Abstract

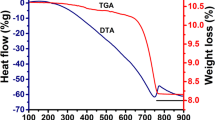

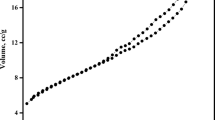

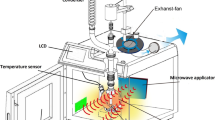

This study consists of the production of biodiesel from methanolysis of Sunn-hemp (Crotalaria juncea) oil, using homogeneous and heterogeneous catalysts. Calcium carbonate enriched sea shells like capiz and conch shell are used as natural catalysts after calcination for trans-esterification. These heterogeneous catalysts are physically characterized in order to locate the active sites using X-ray powder diffraction. Gas chromatography mass spectrometry is used to identify and estimate the fatty acid methyl esters of the biodiesel. Basic fuel properties like specific gravity, moisture content, kinematic viscosity, saponification value, iodine value, flash point, fire point, aniline point, cetane number and heat content are determined to establish this biodiesel as a diesel substitute for a fuel. The fuel properties indicate that after some modifications, Sunn-hemp seed oil based biodiesel could be a promising new source for the production of biofuel. Response Surface Methodology is used to optimize the operating parameters of the process. A Factorial and Box–Behnken Design is used to study the effects of time of reaction, type of catalyst, catalyst concentration and oil to methanol mole ratio on the yield of biodiesel. Statistical analysis shows that the model is significant with a R 2 value of 0.997 having achieved the optimum conditions after 4.15 h, with an oil to methanol molar ratio of 11. 2 wt% catalyst concentration and potassium hydroxide as the best catalyst for the production of 90.25 % biodiesel.

Similar content being viewed by others

References

Eddine, B.T., Salah, M.M.: Solid waste as renewable source of energy: current and future possibility in Algeria. Int. J. Energy Environ. Eng. 3, 17 (2012)

Marasabessy, A., Kootstra, A.M.J., Sanders, J.P.M., Weusthuis, R.A.: Dilute H2SO4-catalyzed hydrothermal pretreatment to enhance enzymatic digestibility of Jatropha curcas fruit hull for ethanol fermentation. Int. J. Energy Environ. Eng. 3(1), 1–11 (2012)

Kouzu, M., Kasuno, T., Tajika, M., Sugimoto, Y., Yamanaka, S., Hidaka, J.: Calcium oxide as a solid base catalyst for transesterification of soybean oil and its application to biodiesel production. Fuel 87(12), 2798–2806 (2008)

Bilgen, S.U., Keles, S., Kaygusuz, A., Sari, A., Kaygusuz, K.: Global warming and renewable energy sources for sustainable development: a case study in Turkey. Renew. Sustain. Energy Rev. 12(2), 372–396 (2008)

Chakraborty, R., Sahu, H.: Intensification of biodiesel production from waste goat tallow using infrared radiation: process evaluation through response surface methodology and artificial neural network. Appl. Energy 114, 827–836 (2014)

Ye, B., Li, Y., Qiu, F., Sun, C., Zhao, Z., Ma, T., Yang, D.: Production of biodiesel from soybean oil catalyzed by attapulgite loaded with C4H5O6KNa catalyst. Korean J. Chem. Eng. 30(7), 1395–1402 (2013)

El-Adawy, M., Ibrahim, A., El-Kassaby, M.M.: An experimental evaluation of using waste cooking oil biodiesel in a diesel engine. Energy Technol. 1(12), 726–734 (2013)

Moser, B.R., Vaughn, S.F.: Biodiesel from corn distillers dried grains with solubles: preparation, evaluation, and properties. BioEnergy Res. 5(2), 439–449 (2012)

Kalbande, S.R., More, G.R., Nadre, R.G.: Biodiesel production from non-edible oils of jatropha and karanj for utilization in electrical generator. BioEnergy Res. 1(2), 170–178 (2008)

Chakraborty, R., Banerjee, A.: Prediction of fuel properties of biodiesel produced by sequential esterification and transesterification of used frying soybean oil using statistical analysis. Waste Biomass Valoriz. 1(2), 201–208 (2010)

Talebian-Kiakalaieh, A., Amin, N.A.S., Mazaheri, H.: A review on novel processes of biodiesel production from waste cooking oil. Appl. Energy 104, 683–710 (2013)

Bangjang, T., Saisangtong, R., Kaewchada, A., Jaree, A.: Modification of diesohol fuel properties by using cashew nut shell liquid and biodiesel as additives. Energy Technol 2(9–10), 825–831 (2014)

Singh, V.P.: Indian biofuel scenario: An assessment of science and policy (2011)

Shibasaki-Kitakawa, N., Tsuji, T., Kubo, M., Yonemoto, T.: Biodiesel production from waste cooking oil using anion-exchange resin as both catalyst and adsorbent. BioEnergy Res. 4(4), 287–293 (2011)

Leung, D.Y.C., Wu, X., Leung, M.K.H.: A review on biodiesel production using catalyzed transesterification. Appl. Energy 87(4), 1083–1095 (2010)

Balat, M., Balat, H.: Progress in biodiesel processing. Appl. Energy 87(6), 1815–1835 (2010)

Takase, M., Zhao, T., Zhang, M., Chen, Y., Liu, H., Yang, L., Wu, X.: An expatiate review of neem, jatropha, rubber and karanja as multipurpose non-edible biodiesel resources and comparison of their fuel, engine and emission properties. Renew. Sustain. Energy Rev. 43, 495–520 (2015)

Gonsalves, J.B.: An assessment of the biofuels industry in India. https://biotechnologie.init-ag.de (2006)

Jose, D.F.M., Raj, R.E., Prasad, B.D., Kennedy, Z.R., Ibrahim, A.M.: A multi-variant approach to optimize process parameters for biodiesel extraction from rubber seed oil. Appl. Energy 88(6), 2056–2063 (2011)

Kumar, S., Chaube, A., Jain, S.K.: Sustainability issues for promotion of Jatropha biodiesel in Indian scenario: a review. Renew. Sustain. Energy Rev. 16(2), 1089–1098 (2012)

Atabani, A.E., Badruddin, I.A., Badarudin, A., Khayoon, M.S., Triwahyono, S.: Recent scenario and technologies to utilize non-edible oils for biodiesel production. Renew. Sustain. Energy Rev. 37, 840–851 (2014)

Chaudhury, J., Singh, D.P., Hazra, S.K.: Sunnhemp (Crotalaria juncea L.). Monograph, Central Research Institute for Jute and Allied Fibres, pp. 1–45 (2007)

Du, W., Xu, Y., Liu, D.: Lipase-catalysed transesterification of soya bean oil for biodiesel production during continuous batch operation. Biotecnol. Appl. Biochem. 38(2), 103–106 (2003)

Vicente, G., Martinez, M., Aracil, J.: Integrated biodiesel production: a comparison of different homogeneous catalysts systems. Bioresour. Technol. 92(3), 297–305 (2004)

Dutta, R., Sarkar, U., Mukherjee, A.: Extraction of oil from Crotalaria Juncea seeds in a modified Soxhlet apparatus: physical and chemical characterization of a prospective bio-fuel. Fuel 116, 794–802 (2014)

Liu, X., He, H., Wang, Y., Zhu, S.: Transesterification of soybean oil to biodiesel using SrO as a solid base catalyst. Catal. Commun. 8(7), 1107–1111 (2007)

Dias, J.M., Alvim-Ferraz, M.C.M., Almeida, M.F., Diaz, J.D.M., Polo, M.S., Utrilla, J.R.: Selection of heterogeneous catalysts for biodiesel production from animal fat. Fuel 94, 418–425 (2012)

Helwani, Z., Othman, M.R., Aziz, N., Kim, J., Fernando, W.J.N.: Solid heterogeneous catalysts for transesterification of triglycerides with methanol: a review. Appl. Catal. A. Gen. 363(1), 1–10 (2009)

Kaur, M., Ali, A.: Lithium ion impregnated calcium oxide as nano catalyst for the biodiesel production from karanja and jatropha oils. Renew. Energy 36(11), 2866–2871 (2011)

Zabeti, M., Daud, W.M.A.W., Aroua, M.K.: Biodiesel production using alumina-supported calcium oxide: an optimization study. Fuel Process. Technol. 91(2), 243–248 (2010)

Hagen, J.: Industrial Catalysis: A Practical Approach. Wiley, New York (2006)

Rashid, U., Anwar, F., Ansari, T.M., Arif, M., Ahmad, M.: Optimization of alkaline transesterification of rice bran oil for biodiesel production using response surface methodology. J. Chem. Technol. Biotechnol. 84(9), 1364–1370 (2009)

Demirkol, S., Aksoy, H.A., Tüter, M., Ustun, G., Sasmaz, D.A.: Optimization of enzymatic methanolysis of soybean oil by response surface methodology. J. Am. Oil Chem. Soc. 83(11), 929–932 (2006)

Chang, S.H., Teng, T.T., Ismail, N.: Screening of factors influencing Cu (II) extraction by soybean oil-based organic solvents using fractional factorial design. J. Environ. Manag. 92(10), 2580–2585 (2011)

Maran, J.P., Manikandan, S., Priya, B., Gurumoorthi, P.: Box–Behnken design based multi-response analysis and optimization of supercritical carbon dioxide extraction of bioactive flavonoid compounds from tea (Camellia sinensis L.) leaves. J. Food Sci. Technol. 52(1), 92–104 (2015)

Fu, H.-Y., Xu, P.-C., Huang, G.-H., Chai, T., Hou, M., Gao, P.-F.: Effects of aeration parameters on effluent quality and membrane fouling in a submerged membrane bioreactor using Box–Behnken response surface methodology. Desalination 302, 33–42 (2012)

Van Gerpen, J.: Cetane number testing of biodiesel. In: Proceedings of the third liquid fuels conference 1996, pp. 197–206

Granados, M.L., Poves, M.D.Z., Alonso, D.M., Mariscal, R., Galisteo, F.C., Moreno-Tost, R., Santamara, J., Fierro, J.L.G.: Biodiesel from sunflower oil by using activated calcium oxide. Appl. Catal. B Environ. 73(3), 317–326 (2007)

Suryaputra, W., Winata, I., Indraswati, N., Ismadji, S.: Waste capiz (Amusium cristatum) shell as a new heterogeneous catalyst for biodiesel production. Renew. Energy 50, 795–799 (2013)

Kouzu, M., Hidaka, J.-S.: Transesterification of vegetable oil into biodiesel catalyzed by CaO: a review. Fuel 93, 1–12 (2012)

Boey, P.-L., Maniam, G.P., Hamid, S.A., Ali, D.M.H.: Utilization of waste cockle shell (Anadara granosa) in biodiesel production from palm olein: optimization using response surface methodology. Fuel 90(7), 2353–2358 (2011)

Di Serio, M., Tesser, R., Pengmei, L., Santacesaria, E.: Heterogeneous catalysts for biodiesel production. Energy Fuels 22(1), 207–217 (2007)

Chouhan, A.P.S., Sarma, A.K.: Modern heterogeneous catalysts for biodiesel production: a comprehensive review. Renew. Sustain. Energy Rev. 15(9), 4378–4399 (2011)

Endalew, A.K., Kiros, Y., Zanzi, R.: Inorganic heterogeneous catalysts for biodiesel production from vegetable oils. Biomass Bioenergy 35(9), 3787–3809 (2011)

Gulum, M., Bilgin, A.: Density, flash point and heating value variations of corn oil biodiesel-diesel fuel blends. Fuel Process. Technol. 134, 456–464 (2015)

Rashid, U., Anwar, F., Moser, B.R., Ashraf, S.: Production of sunflower oil methyl esters by optimized alkali-catalyzed methanolysis. Biomass Bioenergy 32(12), 1202–1205 (2008)

Rashid, U., Anwar, F., Knothe, G.: Evaluation of biodiesel obtained from cottonseed oil. Fuel Process. Technol. 90(9), 1157–1163 (2009)

Silitonga, A.S., Masjuki, H.H., Mahlia, T.M.I., Ong, H.C., Chong, W.T., Boosroh, M.H.: Overview properties of biodiesel diesel blends from edible and non-edible feedstock. Renew. Sustain. Energy Rev. 22, 346–360 (2013)

Rashid, U., Anwar, F., Knothe, G.: Biodiesel from Milo (Thespesia populnea L.) seed oil. Biomass Bioenergy. 35(9), 4034–4039 (2011)

Martinez, G., Sanchez, N., Encinar, J.M., Gonzalez, J.F.: Fuel properties of biodiesel from vegetable oils and oil mixtures. Influence of methyl esters distribution. Biomass Bioenergy 63, 22–32 (2014)

Ivanova-Petropulos, V., Mitrev, S., Stafilov, T., Markova, N., Leitner, E., Lankmayr, E., Siegmund, B.: Characterisation of traditional Macedonian edible oils by their fatty acid composition and their volatile compounds. Food Res. Int. 77(3), 506–514 (2015)

Acknowledgments

The authors are grateful to UGC, India for supporting this project under their Major Research Project Grant. The first author is particularly grateful to CSIR, India for providing her with a fellowship of SRF [File No.: 09/096(787)/2013-EMR-I dated 21.03.2013]. The authors also thank the Bose Institute and National Test House, Kolkata, India for their support during some of the tests.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sadhukhan, S., Sarkar, U. Production of Biodiesel from Crotalaria juncea (Sunn-Hemp) Oil Using Catalytic Trans-Esterification: Process Optimisation Using a Factorial and Box–Behnken Design. Waste Biomass Valor 7, 343–355 (2016). https://doi.org/10.1007/s12649-015-9454-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-015-9454-4