Abstract

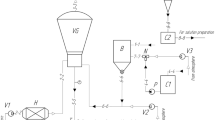

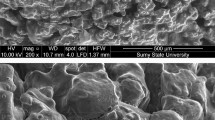

Current paper substantiates the possibility of obtaining porous ammonium nitrate (PAN) granules in apparatuses with intensive hydrodynamics and directional movement of the fluidized bed of granules. We developed a theoretical model for calculating the hydrodynamic performance of vortex granulators allowing to conduct experimental studies of the nanoporous structure of PAN granules. Based on this model, it is possible to determine the residence time of PAN granules in the device workspace. Together with the data on the kinetics of heat-mass exchange in the process of obtaining PAN granules, it seems possible to select the optimal modes of proper humidification and heat treatment of granules. We further confirm the optimality of these modes by the results of experimental studies of the PAN granules samples’ structure. PAN granules obtained under optimal hydrodynamic conditions possess sufficient specific properties that make it possible to successfully use them as a component of ANFO industrial explosive.

Similar content being viewed by others

Availability of data and materials

Not applicable.

Code availability

Not applicable.

References

Ali K (2015) Design of a Spray Tower for the Granulation of Melt. Al-Nahrain J Eng Sci 18(1):111–117

Artyukhov A, Artyukhova N, Krmela J, Krmelova V (2020) Complex designing of granulation units with application of computer and software modeling: Case “Vortex granulator.” IOP Conf Series Mater Sci Eng 776(1):012016

Artyukhov AE, Sklabinskiy VI (2013) Experimental and industrial implementation of porous ammonium nitrate producing process in vortex granulators. Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu 6:42–48

Artyukhov AE, Fursa AS, Moskalenko KV (2015) Classification and separation of granules in vortex granulators. Chem Pet Eng 51(5–6):311–318

Artyukhova NO, Krmela J, Krmelova V (2020a) Final drying of ammonium nitrate granules with nanoporous structure in multistage shelf apparatuses: Embodiment and technological parameters. Nanosistemi, Nanomateriali, Nanotehnologii 18(2):421–436

Artyukhova N, Krmela J, Krmelova V (2020b). Quality Indicators of Ammonium Nitrate with Nanoporous Surface Structure: Final Drying Stage. In: Proceedings of the 2020b IEEE 10th International Conference on "Nanomaterials: Applications and Properties", NAP 2020b, 9309583.

Artyukhova NO, Krmela J, Krmelova V (2021) Theoretical basics of final drying of ammonium nitrate with nanoporous structure in gravitational shelf dryers. Springer Proc Phys 263:253–268

Biessikirski A, Kuterasiński L, Dworzak M, Pyra J, Twardosz M (2019) Comparison of structure, morphology, and topography of fertilizer-based explosives applied in the mining industry. Microchem J 144:39–44

Buczkowski D, Zygmunt B (2011) Detonation properties of mixtures of ammonium nitrate based fertilizers and fuels. Central Eur J Energ Mater 8(2):99–106

Chanson H (2014) Applied Hydrodynamics. CRC Press, An Introduction

Crespo Da Silva MRM (2016) Fundamentals of Dynamics and Analysis of Motion. Dover Pubn Inc.

Erode GM (2013) Ammonium Nitrate Explosives for Civil Applications: Slurries, Emulsions and Ammonium Nitrate Fuel Oils. Wiley-VCH Verlag & Co, Weinheim

Gezerman AO (2020) Mathematical modeling for prilling processes in ammonium nitrate production. Eng Rep 2:e12173

Haiyang S, Qiang T, Cameron-Alexander HP, Lin X, Kun Q, Jian L (2020) Nanoporous core@shell particles: Design, preparation, applications in bioadsorption and biocatalysis. Nano Today 31:100834

Hassankhani-Majd Z, Anbia M (2021) Comparative study of synthesis parameters of nanoporous titania particles to improve structural properties and photocatalytic activity. ChemistrySelect 6(47):13488–13498

Muralidhar P, Bhargav E, Sowmya C (2016) Novel techniques of granulation: a review. Int Res J Pharm 7(10):8–13

Naoki S, Makoto O (2005) Growth of nanoporous silica spherical particles by the Stöber Method Combined with Supramolecular Templating Approach. Bull Chem Soc Jpn 78(6):1154–1159

Obodiak V, Artyukhova N, Artyukhov A (2020) Calculation of the residence time of dispersed phase in sectioned devices: Theoretical basics and software implementation. Advances in Design, Simulation and Manufacturing II. DSMIE 2019. Lecture Notes in Mechanical Engineering, pp 813–820.

Polyanin AD, Kutepov AM, Vyazmin AV, Kazenin DA (2019) Hydrodynamics, Mass and Heat Transfer in Chemical Engineering. Taylor & Francis Ltd.

Salman AD, Hounslow MJ, Seville JPK (2006) Granulation. Elsevier Science Ltd, Amsterdam

Srinivasan S (2015) Granulation techniques and technologies: recent progresses. Bioimpacts 5(1):55–63

Stahl H (2004) Comparing Different Granulation Techniques. Pharm Technol Eur 16(11):23–33

Van Kuringen HPC, Mulder DJ, Beltran E, Broer DJ, Schenning APHJ (2016) Nanoporous polymer particles made by suspension polymerization: spontaneous symmetry breaking in hydrogen bonded smectic liquid crystalline droplets and high adsorption characteristics. Polym Chem 7:4712–4716

Wang LL, Wu GZ, Li D (2014) Factors affecting urea granulation tower simplification of ventilation. Appl Mech Mater 501–504:2293–2296

Funding

This research work had been supported by the Ministry of Science and Education of Ukraine under the project «Technological bases of multistage convective drying in small-sized devices with utilization and heat recovery units», project No. 0120U100476, by the Cultural and Educational Grant Agency of the Slovak Republic (KEGA), Project No. 003TnUAD-4/2022.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethics approval

Not applicable.

Consent to participate.

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Artyukhov, A., Volk, I. & Krmela, J. Production of ammonium nitrate with nanoporous structure in devices with active hydrodynamics. Appl Nanosci 13, 4921–4940 (2023). https://doi.org/10.1007/s13204-022-02650-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-022-02650-z