Abstract

In this study, we attempted to develop a cost-effective activated carbon (AC) from local tea waste. AC was synthesized via a pyrolysis process and used it to treat tannery waste-water. A methylene blue adsorption test was then conducted to determine the highest adsorption capability of synthesized AC. The crystal structure and microstructure of AC were examined by X-ray diffraction (XRD) and scanning electron microscopy (SEM). An average crystallite size of 15 nm was measured from XRD while sub-nano meter scale particle size was confirmed from SEM images. Produced AC was then used for the treatment of industrial waste-water that results in a reduction of about 89–97% chromium from water. In addition, other physical parameters (Biochemical oxygen demand chemical oxygen demand turbidity, conductivity, Cr content) were also significantly reduced from the waste-water. These results suggest the use of AC for the treatment of industrial as well as domestic waste-water.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Activated charcoal is a type of carbon as processed having small, low-volume pores that results increased surface area for adsorption and/or chemical reaction (Kovalova et al. 2013). The high extent of porosity results a very large surface area as for example one gram of AC has an area of more than 3,000 m2 (32,000 sq. ft.) (Romanos et al. 2011). AC is by far the most widely employed adsorbent (Putra et al. 2009), which could be used to air decontamination (Kostoglou et al. 2017), caffeine removal (Melo et al. 2020), purification of gold (Chen et al. 2020), extract metal, water purification (Melo et al. 2020), medication, iste treatment, LICsystem manufacturing (Sun et al. 2017), air purification in face masks and inhalators (Kwong et al. 2021) and many other technological applications. It is also broadly used during tertiary adsorption of toxins from waste-water (Gupta et al. 2011). The AC is more effective than incandescent carbon that is more effective than the cross-linked polymers, organic carbonaceous materials which has been used for long time in water purification system (Morin-Crini and Crini 2013; Meo et al. 2014).Chromium and its compounds are commonly used in the tannery and footwear industries that are harmful to the bio-system (Viscardi et al. 2020). As per the US Environmental Protection Agency (US-EPA) the threshold limit of Chromium in drinking water in US is 0.1 mg/liter (USEPA, Chromium in Drinking Water. 2017). The maximum permitted limit of Cr in the ground water and sewage system is 0.5 mg per liter and 2.0 mg per liter, respectively, depending on the methods of treatment, processing and country’s regulatory system (Mohan et al. 2006). Several toxicological reports indicate that the daily intake of Cr at an excess rate might show carcinogenic, mutagenic and teratogenic effect on human health (Islam 2021). Furthermore, excess amount of Cr in drinking water may cause several harmful diseases such as skin irritation, pain, nagging, vomiting, extreme diarrhea and even lung cancer on prolonged exposure (Islam 2021). So, the involvement of Cr in the waste matter is the serious concerned to tanning industry that utilizing chromium tanning process. Chemical precipitation techniques are usually used to remove Cr from the waste matter but the solid chromium-bearing waste is formed in these processes that lead to generate secondary pollutants. There are also other available methods such as membrane filtration and ion exchange but they are not practical because of their higher operating cost. Recently, graphene foam/TiO2 nano sheet hybrid is also used in this perspective but the process is not for heavy duty application yet (Fu and Wang 2011). For this reason, the AC adsorbent is generally used in extraction processes of heavy metals from wastewater (Yang et al. 2013). The adsorption efficiency of AC dependent on the area for surface pores present in the structure, surface composition and also the existence of responsive groups on the surface of the pores (Tan et al. 2008). Many analytical techniques have been established and implemented to determine maximum adsorption capacity or effectiveness of adsorbent. In this study adsorption of methylene blue by synthesized AC from tea iste is measured for this purpose.

The production and performance study of AC from agricultural waste is reported in literatures such as from coconut husk (Tan et al. 2008), seed coat of rubber plant (Hameed and Daud 2008; Rengaraj et al. 2002), bamboo (Hameed et al. 2007), sunflower seed hull (Thinakaran et al. 2008), passion fruit shell (Karagozoglu et al. 2007), bagasses (Juang et al. 2002), agricultural waste material (Singh et al. 2008), sweet sorghum bagasse (Wright et al. 2017), corncob (Tseng and Tseng 2005), saw dusts (Ismadji et al. 2005) and tea waste (Auta and Hameed 2011; Bulut and Aydın 2006). Though, AC has already been prepared using chemical methods but no report is available on the synthesis of AC from tea waste using pyrolysis method yet. Thus, the effect pyrolysis method on the production of AC from tea waste and the consequent characterizations are performed is presented in this paper. Furthermore, the AC has been used to treat waste-water obtained from tannery industries as well.

Materials and method

Preparation of activated carbon from tea waste

The waste tea is initially cleaned and crushed and sieved to separate larger particle size of 0.5 mm. Crusted tea waste is mixed with KOH solution in a ratio of 1:1.5. After 2 h of incubation with continuous stirring, the sample is collected after washed for 2 times with deionized water. Then sample is dried at 85 °C for 6 h.

Dried sample is then placed in the pyrolyzer under inert condition (presence of N2 gas) and pyrolyzed at various temperatures ranging from 200–1000 °C with the heating rate of 20 °C/min and held at those temperatures for 2 h. After the cooling to the room temperature, the sample is decanted with deionized water for 2 times and resulting sample (activated carbon) is allowed to cool under the same vacuum condition (Ismadji et al. 2005).

Measurement of adsorption properties of activated carbon

The pyrolyzed activated carbon samples at various temperatures (200–1000 °C) were further subjected to judge its adsorption ability. In order to do this a stock solution of 1000 mg per liter was prepared where 1 g of methylene blue (MB) was dissolved in 1 litter of deionized water. The batch mode was used for the adsorption of MB. The tests of the batches were carried out in 250 ml conical flasks with 100 ml, 50 ppm MB solution. The solution was further stayed for 12 h (reaction time) at a steady speed of 200 rpm stir rate with AC of about 0.25 g. The prepared mixture was then filtered with filter paper (41 Whatman) and filtrate was stored at 4 °C before analysis. This concentration of MB was determined by UV spectroscopy at a wavelength of 662 nm before and after adsorption (Bulut and Aydın 2006).

Waste water treatment procedure

The AC obtained by pyrolysis technique at 800 °C was found to exhibit best adsorption properties (among all the batches of prepared AC) that was further used for industrial waste-water (collected from different tanneries) treatment. For this purpose, 100 ml of waste-water samples were taken into 250 ml conical flask and treated with 2 gm of AC for 2 h and shaken at a constant agitation speed of 200 rpm. After complete adsorption of 2 h, the solution was filtered with 41 Whatman filter paper and filtrate was stored at 4 °C before analysis. The initial concentration as well as final concentration of chromium in waste-water was then measured by atomic absorption spectroscopic process (Gupta and Ali 2004).

Results and discussion

Evaluation of activated carbon characteristics

MB adsorption test was performed for determination of maximum adsorption capacity of AC produced at various temperatures ranging from 200 to 1000 °C (Table 1). The AC prepared at 800 °C is found to show highest MB adsorption capacity. The adsorption ability was found to get higher with rise in temperature from 200 to 1000 °C. The adsorption ability is slightly increased after 800 °C, indicating insignificant effect of temperature as can be seen in Table 2 and Fig. 1. For this reason, the AC produced at 800 °C was used for further investigation on the batch studies for chromium removal from tannery waste-water.

Field emission scanning electron microscopy (FESEM) study of activated carbon characteristics

Pyrolyzed (800 °C) activated carbon sample is attached to stubs with double adhesive coated carbon tabs. The AC sample is then sputtered with gold–palladium in a Denton Desk II coated unit. The FESEM images of the sample are captured at 2650 × 1920 pixel resolution displayed in Fig. 2. The fragile and grainy surface morphology (heterogeneous) with nanoscale pores on the surface in various sizes are exhibited by the FESEM images. The presence of pores in the surface is due to removal of volatile organic during pyrolysis process. However, some irregular sized particles were also observed. Most of the particles are within micro and nanometer scale as confirmed by zoomed images atx50000 magnifications. This porous nature of activated carbon increase overall surface area leads higher adsorption capacity.

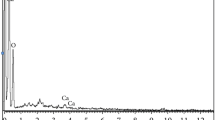

X-ray diffraction (XRD) study of activated carbon

Synthesized Activated Carbons (from tea waste) by pyrolysis at 800 °C were crystallographically characterized x-ray diffraction analysis and shown in Fig. 3. X-ray diffraction is the simplest and two-dimensional the most efficient in terms of measuring crystal size. Detectors are used to collect these diffractions and several computer programs have been developed to analyze the single-crystal diffraction data collected with these detectors (Bulut and Aydın 2006). The amount of x-rays diffracted (at each 2θ angle) is recorded by 3D pixel detector. Where 2θ is the incident angle with respect to the sample plane. The intensities of x-ray are generally recorded as “counts”.

Applying the Bragg’s equation, the inter-planner spacing (d) is ascertained as following:

The crystallite particle size has been determined from the half-width of the diffraction peak using the Scherrer’s equation:

where ‘θ’ is called as ‘Bragg angle of diffraction’, ‘λ’ is wavelength of Cu-Kα radiation’, ‘B’ is mentioned as ‘the full-width at half maximum (FWHM) of the peak & ‘K’ entitled as ‘shape factor’. The lattice dimension is the product of ‘shape factor’, ‘K’. The value of ‘K’ is 0.94 and wavelength of radiation, ‘λ’ = 1.5418 are used to calculating crystallite size, ‘L’ value and inter-planner spacing, ‘d’.

In the experiment, the highest peak value is obtained at 2θ = 26.96832 with intensity of 91,035 counts. Rietveld refinement is performed and the obtained results are presented in Table 3. The average diameter of the particle calculated using Scherrer’s formula based on maximum intensity peak in the XRD pattern is around 15.17 nm shown in Table 3. On the other hand, FESEM (Fig. 2) indicates a wide distribution of particle size ranging from 20 to 200 nm and exhibited only irregular granular feature.

Efficiency on chromium removal

The obtained AC is used to clean tannery waste-water. The tannery waste-water is collected from five different tanneries of Dhaka city. It is found that the AC can be removed 89–97% chromium of initial concentration from waste-water (Table 4). From Fig. 4 it is found that increasing initial concentration of chromium, the removal percentage is reduced with an increase of adsorption capacity from 35.44 to 58.53. This is due to higher chromium content in solution, leads increased contact between adsorbent (AC) and metal ion, consequently greater efficiency.

Isothermal studies

For the purpose of getting a deeper knowledge of adsorption mechanism, the isotherms of equilibrium were experimented. Adsorption equilibrium can be explained by several hypotheses (Gupta and Ali 2004). In this present study, two different isotherm equations, Langmuir and Freundlich, were used (Gupta and Ali 2004).

The Langmuir adsorption isotherm explain a homogeneous surface based on the following assumptions: the activity same for all adsorption sites, the activity of any adsorption is not affected by a nearest adsorption sties and adsorption mechanism is same for all adsorption sites in which the maximum adsorption can form a monolayer (Gupta and Ali 2004).

The Freundlich isotherm describes the equilibrium on heterogeneous surfaces and does not assume monolayer capacity (Freundlich 1906; Nadeem et al. 2009). The adsorption data representation according to the Freundlich equation takes the form:

where ‘Ce’ is called ‘ equilibrium concentration of the Cr ion in mg/l’, ‘Qe’ is entitled as ‘amount of Cr adsorbed at equilibrium in mg/g’ and ‘KF’ and ‘n’ are called ‘Freundlich constants’, which indicates ‘the adsorption capacity’ and ‘the adsorption intensity’, KL is a ‘Langmuir constant (L mg−1)’ related to the adsorption energy.

We found that Freundlich isotherm produces a best fit due to more linearity shown in Fig. 5. This means that adsorption of chromium on the surface of AC is heterogeneous and does not assume monolayer capacity.

Physical parameters check

The waste-water as a sample is collected from the tannery industry where nine separate places were chosen for sample collection. Measurement of in situ data such as pH, conductivity, and turbidity from each sampling section is taken twice, and average value is given in Table 5. Analysis is performed in laboratory for parameters like (Biochemical oxygen demand (BOD), chemical oxygen demand (COD), Cl−. The obtained findings of analysis for water quality index can be seen in Table 5.

As per our knowledge, pH, BOD, COD, Cl−, surface water conductivity ought to be 5.5–9 [34], 5 mg/l [35], 40 mg/l [35], 250 ppm [36], 0.1 S/m [37]. Observing from Table 5 that larger values of pH values is found for all water samples except deliming and bating waste-water before treatment. Therefore, discharging of these waste-waters in to the environment would be dangerous. After treatment using AC the pH values presented in Table were found within reasonable limits (5.05–7.48).The obtained concentration of COD and BOD for the all water samples were also reasonably high compared to the recommended values by WHO for use in irrigation and agriculture perspective. The waste-water is being treated by AC provided by activated H3PO4 in a batch mode module at 25 °C and the concentrations of COD and BOD have been measured for pre and post treatment as seen in Table5. The obtained results (COD and BOD) suggest that the waters (in the river) are not suitable for the life present in the river. A significant reduction of the concentrations of COD and BOD is observed (Fig. 6) after treatment using AC, indicating the capability of AC for adsorption of biological and chemical constituents. The conductivity and turbidity values of waste-water have also been recorded before and after treatment as given in Table 5. It is found that large amounts of conductivity and turbidity (77–92 percent of conductivity and 73–93 percent of turbidity) were decreased after treatment and these values are now within a permissible limit of WHO for waste-water discharging in to atmosphere. In addition, the concentration of Cl− is however substantially reduced (84–94 percent) after treatment.

Conclusions

We have successfully synthesized AC from tea waste and used it effectively to remove chromium from tannery waste-water collected from various industries. Highest adsorption capability of synthesized AC is performed by methylene blue adsorption test. Here, the crystallite size (15 nm) of AC is measured from XRD while the microstructure (sub-nano meter scale particle size) of AC is obtained from SEM images. AC is found to have the ability to remove 89–97% of chromium from waste-water for carbon dosing of 2 g per 100 g of waste-water. The AC is also found to significantly reduce other physical parameters such as COD, BOD, conductivity, and turbidity from waste-water thereby improving water quality for aquatic life. The carbon preparation and rejuvenation is an energy-intensive process. The inexpensive process of AC production presented in this study seems to be of great significance in waste-water treatment as well as other industrial sectors.

Data availability

The data sets generated and/or analyzed in this study are available from the corresponding authors on reasonable request.

References

Auta M, Hameed B (2011) Preparation of waste tea activated carbon using potassium acetate as an activating agent for adsorption of Acid Blue 25 dye. Chem Eng J 171(2):502–509

Bulut Y, Aydın H (2006) A kinetics and thermodynamics study of methylene blue adsorption on wheat shells. Desalination 194(1–3):259–267

Chen Y et al (2020) The use of new modified activated carbon in thiosulfate solution: a green gold recovery technology. Sep Purif Technol 230:115834

Freundlich H (1906) Over the adsorption in solution. J Phys Chem 57(385471):1100–1107

Fu F, Wang Q (2011) Removal of heavy metal ions from wastewaters: a review. J Environ Manage 92(3):407–418

Gupta VK, Ali I (2004) Removal of lead and chromium from wastewater using bagasse fly ash—a sugar industry waste. J Colloid Interface Sci 271(2):321–328

Gupta V et al (2011) Pesticides removal from waste water by activated carbon prepared from waste rubber tire. Water Res 45(13):4047–4055

Hameed B, Daud F (2008) Adsorption studies of basic dye on activated carbon derived from agricultural waste: hevea brasiliensis seed coat. Chem Eng J 139(1):48–55

Hameed B, Din AM, Ahmad A (2007) Adsorption of methylene blue onto bamboo-based activated carbon: kinetics and equilibrium studies. J Hazard Mater 141(3):819–825

Islam M et al (2021) Removal of Cr (III) and other pollutants from tannery wastewater by moringa stenopetela seed. In: IOP conference series: earth and environmental science. IOP Publishing: New Jersey

Ismadji S et al (2005) Activated carbon from char obtained from vacuum pyrolysis of teak sawdust: pore structure development and characterization. Biores Technol 96(12):1364–1369

Juang R-S, Wu F-C, Tseng R-L (2002) Characterization and use of activated carbons prepared from bagasses for liquid-phase adsorption. Colloids Surf, A 201(1–3):191–199

Karagozoglu B et al (2007) The adsorption of basic dye (Astrazon blue FGRL) from aqueous solutions onto sepiolite, fly ash and apricot shell activated carbon: kinetic and equilibrium studies. J Hazard Mater 147(1–2):297–306

Kostoglou N et al (2017) Nanoporous activated carbon cloth as a versatile material for hydrogen adsorption, selective gas separation and electrochemical energy storage. Nano Energy 40:49–64

Kovalova L et al (2013) Removal of highly polar micropollutants from wastewater by powdered activated carbon. Environ Sci Pollut Res 20(6):3607–3615

Kwong LH et al (2021) Review of the breathability and filtration efficiency of common household materials for face masks. ACS Nano 15(4):5904–5924

Melo LL et al (2020) Caffeine removal using Elaeis guineensis activated carbon: adsorption and RSM studies. Environ Sci Pollut Res 27(21):27048–27060

Meo PL et al (2014) Cyclodextrin–calixarene co-polymers as a new class of nanosponges. Polym Chem 5(15):4499–4510

Mohan D, Singh KP, Singh VK (2006) Trivalent chromium removal from wastewater using low cost activated carbon derived from agricultural waste material and activated carbon fabric cloth. J Hazard Mater 135(1–3):280–295

Morin-Crini N, Crini G (2013) Environmental applications of water-insoluble β-cyclodextrin–epichlorohydrin polymers. Prog Polym Sci 38(2):344–368

Nadeem R, Nasir MH, Hanif MS (2009) Pb (II) sorption by acidically modified cicer arientinum biomass. Chem Eng J 150(1):40–48

Putra EK et al (2009) Performance of activated carbon and bentonite for adsorption of amoxicillin from wastewater: mechanisms, isotherms and kinetics. Water Res 43(9):2419–2430

Rengaraj S et al (2002) Removal of phenol from aqueous solution and resin manufacturing industry wastewater using an agricultural waste: rubber seed coat. J Hazard Mater 89(2–3):185–196

Romanos J et al (2011) Nanospace engineering of KOH activated carbon. Nanotechnology 23(1):015401

Singh KP et al (2008) Liquid-phase adsorption of phenols using activated carbons derived from agricultural waste material. J Hazard Mater 150(3):626–641

Sun F et al (2017) A high performance lithium ion capacitor achieved by the integration of a Sn-C anode and a biomass-derived microporous activated carbon cathode. Sci Rep 7(1):1–10

Tan I, Ahmad A, Hameed B (2008) Adsorption of basic dye on high-surface-area activated carbon prepared from coconut husk: Equilibrium, kinetic and thermodynamic studies. J Hazard Mater 154(1–3):337–346

Thinakaran N et al (2008) Removal of Acid Violet 17 from aqueous solutions by adsorption onto activated carbon prepared from sunflower seed hull. J Hazard Mater 151(2–3):316–322

Tseng R-L, Tseng S-K (2005) Pore structure and adsorption performance of the KOH-activated carbons prepared from corncob. J Colloid Interface Sci 287(2):428–437

USEPA (2017) Chromium in drinking water.

Viscardi MH et al (2020) Environmental quality and cytogenotoxic impact of the waters of a stream receiving effluents from tannery industry. Water Air Soil Pollut 231(6):1–13

Wright M, Lima I, Bigner R (2017) Stability and use of sweet sorghum bagasse. Sugar Tech 19(5):451–457

Yang HY et al (2013) Carbon nanotube membranes with ultrahigh specific adsorption capacity for water desalination and purification. Nat Commun 4(1):1–8

Funding

There was no funding for this research.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hossain, M.N., Islam, M.D., Rahaman, A. et al. Production of cost-effective activated carbon from tea waste for tannery waste water treatment. Appl Water Sci 13, 73 (2023). https://doi.org/10.1007/s13201-023-01879-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-023-01879-5