Abstract

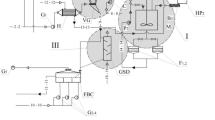

The article studies the final drying stage in the porous ammonium nitrate (PAN) production. Based on the analysis of the ammonium nitrate, authors propose to improve the scheme for the PAN production by introducing the final drying stage after humidification and heat treatment of PAN in a vortex granulator. The analysis of literature proposes a new design for the drying unit—a gravitational shelf dryer with vertical sectioning of the workspace. There is a theoretical and experimental description of the PAN granule heating and dehydration processes in a dryer. The studying results of the PAN granule surface morphology after the final drying stage are presented. Comparative indicators of the quality of PAN granules, obtained with using and without using the final drying stage, are given.

Similar content being viewed by others

References

Alaathar I, Hartge E-U, Heinrich S, Werther J (2013) Modeling and flowsheet simulation of continuous fluidized bed dryers. Powder Technol 238:132–141

Anderson J-O (2014) Energy and resource efficiency in convective drying systems in the process industry (doctoral thesis). Luleå University of Technology

Artyukhov A, Artyukhova N (2018) Utilization of dust and ammonia from exhaust gases: new solutions for dryers with different types of fluidized bed. J Environ Health Sci Eng 16:193–204

Artyukhov AE, Artyukhova NO (2019) Technology and the main technological equipment of the process to obtain N4HNO3 with Nanoporous structure. Springer Proc Phys 221:585–594

Artyukhov AE, Sklabinskiy VI (2013) Experimental and industrial implementation of porous ammonium nitrate producing process in vortex granulators. Naukovyi Visnyk Natsionalnoho Hirnychoho Univ 6:42–48

Artyukhov A, Obodiak V, Boiko P, Rossi P (2017) Computer modeling of hydrodynamic and heat-mass transfer processes in the vortex type granulation devices. CEUR Workshop Proc 1844:33–47

Artyukhov A, Artyukhova N, Ivaniia A (2018) Creation of software for constructive calculation of devices with active hydrodynamics. In: 14th international conference on advanced trends in radioelectronics, telecommunications and computer engineering, TCSET 2018—Proceedings 2018, pp 139–142

Artyukhov A, Artyukhova N, Krmela J, Krmelova V (2020) Complex designing of granulation units with application of computer and software modeling: Case “Vortex granulator.” IOP Conf Ser Mater Sci Eng 776(1):012016

Artyukhova NO (2020) Morphological features of the nanoporous structure in the ammonium nitrate granules at the final drying stage in multistage devices. J Nano Electron Phys 12:4

Artyukhova NO, Krmela J (2019) Nanoporous structure of the ammonium nitrate granules at the final drying: the effect of the dryer operation mode. J Nano Electron Phys 11:4

Barrozo MAS, Mujumdar A, Freire JT (2014) Air-drying of seeds: a review. Drying Technol 32(10):1127–1141

Biessikirski A, Kuterasiński L, Dworzak M, Pyra J, Twardosz M (2019) Comparison of structure, morphology, and topography of fertilizer-based explosives applied in the mining industry. Microchem J 144:39–44

Chen XD, Putranto A (2013) Modelling drying processes. A reaction engineering approach. Cambridge University Press, Cambridge

Dincer I, Zamfirescu C (2016) Drying phenomena: theory and applications. Wiley, Hoboken

Erode GM (2013) Ammonium nitrate explosives for civil applications: slurries, emulsions and ammonium nitrate fuel oils. Wiley-VCH Verlag & Co, Weinheim

Faghri A, Zhang Y, Howell J (2010) Advanced heat and mass transfer. Global Digital Press, Kanpur

Janssen TJ (2011) Explosive materials: classification, composition and properties. Nova Science Publishers Inc, New York

Jittanit W, Srzednicki G, Driscoll RH (2013) Comparison between fluidized bed and spouted bed drying for seeds. Drying Technol 31:1

Kemp IC, Bahu RE (1995) A new algorithm for dryer selection. Drying Technol 13:5–7

Kudra T, Mujumdar AS (2002) Advanced drying technologies. Marcel Dekker, New York

Luikov A (1968) Analytical heat diffusion theory. Academic Press, USA

Martin G, Barbour W (2003) Industrial nitrogen compounds and explosives, chemical manufacture and analysis. Watchmaker Publishing, Gearhart

Motevali A, Minaei S, Banakar A, Ghobadian B, Khoshtaghaza MH (2014) Comparison of energy parameters in various dryers. Energy Convers Manage 87:711–725

Mujumdar AS (2006) Handbook of industrial drying. Taylor & Francis Group, Boca Raton

Obodiak V, Artyukhova N, Artyukhov A (2020) Calculation of the residence time of dispersed phase in sectioned devices: theoretical basics and software implementation. In: Advances in design, simulation and manufacturing II. DSMIE 2019. Lecture Notes in Mechanical Engineering, pp 813–820

Pabis S, Jayas DS, Cenkowski S (1998) Grain drying: theory and practice. Wiley, Hoboken

Sazhin B, Sazhin V (2007) Scientific principles of drying technology. Begell House Inc, New York, Connecticut, Wallingford (U.K.)

Setty YP, Kumar GV, Srinivas G (2011) Drying of solids in a circulating fluidized bed. IUP J Chem Eng 3(4):7–16

Torrecilla JS, Aragon JM, Palancar MC (2006) Improvement of fluidized-bed dryers for drying solid waste (olive pomace) in olive oil mills. Eur J Lipid Sci Technol 108(11):913–924

Van’t Land CM (2012) Drying in the process industry. John Wiley, Hoboken

Viktorov SD, Frantov AE, Lapikov IN, Andreev VV, Starshinov AV (2016) Effect of the microstructure of ammonium nitrate granules on the detonability of composite propellants based on it. Combust Explos Shock Waves 52(6):727–731

Wan Daud WR (2008) Fluidized bed dryers—recent advances. Adv Powder Technol 19(5):403–418

Yukhymenko M, Ostroha R, Artyukhov A, Bocko J (2020) Effect of temperature on formation of nanoporous structure of granule shell in technology of obtaining organo-mineral fertilizers. Nanooptics and photonics, nanochemistry and nanobiotechnology, and their applications. Springer Proc Phys 247:159–169

Acknowledgements

This research work had been supported by the Ministry of Science and Education of Ukraine under the project «Technological bases of multistage convective drying in small-sized devices with utilization and heat recovery units», project No. 0120U100476, by the Cultural and Educational Grant Agency of the Slovak Republic (KEGA), project No. KEGA 002TnUAD-4/2019 and by the project “Advancement and support of R&D for “Centre for diagnostics and quality testing of materials” in the domains of the RIS3 SK specialization“, code NFP313011W442.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Artyukhova, N.O., Krmela, J. & Krmelova, V. Experimental–industrial implementation of the technology for producing nanoporous layers on ammonium nitrate: the final drying stage in multistage devices. Appl Nanosci 12, 1235–1244 (2022). https://doi.org/10.1007/s13204-021-02075-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-021-02075-0