Abstract

It is a critical concern to properly manage the risks associated with the stability of tailings and dredge sludge dams. This requires the knowledge of the pore water pressure (PWP) within a slurried material during and after the deposition. The evaluation of the PWP can also help to estimate the settlement, which is important for the water management and design of the storage facility. An analytical solution based on the Gibson model has been proposed by the authors to evaluate the excess PWP during the slurry deposition. However, there is no solution available to estimate the excess PWP and volume of draining water after the end of slurry deposition. In this paper, a new solution is proposed to evaluate the PWP, settlement, and volume of draining water after the slurry deposition on a pervious base. The proposed PWP solution is partly validated by numerical modeling with SIGMA/W and laboratory results. The influence of the consolidation coefficient and filling rate on the distribution and evolution of PWP is analyzed. The solution development for estimating the excess PWP, volume of draining water and settlement after slurry deposition on an impervious base has been presented in a companion paper (part I).

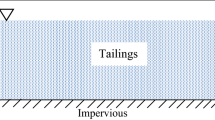

Adapted from Gibson (1958)

Similar content being viewed by others

References

Agapito LA, Bareither CA (2018) Application of a one-dimensional large-strain consolidation model to a full-scale tailings storage facility. Miner Eng 119:38–48

Agurto-Detzel H, Bianchi M, Assumpção M, Schimmel M, Collaço B, Ciardelli C, Barbosa JR, Calhau J (2016) The tailings dam failure of 5 November 2015 in SE Brazil and its preceding seismic sequence. Geophys Res Lett 43:4929–4936

Ahmed SI, Siddiqua S (2014) A review on consolidation behavior of tailings. Int J Geotech Eng 8:102–111

Alam R, Shang J-Q, Islam S (2017) Electrophoresis and its applications in oil sand tailings management. Int J Miner Process 161:41–49

Asif Z, Chen Z (2016) Environmental management in North American mining sector. Environ Sci Pollut Res 23:167–179

Asmar NH (2004) Partial differential equations and boundary value problems. Pearson Education, Upper Saddle River

ASTM International (2011) Standard test methods for one-dimensional consolidation properties of soils using incremental loading. Standard ASTM D2435/D2435M-11, West Conshohocken, PA

Aubertin M, Bussiere B, Chapuis RP (1996) Hydraulic conductivity of homogenized tailings from hard rock mines. Can Geotech J 33:470–482

Been K, Sills GC (1981) Self-weight consolidation of soft soils: an experimental and theoretical study. Geotechnique 31:519–535

Beier N, Wilson W, Dunmola A, Sego D (2013) Impact of flocculation-based dewatering on the shear strength of oil sands fine tailings. Can Geotech J 50:1001–1007

Bolduc FL, Aubertin M (2014) Numerical investigation of the influence of waste rock inclusions on tailings consolidation. Can Geotech J 51:1021–1032

Caughill DL, Morgenstern NR, Scott JD (1993) Geotechnics of nonsegregating oil sand tailings. Can Geotech J 30:801–811

da Silva F (2011) Reducing risks to tailing storage facilities through in-line flocculant addition. GeoFrontiers 2011. Advances in Geotechnical Engineering, Dallas, pp 2937–2946

Doherty JP (2015) A numerical study into factors affecting stress and PWP in free draining mine stopes. Comput Geotech 63:331–341

Eckersley D (1990) Instrumented laboratory flowslides. Geotechnique 40:489–502

El-Mkadmi N, Aubertin M, Li L (2013) Effect of drainage and sequential filling on the behavior of backfill in mine stopes. Can Geotech J 51:1–15

Energy Resources Conservation Board (2009) Directive 074: Tailings performance criteria and requirements for oil sands mining schemes. Calgary, Alberta, Canada

Fahey M, Helinski M, Fourie A (2010) Consolidation in accreting sediments: Gibson’s solution applied to backfilling of mine stopes. Géotechnique 60:877–882

Fernandes GW, Goulart FF, Ranieri BD, Coelho MS et al (2016) Deep into the mud: ecological and socio-economic impacts of the dam breach in Mariana, Brazil. Nat Conser 14:35–45

Fourie AB, Blight GE, Papageorgiou G (2001) Static liquefaction as a possible explanation for the Merriespruit tailings dam failure. Can Geotech J 38:707–719

Garcia LC, Ribeiro DB, Roque FO, Ochoa-Quintero JM, Laurance WF (2017) Brazil's worst mining disaster: corporations must be compelled to pay the actual environmental costs. Ecol Appl 27:5–9

GEO-SLOPE (2008) Stress-deformation modeling with SIGMA/ W 2007. Manual, 3rd edn. GEO-SLOPE International Ltd, Calgary

Gibson RE (1958) The progress of consolidation in a clay layer increasing in thickness with time. Géotechnique 8:171–182

Gibson RE, Schiffman RL, Whitman RV (1989) On two definitions of excess pore water pressure. Geotechnique 39:169–171

Imai G (1979) Development of a new consolidation test procedure using seepage force. Soils Found 19:45–60

James M (2009) The use of waste rock inclusions to control the effects of liquefaction in tailings impoundments. PhD Dissertation, Ecole Polytechnique de Montreal, Montreal, Canada

Jeeravipoolvarn S, Chalaturnyk RJ, Scott JD (2009a) Sedimentation– consolidation modeling with an interaction coefficient. Comput Geotech 36:751–761

Jeeravipoolvarn S, Scott JD, Chalaturnyk RJ (2009b) 10 m standpipe tests on oil sands tailings: long-term experimental results and prediction. Can Geotech J 46:875–888

Karim E (2015) Development of Experimental Protocols for the Characterization of Saturated and Unsaturated Tailings Consolidation from Compression Tests in Columns (in French). Master Thesis, École Polytechnique de Montréal, Montréal, Canada

Khaled SM, Azam S (2014) Depositional characteristics of uranium tailings from Saskatchewan, Canada. Environ Earth Sci 72:4393–4400

Li L (2013) Beneficial experience from teaching and education to research and development. Creat Educ 3:148–153

Li L, Alvarez IC, Aubertin JD (2013) Self-weight consolidation of a slurried deposition: tests and interpretation. Int J Geotech Eng 7:205–213

Malekzadeh M, Sivakugan N (2017) One-dimensional electrokinetic stabilization of dredged mud. Mar Georesour Geotech 35:603–609

Martin TE, McRoberts EC (1999) Some considerations it the stability analysis of upstream tailings dams. In: proceedings of Tailings and Mine Waste’99, Balkema, Rotterdam, Netherlands, pp 287–302

Mathworks (2011) MATLAB—The language of technical computing. https://www.mathworks.com/products/matlab/. Accessed 16 Jan 2018

Priscu C (1999) Behavior of mine tailings dams under high tailings deposition rates. Ph.D. Dissertation, McGill University, Montreal, Canada

Mittal HK, Morgenstern NR (1976) Seepage control in tailings dams. Can Geotech J 13:277–293

Ozcan NT, Ulusay R, Isik NS (2013) A study on geotechnical characterization and stability of downstream slope of a tailings dam to improve its storage capacity (Turkey). Environ Earth Sci 69:1871–1890

Pane V, Schiffman RL (1985) A note on sedimentation and consolidation. Géotechnique 35:69–72

Pedroni L (2011) Étude expérimentale et numérique de la sédimentation et de la consolidation des boues de traitement des eaux acides. Ph.D. thesis, École Polytechnique de Montréal, Montreal, Canada

Pedroni L, Aubertin M (2008) Evaluation of sludge consolidation from hydraulic gradient tests conducted in large size columns. In: Proceedings of the 61st Canadian Geotechnical Conference, Edmonton, Canada

Qiu YX, Sego DC (2001) Laboratory properties of mine tailings. Can Geotech J 38:183–190

Ripley EA, Redmann RE, Maxwell J (1978) Environmental impact of mining in Canada. Centre for Resource Studies, Queen’s University, Kingston, Canada

Saad B, Mitri H (2010) Hydromechanical analysis of upstream tailings disposal facilities. J Geotech Geoenviron 137:27–42

Saleh-Mbemba F, Aubertin M (2018) Characterization of self-weight consolidation of fine-grained mine tailings using moisture sensors. Geotech Test J 41:543–554

Schoenberger E (2016) Environmentally sustainable mining: the case of tailings storage facilities. Resour Policy 49:119–128

Scott JD, Jeeravipoolvarn S, Chalaturnyk RJ (2008) Tests for wide range of compressibility and hydraulic conductivity of flocculated tailings. In: Proceedings of the 61th Canadian Geotechnical Conference, Edmonton, Canada

Seneviratne NH, Fahey M, Newson TA, Fujiyasu Y (1996) Numerical modelling of consolidation and evaporation of slurried mine tailings. Int J Numer Anal Methods Geomech 20:647–671

Shahsavari M, Grabinsky M (2014) Cemented paste backfill consolidation with deposition-dependent boundary conditions. In: Proceedings of the 67th Canadian geotechnical conference, Regina, Canada

Shahsavari M, Grabinsky M (2015) Mine backfill pore water pressure dissipation: numerical predictions and field measurements. In: Proceedings of 68th Canadian geotechnical conference, Quebec City, Canada

Stone KJL, Randolph MF, Sales AA (1994) Evaluation of consolidation behavior of mine tailings. J Geotech Eng 120:473–490

Terzaghi K (1943) Theoretical soil mechanics. Wiley, New York

Wei ZA, Yin GZ, Wan L, Li GZ (2016) A case study on a geotechnical investigation of drainage methods for heightening a tailings dam. Environ Earth Sci 75:106

Wels C, Robertson AM (2003) Conceptual model for estimating water recovery in tailings impoundments. In: Proceedings of the 10th International Conference of Tailings and Mine Waste, Vail, CO. Colorado State University, pp 87–94

Zheng J, Li L, Mbonimpa M, Pabst T (2018a) An analytical solution of Gibson’s model for estimating the pore water pressures in accreting deposition of slurried material under one-dimensional self-weight consolidation. Part I: pervious base. Ind Geotech J 48:72–83

Zheng J, Li L, Mbonimpa M, Pabst T (2018b) An analytical solution of Gibson’s model for estimating pore water pressures in accreting deposition of slurried material under one-dimensional self-weight consolidation. Part II: impervious base. Ind Geotech J 48:188–195

Acknowledgements

The authors would like to acknowledge the financial support from the Natural Sciences and Engineering Research Council of Canada (NSERC 402318), Institut de recherche Rovert-Sauvé en santé et en sécurité du travail (IRSST 2013-0029), Fonds de recherche du Québec—Nature et Technologies (FRQNT 2015-MI-191676), Mitacs Elevate Postdoctoral Fellowship (IT12572), and industrial partners of the Research Institute on Mines and the Environment (RIME UQAT-Polytechnique; https://rime-irme.ca/). The anonymous reviewers are also gratefully acknowledged for their critical and constructive comments and suggestions that significantly helped to improve the quality of the paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Derivation process for the proposed solution (Eq. 5)

Equation (3) can be solved by applying the method of separation of variables (Asmar 2004). The function pw1(z, t1) can be expressed as follows:

where Z(z) and T(t1) are functions of z and t1, respectively.

The boundary conditions pw1 = 0 at z = 0, H can then be met by considering Z(0) = 0 and Z(H) = 0.

Substituting Eq. (13) into Eq. (3) yields

where λ is a non-zero constant (λ ≠ 0).

The former equality of Eq. (14) can be rewritten as

A general solution of Eq. (15) is given as follows

Taking the boundary conditions Z(0) = 0 and Z(H) = 0 into Eq. (16) leads to

The characteristic value of λ can then be obtained from Eq. (17) as follows:

The characteristic function of Z(z) for Eq. (20) can be expressed as follows:

where Aα is a series of constants.

The latter equability of Eq. (14) can be rewritten as follows:

The characteristic function of T(t1) for Eq. (21) can be solved as follows:

where Bα is a series of constants.

Introducing Eqs. (20) and (22) into Eq. (13) leads to

where Cα is a series of constants.

Considering the initial condition (at t1 = 0) of Eq. (4) for the post-deposition process, the following equation can be obtained:

or

The orthogonality of trigonometric function stipulates α = β (otherwise, the right side of Eq. (25) is equal to zero for α ≠ β). One thus has

or

Substituting Eq. (27) into Eq. (23) leads to

Appendix B: MATLAB program for solving Eq. (5)

A MATLAB program is given here to solve Eq. (5) and output the (excess) PWP at an elevation z at a given time t1. An example of calculation is conducted by using typical geometry and property parameters with H = 8 m, γ = 20 kN/m3, m = 0.2 m/h, cv = 1 m2/h, t0 = 40 h, and t1 = 5 h.

Rights and permissions

About this article

Cite this article

Zheng, J., Li, L. & Li, YC. Solutions to estimate the excess PWP, settlement and volume of draining water after slurry deposition. Part II: pervious base. Environ Earth Sci 79, 275 (2020). https://doi.org/10.1007/s12665-020-09014-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-020-09014-2