Abstract

In Morocco, the production of argan oil generates a natural organic residue available at a low cost, which is known as argan cake. It shows potential as a biodiesel resource due to its substantial oil residue content. A kinetic study of transesterification was conducted to evaluate the potential of argan cake oil (ACO) in producing biodiesel. The obtained activation energy is equal to Ea = 30.85 kJ/mol, and the reaction rate falls within the range of 0.0121 to 0.0241 min−1 at temperatures between 40 and 60 °C. Realizing that the catalyst type has a significant impact on the reaction kinetics, a comparison was made between homogeneous, heterogeneous, and enzymatic catalysts using the multi-criteria decision-making (MCDM) method. This method was employed to select the catalyst that maximizes biodiesel yield while minimizing cost and environmental impact. Five catalyst types were studied: homogeneous acid and basic catalysts, heterogeneous acid and basic catalysts, and enzymatic catalysts. In the classification process, eight criteria were considered: catalyst sensitivity to free fatty acid (FFA) and water in the raw material, biodiesel yield, reaction rate, glycerol recovery, catalyst recovery and recycling, energy cost, catalyst cost, and environmental impact. The results from the Fuzzy Technique for Order of Preference by Similarity to the Ideal Solution (FTOPSIS) showed that the basic heterogeneous catalyst outperforms the other four examined catalysts.

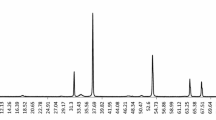

Graphical Abstract

Similar content being viewed by others

Data Availability

Enquiries about data availability should be directed to the authors.

References

Kamzon, M.A., Abderafi, S., Bounahmidi, T.: Promising bioethanol processes for developing a biorefinery in the Moroccan sugar industry. Int. J. Hydrog. Energy 41, 20880–20896 (2016). https://doi.org/10.1016/j.ijhydene.2016.07.035

El-kourdi, S., Aboudaoud, S., Abderafi, S., Cheddadi, A.: Potential assessment of combustible municipal wastes in Morocco and their ability to produce bio-oil by pyrolysis. Mater. Sci. Forum 1073, 149–154 (2022). https://doi.org/10.4028/p-2gg5xu

Bhutto, A.W., Qureshi, K., Abro, R., Harijan, K., Zhao, Z., Bazmi, A.A., Abbas, T., Yu, G.: Progress in the production of biomass-to-liquid biofuels to decarbonize the transport sector–prospects and challenges. RSC Adv. 6, 32140–32170 (2016). https://doi.org/10.1039/C5RA26459F

Tgarguifa, A., Abderafi, S., Bounahmidi, T.: Energy efficiency improvement of a bioethanol distillery, by replacing a rectifying column with a pervaporation unit. Renew. Energy 122, 239–250 (2018). https://doi.org/10.1016/j.renene.2018.01.112

Mohammed, Y.S., Mustafa, M.W., Bashir, N.: Status of renewable energy consumption and developmental challenges in Sub-Sahara Africa. Renew. Sustain. Energy Rev. 27, 453–463 (2013). https://doi.org/10.1016/j.rser.2013.06.044

Chen, H., Fu, X.: Industrial technologies for bioethanol production from lignocellulosic biomass. Renew. Sustain. Energy Rev. 57, 468–478 (2016). https://doi.org/10.1016/j.rser.2015.12.069

Subbarayan, M.R., Senthil Kumaar, J.S., Anantha Padmanaban, M.R.: Experimental investigation of evaporation rate and exhaust emissions of diesel engine fuelled with cotton seed methyl ester and its blend with petro-diesel. Transp. Res. Part Transp. Environ. 48, 369–377 (2016). https://doi.org/10.1016/j.trd.2016.08.024

Yusuf, N.N.A.N., Kamarudin, S.K., Yaakub, Z.: Overview on the current trends in biodiesel production. Energy Convers. Manag. 52, 2741–2751 (2011). https://doi.org/10.1016/j.enconman.2010.12.004

Leung, D.Y.C., Wu, X., Leung, M.K.H.: A review on biodiesel production using catalyzed transesterification. Appl. Energy 87, 1083–1095 (2010). https://doi.org/10.1016/j.apenergy.2009.10.006

Ahmed, T., Souad, A., Tijani, B.: Energetic byproducts of sugar industry. Int. Conf. Compos. Mater. Renew. Energy Appl. (ICCMREA) (2014). https://doi.org/10.1109/ICCMREA.2014.6843787

Aboudaoud, S., El Kourdi, S., Abderafi, S., Abbassi, M.A.: Municipal solid waste generation from Morocco and Tunisia, and their possible energetic valorization. Int. Renew. Sustain. Energy Conf. (IRSEC) (2021). https://doi.org/10.1109/IRSEC53969.2021.9741166

Zeghlouli, J., Guendouz, A., Duchez, D., El Modafar, C., Michaud, P., Delattre, C.: Valorization of co-products generated by argan oil extraction process: application to biodiesel production. Biofuels (2021). https://doi.org/10.1080/17597269.2021.1941573

Chakib, A.: Rapport final de mission Projet de recherche filière Argan, Programme Gouvernance des Entreprises et Organisations du Développement Durable. (2013)

González-Fernández, M.J., Manzano-Agugliaro, F., Zapata-Sierra, A., Belarbi, E.H., Guil-Guerrero, J.L.: Green argan oil extraction from roasted and unroasted seeds by using various polarity solvents allowed by the EU legislation. J. Clean. Prod. 276, 123081 (2020). https://doi.org/10.1016/j.jclepro.2020.123081

Folayan, A.J., Anawe, P.A.L.: Synthesis and characterization of Argania spinosa (Argan oil) biodiesel by sodium hydroxide catalyzed transesterification reaction as alternative for petro-diesel in direct injection, compression ignition engines. Heliyon 5, e02427 (2019). https://doi.org/10.1016/j.heliyon.2019.e02427

Kara, K., Ouanji, F., El Mahi, M., Lotfi, E.M., Kacimi, M., Mahfoud, Z.: Biodiesel synthesis from vegetable oil using eggshell waste as a heterogeneous catalyst. Biofuels 12, 1083–1089 (2021). https://doi.org/10.1080/17597269.2019.1580972

Etim, A.O., Musonge, P., Eloka-Eboka, A.C.: A green process synthesis of bio-composite heterogeneous catalyst for the transesterification of linseed-marula bi-oil methyl ester. Results Eng. 16, 100645 (2022). https://doi.org/10.1016/j.rineng.2022.100645

Simbi, I., Aigbe, U.O., Oyekola, O., Osibote, O.A.: Optimization of biodiesel produced from waste sunflower cooking oil over bi-functional catalyst. Results Eng. 13, 100374 (2022). https://doi.org/10.1016/j.rineng.2022.100374

Xie, W., Gao, C., Li, J.: Sustainable biodiesel production from low-quantity oils utilizing H6PV3MoW8O40 supported on magnetic Fe3O4/ZIF-8 composites. Renew. Energy 168, 927–937 (2021). https://doi.org/10.1016/j.renene.2020.12.129

Mostafa, F., Nourozi, L., Zakarianezhad, M.: Preparation and characterization of magnetic CsH2PW12O40/Fe–SiO2 nanocatalysts for biodiesel production. Mater. Res. Bull. 60, 412–420 (2014). https://doi.org/10.1016/j.materresbull.2014.09.005

Georgogianni, K.G., Kontominas, M.G., Pomonis, P.J., Avlonitis, D., Gergis, V.: Conventional and in situ transesterification of sunflower seed oil for the production of biodiesel. Fuel Process. Technol. 89, 503–509 (2008). https://doi.org/10.1016/j.fuproc.2007.10.004

El Kourdi, S., Aboudaoud, S., Abderafi, S., Cheddadi, A., Ammar, A.M.: Pyrolysis technology choice to produce bio-oil, from municipal solid waste, using multi-criteria decision-making methods. Waste Biomass Valoriz. (2023). https://doi.org/10.1007/s12649-023-02076-w

Ourya, I., Abderafi, S.: Clean technology selection of hydrogen production on an industrial scale in Morocco. Results Eng. 17, 100815 (2023). https://doi.org/10.1016/j.rineng.2022.100815

Folayan, A.J., Anawe, P.A.L., Aladejare, A.E., Ayeni, A.O.: Experimental investigation of the effect of fatty acids configuration, chain length, branching and degree of unsaturation on biodiesel fuel properties obtained from lauric oils, high-oleic and high-linoleic vegetable oil biomass. Energy Rep. 5, 793–806 (2019). https://doi.org/10.1016/j.egyr.2019.06.013

Lima, A.C.C.: Evaluation of alkaline ionic liquids for catalysis of biodiesel from cooking oil. https://search.proquest.com/openview/202cfb41a6f4d78aaedad53234c29793/1?pq-origsite=gscholar&cbl=2026366&diss=y. (2018)

Paul, A.A.L., Adewale, F.J.: Data on optimization of production parameters on Persea Americana (Avocado) plant oil biodiesel yield and quality. Data Brief 20, 855–863 (2018). https://doi.org/10.1016/j.dib.2018.08.064

Suthar, K., Dwivedi, A., Joshipura, M.: A review on separation and purification techniques for biodiesel production with special emphasis on Jatropha oil as a feedstock. Asia-Pac. J. Chem. Eng. 14, e2361 (2019). https://doi.org/10.1002/apj.2361

Salamatinia, B., Abdullah, A.Z., Bhatia, S.: Quality evaluation of biodiesel produced through ultrasound-assisted heterogeneous catalytic system. Fuel Process. Technol. 97, 1–8 (2012). https://doi.org/10.1016/j.fuproc.2012.01.003

Yan, Y., Li, X., Wang, G., Gui, X., Li, G., Su, F., Wang, X., Liu, T.: Biotechnological preparation of biodiesel and its high-valued derivatives: a review. Appl. Energy 113, 1614–1631 (2014). https://doi.org/10.1016/j.apenergy.2013.09.029

Anawe, P.A.L., Adewale, F.J.: Data on physico-chemical, performance, combustion and emission characteristics of Persea Americana Biodiesel and its blends on direct-injection, compression-ignition engines. Data Brief 21, 1533–1540 (2018). https://doi.org/10.1016/j.dib.2018.10.166

Kusdiana, D., Saka, S.: Kinetics of transesterification in rapeseed oil to biodiesel fuel as treated in supercritical methanol. Fuel 80, 693–698 (2001). https://doi.org/10.1016/S0016-2361(00)00140-X

Asri, N.P., Budikarjono, K., Suprapto, S., Roesyadi, A.: Kinetics of palm oil transesterification using double promoted catalyst CaO/KI/γ-Al2O3. J. Eng. Technol. Sci. 47, 353–363 (2015). https://doi.org/10.5614/j.eng.technol.sci.2015.47.4.1

Teo, S.H., Islam, A., Masoumi, H.R.F., Taufiq-Yap, Y.H., Janaun, J., Chan, E.-S., Khaleque, M.A.: Effective synthesis of biodiesel from Jatropha curcas oil using betaine assisted nanoparticle heterogeneous catalyst from eggshell of Gallus domesticus. Renew. Energy 111, 892–905 (2017). https://doi.org/10.1016/j.renene.2017.04.039

Zhang, Y., Li, Y., Zhang, X., Tan, T.: Biodiesel production by direct transesterification of microalgal biomass with co-solvent. Bioresour. Technol. 196, 712–715 (2015). https://doi.org/10.1016/j.biortech.2015.07.052

Talebian-Kiakalaieh, A., Amin, N.A.S., Zarei, A., Noshadi, I.: Transesterification of waste cooking oil by heteropoly acid (HPA) catalyst: Optimization and kinetic model. Appl. Energy 102, 283–292 (2013). https://doi.org/10.1016/j.apenergy.2012.07.018

Wu, X., Qiang, X., Liu, D., Yu, L., Wang, X.: An eco-friendly tanning process to wet-white leather based on amino acids. J. Clean. Prod. 270, 122399 (2020). https://doi.org/10.1016/j.jclepro.2020.122399

Seyfi-Shishavan, S.A., Gündoğdu, F.K., Farrokhizadeh, E.: An assessment of the banking industry performance based on Intuitionistic fuzzy Best-Worst Method and fuzzy inference system. Appl. Soft Comput. 113, 107990 (2021). https://doi.org/10.1016/j.asoc.2021.107990

Jain, N., Singh, A.R.: Sustainable supplier selection under must-be criteria through Fuzzy inference system. J. Clean. Prod. 248, 119275 (2020). https://doi.org/10.1016/j.jclepro.2019.119275

Patil, P., Gude, V.G., Pinappu, S., Deng, S.: Transesterification kinetics of Camelina sativa oil on metal oxide catalysts under conventional and microwave heating conditions. Chem. Eng. J. 168, 1296–1300 (2011). https://doi.org/10.1016/j.cej.2011.02.030

Rao, R.V., Patel, B.K.: A subjective and objective integrated multiple attribute decision making method for material selection. Mater. Des. 31, 4738–4747 (2010). https://doi.org/10.1016/j.matdes.2010.05.014

Chen, C.-T.: Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets Syst. 114, 1–9 (2000). https://doi.org/10.1016/S0165-0114(97)00377-1

Alao, M.A., Ayodele, T.R., Ogunjuyigbe, A.S.O., Popoola, O.M.: Multi-criteria decision based waste to energy technology selection using entropy-weighted TOPSIS technique: the case study of Lagos. Nigeria. Energy. 201, 117675 (2020). https://doi.org/10.1016/j.energy.2020.117675

da Silva, D.J.C., Schaefer, J.L., Baierle, I.C., da Veiga, C.P., Júnior, A.N.: Proposition of the waste management model. Resour. Conserv. Recycl. Adv. 15, 200114 (2022). https://doi.org/10.1016/j.rcradv.2022.200114

Hidalgo, P., Toro, C., Ciudad, G., Navia, R.: Advances in direct transesterification of microalgal biomass for biodiesel production. Rev. Environ. Sci. Biotechnol. 12, 179–199 (2013). https://doi.org/10.1007/s11157-013-9308-0

Veny, H., Aroua, M.K., Sulaiman, N.M.N.: Kinetic study of lipase catalyzed transesterification of jatropha oil in circulated batch packed bed reactor. Chem. Eng. J. 237, 123–130 (2014). https://doi.org/10.1016/j.cej.2013.10.010

Wu, L., Huang, K., Wei, T., Lin, Z., Zou, Y., Tong, Z.: Process intensification of NaOH-catalyzed transesterification for biodiesel production by the use of bentonite and co-solvent (diethyl ether). Fuel 186, 597–604 (2016). https://doi.org/10.1016/j.fuel.2016.08.106

Wu, L., Wei, T., Lin, Z., Zou, Y., Tong, Z., Sun, J.: Bentonite-enhanced biodiesel production by NaOH-catalyzed transesterification: Process optimization and kinetics and thermodynamic analysis. Fuel 182, 920–927 (2016). https://doi.org/10.1016/j.fuel.2016.05.065

Cahyo Kumoro, A., Saeed, M.T.M.N.: Ultrasound-assisted transesterification of tropical goat fat: palm oil blend for biodiesel synthesis. Energy Convers. Manag. X 14, 1213 (2022). https://doi.org/10.1016/j.ecmx.2022.100213

Wang, L., He, H., Xie, Z., Yang, J., Zhu, S.: Transesterification of the crude oil of rapeseed with NaOH in supercritical and subcritical methanol. Fuel Process. Technol. 88, 477–481 (2007). https://doi.org/10.1016/j.fuproc.2006.12.003

Verma, P., Dwivedi, G., Sharma, M.P.: Comprehensive analysis on potential factors of ethanol in Karanja biodiesel production and its kinetic studies. Fuel 188, 586–594 (2017). https://doi.org/10.1016/j.fuel.2016.10.062

Muthukumaran, C., Praniesh, R., Navamani, P., Swathi, R., Sharmila, G., Manoj Kumar, N.: Process optimization and kinetic modeling of biodiesel production using non-edible Madhuca indica oil. Fuel 195, 217–225 (2017). https://doi.org/10.1016/j.fuel.2017.01.060

Akhabue, C.E., Okwundu, O.S.: Monitoring the transesterification reaction of castor oil and methanol by ultraviolet visible spectroscopy. Biofuels 10, 729–736 (2019). https://doi.org/10.1080/17597269.2017.1338128

Oraegbunam, J.C., Oladipo, B., Falowo, O.A., Betiku, E.: Clean sandbox (Hura crepitans) oil methyl esters synthesis: a kinetic and thermodynamic study through pH monitoring approach. Renew. Energy 160, 526–537 (2020). https://doi.org/10.1016/j.renene.2020.06.124

Encinar, J.M., González, J.F., Martínez, G., Nogales-Delgado, S.: Transesterification of Soybean oil through different homogeneous catalysts: kinetic study. Catalysts 12, 146 (2022). https://doi.org/10.3390/catal12020146

Freedman, B., Butterfield, R.O., Pryde, E.H.: Transesterification kinetics of soybean oil 1. J. Am. Oil Chem. Soc. 63, 1375–1380 (1986). https://doi.org/10.1007/BF02679606

Lopez, D., Goodwinjr, J., Bruce, D.: Transesterification of triacetin with methanol on Nafion® acid resins. J. Catal. 245, 381–391 (2007). https://doi.org/10.1016/j.jcat.2006.10.027

Thinnakorn, K., Tscheikuna, J.: Biodiesel production via transesterification of palm olein using sodium phosphate as a heterogeneous catalyst. Appl. Catal. Gen. 476, 26–33 (2014). https://doi.org/10.1016/j.apcata.2014.02.016

Gurunathan, B., Ravi, A.: Process optimization and kinetics of biodiesel production from neem oil using copper doped zinc oxide heterogeneous nanocatalyst. Bioresour. Technol. 190, 424–428 (2015). https://doi.org/10.1016/j.biortech.2015.04.101

Baskar, G., Gurugulladevi, A., Nishanthini, T., Aiswarya, R., Tamilarasan, K.: Optimization and kinetics of biodiesel production from Mahua oil using manganese doped zinc oxide nanocatalyst. Renew. Energy 103, 641–646 (2017). https://doi.org/10.1016/j.renene.2016.10.077

Feyzi, M., Shahbazi, Z.: Preparation, kinetic and thermodynamic studies of Al–Sr nanocatalysts for biodiesel production. J. Taiwan Inst. Chem. Eng. 71, 145–155 (2017). https://doi.org/10.1016/j.jtice.2016.11.023

Kaur, N., Ali, A.: Kinetics and reusability of Zr/CaO as heterogeneous catalyst for the ethanolysis and methanolysis of Jatropha crucas oil. Fuel Process. Technol. 119, 173–184 (2014). https://doi.org/10.1016/j.fuproc.2013.11.002

Vyas, A.P., Subrahmanyam, N., Patel, P.A.: Production of biodiesel through transesterification of Jatropha oil using KNO3/Al2O3 solid catalyst. Fuel 88, 625–628 (2009). https://doi.org/10.1016/j.fuel.2008.10.033

Ho, W.W.S., Ng, H.K., Gan, S., Tan, S.H.: Evaluation of palm oil mill fly ash supported calcium oxide as a heterogeneous base catalyst in biodiesel synthesis from crude palm oil. Energy Convers. Manag. 88, 1167–1178 (2014). https://doi.org/10.1016/j.enconman.2014.03.061

Krishnamurthy, K.N., Sridhara, S.N., Ananda Kumar, C.S.: Optimization and kinetic study of biodiesel production from Hydnocarpus wightiana oil and dairy waste scum using snail shell CaO nano catalyst. Renew. Energy 146, 280–296 (2020). https://doi.org/10.1016/j.renene.2019.06.161

Ma, Y., Wang, Q., Sun, X., Wu, C., Gao, Z.: Kinetics studies of biodiesel production from waste cooking oil using FeCl3-modified resin as heterogeneous catalyst. Renew. Energy 107, 522–530 (2017). https://doi.org/10.1016/j.renene.2017.02.007

Olagbende, O.H., Falowo, O.A., Latinwo, L.M., Betiku, E.: Esterification of Khaya senegalensis seed oil with a solid heterogeneous acid catalyst: modeling, optimization, kinetic and thermodynamic studies. Clean. Eng. Technol. 4, 100200 (2021). https://doi.org/10.1016/j.clet.2021.100200

Marques Cardoso, C.M., Zavarize, D.G., Gama Vieira, G.E.: Transesterification of Pequi (Caryocar brasiliensis Camb.) bio-oil via heterogeneous acid catalysis: catalyst preparation, process optimization and kinetics. Ind. Crops Prod. 139, 1485 (2019). https://doi.org/10.1016/j.indcrop.2019.111485

Konwar, L.J., Wärnå, J., Mäki-Arvela, P., Kumar, N., Mikkola, J.-P.: Reaction kinetics with catalyst deactivation in simultaneous esterification and transesterification of acid oils to biodiesel (FAME) over a mesoporous sulphonated carbon catalyst. Fuel 166, 1–11 (2016). https://doi.org/10.1016/j.fuel.2015.10.102

Liu, Y., Yan, Y., Hu, F., Yao, A., Wang, Z., Wei, F.: Transesterification for biodiesel production catalyzed by combined lipases: optimization and kinetics. AIChE J. 56, 1659–1665 (2010). https://doi.org/10.1002/aic.12090

Tran, D.-T., Chang, J.-S.: Kinetics of enzymatic transesterification and thermal deactivation using immobilized Burkholderia lipase as catalyst. Bioprocess Biosyst. Eng. 37, 481–491 (2014). https://doi.org/10.1007/s00449-013-1017-0

Malani, R.S., Umriwad, S.B., Kumar, K., Goyal, A., Moholkar, V.S.: Ultrasound–assisted enzymatic biodiesel production using blended feedstock of non–edible oils: Kinetic analysis. Energy Convers. Manag. 188, 142–150 (2019). https://doi.org/10.1016/j.enconman.2019.03.052

Mandari, V., Devarai, S.K.: Biodiesel production using homogeneous, heterogeneous, and enzyme catalysts via transesterification and esterification reactions: a critical review. Bioenergy Res. 15, 935–961 (2022). https://doi.org/10.1007/s12155-021-10333-w

Dall’Oglio, E.L., de Sousa, P.T., Campos, D.C., Gomes de Vasconcelos, L., da Silva, A.C., Ribeiro, F., Rodrigues, V., Kuhnen, C.A.: Measurement of dielectric properties and microwave-assisted homogeneous acid-catalyzed transesterification in a Monomode reactor. J. Phys. Chem. A 119, 8971–8980 (2015). https://doi.org/10.1021/acs.jpca.5b04890

Ruhul, A.M., Kalam, M.A., Masjuki, H.H., Fattah, I.M.R., Reham, S.S., Rashed, M.M.: State of the art of biodiesel production processes: a review of the heterogeneous catalyst. RSC Adv. 5, 101023–101044 (2015). https://doi.org/10.1039/C5RA09862A

Jayakumar, M., Karmegam, N., Gundupalli, M.P., Bizuneh Gebeyehu, K., Tessema Asfaw, B., Chang, S.W., Ravindran, B., Kumar Awasthi, M.: Heterogeneous base catalysts: synthesis and application for biodiesel production—a review. Bioresour. Technol. 331, 125054 (2021). https://doi.org/10.1016/j.biortech.2021.125054

Christopher, L.P., Hemanathan, K., Zambare, V.P.: Enzymatic biodiesel: challenges and opportunities. Appl. Energy 119, 497–520 (2014). https://doi.org/10.1016/j.apenergy.2014.01.017

Saifuddin, N.M.: A review on processing technology for biodiesel production. Trends Appl. Sci. Res. 10, 1–37 (2015). https://doi.org/10.3923/tsar.2015.1.37

Borges, M.E., Díaz, L.: Recent developments on heterogeneous catalysts for biodiesel production by oil esterification and transesterification reactions: a review. Renew. Sustain. Energy Rev. 16, 2839–2849 (2012). https://doi.org/10.1016/j.rser.2012.01.071

Khoobbakht, G., Kheiralipour, K., Yuan, W., Seifi, M.R., Karimi, M.: Desirability function approach for optimization of enzymatic transesterification catalyzed by lipase immobilized on mesoporous magnetic nanoparticles. Renew. Energy 158, 253–262 (2020). https://doi.org/10.1016/j.renene.2020.05.087

Endalew, A.K., Kiros, Y., Zanzi, R.: Inorganic heterogeneous catalysts for biodiesel production from vegetable oils. Biomass Bioenergy 35, 3787–3809 (2011). https://doi.org/10.1016/j.biombioe.2011.06.011

Nomanbhay, S., Ong, M.: A review of microwave-assisted reactions for biodiesel production. Bioengineering 4, 57 (2017). https://doi.org/10.3390/bioengineering4020057

Basumatary, B., Basumatary, S., Das, B., Nath, B., Kalita, P.: Waste Musa paradisiaca plant: an efficient heterogeneous base catalyst for fast production of biodiesel. J. Clean. Prod. 305, 127089 (2021). https://doi.org/10.1016/j.jclepro.2021.127089

Folayan, A.J., Anawe, P.A.L., Ayeni, A.O.: Synthesis and characterization of Salicornia bigelovii and Salicornia brachiata halophytic plants oil extracted by supercritical CO 2 modified with ethanol for biodiesel production via enzymatic transesterification reaction using immobilized Candida antarctica lipase catalyst in tert-butyl alcohol (TBA) solvent. Cogent. Eng. 6, 1625847 (2019). https://doi.org/10.1080/23311916.2019.1625847

Goodridge, W.: Sensitivity analysis using simple additive weighting method. Int. J. Intell. Syst. Appl. 8, 27–33 (2016). https://doi.org/10.5815/ijisa.2016.05.04

Sakti La Ore, M., Wijaya, K., Trisunaryanti, W., Saputri, W.D., Heraldy, E., Yuwana, N.W., Hariani, P.L., Budiman, A., Sudiono, S.: The synthesis of SO4/ZrO2 and Zr/CaO catalysts via hydrothermal treatment and their application for conversion of low-grade coconut oil into biodiesel. J. Environ. Chem. Eng. 8, 1005 (2020). https://doi.org/10.1016/j.jece.2020.104205

Lam, M.K., Lee, K.T., Mohamed, A.R.: Homogeneous, heterogeneous and enzymatic catalysis for transesterification of high free fatty acid oil (waste cooking oil) to biodiesel: a review. Biotechnol. Adv. 28, 500–518 (2010). https://doi.org/10.1016/j.biotechadv.2010.03.002

Taufiq-Yap, Y.H., Lee, H.V., Hussein, M.Z., Yunus, R.: Calcium-based mixed oxide catalysts for methanolysis of Jatropha curcas oil to biodiesel. Biomass Bioenergy 35, 827–834 (2011). https://doi.org/10.1016/j.biombioe.2010.11.011

Marwaha, A., Dhir, A., Mahla, S.K., Mohapatra, S.K.: An overview of solid base heterogeneous catalysts for biodiesel production. Catal. Rev. 60, 594–628 (2018). https://doi.org/10.1080/01614940.2018.1494782

Boey, P.-L., Maniam, G.P., Hamid, S.A.: Biodiesel production via transesterification of palm olein using waste mud crab (Scylla serrata) shell as a heterogeneous catalyst. Bioresour. Technol. 100, 6362–6368 (2009). https://doi.org/10.1016/j.biortech.2009.07.036

Viriya-empikul, N., Krasae, P., Puttasawat, B., Yoosuk, B., Chollacoop, N., Faungnawakij, K.: Waste shells of mollusk and egg as biodiesel production catalysts. Bioresour. Technol. 101, 3765–3767 (2010). https://doi.org/10.1016/j.biortech.2009.12.079

Lukić, I., Kesić, Ž, Zdujić, M., Skala, D.: Calcium diglyceroxide synthesized by mechanochemical treatment, its characterization and application as catalyst for fatty acid methyl esters production. Fuel 165, 159–165 (2016). https://doi.org/10.1016/j.fuel.2015.10.063

Soares Dias, A.P., Puna, J., Gomes, J., Neiva Correia, M.J., Bordado, J.: Biodiesel production over lime. Catalytic contributions of bulk phases and surface Ca species formed during reaction. Renew. Energy 99, 622–630 (2016). https://doi.org/10.1016/j.renene.2016.07.033

Catarino, M., Martins, S., Soares Dias, A.P., Costa Pereira, M.F., Gomes, J.: Calcium diglyceroxide as a catalyst for biodiesel production. J. Environ. Chem. Eng. 7, 103099 (2019). https://doi.org/10.1016/j.jece.2019.103099

Kostić, M.D., Bazargan, A., Stamenković, O.S., Veljković, V.B., McKay, G.: Optimization and kinetics of sunflower oil methanolysis catalyzed by calcium oxide-based catalyst derived from palm kernel shell biochar. Fuel 163, 304–313 (2016). https://doi.org/10.1016/j.fuel.2015.09.042

Zhang, P., Han, Q., Fan, M., Jiang, P.: A novel waste water scale-derived solid base catalyst for biodiesel production. Fuel 124, 66–72 (2014). https://doi.org/10.1016/j.fuel.2014.01.091

Obadiah, A., Swaroopa, G.A., Kumar, S.V., Jeganathan, K.R., Ramasubbu, A.: Biodiesel production from Palm oil using calcined waste animal bone as catalyst. Bioresour. Technol. 116, 512–516 (2012). https://doi.org/10.1016/j.biortech.2012.03.112

Acknowledgements

This study was performed within the framework of a research project funded by the Ministry of National Education, Vocational Training, Higher Education and Scientific Research (Morocco) / Department of Higher Education and Scientific Research (MENFPESRS/DESRS). The authors would like to thank MENFPESRS/DESRS for the financial support.

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bahani, N., El Kourdi, S. & Abderafi, S. Argan Cake Oil Transesterification Kinetics and an Optimized Choice of a High-Performance Catalyst for Biodiesel Production. Waste Biomass Valor 15, 2591–2610 (2024). https://doi.org/10.1007/s12649-023-02315-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02315-0