Abstract

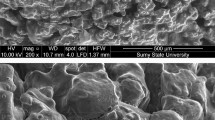

The article describes a new technology for the formation of nanoporous layers on the ammonium nitrate granule as a component of an industrial explosive. The main methods of porous ammonium nitrate (PAN) production are defined. The authors substantiate the effective implementation of the combined method of humidification and heat treatment. It is proposed to use a new granulator (vortex granulator) for the PAN obtaining method using humidification followed by heat treatment. The necessity to form a developed network of nanopores on the PAN granule surface is proved. A theoretical model describing the kinetics of humidifier’s film applying to the granule surface for subsequent drying and the nanoporous coating formation is presented. The phase composition of various samples of ammonium nitrate is studied. It is shown that all PAN samples do not undergo chemical transformations. The morphology of the PAN granule surface is studied to determine the porous structure nature. The studying results of the effect made by the type of humidifier, the heat treatment time and the number of heat treatment cycles on the PAN quality are demonstrated.

Similar content being viewed by others

References

Artyukhov A, Artyukhova N (2018) Utilization of dust and ammonia from exhaust gases: new solutions for dryers with different types of fluidized bed. J Environ Health Sci Eng 16:193–204

Artyukhov AE, Artyukhova NO (2019) Technology and the main technological equipment of the process to obtain N4HNO3 with nanoporous structure. Springer Proc Phys 221:585–594

Artyukhov AE, Sklabinskiy VI (2013) Experimental and industrial implementation of porous ammonium nitrate producing process in vortex granulators. Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu 6:42–48

Artyukhov AE, Sklabinskyi VI (2017) Investigation of the temperature field of coolant in the installations for obtaining 3d nanostructured porous surface layer on the granules of ammonium nitrate. J Nano Electronic Phys 9(1):01015

Artyukhov AE, Fursa AS, Moskalenko KV (2015) Classification and separation of granules in vortex granulators. Chem Petrol Eng 51(5–6):311–318

Artyukhov A, Artyukhova N, Ivaniia A, Gabrusenoks J (2017) Multilayer modified NH4NO3 granules with 3D nanoporous structure: effect of the heat treatment regime on the structure of macro and mezopores. Proc IEEE International Young Scientists Forum on Applied Physics and Engineering (YSF-2017) 315–318

Artyukhov A, Artyukhova N, Krmela J, Krmelova V (2020) Complex designing of granulation units with application of computer and software modeling: case “vortex granulator.” Mater Sci Eng 776(1):012016

Artyukhova NO (2020) Morphological features of the nanoporous structure in the ammonium nitrate granules at the final drying stage in multistage devices. J Nano Electron Phys 12(4):04036

Artyukhova NO, Krmela J (2019) Nanoporous structure of the ammonium nitrate granules at the final drying: the effect of the dryer operation mode. J Nano Electron Phys 11(4):04006

Biessikirski A, Kuterasiński L, Dworzak M, Pyra J, Twardosz M (2019) Comparison of structure, morphology, and topography of fertilizer-based explosives applied in the mining industry. Microchem J 144:39–44

Buczkowski D, Zygmunt B (2011) Detonation properties of mixtures of ammonium nitrate based fertilizers and fuels. Centr Eur J Energetic Mater 8(2):99–106

Erode GM (2013) Ammonium nitrate explosives for civil applications: slurries, emulsions and ammonium nitrate fuel oils. Wiley-VCH Verlag and Co, Weinheim

Gupta SK, Singhvi IJ, Shirsat MK, Karwani G, Agarwal A (2011) Microencapsulation techniques and its application in pharmaceutical. Asian J Pharm Sci Clin Res 1(3):67–77

Hu X, Cunningham JC, Winstead D (2008) Study growth kinetics in fluidized bed granulation with at-line FBRM. Int J Pharm 347(1–2):54–61

Jackson SI (2017) The dependence of ammonium-nitrate fuel-oil (ANFO) detonation on confinement. Proc Combust Inst 36(2):2791–2798

Janssen TJ (2011) Explosive materials: classification, composition and properties. Nova Science Publishers Inc

Kubota N (2015) Propellants and explosives: thermochemical aspects of combustion, 3rd edn. Wiley-VCH Verlag and Co, Weinheim

Litster J, Ennis B (2004) The science and engineering of granulation processes. Springer-Science+Business Media

Martin G, Barbour W (2003) Industrial nitrogen compounds and explosives, chemical manufacture and analysis. Watchmaker Publishing

Muralidhar P, Bhargav E, Sowmya C (2016) Novel techniques of granulation: a review. Int Res J Pharm 7(10):8–13

Obodiak V, Artyukhova N, Artyukhov A (2020) Calculation of the residence time of dispersed phase in sectioned devices: theoretical basics and software implementation. Advances in design, simulation and manufacturing II. DSMIE 2019. Lecture Notes in Mechanical Engineering

Parikh D (2009) Handbook of pharmaceutical granulation technology. Informa Healthcare

Pat. № 102093146, CN (2011) Microporous granular ammonium nitrate and preparation methods thereof

Pat. № 102173968, CN (2011) Production method of porous granular ammonium nitrate

Pat. № 103896695, CN (2014) Microporous pelletal ammonium nitrate and preparation method thereof

Pat. № 104311372, CN (2016) Porous ammonium nitrate production caking ammonium nitrate recycling apparatus and method of use

Pat. № 2004–256365, JP (2004) Method of manufacturing porous granular ammonium nitrate

Pat. № 2005–350276, JP (2005) Method for producing porous granular ammonium nitrate

Pat. № 204237724, CN (2015): Recycling device for caked ammonium nitrate during production of porous ammonium nitrate

Pat. № 204384319, CN (2015) Device for producing porous ammonium nitrate and industrial ammonium nitrate

Pat. № 2093727, CA (2004) Hardened porous ammonium nitrate

Pat. № 2118074, CA (2002) Porous prilled ammonium nitrate

Pat. № 2221717, CA (2005): Procedure and installation for the manufacture of porous ammonium nitrate

Pat. № 2452719, RU (2012) Device for production of porous granulated ammonium nitrate and method for production of porous granulated ammonium nitrate

Pat. № 2599170, RU (2016): Method of producing porous granulated ammonium nitrate

Pat. № 2600061, RU (2016) Method of porous granulated ammonium nitrate producing and device for its implementation

Pat. № 391973, PL (2012) Method for producing granulated porous ammonium nitrate

Patel P, Telange D, Sharma N (2011) Comparison of different granulation techniques for lactose monohydrate. Int J Pharm Sci Drug Res 3:222–225

Saikh MA (2013) A technical note on granulation technology: a way to optimise granules. Int J Pharm Sci Rev Res 4:55–67

Shanmugam S (2015) Granulation techniques and technologies: recent progresses. Bioimpacts 5(1):55–63

Solanki HK, Basuri T, Thakkar JH, Patel CA (2010) Recent advances in granulation technology. Int J Pharm Sci Rev Res 5(3):48–54

Srinivasan S (2015) Granulation techniques and technologies: recent progresses. Bioimpacts 5(1):55–63

Stahl H (2004) Comparing different granulation techniques. Pharm Technol Eur 16(11):24–33

Stahl H (2010) Comparing granulation methods. GEA Pharma Systems, Hürth

Viktorov SD, Frantov AE, Lapikov IN, Andreev VV, Starshinov AV (2016) Effect of the microstructure of ammonium nitrate granules on the detonability of composite propellants based on it. Combust Explos Shock Waves 52(6):727–731

Warren BE (1990) X-ray Diffraction. Dover, New York

Yukhymenko M, Ostroha R, Artyukhov A, Bocko J (2020) Effect of temperature on formation of nanoporous structure of granule shell in technology of obtaining organo-mineral fertilizers. Nanooptics and photonics, nanochemistry and nanobiotechnology, and their applications. Springer Proc Phys 247:159–169

Acknowledgements

This research work had been supported by the Ministry of Science and Education of Ukraine under the project «Technological bases of multistage convective drying in small-sized devices with utilization and heat recovery units», Project No. 0120U100476, by the Cultural and Educational Grant Agency of the Slovak Republic (KEGA), Project No. KEGA 002TnUAD-4/2019 and by the project “Advancement and support of R and D for “Centre for diagnostics and quality testing of materials” in the domains of the RIS3 SK specialization“, code NFP313011W442.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Artyukhov, A.E., Artyukhova, N.O., Krmela, J. et al. Ammonium nitrate with nanoporous structure: production methods, phase composition and morphological features of the surface. Appl Nanosci 12, 1213–1226 (2022). https://doi.org/10.1007/s13204-021-01800-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-021-01800-z