Abstract

This paper surveys the various developments in the usage of tea beverage industry-based wastes for adsorption and the generation of activated carbon while emphasizing the applied methodology, removal efficiencies, characteristics of the material and the production methods. From the review, it can be determined that the tea industry-based wastes offer a promising, low-cost and effective alternative adsorbent for the removal of various effluents from the water. The full review is about the usage of waste tea as an adsorbent has been done while considering two aspects. Firstly, initial emphasis was placed on reviewing the research work on the removal of various heavy metal ions and pollutants such as copper, chromium, lead, reactive dyes and phenols using tea leaves as an adsorbent. Secondly, research work on the various activation methods and conditions, and the usage of physical and chemical activating agents such as steam, carbon dioxide, phosphoric acid, zinc chloride and potassium salts for the activation of tea leave-based activated carbon have been reviewed and presented here.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The rise of industrialization has been of great economic benefit around the world, but unfortunately, it has come with a firm price. Reckless and unchecked growth has resulted in detrimental consequences where we increasingly find our natural resources being polluted to levels beyond imaginable. Water being the elixir of life; its contamination is of particular concern. The hydrosphere is being increasingly contaminated by growing levels of organic and inorganic industrial effluents including heavy metals such as chromium and copper, waste acids and bases, phenols and oils. A significant number of the effluents found in wastewater cannot be degraded nor destroyed. While a number of techniques such as evaporation, ion–ion exchange, reverse osmosis, membrane-based solvent extraction, destruction by catalytic wet air oxidation (Bhargava et al. 2006), photocatalytic oxidation, membrane pervaporation, (Kondo and Sato 1994) precipitation have been devised for the treatment of wastewater, the disadvantages allied with these methods cannot be ignored. Adsorption, on the other hand, has been considered a comparatively efficient method and has been used extensively for the removal of organic and inorganic micropollutants from wastewater.

However, the production of commercially available activated carbon that is widely used for adsorptive purposes entails high manufacturing costs (Ajmal et al. 2005; Ahmad and Hameed 2009; Mahvi 2009; Pajooheshfar and Saeedi 2009; Demiral and Gündüzog 2010). The precursor materials such as coal, wood and coconut shells that are widely used for the production of activated carbon are expensive and often need to be imported (Baccar et al. 2009). As a result, several studies have been undertaken that investigated the potential of using agricultural and household wastes such as olive stones (Shalaby et al. 2006; Ubago-Pérez et al. 2006; Kula et al. 2008), spent grains (Li et al. 2010), rice husks (Khan et al. 2010), almond shells (Plaza et al. 2010), herb residues (Yang and Qiu 2011), cotton stalks (Deng et al. 2009), bamboo (Ahmad and Hameed 2009), macadamia nutshells (Ahmadpour and Do 1997), durian shells (Chandra et al. 2009), giant reeds (Yue et al. 2010) and coffee husks (Oliveira et al. 2009) as AC precursors for the treatment of wastewater. Furthermore in recent times, the usage of dead biomass such as fertilizer husk (Srivastava et al. 1997), rice husks (Srinivasan et al. 1988), mustard oil cake (Ajmal et al. 2005), green algae (Nuhoglu et al. 2002; Malkoç and Nuhoglu 2003), pine bark and almond shell (Rossner and Snyder 2009) for the removal of pollutants from wastewater has shown increasing promise. One particular area of interest revolved around the usage of waste tea leaves for the adsorptive purposes due to the comparatively easier availability. Tea is obtained from the leaves of the Camellia sinensis L Camellia assamica and Cambodiensis plants (Kazmi et al. 2013). Although there exists a wide variety of tea in the commercial realm, those derived from the leaves of the plants mentioned above can be divided into six main categories: black, oolong, green, white, pure and dark. The differences among the varieties arise from the variations in the withering and oxidation processes.

Several studies have evaluated the usage of waste tea leaves (Khosla et al. 2011; Cheraghi et al. 2015) or tea factory wastes (Wasewar et al. 2008) or factory-rejected tea (Nasuha and Hameed 2011a, b) as an adsorbent for the removal of effluents from water. Composition wise, black tea consists of the cell wall material, hot water soluble polysaccharides and proteins along with hot water insoluble proteins, lignin, a structural protein and cellulose (Tan 1985). The insoluble cell walls themselves contain cellulose, hemicellulose, lignin and condensed tannins (Thapak et al. 2015). About 3% of the dry weight of tea is constituted by caffeine which translates to somewhere between 30 to 90 mg per 250 ml cup depending on the type of tea and the brewing method. Polyphenols such as flavonoids and epigallocatechin gallate are the most abundant compounds in tea leaves, and they constitute about 30–40% of its dry weight. These compounds contribute to the astringency found in tea beverages (Chatterjee et al. 2012). A minuscule amount of theobromine and theophylline are also found in tea leaves (Harbowy et al. 1997). In a physical sense, tea possesses the properties of a suspension and solution as well, i.e., it is a solution that contains all the water soluble compounds such as the polyphenols and amino acids while at the same time being a suspension resulting from the presence of insoluble components such as cellulose and lignin (Troup et al. 2015). The percentage composition of insoluble material present in black tea is shown in Table 1.

It is without a doubt that the tea is the most popular and widely consumed beverage that is consumed around the world. The consumption of tea alone equals that of coffee, chocolate, soft drinks and alcohol combined (Macfarlane and Macfarlane 2011). It has been estimated that around the world somewhere between 18 to 20 billion cups of tea are drunk on a daily basis. The prosperity of the tea beverage industry in China has resulted in it being accountable for over 20% of the domestic beverage market alone. Such a staggering level of consumption brings forth with the issues regarding the safe disposal of the tea leaves as about 90% of the tea is left behind post-extraction and consumption (Auta and Hameed 2011b; Peng et al. 2013). The issues do not stop with the waste generated post-consumption as the manufacturing process also contributes to the amount of tea-based organic wastes. It has been reported that about 30,000 tons of tea factory waste in Turkey are disposed of in the small bays surrounding Black Sea (Malkoç and Nuhoglu 2003; Yagmur et al. 2008). The factory-rejected tea that is generated mainly during the withering process of production alone amounted to 100,000 tons per annum in Malaysia (Nasuha and Hameed 2011a, b). The annual production of about 857,000 tons of tea in India results in the generation of about 190,000 tons of tea factory waste (Wasewar et al. 2008). Furthermore, the rising popularity of tea seed oil results in the generation of over a million tons of tea seed shells as agro-industrial wastes in China alone (Gao et al. 2013). It is quite evident that the generation of such massive quantities of wastes from the tea industry alone will undoubtedly result in a host of environmental problems associated with their improper disposal. Furthermore, the lack of sustainable waste management practices concerning tea industry wastes exacerbates the issue further. Waste tea leaves and the factory generated tea wastes can be classified as carbonaceous adsorbents. Their physiochemical characteristics such as large surface capacity and the fast kinetics of adsorption make it suitable low-cost adsorbent for the removal of effluents from wastewater and also as an inexpensive precursor material for the production of activated carbon.

This paper focuses its attention on the review and evaluation of the literature that focuses on the usage of tea-based organic material as an adsorbent for the removal of various effluents from wastewater with or without carbonization while summarizing various aspects such as methodology, adsorption mechanisms, results of characterization studies and effluent removal efficiencies.

Adsorption using waste tea

Material pre-treatment

Before the actual usage of waste tea leaves or tea factory waste either as an adsorbent or a precursor for the production of activated carbon, it needs to undergo few preliminary stages such as milling, sieving and washing. Washing plays an essential role in the pre-treatment process as tea-based wastes contain considerable amounts of hydrolyzable tannins, polysaccharides and proteins along with other soluble and colored components which need to be eliminated before being used to avoid undue contamination. The usage of hot distilled water to wash the raw material several times until the supernatant solution remained colorless, was a technique shared among several studies. Wasewar et al. (2008) and Cay et al. (2004) reported that the usage of hot dilute solutions of NaOH for washing the raw material reduced the number of washing cycles required. Particle size plays a vital role in the handling of the raw material when it comes to mixing with a catalyst or impregnation and can also affect the properties of the subsequent AC. Malakahmad et al. (2016) reported that the particle size distribution determined the surface area of the adsorbent and smaller particle size account for larger surface area available for adsorption. Few researchers used the raw material in the original form, whereas others either milled or sieved the raw material to a particle size below 300 µm. The adsorbents were always oven-dried before the usage.

Waste tea as an adsorbent

About one-third of the net dry matter in tea leaves contains mainly carboxylate, aromatic, phenolic, hydroxyl and oxyl groups. This composition is responsible for its ion-exchange behavior (Ahmaruzzaman and Gayatri 2010) which in turn improves its potential to be used as a metal scavenger from solutions and wastewaters. The EDS curve of tea wastes as shown in Fig. 1 revealed the presence of a high concentration of elements found in commercial activated carbon such as carbon and calcium that allowed waste tea to demonstrate a high adsorption capacity (Matta et al. 2008).

EDS curve of tea waste (Malakahmad et al. 2016)

Removal of copper and chromium ions

The efficiency of tea waste in removing heavy metals from synthetic wastewater was studied by Kumar et al. (2015). Sulfuric acid of 1.0 M was used to chemically activate the tea waste sample. The effect of contact time, pH and adsorbent dose on the percentage removal of heavy metals, copper and chromium was evaluated through spectrophotometric analysis of the concentration of the metals in residue at 312 nm and 540 nm. The experiment revealed maximum removal percentage of the metals to be 91% and 94% for copper and chromium at their respective optimum conditions as indicated in Table 2. A similar study done by Thapak et al. (2015) activated the tea wastes using 1.0 M sulfuric acid and used it to adsorb copper ions from synthetic wastewater. The effect of contact time, pH and adsorbent dose on the percentage removal of heavy metals was studied, and maximum removal of copper by tea waste calculated to be around 90% on an average.

Tan (1985), however, focused on evaluating the usage of tea wastes that were physically activated by heating in the oven at 110 °C, as opposed to chemical activation. The batch adsorption experiment involved the addition of specific amounts of activated and non-activated adsorbents separately to a stock solution for a residence time of 4 h after which the remaining concentration of Cu (II) was measured. The study evaluated the changes in the Cu (II) removal efficiency corresponding to an increase in pH and initial metal ion concentration that revealed that optimal removal occurred at pH 6 and an adsorbent loading of 10 g. It was also observed that an increase in the concentration of foreign ions such as K+ and Pb+ negatively affected the adsorption of Cu (II). Provided that the process parameters be kept constant, activated absorbent demonstrated a higher removal efficiency when compared to the non-activated adsorbent.

Jeyaseelan and Gupta (2016) designed this experiment to deal with the efficiency of unmodified waste green tea leaves to remove chromium [Cr(VI)] ions from aqueous solution of Cr(VI) concentration 1000 mL/L by the batch method. Dried tea waste was agitated at a constant speed with the stock solution until equilibrium was reached followed by concentration of the sample analyzed using UV spectrophotometer at 540 nm. The study revealed the maximum removal efficiency of Cr(VI) by the adsorbent sample as nearly 99% for an optimum condition of 2 pH, 180 min. Contact time and 0.8 g/L dosage of adsorbent, as well as the presence of metal ions such as Zn2+ and Cd2+ in the stock solution, seem to increase the removal percentage, whereas ions such as Ni2+, Cu2+ and Fe2+ showed the opposite effect. The adsorption of copper and chromium ions could be better explained using the Freundlich model, while its kinetics best fit the pseudo-second-order model.

Removal of lead ions

Zuorro and Lavecchia (2010) investigated the lead ions removal efficiency of untreated black and green tea waste and found advantageous over fuller’s earth and activated carbon. Batch adsorption experiments involved the addition of 0.2 g of dried tea leaves to 40 ml of stock solution for 20 h; the results of which revealed a removal efficiency exceeding 95%. Colorimetric analysis of 50 ml of 0.1 g/L lead concentration solution after contacting it with 0.5 g of different adsorbents for 2 h revealed that at an optimum temperature of 25 °C, black and green tea wastes, respectively, showed better adsorptive properties with adsorption capacities of around 115.4 mg/g and 83.8 mg/g. Comparison of the experimental data against Langmuir and Freundlich isotherms revealed that the adsorption process could be better explained by the Langmuir model.

Similarly, Cheraghi et al. (2015) assessed the adsorption capacity of waste tea leaves to remove lead [Pb(II)] ions from a stock solution. At varying parameters, a certain amount of dried tea leaves were stirred with 100 ml of the aqueous solution for 6 h at a constant speed of 160 rpm after which the final lead ion concentration was analyzed using inductively coupled mass spectrometer. The tea leaves had humidity, dissolved-material, organic matter and ash content percentages as 10.5, 81, 85 and 2.85%, respectively, with density and total solution particle being 0.353 g/cm3 and 108 mg/L. The study revealed the maximum adsorptive capacity of the tea waste as 166.6 mg/g which was observed to increase with adsorbent dose and pH until optimum at 2 g and pH six, whereas an increase in temperature and initial metal ion concentration showed reverse effect with optimum temperature being 25 °C. Additionally, the pseudo-second-order model better described the adsorption kinetics, while the adsorption process could be better explained by the Langmuir model, thereby indicating monolayer adsorption on a homogenous surface.

The effect of varying the adsorbent dosage on the adsorption of lead (II) ions on tea waste was studied by Fauziah et al. (2015). The adsorbent seems to show increasing removal percentage of 87.89, 88.33 and 89.6% for an adsorbent dose of 0.5 g, 1.0 g and 1.5 g, respectively. The removal percentage also seemed to increase linearly with a contact time of 60 min onwards.

Removal of heavy metal ions

Orhan and Büyükgüngör (1993) studied the removal of Cr(IV), Cd(II) and Al(III) metal ions from synthetic wastewater using waste tea, Turkish coffee, exhausted coffee, granular activated carbon, nut and walnut shells as adsorbents. The batch adsorption tests determined that equilibrium was reached after 120 min and could be described as a first-order reversible reaction and the sorption equilibrium data best fit the Freundlich isotherm irrespective of the adsorbent used. Waste tea was determined to have a removal efficiency of 93, 98, and 98%, respectively, for Cr(IV), Cd(II) and Al(III) ions as compared to 98.5, 99 and 99.8%, respectively, for granular activated carbon. Furthermore, waste tea’s Cd (II) removal efficiency (98%) was comparatively higher than that of Turkish coffee (70%), exhausted coffee (89%), nut (78%) and walnut shells (90%), respectively.

Ahluwalia and Goyal (2005) evaluated the efficiency of using biomass of tea leaves to remove heavy metals from aqueous solution at pH 5. Results from batch adsorption test revealed percentage removal of lead (Pb), iron (Fe), zinc (Zn) and nickel (Ni) as 96, 91, 72 and 58%, respectively. Using the same adsorbent in a multi-metallic mixture having an initial concentration of 92.5 mg/L, 21.5 mg/L and 10 mg/L of lead, iron and zinc showed removal percentage of 92.5, 84 and 73.2%, respectively. The usage of dried biomass in the adsorption column revealed a sorption capacity of 73 mg-Pb/g. A similar study by Thakur and Parmar (Thakur and Parmar 2013) investigated the efficiency of untreated tea waste in the removal of heavy metals through batch adsorption at 30 °C. Results from the experiment showed removal percentage of 94, 89 and 90% for nickel (Ni2+), copper (Cu2+) and zinc (Zn2+), respectively, under the optimal condition of pH 5, 120 min residence time and an adsorbent dose of 0.5 g/100 ml.

The usage of bio-sorbents entails with it the problems related to leaching Shah et al. (2015) used formaldehyde to improve the structural stability of the waste tea leaves. 100 ml of 0.4% formaldehyde solution was added to every 10 g of waste tea leaves for 24 h. The resultant adsorbent having a BET surface area of 636.023 m2/g was used in batch adsorption experiments where the effects of varying the initial ion concentration, pH of the solution, temperature, adsorbent dosage and contact time on the percentage removal of Ni(II) were investigated. The equilibrium data could be best described by the Langmuir adsorption model, and the maximum monolayer sorption capacity was evaluated to be 120.5 mg/g. Optimal sorption of Ni(II) ions was found out at an adsorbent dosage and pH of 0.13 g and 7, respectively. Evaluation of the sorption thermodynamics revealed it to be of spontaneous and exothermic in nature.

Similarly, Malakahmad et al. (2016) characterized and evaluated the efficiency of waste black tea (WBT) as a low-cost adsorbent for the removal of Ni2+ and Zn2+ ions from aqueous solutions. Batch adsorption experiments determined that optimal adsorption of phenol on waste tea leaves occurs at an adsorbent dosage of 20 g/L, pH 5 and contact time of 250 min where the maximum capacity of WBT would be 90.91 Mg–Ni/g and 166.67 Mg–Zn/g.

Removal of zinc ions

Wasewar et al. (2008) investigated the feasibility of using tea waste as an adsorbent for the removal of zinc from wastewater. The characterization studies revealed the tea waste to have a BET surface area of 1.3196 m2/g along with a 46.74% carbon content on a dry basis. The batch adsorption experiments determined that maximum adsorption of Zn2+ ions be 14.2 mg/g at a pH of 4.2 and temperature of 333 K. The results from the kinetic testing suggested that the adsorption of Zn(II) closely followed pseudo-second-order kinetics. Although the adsorption pattern followed Freundlich, Langmuir, Tempkin and Redlich–Peterson isotherms at all temperatures, the equilibrium data could be best described by the Freundlich model. The ΔH0 and the ΔS0 values for the sorption processes were calculated to be 11.55 kJ/mol and 31.24 kJ/mol K, respectively, thereby indicating an endothermic and feasible nature of the adsorption process.

Rather than using waste tea leaves in their original form, Abbas (2014) used the residue remaining after the extraction of peroxidase enzymes from it for the adsorption of zinc ions from synthetic wastewater. The batch adsorption experiments evaluated the effects of changes in the initial concentration, agitation speed, adsorbent dosage, contact time and pH on the amount of zinc ions adsorbed. The results from the experiments revealed that maximum adsorption occurred at pH 1 and adsorbent dosage of 0.1 g. Also, an increase in the agitation speed from 100 to 400 rpm increased the percentage removal of zinc ions, whereas an increase in the initial concentration from 1 to 100 mg/L resulted in a proportional decrease.

Removal of dyes

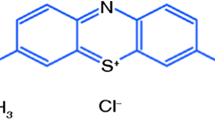

Nasuha and Hameed (2011a, b) used the batch method at equilibrium to study the chemical modification of dried rejected tea by 0.05 M sodium hydroxide to adsorb methylene blue (MB) from its aqueous solution of concentration 1 g/L. (0.5) g of adsorbent sample was added to the 200 ml stock solution after which double-beam UV–Vis spectrometer was used to analyze the MB concentration. The experiment result showed economic enhancement in monolayer adsorption capacity to a maximum of around 242.11 mg/g. Furthermore, according to the data collected the adsorption isotherm and kinetics seem to fit into Langmuir and pseudo-second-order models, respectively.

Khosla et al. (2011) investigated the effectiveness of using untreated tea waste (TW) and sodium dodecyl sulfate modified tea waste (SDS-TW) to remove Basic Red 12 (BR-12) dye from its aqueous solution. The maximum adsorption capacity of 97.28 mg/g and 96.77 mg/g was shown by TW and SDS-TW under the optimal condition of 5 g/L adsorbent dose and pH 3 and pH 4, respectively. The adsorption capacity of both adsorbents seemed to increase with an increase in temperature and initial dye concentration. Experimental data revealed the adsorption isotherm and kinetics to fit into Langmuir and pseudo-second-order model, respectively. The thermodynamic evaluation indicated the adsorption to be random, spontaneous and endothermic in nature.

Jung et al. (2014) investigated the efficiency of different spent tea leaves in the removal of Malachite green dye from aqueous solution using batch equilibrium test at room temperature. Through spectrophotometric analysis Peppermint (PM), Decaffeinated Green Tea (DGT), Green Tea (GT) and Chamomile (CM) were found to show maximum monolayer adsorption capacity in decreasing order under optimal conditions. The highest maximum adsorption capacity of 60.7 mg/g was shown by PM. The adsorption capacity showed a decrease with an increase in salinity and heavy metal effect. Experimental data revealed that the process adsorption capacity, binding affinity and adsorption energy fit into Langmuir, Freundlich and Dubinin–Radushkevich models, respectively.

Reza et al. (2016) studied the effectiveness of using untreated tea waste in the removal of reactive blue (RB21) dye from aqueous solution. The adsorbent showed maximum monolayer adsorption capacity of around 28.99 mg/g under the optimal condition of the residence time of 90 min, pH 6 and 4.0 g/100 ml adsorbent dose. The adsorption capacity showed a decrease with an increase in dye concentration from an initial value of 5 mg/l. Experimental data revealed that adsorption isotherm fits more into the Langmuir model than that of the Freundlich model.

Removal of phenol

A comparative study by Okasha and Ibrahim (2010) investigated the phenol removal efficiency of almond shell residues, coffee grounds, black tea leaves, olive leaves and activated carbon. The results of the batch adsorption tests determined that irrespective of the adsorbent, the phenol adsorption reaches an equilibrium after 3 h and the percentage of phenol removed increases with a decrease in initial phenol concentration. Maximum percentage removal of phenol was found out to be 98.6 ± 0.06, 86 ± 0.11, 72 ± 0.51, 87 ± 0.4, 94 ± 0.46 and 88 ± 0.12% for activated carbon, black tea residues, coffee ground, almond shell, date stone and olive leaves, respectively. The equilibrium data for each of the phenol–adsorbent system fit the Freundlich isotherm best particularly at concentrations below 100 ppm. On the other hand, Kazmi et al. (2013) investigated the efficiency of chemically activated tea leaves in the removal of phenol from its aqueous solution. The tea leaves were chemically modified by phosphoric acid and through UV-spectrophotometric analysis and through batch adsorption test; the adsorbent samples were found to show a maximum adsorption capacity of 63.13 mg/g under the optimal condition of pH 2, 180 min contact time and 2 g/L adsorbent dose. For an increase in initial phenol concentration, the adsorption capacity seemed to increase, whereas the percentage removal of phenol decreases. Experimental data revealed that the adsorption process and kinetics fit into Langmuir and pseudo-second-order models, respectively.

Removal of progesterone

Ifelebuegu and Onwugbuta (2016) investigated the efficiency of modified black tea and granulated activated carbon (GAC) at pH 7 and 25 °C temperature to remove progesterone from its aqueous solution. The experiment revealed black tea to have a higher maximum adsorption capacity of 1.8 mg/g than that of 1.4 mg/g capacity of GAC. The results from the batch adsorption determined that the adsorption be spontaneous and exothermic as the values of Gibb’s free energy, enthalpy and entropy are calculated to be − 6.0 kJ/mol, − 3.7 kJ/mol and 8.0 J/mol K, respectively. The usage of intra-particle diffusion model to express the kinetics of progesterone adsorption showed that it was not the rate-determining step, thus indicating the adsorption was controlled by diffusion within the pores of the adsorbents.

Removal of antibiotics

Hassan and Ali (2013) investigated the potential for using spent black tea leaves for removal of tetracycline hydrochloride antibiotic from its aqueous solutions. The batch adsorption experiments evaluated the effects of variance in adsorbent dosage, contact time, pH of the solution and temperature on the percent removal of the TCH antibiotic. The results revealed that an increase in the adsorbent dosage after 0.2 g and contact time after 30 min did not increase the percent removal, whereas maximum removal occurred at a temperature and pH of 58 °C and 6, respectively. The equilibrium data best fit Tempkin, and D–R equations and the kinetic studies revealed the adsorption mechanism to be of the pseudo-second-order model.

Removal of benzene

Adachi et al. (2008) investigated the use of tea leaves for the adsorption of benzene from wastewater. The spherosomes were isolated from varying amounts of tea lees using a method developed by Moreau et al. to understand the benzene removal process. The equilibrium adsorption isotherms fit the Freundlich model, and the batch adsorption tests revealed that the amount of adsorption on tea leaves was constant regardless of the pH. The average removal efficiency was calculated to be around 72.8%, which was lower than that of activated carbon under similar experimental conditions. It was determined that the removal of benzene by tea lees occurs due to the uptake by intracellular particles otherwise known as spherosomes.

Removal of endocrine disrupting compounds (EDC)

Ifelebuegu et al. (2015) compared the potential of untreated black tea waste and granular activated carbon in the adsorption of endocrine disrupting compounds 17 β-estradiol, 17 α-ethinylestradiol and bisphenol A from their aqueous solutions. The batch adsorption experiments determined that optimal adsorption of EDCs on black tea leaves occurs at an adsorbent dosage of 1 g and pH 5. Maximum adsorption capacities of 4.01, 2.97 and 16.26 mg/g were achieved by GAC as compared to that of 3.46, 2.44 and 18.35 mg/g for tea leaves waste for 17 β-estradiol, 17 α-ethinylestradiol and bisphenol A. An analysis of the kinetics and thermodynamic data revealed that the adsorption process for tea wastes was predominantly due to physisorption as opposed to chemisorption for GAC. The adsorption of the EDCs onto black tea wastes followed pseudo-first-order kinetics, whereas pseudo-second-order kinetics fit GAC. However, the experimental isotherm data for both the adsorbents fit Langmuir model more closely than Freundlich or Temkin.

Thereby it is quite evident that despite the problems related to leaching posed by the use of waste tea leaves for adsorptive purposes, they prove to be a useful alternative adsorbent under the optimal conditions. Specific studies that compared the adsorptive potential of waste tea leaves to commercially available activated carbon have successfully concluded that waste tea leaves can be used as a safe, environmentally friendly and economical alternative in its original form with little or no pre-treatment. Table 2 lists out the optimal conditions for adsorption of various metal ions and compounds as reported by the literature (Table 2).

Adsorption using waste tea derived activated carbon

The relatively high content of cellulose, hemicellulose and lignin within the cell walls of tea leaves and tea factory wastes make it a suitable precursor material for the production of activated carbon (Li et al. 2010; Wang et al. 2006). There have been several studies that utilized either factory-rejected tea waste or spent tea leaves to produce AC which in turn were used as an adsorbent for the removal of organic and inorganic pollutants from wastewater.

Physical activation

Physical activation methods for the preparation of AC involved the usage of a stream of oxidizing gas for controlled gasification that was carried out post-carbonization (Shalaby et al. 2006). Fadhil et al. (2012) examined the potential of using physically activated biochar derived from spent tea waste for the purification of biodiesel. The dried spent tea leaves were simultaneously carbonized and activated either by carbonization in an electric tubular furnace at 600 °C or heating the samples under a gradual flow of steam up to 600 °C for 2 h. Physical activation using steam showed a lower activated carbon yield of 27% as opposed to 41% of the purely thermal activation process. The use of steam in the activation process resulted in AC samples having higher surface areas but a lower methylene blue number of 39.3 mg/g as opposed to 43 mg/g. Continuous adsorption tests revealed that the usage of derived activated carbon samples demonstrated greater clean biodiesel yields along with better fuel properties when compared to traditional biodiesel purification methods. The regeneration and reusability of the derived AC samples proved to be significantly more economical for biodiesel purification purposes.

Garba et al. (2015) studied the equilibrium and kinetics of the adsorption of methylene blue dye onto the surface of the activated carbon prepared from spent tea leaves. The activated carbon was prepared by carbonization at a temperature of 800 °C for 2 h followed by physical activation using carbon dioxide gas injected into the muffle furnace at a rate of 150 ml/min for 1.5 h. The resultant activated carbon which had a BET surface area, micropore volume and average pore size was found to be 232.95 m2/g, 209.34 m2/g, 0.0833 cm3/g and 3.31 nm, respectively, demonstrated an increase in the methylene blue removal when the initial concentrations, contact time and solution pH were increased. The absorption process followed pseudo-second-order model, and the resultant equilibrium data could be best expressed by Langmuir and Temkin isotherms that showed a maximum adsorption capacity of 114.943 mg/g, 119.048 mg/g and 121.951 mg/g at 303 K, 313 K and 323 K, respectively.

Shen et al. (2015) used a combination of physical activation methods to prepare activated carbon from spent Jasmine tea leaves for mercury removal. The prepared precursor material was carbonized inside a muffle furnace for 2 h at a temperature of 500 °C before being calcined at a temperature of 700 °C for 45 min in a quartz bottle reactor with an activation gas mixture consisting of steam and nitrogen whose flow rates were maintained at 5 ml/min and 55 ml/min, respectively. The activated biochar was modified with NH4Cl solutions whose concentration varied from 1 to 9%. The surface characterizations revealed that the samples of the biochar that were treated with higher concentrations of NH-4Cl solutions and subjected to ultrasonic treatment had higher BET surface areas as well net pore volume and average pore diameter. The study revealed that the adsorption of mercury was highest when the reaction temperature and O2 concentration were at 120 °C and 5%, respectively; whereas an increase in the space velocity and the presence of water had a detrimental effect on mercury adsorption.

A combination of physical and microwave activation was used by Dutta et al. (2015) for the preparation of activated carbon derived from waste tea leaves to adsorb acetaminophen from wastewater. The dried precursor material was carbonized for one hour in a muffle furnace where the heating rate was maintained at 4 °C/min. The char was then placed inside a domestic microwave oven for 5 min at an input power of 800 w and a frequency of 2450 MHz. The prepared char was found to possess a BET surface area, total pore volume, average pore size and PhZPC of 493.1 m2/g, 0.37 cc/g, 30.07 Å and 7.3, respectively. The batch adsorption tests revealed that the adsorption capacity of the derived AC was evaluated to be 195.95 mg/g and the maximum adsorption of acetaminophen occurred at an adsorbent dosage of 1 g/L and a pH of 2. Furthermore lowering the temperature from 40 °C to 5 °C resulted in an increase in the adsorption from 52.72 to 58.45 mg/g due to the exothermic nature of the adsorption process.

Removal of carbon dioxide on waste tea derived activated carbon

Auta et al. (2015) focused on the modification of the mesoporous activated carbon derived from waste tea leaves by impregnating it with diethanolamine to be used as a CO2 adsorbent. The AC was prepared using the same technique as developed by Auta and Hameed (2011a), while the modification process involved the mixing of 10 g of AC to 300 ml of 1.0 M diethanolamine. The modified AC packed into an adsorption column where the effects of column temperature, adsorbent loading, feed flow rate, initial diethanolamine concentration and CO2 feed concentration on the breakthrough curves were evaluated. The study found out that the adsorption process was physisorptive due to an increase in the adsorption at lower temperatures. However, maximum CO2 capture by modified waste tea activated carbon (MWTAC) occurred when the temperature inside the adsorption column was 30 °C; feed concentration was 10% CO2 and 1.0 M of diethanolamine used for modification while maintaining the influent feed flow rate at 90 mL/min.

Activated carbon prepared from waste tea leaves for CO2 adsorption was investigated by Menon et al. (2015) where the effect of the activating agents, activation sequence, activating agent to waste tea leaves precursor impregnation ratio, carbonization temperature and the carbonization heating rate were evaluated. The process of chemical activation involved the usage of phosphoric acid at an impregnation ratio of 1:1 and 2:1 (g/g) potassium hydroxide at a ratio of 2:1(g/g) and potassium carbonate at a ratio of 1.5:1 (g/g) before being carbonized in a muffle furnace at a temperatures ranging from 600 °C to 800 °C for 2 h. Pre-chemical treatment involved the pyrolysis of the waste tea leaves at a temperature of 600 °C under a nitrogen atmosphere before its impregnation with phosphoric acid at an activating agent to tea leaves ratio of 1:1 and 2:1 (g/g), respectively. Post-drying of the mixture at 110 °C for 15 h, the dried samples were then heated to a temperature of 800 °C inside a furnace for 2 h. The surface and pore analysis of the samples obtained found out that the pre-chemical treated samples had the lowest surface areas of 336 m2/g and 311 m2g, respectively, whereas the chemical activation using H3PO4 at an impregnation ratio of 2:1 and carbonization at 700 °C resulted in activated carbon having the highest surface area, micropore volume and total volume of 1044 m2/g, 0.39 and 0.59 cm3/g, respectively. Also, the study was able to determine that carbonization at a temperature of 600 °C was ideal as the resulting AC would have more pores of width 1 nm that would be suitable for CO2 gas adsorption.

Sodium hydroxide as the activating agent

Rani et al. (2007) studied the effectiveness of the activated carbon prepared by using the same procedure as Nasuha and Hameed (2011a, b) for the adsorptive removal of basic violet-14 dye from its aqueous solution by carrying out batch adsorption studies where parameters such as pH, temperature, adsorbent dosage and initial dye concentration were varied. The results of the experimentations revealed that the maximum adsorption occurred at pH of 3.5 and an increase in the temperature of the system from 30 °C to 50 °C resulted in the amount of BV-14 dye removed increasing from 40 mg/g to 41.67 mg/g. Data from adsorption isotherms closely matched Freundlich isotherm than Langmuir, and the parameters suggested that the adsorption of BV-14 onto tea waste activated carbon (TWAC) followed the monolayer adsorption and pseudo-second-order kinetics. The adsorption process was spontaneous and endothermic with a positive ΔH0 value that ranged from 20 to 26 kJ/mol and negative ΔG0 that ranged from − 1.75 to − 5.03 kJ/mol.

Akar et al. (2013) focused on the use of activated carbon derived from spent tea leaves for the removal of malachite green from its aqueous solution and the comparison of the derived activated carbon to the non-treated waste tea leaves. The dried tea leaves were sieved to less than 210 µm before being chemically activated for an hour using 4% NaOH solution. The chemically activated precursor material was then carbonized for 1 h at a temperature of 450 °C inside a muffle furnace under a nitrogen atmosphere whose flow rate was maintained at 10 ml/min. The surface characterization studies revealed that the chemical treatment resulted in the increase in surface area from 73 to 423 m2/g along with the formation of micropores. The batch equilibrium studies revealed that increasing the amount of adsorbent from 0.8 to 6 g/L resulted in a decrease in the amount of dye adsorbed. Also, the elevation of pH from 2 to 4 resulted in the adsorption of malachite green on the activated carbon showing a decrease in the adsorption capacity marked a rapid increase from 18.7 to 123.5 mg/g while an increase in the ionic strength at pH 3. Also, it was found out that the adsorption data better fit the Langmuir model than Freundlich or Dubinin–Radushkevich due to a higher value of correlation coefficient, while the pseudo-second-order model best explained the kinetics of the adsorption.

Islam et al. (2015) studied the effect of varying the activating agent to precursor material impregnation ratio on the surface characteristics of the activated carbon derived from factory-rejected tea and its effectiveness in the removal of methylene blue dye from aqueous solutions. The waste tea was converted into activated carbon by carbonization at a temperature of 200 °C inside a hydrothermal reactor for 5 h followed by chemical activation with NaOH solutions at impregnation ratios that varied from 1:1 to 3:1 (w/w). The surface characterizations studies revealed that an increase in the amount of activation agent resulted in a significant improvement in the BET surface areas and total pore volumes from 24.45 to 368.92 m2/g and 0.02 to 0.21 cm3/g, respectively. The FTIR analysis of the adsorbent was performed before and after the adsorption of methylene blue. Before the adsorption, it was found out that the treatment of the waste tea leaves with NaOH resulted in the hydrolysis of the esters and the protein peptide bonds into carboxylic acids and alcohols and sodium salts of the amino acids, respectively. Post-adsorption, it was observed that several functional groups had either shifted to different bands or disappeared altogether. Furthermore, it was also noted that new bands appeared correspond to Si–OH, N–H stretching, C–H aromatic benzene, asymmetric and symmetric CH2 groups in the lignin and cellulose, C–N and N–O (nitro). Maximum methylene blue adsorption capacity of 487.4 mg/g at 30 °C was observed on the AC that was obtained when the activating agent to precursor material ratio was set at 3:1.

Sulfuric acid as the activating agent

A study undertaken by Duran et al. (2011) examined the usage of tea industry waste based activated carbon for separation, preconcentration and speciation of chromium species. The activated carbon prepared by chemically activating the dried tea industry wastes with concentrated H2SO4 in 1:1.5 (w/v) ratio had a BET surface area, total volume, iodine and methylene blue number of 45.5 m2/g, 0.136 cm3/g, 167.9 mg/g and 39.1 mg/g, respectively. The results of batch adsorption tests on synthetic and real wastewater samples revealed that the derived activated carbon’s high adsorption capacity of 61.0 mg/g, high preconcentration factor of 50 per 200 ml of sample volume and low detection limit of 0.27 µg/L were advantageous to the applied method that eliminated the usage of a complexing agent for the preconcentration of the chromium species. Comparison of the experimental data against different kinetic models revealed that the adsorption of chromium ions onto the derived activated carbon could be best described by the pseudo-second-order model. Furthermore, it was determined that the adsorption process is rate-limited by both intra-particle diffusion and surface adsorption.

The usage of sulfuric acid as an activating agent preparing activated carbon from spent tea leaves was investigated by Amey (2013). The waste tea leaves were digested with dilute sulfuric acid in a 0.7:1 activating agent to precursor material ratio for 12 h before being carbonized at a temperature of 500 °C inside a muffle furnace for 15 min. The study found out that complete carbonization took place at a temperature of 450 °C and above 550 °C the material was wholly converted into ash. The XRD analysis of the precursor material and the activated carbon derived from the above process revealed a phase change from an amorphous to a crystalline form. Roy and Das (2016) prepared activated carbon from waste tea by digesting the precursor material with dilute sulfuric acid followed by carbonization at 723 K for defluoridation. The resultant AC has yield, bulk density, porosity and ash content of 74%, 0.8 g/cm3, 0.79 and 12.5%. The effects of adsorbent dosage, contact time and solution temperature were studied, and response surface methodology statistical technique was used to determine the optimum conditions at which defluoridation occurred by applying a two-level three-factor central composite design with the help of design expert software. It was determined that the three parameters have a significant role in determining the fluoride removal efficiency with maximum removal efficiency of 99.59% occurring at a temperature of 333 K, contact time of 70 min and an adsorbent dosage of 1 g.

The characterization of the activated carbon produced from waste tea residues was investigated by Hammud et al. (2016). Before the chemical activation using Clorox and concentrated H2SO4 and HNO3 mixtures, the waste tea was carbonized inside a muffle furnace for 15 min at a temperature of 500 °C. One of the mixtures containing the 0.36 gm of carbonized material and 5 ml Clorox solution was mixed for an hour inside an ultrasonic apparatus, whereas the other mix consisting of 7.5 g of carbonized material and 70 ml of Clorox solution was left undisturbed for 24 h. The concentrated mixture of H2SO4 and HNO3 was added to the carbonized sample obtained from the muffle furnace in a 1:1 impregnation ratio and was allowed to react for over 100 h. The SEM analysis revealed that although the usage of chemical activation agents post-carbonization in all the samples did result in the formation of microscopic porous structures on the surface, the amount of porosity was higher when the acid mixture was used as the activating agent. The results from the AFM analysis revealed that the AC obtained by using the acid mixture as the activating agent had the highest values of total volume % as well as average surface roughness, surface kurtosis and surface area ratio of 82.6%, 0.901 nm, 1.97 nm and 0.248, respectively. However, the XRD analysis (Table 3) pointed out that the usage of Clorox as an activating agent resulted in AC having a larger average crystallite size of 41.4 nm as compared to the rest of the samples.

Potassium salts as the activating agents

Work done by Auta and Hameed (2011a, b) involved the production of activated carbon from waste tea leaves and its characterization using techniques such as Brunauer–Emmett–Teller (BET and Boehm titration; as well as the comparison of the effect of solution pH, initial concentration and temperature on the adsorption of acid blue 25 dye on the waste tea activated carbon (WTAC). The dried waste tea leaves chemically activated using potassium acetate. The resultant WTAC had a BET surface area, Langmuir surface area, average pore diameter and cumulative pore volume of 820 m2/g, 1224 m2/g, 2.458 nm and 0.219 cm3/g, respectively, and maximum adsorption capacity of 203.34 mg/g of acid blue 25 dye at the optimum conditions. The Langmuir isotherm model represented the adsorption process quite well, and the adsorption kinetics of acid blue 25 on WTAC could be described ideally by pseudo-second-order model.

Additionally, Auta and Hameed (2011a) focused their work on the optimization of process conditions in the production of activated carbon from spent tea leaves for the adsorption of cationic and anionic dyes by using response surface methodology. The parameters studied were activation temperature, activation time and potassium acetate to waste tea leaves impregnation ratio and the percentage yield and removal were the targeted responses. The results of the statistical analysis showed that activation temperature and impregnation ratios were the factors had the most significant impact on the yield of the AC as well as the removal of methylene blue and acid blue 29 dyes. The optimal parameters for obtaining AC with properties that corresponded to the maximum possible yield as well as percentage removal of dyes were found out to be 800 °C, IR of 1.4 and carbonization time of 120 min. The AC produced under the optimum conditions had a BET surface area of 854.3 m2/g and had adsorption capacities of 453.12 and 554.3 mg/g for acid blue 29 and methylene blue dye, respectively. The FTIR spectra of the activated carbon derived under optimum conditions indicated the presence of saturated and unsaturated vinyl/vinylidene groups (around 3425.71 cm−1 bandwidth), derivatives of carboxylic acid group (2500–1497 cm−1), S–O inorganic sulfates and Si–O–Si asymmetric silica stretches (1132.47 cm−1), carboxylic acids O–H and meta-benzene bending C–H (955.34 and 759.15 cm−1, respectively). It was found out that the presence of these functional groups contributed immensely to the massive adsorption capacities of both methylene blue and acid blue 29 dyes from wastewater.

The effects of variance in conditions such as the carbonization temperature and time and the impregnation ratio and period on the characteristics of the activated carbon prepared from factory generated tea wastes were evaluated by Gurten et al. (2012). The grounded tea factory waste impregnated with K2CO3 in an impregnation ratio of 1:1 in all the cases before being carbonized under a nitrogen atmosphere. The change in carbonization temperature from 400 °C to 700 °C resulted in an increase in the BET surface area from 19 m2/g to 1722 m2/g, a sharp increase in the micropore volumes from 0.002 to 0.570 cm3/g and a gradual decrease in the yield. A similar increase was noted upon elevating the impregnation ratio from 0.5 to 2.0 and extending the impregnation period from less than an hour to 24 h. However, extending the carbonization time from half an hour to 2 h did result in a drop in the yield from 18.6 to 13.2% and the BET surface area and from 1041 to 979 m2/g.

Auta (2012) prepared activated carbon from waste tea using potassium hydroxide as the activating agent for the removal of cibacron yellow dye from textile wastewaters. The following factors were taken into consideration while preparing the AC: activation temperature (500 °C to 800 °C), activation time (60–150 min) and an impregnation ratio of the activating agent to waste tea (0.3 to 2.5). From the central composite design (CCD), two quadratic models were developed to correlate the preparation variables with the targeted responses of yield and percentage dye removal. The results indicated that yield and percentage dye removal of 21.30 and 95.07%, respectively, occurred at the optimum preparation conditions of 760 °C, IR 1.4 and a residence time of 120 min. The AC prepared under the optimum conditions had a BET surface area and total pore volume of 830 m2/g and 0.563 cm3/g, respectively. Analysis of the adsorbate distribution between the liquid and solid phase by Langmuir, Freundlich and Tempkin isotherms revealed that the cibacron yellow adsorption on the waste tea activated carbon was best described by a monolayer coverage phenomenon and the adsorbent surface was heterogeneous, i.e., it best fit the Langmuir model. The kinetics of the adsorption of the cibacron yellow dye was better described by the pseudo-second-order model due to its higher correlation coefficient values.

Phosphoric acid as the activating agent

The usage of phosphoric acid as the chemical activating agent for the preparation of activated carbon was favored in some studies as it offered several distinct advantages. Girgis and El-Hendawy (2002) reported that phosphoric acid inflicted physical and chemical modifications on the biological structure by penetration, particle swelling and partial dissolution of the biomass, bond cleavage and reformation of new polymeric structures resistant to thermal decomposition.

The influence of microwave treatment alongside chemical activation on waste tea precursor material was examined by Yagmur et al. (2008) where the characterization studies compared the effect of pre-treatment methods, carbonization temperatures and impregnation ratios on activated carbons. The tea factory wastes were chemically activated with 85% H3PO4 solution at the various activating agent to precursor material impregnation ratios that ranged from 1:1 to 3:1. Microwave treatment of the impregnated samples occurred at an input power of 900 W and a frequency of 2.45 GHz for the 30 s. The changes caused by microwave treatment on the surface morphology and chemical structure of the waste tea were revealed by the characterization studies that showed that the microwave pre-treatment method resulted in shorter chemical activation times and consistent improvements in the micropore surface area and pore volume of the AC samples as compared to that obtained by conventional treatment. The Dubinin–Radushkevich (DR) method of analysis revealed that increasing the impregnation ratio from 1:1 to 3:1 resulted in the micropore surface areas increasing from 1459 m2/g to 1630 m2/g, but an increase in the carbonization temperature while keeping the impregnation ratio constant at 3:1 from 300 °C to 700 °C was marked by a rapid increase in the surface area until 350 °C followed by a gradual decline.

The potential for using tea plantation wastes as a low-cost precursor material for preparing activated carbon to adsorb p-nitrophenol from wastewater was investigated by Ahmaruzzaman and Gayatri (2010). The preparation of the AC evaluated the potential of NaOH, KOH, ZnCl2, MnO2, H3PO4 and H2O2 as activating agents before the carbonization of the mixture at a temperature of 500 °C. It was determined that the usage of H3PO4 results in AC samples demonstrating a greater p-nitrophenol adsorption capacity. The resultant AC had a BET surface area, pore size and fixed carbon content of 29.5 m2/g, 2.1 nm and 57.1%. The data obtained from the batch adsorption experiments fit the Langmuir model more closely thereby indicating monolayer adsorption of p-nitrophenol molecules on the surface of the adsorbent with a maximum adsorption capacity of 142.85 mg/g.

The characterization and the ability of the activated carbon prepared from waste tea leaves as the precursor material for the adsorption of Ni(II) ions were investigated by Goswami et al. (2014). The tea waste was converted into activated carbon by chemical activation using 2 M phosphoric acid or sodium hydroxide at an activating agent to precursor material impregnation ratio of 3:1 followed by carbonization at a temperature of 400 °C for 4 h. The characterization studies revealed that the AC obtained by using H3PO4 as the activating agent had a BET surface area and total pore volume of 929 m2/g and 0.547 cm3/g, respectively. This was significantly higher in comparison with the AC obtained by using NaOH as the activating agent as it had a surface area of 320.68 m2/g and net pore volume of 0.2051 cm3/g. The batch adsorption tests revealed that the former exhibited a maximum adsorption capacity of 98 mg/g of Ni(II) ions at pH 5. Comparison of the experimental data against Langmuir, Tempkin and Freundlich isotherms indicated that the Langmuir isotherm is the best-fitted model for Cr(IV) adsorption on activated carbon. The kinetics of the adsorption could be well described by the pseudo-second-order model, while linearity of the qt versus t0.5 indicated that intra-particle diffusion played a significant role in the adsorption of Cr(IV) ions.

Goswami et al. (2014) investigated the equilibrium modeling as well as kinetic and thermodynamics of the adsorption of Cr(IV) on the activated carbon derived from waste tea leaves. The AC was prepared by adding 85% orthophosphoric acid to the waste tea precursor before carbonization at a temperature of 500 °C for 1 h. The resultant material had a BET surface area and total pore volume of 1313.41 m2/g and 1.359 cm3/g, respectively. The batch adsorption experiments revealed that the adsorption capacity remained optimum between pH 1.5 and 4.8, whereas an increase in the temperature improved the adsorption capacity from 25.36 to 32.04 mg/g when the initial Cr(IV) concentration was maintained at 60 mg/L. The experimental data obtained best fit the Langmuir isotherm, and the adsorption process itself followed the pseudo-second-order kinetic model. The values ΔG0, ΔH0 and ΔS at 313 k were calculated to be − 1.09 kg/mol, 28.6 kg/mol and 94.87 J/mol K, respectively, indicating a spontaneous and endothermic nature of the adsorption process.

Shalna and Yogamoorthi (2015) examined the differences in the characterizations of commercially available activated carbon derived from Jatropha husk and activated carbon prepared from spent tea dust. The tea dust was chemically activated with orthophosphoric acid for 24 h before being carbonized at a temperature of 600 °C for half an hour. The characterizations studies revealed that the AC prepared from tea dust had a significantly lower moisture content (1.9%) but a higher ash content. The commercially available AC had a greater surface area and carbon content of 890 m2/g and 89.98%, respectively, as compared to 280 m2/g and 73.09% of the tea dust-based AC.

Zinc chloride as the activating agent

Zinc chloride is widely used for the chemical activation of carbonaceous material as it results in ACs being more porous and having a high surface area while acting as a dehydrating agent that promotes the decomposition of carbonaceous material, restricts tar formation and increases the carbon yield (Ahmadpour and Do 1997; Khalili et al. 2000). Gao et al. (2013) studied and compared the properties of the AC produced from tea fruit peel residue using zinc chloride and phosphoric acid as the activation agents. The impregnation ratio was maintained at 1:1 (w/w) in both the cases, and the carbonization was done in a muffle furnace at a temperature of 500 °C for 20 min under an N2 atmosphere. The characterization studies revealed that the use of zinc chloride as the activating agent resulted in the AC samples having greater BET surface area, micropore volume and pH zero point charge but lower average pore diameter, mesopore volume and overall yield. The results from the batch adsorption tests revealed that zinc chloride-based AC had a higher methylene blue adsorption capacity of 342.5 mg/g as opposed to 291.5 mg/g of the phosphoric acid-based AC.

Gundogdu et al. (2013) study focused on understanding the changes in the physiochemical characteristics of the activated carbon that was produced from tea industry wastes by varying the activating agent to tea waste precursor impregnation ratios. Zinc chloride was added at impregnation ratios of 0.5:1, 1:1 and 2:1 (g/g) separately to the waste tea. The samples were carbonized inside a high-temperature furnace for 4 h at a temperature of 700 °C under an atmosphere of nitrogen whose flow rate was maintained at 100 ml/min. An extensive characterization study including quantitative measurement of various parameters by proximate analysis revealed that increasing the amount of zinc chloride as the activating agent results in a comparatively higher yield of AC as compared to the usage of KOH. Increasing the activating agent to the tea waste impregnation ratio resulted in more structural fractures that contributed to the lower carbonization yield. Comparison of the SEM micrographs of the three samples of AC revealed that the increase in the amount of activating agent resulted in higher levels of mesoporosity in the surface. BET analysis of the three samples confirmed that the increase in the amount of activating agent resulted in an increase in the surface area of the material along with an enhanced porous structure. The AC obtained by using the addition of ZnCl2 in a 3:1 impregnation ratio had a BET surface area, total pore volume and average pore diameters of 1141 m2/g, 0.806 cm3/g and 2.83 nm, respectively.

Gundogdu et al. (2012)also studied the kinetic, equilibrium and thermodynamic parameters to evaluate the ability of activated carbon derived from waste tea leaves to adsorb phenol molecules from an aqueous solution. The activated carbon was produced by chemical activation with zinc chloride in a precursor to activating agent ratio of 1:1 followed by carbonization inside a high-temperature furnace for 4 h at a temperature of 700 °C. The characterization study revealed that the resultant activated carbon had a significantly high carbon content of 79.32% along with a BET surface area, total pore volume, iodine number and methylene blue number of 1066 m2/g, 0.580 cm3/g, 605.8 mg/g and 100.2 mg/g, respectively. The batch adsorption tests revealed that the adsorption of phenol molecules on the activated carbon could be better understood by Langmuir adsorption and pseudo-second-order kinetic model and both boundary layer diffusion as well as intra-particle diffusion controlled the adsorption rate. The linear Langmuir equation revealed that the maximum adsorption capacity was 142.9 mg/g and this adsorption capacity was adversely affected by an increase in temperature due to the exothermic nature of the adsorption process. Furthermore, the increase in the ionic strength of the aqueous solution had a corresponding increase in the adsorption of phenol molecules on the AC.

Tea seed shell base activated carbon was prepared by Gao et al. (2013). Zinc chloride was added to the precursor material at an impregnation ratio of 1:1 before being carbonized in a muffle furnace at a temperature of 500 °C for 1 h. The N2 adsorption and desorption isotherms at 77 K revealed it to be a type 1 isotherm as per IUPAC standards, which indicated the presence of a large percentage of micropores along with smaller fractions of mesopores. The BET surface area and the total pore volume of the AC were 1530.67 m2/g and 0.7826 cm3/g, respectively. The FTIR analysis of the activated carbon samples revealed that the existence of the various functional groups including hydroxyl, phenol and other oxygen-containing compounds. The study came to the conclusion that the functional groups present on the surface of the activated carbon were connected to the adsorption mechanism by hydrogen bonding and π–π dispersion interaction between the electrons of the adsorbent and the adsorbate. The data obtained from the equilibrium adsorption tests closely collaborated to the Langmuir isotherm model, and the maximum monolayer adsorption capacity of methylene blue was 324.7 mg/g. Kinetic and thermodynamic analysis revealed that the rate of adsorption was not controlled just by intra-particle diffusion and the sorption process itself was spontaneous and exothermic.

Abbas (2014) prepared activated carbon from waste tea leaves that were previously used for the adsorption of zinc ions by chemically activating them using zinc chloride solution of concentration 11 g/L before being carbonized at a temperature of 500 °C under an N2 atmosphere. The characterization studies on the resultant AC revealed it to have a BET surface area, total pore volume and pore diameter of 613.35 m2/g, 0.285 cm3/g and 1.75 nm, respectively. Batch adsorption experiments determined that under optimal conditions of pH 1 and an agitation speed of 400 rpm, 0.1 g of activated carbon had a thiophenol removal efficiency of 97.99%. The experimental data about the adsorption of thiophenol best fit the Langmuir adsorption isotherm, while the kinetics of the adsorption could be explained more accurately by the pseudo-second-order model.

The characteristics of the activated carbon produced by using waste tea leaves or related organic material as the precursor depend significantly on the activating conditions, activation temperature, activation time and the activating agent and the chemical used. Furthermore, the activated carbon produced from tea leaves can be tailored made for specific adsorptive applications. The data presented provide ease of comparison between the characteristics and the production conditions as reviewed in the literature (Table 3).

Conclusions

The widespread ability and the ease with which waste tea leaves can be obtained combined with attractive physiochemical characteristics make it a potential replacement for commercially used adsorbents. In addition to the cost-benefits, the usage of tea leaves as a bio-adsorbent eliminates the multitude of environmental issues generated by its disposal. Adequate pre-treatment methods such as the usage of formaldehyde can reduce the problems associated with leaching when tea leaves are used for sorption purposes. Furthermore, it is an ideal low-cost precursor material for the production of activated carbon using conventional physical activation or impregnation methods due to its widespread availability when compared to the commonly used adsorbents. The properties of the activated carbons produced from waste tea leaves depend heavily on the activation method, type of activating agent and the process conditions such as temperature, retention time and impregnation ratios. Chemical activation methods seem to produce activated carbons possessing better properties as compared to physical activation methods. Results from the studies show that under ideal conditions, waste tea derived activated carbons can have features that are at par with the commercially available one. Waste tea-based AC’s demonstrates a high level of efficiency in the removal of several classes of pollutants at the optimum parameters.

-

Waste tea leaves when chemically activated have potential to be used as low-cost adsorbents for various metal ions and other wastewater effluents. The problems related to leaching commonly associated with tea-based adsorbents can be overcome by treating it with mild solutions of formaldehyde.

-

It is preferable to convert the waste tea leaves into activated carbon before being used for adsorptive purposes as the latter boasts significantly higher effluent adsorptive capacities which in turn reduces the amount of adsorbent needed.

-

Under right impregnation ratios, activation temperature and time, the activated carbon produced from waste tea precursor possess properties similar to some grades of commercially available granular activated carbon. However, when the use of potassium acetate as the chemical activating agent is combined with a prolonged activation time, the resultant AC possesses remarkably high values of BET surface area and net pore volume.

-

One of the limitations of the study was that the influence of using microwave energy-assisted activation for the synthesis of activated carbon from waste tea leaves was not critically evaluated. Although this was attributed to the limited number of associated literature, it does represent untapped potential for expanding this work.

-

However, detailed studies are required to comprehend the efficiency of using waste tea for adsorption purposes in real life and the economics of using it as an alternative precursor material for the industrial production of activated carbon.

References

Abbas MN (2014) Application of used tea leaves for multi functions. Eur Acad Res 2(7):8660–8690

Adachi A, Ioku A, Taniyama K, Okano T (2008) Use of tea or coffee lees as adsorbent for removal of benzene from wastewater. J Health Sci 54(4):478–481

Ahluwalia SS, Goyal D (2005) Removal of heavy metals by waste tea leaves from aqueous solution. Eng Life Sci 5(2):158–162. https://doi.org/10.1002/elsc.200420066

Ahmad AA, Hameed BH (2009) Reduction of COD and color of dyeing effluent from a cotton textile mill by adsorption onto bamboo-based activated carbon. J Hazard Mater 172(2–3):1538–1543. https://doi.org/10.1016/j.jhazmat.2009.08.025

Ahmadpour A, Do DD (1997) The preparation of activated carbon from macadamia nutshell by chemical activation. Carbon 35(12):1723–1732. https://doi.org/10.1016/S0008-6223(97)00127-9

Ahmaruzzaman M, Gayatri SL (2010) Activated tea waste as a potential low-cost adsorbent for the removal of p -nitrophenol from wastewater. J Chem Eng Data 55(11):4614–4623. https://doi.org/10.1021/je100117s

Ajmal M, Rao RAK, Khan MA (2005) Adsorption of copper from aqueous solution on Brassica cumpestris (mustard oil cake). J Hazard Mater 122(1–2):177–183. https://doi.org/10.1016/j.jhazmat.2005.03.029

Akar E, Altinişik A, Seki Y (2013) Using activated carbon produced from spent tea leaves for the removal of malachite green from aqueous solution. Ecol Eng. https://doi.org/10.1016/j.ecoleng.2012.12.032

Amey WA (2013) Preparation of low cost activated carbon from tea waste using sulphuric acid as activating agent. ISSN Int Res J Environ Sci 2(4):2319–2414

Auta M (2012) Optimization of tea waste activated carbon preparation parameters for removal of cibacron yellow dye from textile waste waters. Int J Adv Eng Res 1(4):50–56

Auta M, Hameed BH (2011a) Optimized waste tea activated carbon for adsorption of Methylene Blue and Acid Blue 29 dyes using response surface methodology. Chem Eng J. https://doi.org/10.1016/j.cej.2011.09.100

Auta M, Hameed BH (2011b) Preparation of waste tea activated carbon using potassium acetate as an activating agent for adsorption of Acid Blue 25 dye. Chem Eng J. https://doi.org/10.1016/j.cej.2011.04.017

Auta M, Umaru M, Yahya M, Adeniyi O, Aris IM, Suleiman B (2015) Diethanolamine functionalized waste tea activated carbon for CO2 adsorption (C). In: International conference on chemical, environmental and biological science. Dubai

Baccar R, Bouzid J, Feki M, Montiel A (2009) Preparation of activated carbon from Tunisian olive-waste cakes and its application for adsorption of heavy metal ions. J Hazard Mater 162:1522–1529

Bhargava SK, Tardio J, Prasad J, Föger K, Akolekar DB, Grocott SC (2006) Wet oxidation and catalytic wet oxidation. Ind Eng Chem Res 45(4):1221–1258. https://doi.org/10.1021/ie051059n

Cay S, Uyan\ik A, Öza\cs\ik A (2004) Single and binary component adsorption of copper (II) and cadmium (II) from aqueous solutions using tea-industry waste. Sep Purif Technol 38(3):273–280

Chandra TC, Mirna MM, Sunarso J, Sudaryanto Y, Ismadji S (2009) Activated carbon from durian shell: preparation and characterization. J Taiwan Inst Chem Eng 40(4):457–462. https://doi.org/10.1016/j.jtice.2008.10.002

Chatterjee A, Saluja M, Agarwal G, Alam M (2012) Green tea: a boon for periodontal and general health. J Indian Soc Periodontal 16:161–167

Cheraghi M, Sobhanardakani S, Zandipak R, Lorestani B, Merrikhpour H (2015) Removal of Pb(II) from aqueous solutions using waste tea leaves. Iran J Toxicol 9(28):1247–1253

Demiral H, Gündüzog G (2010) Bioresource technology removal of nitrate from aqueous solutions by activated carbon prepared from sugar beet bagasse. Biores Technol 101(101):1675–1680. https://doi.org/10.1016/j.biortech.2009.09.087

Deng H, Yang L, Tao G, Dai J (2009) Preparation and characterization of activated carbon from cotton stalk by microwave assisted chemical activation-Application in methylene blue adsorption from aqueous solution. J Hazard Mater 166(2–3):1514–1521. https://doi.org/10.1016/j.jhazmat.2008.12.080

Duran C, Ozdes D, Gundogdu A, Imamoglu M, Senturk HB (2011) Tea-industry waste activated carbon, as a novel adsorbent, for separation, preconcentration and speciation of chromium. Anal Chim Acta. https://doi.org/10.1016/j.aca.2010.12.029

Dutta M, Das U, Mondal S, Bhattachriya S, Khatun R, Bagal R (2015) Adsorption of acetaminophen by using tea waste derived activated carbon. Int J Environ Sci. https://doi.org/10.6088/ijes.6031

Fadhil AB, Dheyab MM, Abdul-Qader AQY (2012) Purification of biodiesel using activated carbons produced from spent tea waste. J Assoc Arab Univ Basic Appl Sci. https://doi.org/10.1016/j.jaubas.2011.12.001

Fauziah S, Draman S, Mohd N, Hafiza N, Wahab I, Zulkfli NS, Fatin N (2015) Adsorption of lead (Ii) ions in aqueous solution using selected agro-waste. ARPN J Eng Appl Sci 10(1):297–300

Gao J, Kong D, Wang Y, Wu J, Sun S, Xu P (2013) Production of mesoporous activated carbon from tea fruit peel residues and its evaluation of methylene blue removal from aqueous solutions. BioResources 8:2145–2160

Garba ZN, Faezah S, Soib B, Rahim AA (2015) Valuation of activated carbon from waste tea for the removal of a basic dye from aqueous solution. J Chem Eng Chem Res 2(5):623–633

Girgis BS, El-Hendawy ANA (2002) Porosity development in activated carbons obtained from date pits under chemical activation with phosphoric acid. Microporous Mesoporous Mater 52(2):105–117. https://doi.org/10.1016/S1387-1811(01)00481-4

Goswami M, Borah L, Mahanta D, Phukan P (2014) Equilibrium modeling, kinetic and thermodynamic studies on the adsorption of Cr(VI) using activated carbon derived from matured tea leaves. J Porous Mater. https://doi.org/10.1007/s10934-014-9852-1

Gundogdu A, Duran C, Senturk HB, Soylak M, Ozdes D, Serencam H, Imamoglu M (2012) Adsorption of phenol from aqueous solution on a low-cost activated carbon produced from tea industry waste: equilibrium, kinetic, and thermodynamic study. J Chem Eng Data. https://doi.org/10.1021/je300597u

Gundogdu A, Duran C, Senturk HB, Soylak M, Imamoglu M, Onal Y (2013) Physicochemical characteristics of a novel activated carbon produced from tea industry waste. J Anal Appl Pyrol. https://doi.org/10.1016/j.jaap.2013.07.008

Gurten II, Ozmak M, Yagmur E, Aktas Z (2012) Preparation and characterisation of activated carbon from waste tea using K2CO3. Biomass Bioenerg. https://doi.org/10.1016/j.biombioe.2011.12.030

Hammud KK, Raouf AM, Mohammed A, Al-Sammarrie A, Neema RR (2016) New chemically prepared–waste cooked tea based activated carbon: FTIR, XRD, AFM, and SEM spectroscopic studies. Int J Res Pharm Chem 6(2):220–229

Harbowy ME, Balentine AD, Davies AP (1997) Tea chemistry. Crit Rev Plant Sci 16(5):415–480. https://doi.org/10.1080/713608154

Harler C (1963) Tea manufacture. Oxford University Press, London

Hassan S, Ali F (2013) Usability study of spent black tea leaves and pomegranate peel in adsorption. Int J Curr Res 5(9):2530–2538

Ifelebuegu AO, Onwugbuta NE (2016) An evaluation of the removal of progesterone in wastewater by adsorption onto waste tea leaves. In: Fourth International conference on advances in applied science and environmental technology. https://doi.org/10.15224/978-1-63248-097-2-43

Ifelebuegu AO, Ukpebor JE, Obidiegwu CC, Kwofi BC (2015) Comparative potential of black tea leaves waste to granular activated carbon in adsorption of endocrine disrupting compounds from aqueous solution. Glob J Environ Sci Manag 1(3):205–214. https://doi.org/10.7508/GJESM.2015.03.003

Islam MA, Benhouria A, Asif M, Hameed BH (2015) Methylene blue adsorption on factory-rejected tea activated carbon prepared by conjunction of hydrothermal carbonization and sodium hydroxide activation processes. J Taiwan Inst Chem Eng. https://doi.org/10.1016/j.jtice.2015.02.010

Jeyaseelan C, Gupta A (2016) Green tea leaves as a natural adsorbent for the removal of Cr(VI) from aqueous solutions. Air, Soil Water Res. https://doi.org/10.4137/ASWr.S35227

Jung S, Naidoo M, Shairzai S, Navarro AE (2014) On the adsorption of a cationic artificial dye on spent tea leaves. WIT Trans Built Environ 139:231–241. https://doi.org/10.2495/UW140201

Kazmi M, Saleemi AR, Feroze N, Yaqoob A, Ahmad SW (2013) Removal of phenol from wastewater using activated waste tea leaves. Polish J Chem Technol 15(2):1–6

Khalili NR, Campbell M, Sandi G, Golas J (2000) Production of micro-and mesoporous activated carbon from paper mill sludge I. Effect of zinc chloride activation. Pergamon Carbon 38(38):1905–1915

Khan N, Yahaya EM, Faizal M, Mohamed P, Abustan I, Azmier M (2010) Effect of preparation conditions of activated carbon prepared from rice husk by ZnCl2 activation for removal of Cu (II) from aqueous solution. J Eng Technol 6:1–5

Khosla E, Kaur S, Dave PN (2011) Surfactant modified tea waste as a novel adsorbent for the removal of Basic dye. Pelagia Res Library Der Chem Sin 2(5):87–102

Kondo M, Sato H (1994) Treatment of wastewater from phenolic resin process by pervaporation. Desalination 98(1–3):147–154. https://doi.org/10.1016/0011-9164(94)00139-1

Kula I, Uğurlu M, Karaoğlu H, Celik A (2008) Adsorption of Cd (II) ions from aqueous solutions using activated carbon prepared from olive stone by ZnCl2 activation. Biores Technol 99(3):492–501

Kumar H, Sumint T, Trivedia S, Pandey LK (2015) Tea waste adsorbent for the removal of chromium and copper from synthetic wastewater. IJIRST Int J Innov Res Sci Technol 2(2):70–74

Li Q, Chai L, Yang Z, Wang Q, Wang Y (2010) A comparative study of Ag(I) adsorption on raw and modified spent grain: kinetic and thermodynamic aspects. WaterEnvironRes 82:2290–2296

Macfarlane A, Macfarlane I (2011) Green gold: the empire of tea. The OverLook Press. https://books.google.co.in/books?hl=en&lr=&id=4SCZJFFf6ZsC&oi=fnd&pg=PT4&dq=+tea+mania++Assam+Tea&ots=EDzCP_nPh0&sig=gomQum3z1ckVQppXiudzQhk1GpY

Mahvi AH (2009) Application of agricultural fibers in pollution removal from aqueous solution. Int J Environ Sci Technol 5(2):275–285. https://doi.org/10.1007/BF03326022

Malakahmad A, Tan S, Yavari S (2016) Valorization of wasted black tea as a low-cost adsorbent for nickel and zinc removal from aqueous solution. J Chem. https://doi.org/10.1155/2016/5680983

Malkoç E, Nuhoglu Y (2003) The removal of Chromium (VI) from synthetic Wastewater by Ulothrix zonata. Fresenius Environ Bull 12(4):376–381

Matta GK, Barros MAS, Lambrecth R, Da Silva E, da Motta Lima O (2008) Dynamic isotherms of dye in activated carbon. Mater Res 2(3):365–369

Menon R, Singh J, Doshi V, Lim XY (2015) Investigation on spent tea leaves derived activated carbon for co 2 adsorption. J Eng Sci Technol EURECA 2014 Special Issue April, pp 50–61

Nasuha N, Hameed BH (2011a) Adsorption of methylene blue from aqueous solution onto NaOH-modified rejected tea. Chem Eng J 166(2):783–786. https://doi.org/10.1016/j.cej.2010.11.012

Nasuha N, Hameed BH (2011b) Adsorption of methylene blue from aqueous solution onto NaOH-modified rejected tea. Chem Eng J. https://doi.org/10.1016/j.cej.2010.11.012

Nuhoglu Y, Malkoc E, Gürses A, Canpolat N (2002) The removal of Cu (II) from aqueous solutions by Ulothrix zonata. Biores Technol 85(3):331–333. https://doi.org/10.1016/S0960-8524(02)00098-6

Okasha AY, Ibrahim HG (2010) Phenol removal from aqueous systems by sorption of using some local waste materials. Electron J Environ Agric Food Chem 9:796–807

Oliveira L, Pereira E, Guimaraes I, Vallone A, Pereira M, Mesquita J, Sapag K (2009) Preparation of activated carbons from coffee husks utilizing FeCl3 and ZnCl2 as activating agents. J Hazard Mater 165:87–94

Orhan Y, Büyükgüngör H (1993) The removal of heavy metals by using agricultural wastes. Water Sci Technol 28(2):247–255

Pajooheshfar SP, Saeedi M (2009) Adsorptive removal of phenol from contaminated water and wastewater by activated carbon, almond, and walnut shells charcoal. Water Environ Res 81(6):641–648. https://doi.org/10.2175/106143008x390780

Peng C, Yan X Bin, Wang RT, Lang JW, Ou YJ, Xue QJ (2013) Promising activated carbons derived from waste tea-leaves and their application in high performance supercapacitors electrodes. Electrochim Acta 87(87):401–408. https://doi.org/10.1016/j.electacta.2012.09.082

Plaza MG, Pevida C, Martín CF, Fermoso J, Pis JJ, Rubiera F (2010) Developing almond shell-derived activated carbons as CO2 adsorbents. Sep Purif Technol 71(1):102–106. https://doi.org/10.1016/j.seppur.2009.11.008

Rani KM, Palanisamy PN, Gayathri S, Tamilselvi S, Professor A (2007) Adsorptive removal of basic violet dye from aqueous solution by activated carbon prepared from tea dust material. Int J Innov Res Sci Eng Technol. https://doi.org/10.15680/IJIRSET.2015.0408020

Reza A, Sheikh FA, Kim H, Zargar MA, Zainal Abedin M (2016) Facile and efficient strategy for removal of reactive industrial dye by using tea waste. Adv Mater Lett Adv Mater Lett 7(711):878–885. https://doi.org/10.5185/amlett.2016.6363

Rossner A, Snyder S (2009) Removal of emerging contaminants of concern by alternative adsorbent. Water Res 43(15):3787–3796

Roy S (2015) Batch adsorption of Ni(II) on low cost activated carbon prepared from tea waste precursor. Int J Eng Sci Res-IJESR, 3(1). http://technicaljournals.org