the products. Furthermore, the digital twin is seen as an effective means to improve the efficiency of companies in the field of development, as well as to save time and costs [6].

The digital twin is intended to reflect the entire life cycle of a product, so that product design, production, and maintenance can be made more efficient. For example, NASA and the US Air Force apply the technology in the design phase of new products, using ultra-high fidelity simulation models to better predict the performance and condition of vehicles [5]. Further predictions can be determined for the product and process development phases, as well as for operation and maintenance, without creating expensive and time-consuming physical mock-ups. Schleich et al. consider the realistic 3D models of digital twins as a great advantage, especially for the design phase, since decisions on the quality and function of the products can be evaluated early and efficiently. Thus, the 3D models contribute to validation and verification, especially in the design phase, for checking the product specification with the design intent and customer requirements. By virtual testing products in the 3D environments, producibility and further functions can be virtually simulated, without the time-consuming and cost-intensive construction of physical mock-ups. In this way, design flaws, such as exceeding the installation space, can be identified and corrected prior to assembly [4, 6].

The synchronization of data between the physical and the virtual world is currently still a problem. Schleich et al. see insufficient closed-loops capabilities, as well as the lack of high-resolution models for multi-scale virtual testing [4]. In addition, constant changes in the research environments reflect in constant and synchronized updates of the virtual images in the digital twin [6].

3D sensors are suitable for capturing and transferring the geometric data and dimensions from physical to virtual products. They reflect the actual geometry of the objects as triangulated surface meshes in the digital twin [6, 10]. A description of the acquisition process and the influence of realistic surface meshes in the context of a digital twin is discussed in more detail in sections “Digitization of physical objects” and “Geometric models within the digital twin”.

2.2 Digital thread

To add data and information to the digital twin, an infrastructure must be created that analyzes and intelligently links all knowledge across all phases of the product life cycle. This concept, knows as digital thread, enables the digital consistency of all recorded data and provides them entirely to the digital twin.

The digital thread describes a system that contains all information and data across all life phases of a product and links them in a central data system. It contains all means to generate the technical system architecture of a digital twin. With the help of additional data, information, and knowledge within the digital thread, updates for the digital twin are generated and provided, as well as information-based decision-making is facilitated.

The term digital consistency implies a connected data flow throughout all phases of the life cycle in both directions, as shown in Fig. 4. This should also enable a data flow through traditionally isolated perspectives, such as design, simulation, production, and others. This requires a central data system.

3 CPACS: a central data model

The previous section claims a central data model for geometry data and additional information, which describes the system and configurations. This model is provided by the aircraft data scheme CPACS. CPACS, the acronym for Common Parametric Aircraft Configuration Schema, is explained in the following section “Introduction into CPACS”. The integration of external geometry models is described in section “Linking external geometry data”.

3.1 Introduction into CPACS

In order to realize the interoperability of information and models between different systems and applications, the exchange of data in a common data format is necessary. One example for the interoperability of models is the CPACS scheme [11] developed by DLR. It contains a parametric description of an aircraft and enables the exchange of data and information across application boundaries [12]. It is defined as a data-centric model, where the geometries are created by data, and allows the exchange of knowledge across application boundaries (Fig. 5a). CPACS is based on a hierarchically structured data set in XMLFootnote 3 format (Fig. 5b) and enables the storage of data and knowledge beyond the product geometry, such as the mass of elements [13]. The analysis capabilities within the digital thread evaluates the CPACS linked data of different life cycle phases.

The seamless availability and intelligent linkage of knowledge from every phase of a product life cycle, from design to production, operation, maintenance, and decommissioning, are the core of the concept of the digital thread. The versioning of CPACS files enables the traceability of different states and configurations, so that changes over time become visible.

3.2 Linking external geometry data

With the introduction of the decksElements-node within the cabin definition in CPACS, an aircraft cabin can be assembled from standard parts for a given configuration [14]. Definitions of cabin elements, such as seats, sidewall and ceiling panels, luggage compartments, and others, are available for this purpose. In addition to the simple description of the elements as boundary cuboids, which indicate the length, height, and width of the respective elements, CPACS offers the possibility to integrate external geometry models via the genericGeometryComponents-node. CAD models in STEP- or IGES-file formats as well as triangulated geometry models in STL-format can be included. 3D scanned objects, which consists of a triangulated surface mesh, can thereby be inserted into the digital thread for visualization purposes. Further information on the scanned models is found in section “Digitization of physical objects”. The geometry models stored in the genericGeometryComponents-node are linked to the respective deckElements-node via unique identifiers (uIDs). uIDs are globally valid and unique within CPACS, that allow references to other nodes within the data set.

This way, a CPACS file is created, where digitized elements and components are placed in the model with their actual geometries. Within CPACS, a selection of cabin elements is defined in the deck and deckElements-nodes, as shown in Fig. 6. Other cabin elements, such as components of the air conditioning system, are placed in the model using the genericFloorElements.

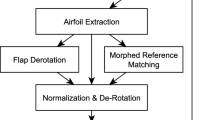

4 Digitization of physical objects

Optical metrology, combined with the use of 3D scanners, is most suitable for digitizing physical objects. To capture detailed recordings of large, as well as small scenes and components, the structured light method suits best. A finite number of measuring points is recorded in a short time, without contact to the object. The structured light method, which setup is shown in Fig. 7, uses the triangulation principle to calculate the distance a between the sensor and the object. Therefore, the exact distance b and the angle \(\alpha \) between the two cameras must be known. Schuth and Buerakov [15] state a maximum accuracy for these sensors of up to 0.003 mm for small measuring fields. To guarantee a high accuracy for larger objects and scenes and to prevent a continuous error, the process can be supplemented by photogrammetry systems. Reference points, that can be identified in both recordings, the structured light as well as photogrammetry, are superimposed [16]. Color sensors in the cameras of the photogrammetry system detect surface colors and textures, which are transferred to the scanned surface mesh. This creates realistic-looking digital copies of the physical objects. For more information on digitization with optical measuring methods, see Rauscher et al. [17] and Schuth and Buerakov [15].

The process for digitizing physical objects is seen in Fig. 8 on the example of an individual air outlet located in the passenger supply channel. Table 1 describes the time [in percentage) and methodology used in the process, as well as implementation. The complete scanning and post-processing of the individual air outlet takes about 2 h, with the structured light method explained above. Larger objects take longer, due to the increased number of individual images and a longer time for post-processing. For a better understanding of the duration of the process, two examples are given. For a row of 3 seats about 8 h are needed, distributed according to the time schema shown in Table 1. If now a whole laboratory environment is to be captured, like the cabin mock-up shown in Fig. 1 in the assembled state, 3–4 days are needed. All these time figures are based on a measurement volume of \(700 \times 500 \times 500\) mm.

Step 1 describes the preparation and placement of the physical object to be scanned. Therefore, reference points are distributed on the object in order to observe and track its orientation relative to the 3D sensor. Using the reference points, recordings from the top and bottom of the objects are superimposed to generate a complete and closed virtual model. Depending on the scenes or objects to be scanned, either the 3D-scanner is located in the laboratory environment or the objects are placed before the scanner. Smaller objects are placed on a rotation table for automation, as seen in Fig. 8, step 2. In the second step, the 3D sensor captures the physical object. To capture the whole object, either the sensor has to be moved through the room respectively around the object. For smaller objects, the turning is done by the rotation table, so that the scanner only has to be adjusted in height. Step 3 shows a point cloud of the object. A finite number of numerical measuring points are recorded that describe the surface in Cartesian coordinate form. The distance from the sensor to the object is calculated by the triangulation principle described in Fig. 7. To generate a mesh that connects the points (step 4), a triangulation algorithm, mostly the Delaunay triangulation [18], is used. In step 5, the planes that arise between the lines of the mesh are filled to generate a polygon mesh, which represents the surface of the object. Step 3–5 are automated within the software [19] used to control the 3D sensor and the post processing of the 3D data. The sixth step describes the optimization and post processing of the surface mesh. During the scanning and triangulation process, holes can occur in the surface mesh, which are repaired partly automated to create a closed surface. Post processing also includes the reduction of surface points, and thus triangles, that describe the virtual object. The reduction results in fewer entries in the exported files, such as STL- or PLY-files, which reduces their storage volume. This allows a better use of the digital objects in subsequent applications, such as in virtual reality models. The original files, with all captured points, are retained for analysis purposes. Last, the polygon mesh is colorized. The color information from the camera sensor is used, to assign a color value in the RGB scheme to each point. The color of the triangular areas between the points is interpolated. Finally, in step 7, the colorized polygon mesh is exported and saved for a further use.

As seen in Table 1, step 2 and step 6 take the longest time. When ever possible, the automated rotation table for the data acquisition should be used to accelerate the process. For step 6, some operations like filling small holes or the colorization of the points are automated. Here, the individual operations are to be connected in order to partly automate this step. Nevertheless, these two steps will always take the longest and are therefore the critical path of this process.

5 Geometric models within the digital twin

Geometric models are required to represent the actual state of objects or environments, such as research laboratories or -cabins, in the digital twins or digital threads with all its details. They represent the geometric shape of physical objects in a virtual world. Grégorio et al. [10] and Schleich et al. [4] recommend the use of surface meshes for this purpose, such as those created by the above described scanning process (section “Digitization of physical objects”). Surface meshes describe the interface between a physical object and its environment [4] and are intended to be true-to-original replicas of the physical geometries in terms of shape, size, tolerance, and structural relationships.

With the help of meshes, the actual geometry data of existing components are updated in the digital twin and serve as the basis for further test planning and the assembly of retrofits [10]. Thus, the current as—is state of geometric shapes, is recorded throughout the entire life cycle of a system and any changes can be tracked over time. The need for up-to-date geometric models is very high for both, the design and the production phase. In the design phase, new elements for the laboratory structures can be created on the basis of the latest geometric models. The use of real geometry data in production is discussed in more detail in section “Actual geometry data in production”.

Virtual geometric models have to meet requirements in terms of standardization, modularization, lightness, and robustness. The standardization of interfaces and communication protocols facilitates the integration of meshes with one another and the exchange of information. Lightness refers to small data files, that reduce the time and costs involved in transferring information. In order to be able to deal with various uncertainties, the meshes must demonstrate a certain robustness. However, the greatest importance is attached to modularization. Separating components from the entire mesh promotes a flexibility of the virtual models, whereby individual components contribute to new combinations and reconfiguration through separation and reuse. Since the effectiveness of the digital twin depends on the accuracy of the surface meshes, the meshes should be subject to a validation process and optimized through optimization steps, as mentioned in section “Digitization of physical objects” [6].

Realistic 3D models of research environments allow early and efficient decisions on quality and function. This includes product specifications and customer requirements, as well as operational and service decisions, all without setting up costly physical mock-ups. In addition, it supports validation and verification processes of new developments or adjustments to the research environments [4].

By integrating virtual environments or objects and people into the geometry models of the digital twin, virtual development environments can be created or virtual inspections can be performed. Figure 9 shows the virtual development platform with a short section of the aircraft cabin. For the visualization of the cabin, scanned geometric models of physical subcomponents (seat, sidewall) were used. In this virtual environment, the user can interactively explore the cabin and directly make changes to the layout with virtual reality hardware. For example, the user can directly change the position of the seats. However, the dependencies between the individual cabin components remain. Thus, direct feedback on the fulfillment of requirements can be given visually for the new position of the seat. Two test cases demonstrate the method. In both cases of Fig. 9, the defined area for the placement of the oxygen masks in the cabin is shown in the form of a block. For case 1, the block is shown in green because an oxygen mask was found within the defined area for the seat. For the new position of the seat, the accessibility of the oxygen mask is checked in case 2 (Fig. 9) and the user is visually informed whether the corresponding requirement can still be met in the new position or whether changes must be made here as well. Here, the area for the oxygen mask turns red because no corresponding cabin object could be found.

By linking design data with realistic 3D models in a virtual design platform, changes that arise during direct testing of new design variants in virtual reality become traceable [12]. In addition to checking requirements, further investigations can also be carried out in the virtual development platform, such as for passenger comfort or the integration of new technologies, as shown by Fuchs et al. [20]. The integration of scanned data into XR (EXtended Reality) platforms offers even more opportunities. Thus, as shown by De Crescenzio et al. [21], cabin interiors for business jet aircraft can be evaluated with test persons regarding criteria such as accessibility or style (through textures). Or perform human in the loop simulations early on [22]. So, the use of virtual reality or augmented reality (AR) allows stakeholders to experience the environment and 3D model at any location to work collaboratively.

6 Identification of components

For the automated identification and registration of components in the scanned environments, codes, like QR-codes, are placed on the objects. When they are scanned, the information stored in the codes is read by the camera sensors, as shown in Fig. 10.

QR stand for Quick Response and the codes belong to the classification of 2D matrix codes. They are constructed by white and black squares which represent the coded data in the binary system. By that, information, such as product name, size, weight, and others, can be saved in the code, but it also enables comparisons to entries in databases. They were originally developed to identify components and track them along production lines. Today they are used in a wide variety of applications, such as labeling goods for storage and logistics, tracking of parcels and flight baggage, as admission tickets or in marketing [23].

In this application, information about the components is stored in the QR-code. Figure 11 shows a highlighted component of a research environment with its corresponding properties. The properties field shown in the figure can be expanded by additional attributes, that are of interest to the user. The information on the dimensions allows to define intersections around the object, separating the individual components from the overall model and thus stores them individually in the digital twin. This will automate the process of the modularization requirement stated in section “Geometric models within the digital twin”. If changes are made to the physical model, the modified components can be automatically placed or exchanged using the position information. A separate scanning of the elements prior installation in the laboratory or on a rotation table is possible. The virtual object can then be automatically updated to the digital twin with the object of the same name or ID in the properties.

The information of the components properties, which can be supplemented by, for example, information on installation or conversion, dimensions or acquisition date, can be shown in the digital twins 3D models or VR applications by the user.

7 Actual geometry data in production

In the assembly and production of industrial companies, the concept of the digital twin is primarily understood and used for the virtual mapping of production processes. However, there are further fields of application for realistic geometric models in production, which are discussed in this section.

7.1 Actual geometry data for assembly and manufacturing planning

Cabin production is a complex decision-making process requiring intense interaction between designers and the engineering department. The engineering department is responsible for realizing and optimizing the production of the designed cabin. The digital thread is the essential link between high fidelity models, mathematical optimization, and human and robot interaction to improve efficiency and quality in aircraft cabin manufacturing. The designer’s iteration in the model causes the optimization process to dynamically change by adding, deleting, and modifying objectives, constraints, and other parameters. The digital twin simplifies the implementation of these changes and synchronizes with material, energy, and information flows from the designer’s department to the production hall.

However, during the design phase of product development, a detailed overview of the production facility with the exact placement of the machines and details such as pipelines or electrical cables is not considered. Therefore at the engineering department, 3D scans serve as the basis for realistic, virtual images of the production hall with all the above-mentioned details. For this purpose, most terrestrial laser scanners capture the entire production facility. The advantage of these scanners is the quick capture of large areas in a short time, whereby literature states the accuracy of this method at a maximum of 0.1 mm [15] within best condition. During the use in field, however, an accuracy in the millimeter range should be assumed. The result is a point cloud from which many details can be identified or detailed 3D models can be reconstructed.

At the industrial level, analytical analysis are first run for product evaluation. For instance, decision algorithms that extracts data from the products architecture are implemented, to plan and improve the assembly process. This section considers an example taken from a study by Markusheska et al. [24]. It describes the optimized scheduling and installation process of aircraft cabin components, such as sidewall panels, linings between sidewall panels, and ceiling panels, using a decision algorithm and validate the results with a kinematic simulation. The sequence planing of this assembly process is shown in Fig. 12. To identify individual assembly steps of each component and plan the execution of process steps, high detailed 3D models are required. It is difficult to determine the best and therefore fastest solution without a 3D kinematic simulation, which validates and verifies the identified installation process. The simulation demonstrates the analytical analysis realistically and intuitively and offers the possibility to adjust parameters like number of cabin components (two or three seats) instantaneously. It is also a sustainable and cost-effective visual feedback, as it reduces the resources required for new product development. The simulation helps to prevent mistakes and to validate the assembly process virtually, which supports the quality of the process planning results. It is not only important to have a sustainable product, but also sustainable design, development and manufacturing.

Based on realistic virtual images of scanned objects and environments, employees can carry out virtual trainings in VR applications, without their presence at the specific location, where the physical mock-up or the training surroundings are installed. It can either be a 3D scan of a whole physical mock-up or only specific parts, that are later added into an existing VR environment. In this way, digital copies are used to train the processes without having to build more physical mock-ups or to ship them to a different location. They can be used for the simulation of new and innovative assembly processes for components and its optimization in the virtual environment. The highly precise virtual images in the digital twin create a detailed and realistic feeling for the user. This scenario is shown in Fig. 13, using the example of the laboratory environment with a A319 mock-up.

In the context of quality analysis and assurance, 3D scan data has been used for a long time. For this purpose, comparisons are made between reference data and geometry data of the manufactured product, the actual data, as shown in Fig. 14 using an individual air outlet. To identify manufacturing related inaccuracies fast, actual geometry data is captured and automatically compared with data stored on the digital twin. This information allows to adjust production processes to eliminate or minimize the errors. Possible defects are wear on tools or molds for plastic parts. The location and position of the assembled components can also be checked.

7.2 Actual geometry data for assembly simulation

In addition to manual assembly, robot support is becoming increasingly relevant in production, not only in aviation. Approaches based on human-robot collaboration,Footnote 4 opens up new fields of applications, where work is made easier for the employee. To plan the assembly process with robots, virtual simulations are carried out. An extracted scene of such simulation can be seen in Fig. 15. For these simulations, the 3D models must be high-resolution and have to show many details, such as brackets or attachment points, in their exact positions. It is important, to not only reflect the position of the details, but also visualize their exact appearance. Figure 16 shows an example of the assembly of sidewall panel at the lower attachment point. The components are shown in their exact appearance and the insertion can be simulated. Besides these details, the exact location of non-rigid components and objects, such as the electrical system or isolation, can be identified. The assembly processes are designed accordingly to their visualization and identification in the 3D models [25].

8 Conclusion

This paper clarifies the use and benefits of actual geometry data of objects and systems within the digital twin and explains the process of digitizing physical objects. For this purpose, the importance of a central data system for linking the captured geometry models by 3D scanning is described. Due to the ongoing conversions of research environments, the actual geometry data in the digital twin has to be continuously updated. In order to not continually recapture the entire environment, requirements for the surface mesh are presented and methods for exchanging certain areas or components in the mesh are explained. For this purpose, further application areas of detailed actual geometry data are shown. For example, VR applications for virtual testing or preparation and training of assembly, as well as its simulation in robot-assisted production are shown.

Adding the geometry data to the digital thread and displaying it in the digital twin can make the planning and development time of new conversions in research environments more efficient, saving time and money. The development of modifications in actual geometry models enables identification of the transgressions of installation space in an early stage. The assembly of new elements can also be tested in the digital mock-ups. All this is possible without the time-consuming and costly construction of physical mock-ups, or iterative adjustments in the research environment itself.

The next steps will be to create a geometric image for the digital twin of the institute’s A319 cabin mock-up. For this purpose, further elements and details of the mock-up are to be 3D scanned and combined to form an entire model. The beginnings are shown in Fig. 17 with a comparison of a detailed view on the overhead storage compartment. For this purpose, the elements are recorded individually and the surface meshes are post-processed, such as the separation of individual components and the texture mapping, in order to highlight details. Entries should be created in CPACS for the elements in order to manage the data in a central data system, with access to it. By attaching the QR-codes, an automated identification and placement of geometry models in the digital twin should take place.

Notes

Digital Mock-Up.

National Aeronautics and Space Administration.

eXtensible Markup Language.

People and robots working in the same environment.

References

Deutsches Zentrum für Luft- und Raumfahrt: Programm und Strategie: Luftfahrtforschung im DLR. https://www.dlr.de/DE/forschung/luftfahrt/programm-strategie.html. Accessed 18 June 2021

German Aerospace Center (DLR e.V.): Proposal for a Helmholtz Research Program Aeronautics, Strategic Evaluation for the Fourth Period of Program-oriented Funding, 2021–2027 (2019)

Deutsches Zentrum für Luft- und Raumfahrt: DLR Leitkonzept: Das Virtuelle Produkt. https://www.dlr.de/content/de/artikel/luftfahrt/leitkonzepte/virtuellesprodukt.html. Accessed 18 June 2021

Schleich, B., Anwer, N., Mathieu, L., Wartzack, S.: Shaping the digital twin for design and production engineering. CIRP Ann 66(1), 141–144 (2017). https://doi.org/10.1016/j.cirp.2017.04.040

Zheng, Y., Yang, S., Cheng, H.: An application framework of digital twin and its case study. J. Ambient Intell. Hum. Comput. 10 (2019). https://doi.org/10.1007/s12652-018-0911-3

Qi, Q., Tao, F., Hu, T., Anwer, N., Liu, A., Wei, Y., Wang, L., Nee, A.Y.C.: Enabling technologies and tools for digital twin. J. Manuf. Syst. 58, 3–21 (2021). https://doi.org/10.1016/j.jmsy.2019.10.001. Digital Twin towards Smart Manufacturing and Industry 4.0

Boschert, S., Rosen, R.: Digital twin—the simulation aspect. In: Hehenberger, P., Bradley, D. (eds.) Mechatronic futures: challenges and solutions for mechatronic systems and their designers, pp. 59–74. Springer, Cham (2016). https://doi.org/10.1007/978-3-319-32156-1_5

Shafto, M., Conroy, M., Doyle, R., Glaessgen, E., Kemp, C., LeMoigne, J., Wang, L.: NASA Technology Roadmap: Modeling, Simulation, Information Technology and Processing Roadmap Technology Area 11 (2012)

Grieves, M.W.: Virtually intelligent product systems: digital and physical twins. In: Flumerfelt, S., Schwartz, K.G., Mavris, D., Briceno, S. (eds.) Complex Systems Engineering: Theory and Practice, vol. 411, pp. 175–200. American Institute of Aeronautics and Astronautics Inc, Reston (2019). https://doi.org/10.2514/5.9781624105654.0175.0200

Grégorio, J.-L., Lartigue, C., Thiébaut, F., Lebrun, R.: A digital twin-based approach for the management of geometrical deviations during assembly processes. J. Manuf. Syst. 58, 108–117 (2021). https://doi.org/10.1016/j.jmsy.2020.04.020

Alder, M., Moerland, E., Jepsen, J., Nagel, B.: Recent advances in establishing a common language for aircraft design with CPACS. In: Aerospace Europe Conference 2020 (2020). https://elib.dlr.de/134341/

Fuchs, M., Beckert, F., Biedermann, J., Nagel, B.: Experience of conceptual designs and system interactions for the aircraft cabin in virtual reality. Paper presented at the AIAA Aviation Forum, 2021 (2021). https://doi.org/10.2514/6.2021-2773

Walther, J.-N., Hesse, C., Biedermann, J., Nagel, B.: High fidelity digital cabin mock-up based on preliminary aircraft design data for virtual reality applications and beyond. Paper presented at the AIAA Aviation Forum, 2021 (2021). https://doi.org/10.2514/6.2021-2775

Walther, J.-N., Kocacan, B., Hesse, C., Gindorf, A., Nagel, B.: Automatic cabin virtualization based on preliminary aircraft design data. CEAS Aeronaut. J. (2022). https://doi.org/10.1007/s13272-021-00568-w

Schuth, M., Buerakov, W.: Handbuch Optische Messtechnik. Carl-Hanser-Verlag, München (2017)

Bauer, N., Bichmann, S.: Handbuch zur Industriellen Bildverarbeitung - Qualitätssicherung in der Praxis. Fraunhofer IRB Verlag, Stuttgart (2008)

Rauscher, F., Biedermann, J., Gindorf, A., Meller, F., Nagel, B.: Permanente Geometrische Digitalisierung der Flugzeugkabine zur Änderungsnachverfolgung. Paper presented at the German Aerospace Conference 2020, German Aerospace Society Lilienthal-Oberth e.V., 1–3 September 2020 (2020). https://doi.org/10.25967/530008

Lo, D.S.H.: Finite Element Mesh Generation. Taylor & Francis Group, London (2014)

GOM GmbH: GOM ATOS Professional. http://www.gom.de

Fuchs, M., Beckert, F., Biedermann, J., Nagel, B.: A collaborative knowledge-based method for the interactive development of cabin systems in virtual reality. Comput. Ind. 136 (2022). https://doi.org/10.1016/j.compind.2021.103590

De Crescenzio, F., Bagassi, S., Asfaux, S., Lawson, N.: Human centred design and evaluation of cabin interiors for business jet aircraft in virtual reality. Int. J. Interact. Des. Manuf. 13 (2019). https://doi.org/10.1007/s12008-019-00565-8

De Crescenzio, F., Bagassi, S., Starita, F.: Preliminary user centred evaluation of regional aircraft cabin interiors in virtual reality. Sci. Rep. 11 (2021). https://doi.org/10.1038/s41598-021-89098-3

Uitz, I., Harnisch, M.: Der QR-Code—aktuelle Entwicklungen und Anwendungsbereiche. Informatik-Spektrum 35 (2012). https://doi.org/10.1007/s00287-012-0608-5

Markusheska, N., Srinivasan, V., Walther, J.-N., Gindorf, A., Biedermann, J., Meller, F., Nagel, B.: Implementing a system architecture model for automated aircraft cabin assembly processes. CEAS Aeronaut. J. (2022). https://doi.org/10.1007/s13272-022-00582-6

Srinivasan, V., Markusheska, N., Walther, J.-N., Gindorf, A., Hesse, C., Biedermann, J., Meller, F., Nagel, B.: Autonomous control of an industiral robot based on formalized process description for cabin assembly. Paper presented at the German Aerospace Conference 2020, German Aerospace Society Lilienthal-Oberth e.V., 1–3 September 2020 (2020). https://doi.org/10.25967/530315

Funding

Open Access funding enabled and organized by Projekt DEAL. No funding was received for conducting this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rauscher, F., Fuchs, M., Ghanjaoui, Y. et al. Permanently updated 3D-model of actual geometries of research environments. CEAS Aeronaut J 14, 739–751 (2023). https://doi.org/10.1007/s13272-023-00661-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13272-023-00661-2