Abstract

This work investigates the potential of 70% ethanolic leaf extracts of Rubus idaeus L., Cistus ladanifer L. and Erica andevalensis in the metal separation from synthetic unimetallic solutions of different metals and a leachate obtained from the leaching of PCBs. Results from the experiments with unimetallic solutions revealed R. idaeus and E. andevalensis extracts induced separation of more than 95% of the initial Au(III), while C. ladanifer separated ~78% of this metal. Thereafter, application of three plant extracts to real Au bearing leachate obtained from PCBs leaching, revealed about 96, 95 and 90% Au recovery with R. idaeus, C. ladanifer and E. andevalensis extracts, respectively with 15–60% co-removal of Pb and less than 15% of other metals. The reduction of Au(III) ions into Au(0) nanoparticles by R. idaeus extract was confirmed by molecular UV–Visible, and FT-IR analysis showed the involvement of plant secondary metabolites in Au bio-reduction and bio-stabilization. Particles obtained from the application of R. idaeus extract to the leachate were initially analyzed with XRD and results confirmed the presence of Au(0) with contamination of PbSO4, which was completely removed by washing with 1 M HCl. Thereafter, results from STEM-EDS analysis showed the presence of Au particles conjugated with organic material and other metals. Consequently, particles were subjected to another washing step with acetone. Afterwards, STEM-EDS showed pure Au microparticle clusters (~0.8 μm) with flower-shaped or apparently cubic morphologies, and HRSTEM showed the tiny nanoparticles (~20 nm), which form the clusters.

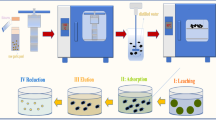

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

This article describes an application of green synthesis of gold nanoparticles (NP), a process already widely tested with synthetic gold solutions and several types of plant extracts. However, in this work, such an approach was applied for the first time on a solution bearing gold and other (contaminant) metals obtained from the leaching of Printed Circuit Boards’ wastes. On the other hand, the plant material used to induce the production of gold NP, the waste leaves of raspberry production, were tested for the first time with this goal.

Introduction

In the last decades, due to the rapid industrialization, application of precious metals has been emerged in various industrial sectors. Nowadays, global demand for precious metals, such as Au, in the industry is continuously increasing and it is reported that more than 90% of this metal’s industrial utilization is in the electronic devices [1]. This high demand has been growing faster than the demand for base metals that are also used in the electronic devices industry [2, 3].

Waste electrical and electronic equipment in urban mining are considered as a secondary source of metals due to their higher metal content than those in primary ores [4]. Estimations demonstrate that in 2019, electronic wastes produced by consumer products alone were about 54 million metric tons (Mt), which is predicted to surpass 74 Mt by 2030 [5]. Printed Circuit Boards (PCBs) are the essential constituent of every electronic device. Metal recovery from waste PCBs has been attracted more attention since they normally contain 40% of wide range of metals including precious metals (e.g., Au, Ag, Pt, Pd), rare metals (e.g. Be, In), base metals (e.g. Cu, Al, Ni, Sn, Zn, Fe), and toxic heavy metals (e.g. Pb, Cd, Sb) [6,7,8].

Considering this increasing secondary source of Au in PCBs, the need for recycling these metals is highly important for economic and environmental reasons. Recycling and sustainable management of these wastes are important steps toward development of mining resources sustainability and to mitigate the growing shortage of resources [9]. However, the recycling methods for Au from secondary sources is still a challenge due to the low content of Au and high metal complexity of these wastes [10, 11]. Exploring novel methods for gold recovery from complex solutions, such as those derived from electronic wastes, is of utmost importance to address the growing demand for precious metals and reduce reliance on primary mining [2, 12, 13].

Nowadays, hydrometallurgical methods are preferred over pyrometallurgical methods for the metals recovery from PCBs as they consume less energy and are less environmentally harmful. Metal recycling from these wastes through hydrometallurgical methods are normally performed by a leaching process (usually non-metal specific), followed by a metal recovery step from the obtained leachates. By now, different hydrometallurgical leaching methods are established and are expanding rapidly as they are economically and environmentally viable since they have a wide range of reagent options, they perform well in different scales (from small scales to larger ones), are applicable on very low to high-grade metals in raw materials, and have low recycling cost and energy consumption [14,15,16]. In the pursuit of Au leaching from PCBs, various leaching methods including chemical leaching (by substances like cyanide, aqua regia, or thiourea), acidic leaching (utilizing acids such as sulfuric acid or hydrochloric acid), electrochemical leaching and bacterial leaching are employed for the Au leaching and recovery from PCBs [8, 17, 18]. Each one of these methods have their own advantages and limitations [18, 19]. Aqua regia provides a potent and efficient leaching solution, ensuring high gold recovery and rapid reaction rates from PCBs [20]. Its effectiveness, coupled with its relatively safer handling compared to cyanide-based methods, makes it a preferred choice for efficient gold leaching from printed circuit boards [21].

Furthermore, various methods have been described for the separation and recovery of Au from leaching solutions such as chemical precipitation, solvent extraction, electrowinning, cementation, selective adsorption and coagulation [16, 22]. Application of these methods are not usually economically viable due to their insufficient recovery rates (especially when applied to low concentration of Au), intensive electricity and energy consumption, high costs of chemicals assisting to other environment related issues [17, 23]. The limitations of conventional gold recovery methods, such as chemical precipitation and solvent extraction, have led researchers to explore alternative approaches, including biological methods, which offer the potential for higher recovery rates and lower energy consumption [24, 25]. Thereby, in the recent years, potential biological methods for metals’ bio-recovery are gaining more attention over other methods [23]. In this context, beneficiation of plant-based compounds as a potent alternative to other methods deserves more investigations.

Plants synthesize numerous compounds with many functional abilities, including those with metal interaction capabilities such as phenols, alkaloids, saponins, polysaccharides, proteins and organic acids [26]. These compounds, based on their nature, contain polar functional groups, such as carboxyl, phenolic, hydroxyl, sulfo and amino groups, that are capable to interact with metal ions through different mechanisms like complex/chelate formation [27,28,29], reduction [28, 30, 31], precipitation [28, 32]. These secondary metabolites with suitable metal interaction characteristics can be promising substitutes of other compounds that are currently employed for Au recovery, since they are renewable resources, cheap and environmentally friendly. They have potential application in different metal related industrial applications and have already been explored for example in Au separation and recovery, and in Au nanoparticle synthesis and stabilization [33,34,35]. Beneficiation of plant extracts for gold recovery from PCB leachates represents a significant step towards a greener and more sustainable approach to metal extraction, aligning with the principles of resource conservation and sustainability [36, 37]. In addition, its substitution with conventional compounds in gold recovery offers economic advantages, as these extracts are easily prepared, cost-effective, and sustainable sources [38,39,40].

In the previous studies by the team, effective potential of plant extracts in Pd separation and recovery as Pd nanoparticles from spent catalytic converter leachates were illustrated [41]. However, to our knowledge, the potential of any plant extract for the separation and recovery of Au from complex Au bearing solutions and leachates was not yet evaluated. Therefore, after tests with unimetallic solutions to confirm the potential application of three plant extracts (Rubus idaeus L., Cistus ladanifer L. and Erica andevalensis) applied for first time for this purpose, additional experiments were performed with real PCBs leaching solutions. Finally, the best plant extract was selected for further optimization and characterization of the Au recovered particles. Overall, this study not only expands our knowledge regarding the use of plant extracts for gold recovery but also underscores their potential as renewable resources in mitigating the challenges associated with traditional methods. These findings have significant implications for the fields of resource sustainability, electronic waste management, and the pursuit of greener metallurgical practices, which lays the foundation for future advancements and potential industrial implementation.

Materials and Methods

Unimetallic Solutions

The unimetallic solutions were prepared by diluting 1/10 (v/v) the following 1000 mg/L metal standard solutions in 0.02 M HCl: HAuCl4 in 2 M HCl (Merck Certipur, Germany), Fe(NO3)3 in 0.5 M HNO3, Al(NO3)3 in 0.5 M HNO3, Cu(NO3)2 in 0.5 M HNO3, Zn(NO3)2 in 0.5 M HNO3 and Pb(NO3)2 in 0.5 M HNO3.

Au Leaching from PCBS

Mechanical Fragmentation

Initially, some electronic components (ECs), such as processor units, memory slots, power supplies, etc., were manually separated from the PCBs and then, the PCBs were broken in pieces of about 5 cm2. The approach of breaking PCBs into small parts, rather than grinding them, was adopted for several reasons. Firstly, it facilitated the handling of PCBs, making them more manageable for subsequent processing steps. Secondly, by avoiding the grinding process, the study aimed to demonstrate the viability of metal recovery from PCBs without the need for costly and energy-intensive grinding procedures. While other works [22, 42,43,44] have explored the grinding of PCBs to achieve smaller particle sizes, this study sought to showcase an alternative approach that highlights the feasibility of metal extraction while minimizing the associated costs and energy requirements.

Leaching Process

In this step, PCBs pieces together with the separated ECs (hereafter called just as PCBs) were used for Au recovery in two subsequent leaching steps:

Initially, a chemical pre-treatment for the separation of Cu, Zn, Fe, Al and Ni was accomplished using a mixture of 2 M sulfuric acid and 0.2 M of hydrogen peroxide. Small increments of PCBs were added to the leaching solution until a final 1 to 6 ratio (w/v), in order to prevent the excessive heating and extreme froth formation as a result of the reaction, and the leaching occurred for 3 h. Then, the aqueous solution was separated from large solids by decantation and from small solids by filtration with filter paper. In order to improve Cu and other metals’ separation, this step was repeated two more times as suggested by [45].

Subsequently, a second leaching step was performed overnight to leach Au, Ag and platinum group metals from the solids obtained in the previous step, using aqua regia in a 1/20 ratio (w/v) [46].

The reaction of Au leaching by aqua regia is described below [47]:

Finally, the solution was diluted 1/3 (v/v) in distilled water and the obtained diluted leachate was characterized for the concentrations of Au, Ag, Pd, Pt, Cu, Pb, Zn, Fe, Al and Ni.

Separation of Pb from the Au Bearing Solution

Considering the low solubility of PbSO4 (Ksp = 6.7 × 10–7) [48], Pb can be recovered from the diluted aqua regia leachate as PbSO4 [49]. Therefore, based on the chemical reaction ratio of Pb and SO4 and the concentration of Pb in the solution, two times of the amount of sulfate required to remove the Pb content from the leachate was added as sodium sulfate solution to the leachate in 1/1 ratio (v/v). Then, 72 h after sodium sulfate addition to the leachate, the formed white precipitates (PbSO4) were separated through centrifugation at 2500×g for 10 min at room temperature.

Plant Extract Preparation

Three types of plant leaves were collected for this study: leaves from C. ladanifer L. (crimson spot rockrose); from E. andevalensis Cabezudo & Rivera (a shrub growing in the Iberian Peninsula next to acidic mine waters contaminated with sulfate and metals) and from R. idaeus L. (red raspberry). The choice of plants for this work considered criteria such as being available in the region, being reported as metal accumulators and/or being plants (or parts of them) considered industrial or agricultural waste. C. ladanifer has developed several tolerance mechanisms that allow its adaptability to contaminated environments. The immobilization of metallic elements in roots and accumulation in senescent leaves are examples of these adaptability mechanisms and make this plant a promising species for phyto-stabilization of mining areas [50,51,52,53,54]. E. andevalensis is an endemic species of the Iberian pyrite Belt (IPB) [55] that grows under extreme conditions of pH values between 3 and 4 and high metal contents, being able to accumulate Mn [56]. It colonizes mine tailings and the bank sediments of water bodies contaminated with acid mine drainage (AMD), such as the Tinto and Odiel rivers in Spain and the channels and dams at the São Domingos mine in Portugal [57,58,59]. R. idaeus is an agricultural crop widely cultivated in Asia, Europe, and North America for its fruits, being its leaves a residue highly rich in phenolic compounds [60, 61].

Young and mature leaves were collected and immediately dried to remove the moisture in an INCU-Line oven (VWR international) at 45 °C until their weights stabilized. The dried leaves were then grinded into powder using an electric coffee grinder and the powder was mixed at a 10% (w/v) ratio with 70% (v/v) ethanol. Afterwards, the mixture was sonicated using an ultrasonic bath FB15054 (Fisher Scientific, USA) for 1 h and homogenized by orbital shaking at 150 rpm for 16 h. Finally, the mixture was centrifuged at 2800×g for 5 min at room temperature and the supernatant was filtered using 310–150 mm qualitative filter paper (VWR international) in a vacuum system. Plant extracts were stored in the refrigerator at 4 °C and were used within one week. Throughout this period, extracts remained stable and clear, with no signs of precipitate formation or any other noticeable changes.

Au Recovery Using Plant Extracts

The capacity of 70% (v/v) ethanolic plant extracts for metals separation was tested on different metal bearing aqueous solutions: (1) three plant extracts were independently mixed and homogenized at 1/1 (v/v) with artificial unimetallic solutions prepared from standards commercialized for metals analysis; (2) three plant extracts were independently mixed and homogenized at 1/1 (v/v) with the diluted (1/6) PCBs leachate; (3) a selected plant extract (R. idaeus) was mixed in 1/1, 1/5 and 1/10 (v/v) ratios with the diluted (1/6) PCBs leachate. Simultaneously, mixtures prepared the same way but using pure 70% ethanol (without plant compounds) were used as negative controls. Experiments were carried out in triplicates in 50 mL centrifuge tubes at room temperature (20 ± 3 °C), and after 1 and 48 h of reaction aqueous samples were collected for metal analysis after centrifugation for 30 min at 2500×g to separate solids. Metal concentrations of the initial and final solutions in the mixtures were used for calculations of metal removal percentages. The significance of differences between means of different experimental treatments (test 1 h, test 48 h, control 1 h and control 48 h) was assessed by the single factor analysis of variance (ANOVA) considering a significance threshold level of 5%. Then, when ANOVA [62] revealed significant differences among treatments, post-hoc tests were carried out with Tukey Kramer's tests (also for 5% significance level) [63]. The particles recovered from the PCB leachate using selected plant extract and conditions were characterized by XRD.

In addition, the putative effect of pH changes on metal removals was evaluated by comparing the initial pH measured in the metal bearing solutions, the pH values in the mixtures, and the estimated lowest pH at which metals precipitation is expected to occur according to theoretical simulations on the Medusa-Hydra software [64] for increasing pH values (−1 to 14) in aqueous solutions using parameters that mimic the tested matrices.

Pb Washing From the Au Precipitates

To eliminate any Pb content and other impurities from the particles obtained after the addition of plant extract to the PCBs leachates, a washing step was tested using different solutions: 1 M hydrochloric acid, 1 M nitric acid, 1 M sodium hydroxide and 1 M ammonium acetate. A ratio of 1/1000 (w/v) of the particles to the washing solution was applied, the mixture shaken for 15 min by orbital shaker at room temperature, the supernatant separated through centrifugation for 30 min at 2500×g and the pellet dried in oven at 40 °C overnight. Then, the concentration of Pb was analyzed on the four tested solutions to evaluate the Pb leaching efficiency. Finally, the washing step was repeated, but with deionized water to eliminate traces of the washing agent and then with 96% (v/v) ethanol. Finally, the particles recovered from the best Pb washing solution (1 M hydrochloric acid) were dried and characterized by XRD and electronic microscopy.

Organic Materials Washing from the Au Precipitates

After confirming the removal of Pb and having a more detailed characterization of the particles, they were further washed in two steps with pure acetone and the supernatant separated by centrifugation, aiming to eliminate organic compounds and metal contaminants. The final particles were also characterized by electronic microscopy.

Analytical Methods

A bench centrifuge (Hettich, ROTOFIX 32A) was used to separate solid and liquid phases at specific conditions described above for each step.

For metal analysis, 1 mL of sample was diluted in 6.5 mL of 30% HNO3 and 2.5 mL of 30% hydrogen peroxide (in 50 mL centrifuge tubes with loose caps) and heated in a water bath at 70 °C during 1 h to digest organic compounds (if present). The concentrations of Au, Cu, Pb, Zn and Al were determined by microwave plasma atomic emission spectrometry with a 4200 MP-AES (Agilent Technologies, USA).

Calibration curves were built using standards prepared from the following stock solutions: HAuCl4 in 2 M HCl, AgNO3 in 0.5 M HNO3, Cu(NO3)2 in 0.5 M HNO3, Pb(NO3)2 in 0.5 M HNO3, Zn(NO3)2 in 0.5 M HNO3, Fe(NO3)3 in 0.5 M HNO3, Al(NO3)3 in 0.5 M HNO3 and Ni(NO3)2 in 0.5 M HNO3, Pd(NO3)2 in 0.5 M HNO3 and PtCl2 in 5% HCl from (Sigma-Aldrich standard for AAS, EUA).

The bio-reduction of Au ions and particles formation was monitored by molecular UV–visible spectroscopy. The optical absorption of the particles was investigated using the BioTek Synergy 4 microplate reader (BioTek Instruments, Inc., USA) using wavelengths between 200 and 700 nm at intervals of 1 nm.

Fourier Transform InfraRed (FTIR) Spectroscopy measurements of Au solution, R. idaeus extract and the mixture of Au solution and R. idaeus extract were performed using a Nicolet iN10MX micro-FTIR (Thermo Scientific, USA) equipped with a MCT detector cooled with liquid nitrogen. Analyzes were conducted in reflection mode, by spreading a drop of the sample onto a reflectance holder. Spectra were collected in the infrared region (from 4000 to 675 cm−1). Three measurements were performed for each sample to assure the robustness of the analysis.

The crystallographic structures of obtained particles were analyzed by X-ray diffraction (XRD) using a PANalytical XPERT-PRO powder diffractometer operating at 45 kV and 35 mA with Cu Kα radiation filtered by Ni. The XRD patterns were recorded using an X'Celerator detector with a step size (2θ) of 0.03° and a time per step of 250 s. Peak analysis and the identification of crystalline phases were based on comparison using High-Score Plus software with the ICDD PDF-2 database.

The morphology and elemental composition of particles was analyzed either by Transmission Electron Microscopy (TEM) and/or by Scanning Transmission Electron Microscopy (STEM) imaging, in both cases coupled with Energy Dispersive X-ray Spectroscopy (EDS) analysis. Before TEM and STEM analysis, the particles were resuspended in ethanol and sonicated for 30 min for sample pulverization. Then, 5 μl of sample was dispersed on carbon coated grids of Cu for TEM and of molybdenum for STEM, and the grids were dried and stored in a desiccator until imaging. TEM was carried out on a H8100 microscope (Hitachi, Tokyo, Japan) with a LaB6 filament, coupled with an EDS NORAN System (Thermo Scientific, Waltham, USA). STEM was carried out on the Titan ChemiSTEM (Thermo Fisher Scientific, Waltham, United States) microscope operating with a field emission gun and aberration corrector on the probe and four energy dispersive X-ray spectroscopy (EDS) detectors operating at 200 kV.

Results and Discussion

Evaluation of Au Recovery from Unimetallic Solutions Using Plant Extracts

Experiments with unimetallic solutions diluted in HCl (final concentration ~ 100 mg/L) were performed to analyze the interaction potential of 70% hydroalcoholic extracts of R. idaeus, C. ladanifer and E. andevalensis with some of the metals known to be present in PCB leachates: Zn, Fe, Cu, Al, Pb and Au [49]. In these experiments, metal removal in the tests were significantly different from the negative controls and all the three plant extracts revealed a high Au removal from solution compared to the other metals (Fig. 1). As depicted in Fig. 1, after 48 h of reaction R. idaeus and E. andevalensis extracts effectively removed 99 ± 1% and 98 ± 4% of the initial Au, respectively, while 78 ± 17% of the Au was removed by the C. ladanifer extract. Beside Au, other metals with relatively high removals from the unimetallic solutions were Pb (10–40%), Fe (10–40%), Al (5–30%), Cu (2–20%) and Zn (1–10%) (Fig. 1). In addition, it should be mentioned that the removals achieved in the unimetallic solutions of Au3+, Pb2+, Cu2+ and Al3+ were not caused by alkalization, since the pH values in the mixtures were below the estimated pH at which these metals are expected to start precipitating according to simulations using the Medusa-Hydra software [64] (Table OR1).

Metal removals achieved after 1 and 48 h of mixing R. idaeus, C. ladanifer, E. andevalensis 70% hydroalcoholic extract, at a 1/1 (v/v) ratio to the unimetallic solutions (~ 100 mg/L) at room temperature (25 ± 3 °C). Results for controls, consisting of the addition of just 70% ethanol (without plant extract), are included. Removals with the same letters do not significantly differ at 0.05 level (ANOVA and Tukey Kramer’s tests)

The interesting tendency of these plant extracts to cause Au separation from the tested solutions, especially in the tests with R. idaeus and E. andevalensis extracts, confirms the interaction of their plants’ compounds with Au. Probably such interaction was favored by the high reduction potential of Au(III) (E̊ = 1.50 V), as reported in the reduction potential table of metals published by Bard et al. [65] and Milazzo et al. [66], and the high reduction (antioxidant) potential of plant compounds present in the extracts. In fact, other studies have previously demonstrated the potential of phytochemicals present in plant extracts to induce the formation of Au nanoparticles in aqueous solutions, as for example: extracts of Sageretia thea [67], Spinacia oleracea L. [68], Solidago canadensis [69], Persea americana [70].

Characterization of Particles Obtained from the Au(III) Unimetallic Solution

The particles obtained from the reaction of Au(III) unimetallic solution with R. idaeus extract were selected for further analysis due to high Au removal efficiency by this plant extract and also vast availability of R. idaeus leaves as an agricultural waste. These particles were analyzed by XRD, EDS and TEM for the investigation of their elemental composition, size and morphology. The XRD pattern recorded with the particles illustrated the crystalline nature of the Au particles with strong peaks correlated to Au (Figure OR 1). Moreover, the EDS spectra of the particles confirmed the presence of Au as the sole element present in the precipitates (Figure OR 2). The peak observed for Cu corresponds to the used Cu based grid. The TEM analysis of the particles showed that the Au nanoparticles were monodispersed and had quasi-spherical and irregular shapes with a ferret particle size ranging from 31 to 85 nm with an average size of 57 nm. The selected-area electron diffraction (SAED) patterns of the nanoparticles added further evidence that Au nanoparticles are highly crystalline (Figure OR 3). Demirbas et al. [71], in a similar study with synthetic Au(III) solutions but with addition of 5% (w/w) R. idaeus fruit extract (not leaves extract) showed formation of spherical Au nanoparticles with an average size of 18 ± 3 nm.

All of these evidences encouraged the attempt to use the leaf extracts in a real multimetallic solution containing Au, namely a PCBs leachate.

Au Leaching from PCBs

After the mechanical fragmentation described in materials and methods, the PCBs were initially subjected to three cycles of leaching with 2 M H2SO4 and 0.2 M H2O2 aiming to leach the base metals and leave the Au parts more exposed to the leaching of this metal in the next step. This process provided satisfactory results by successful leaching mainly of the base metals (Cu, Ni, Zn and Fe) (Table 1) and separating the PCBs’ parts as well as realizing small Au films, which were visible at the bottom of the leaching container. Moreover, during the leaching of base metals, a white precipitate was formed and settled in the bottom of the container together with PCBs’ parts and Au particles. According to previous reports on PCBs leaching works this white precipitate is composed of PbSO4 particles, which has low solubility in sulfuric acid solutions [49]. Therefore, this indicates that Pb was also leached from the PCBs.

After the leaching steps with sulfuric acid, the electronic components, except the supporting bases which were now free of metal parts, as well as the remaining solids (including the white precipitates which were mixed with Au particles) were treated with aqua regia in a 1/20 ratio (w/v) during 24 h. Thereafter, the obtained solution was diluted in a 1/3 ratio with deionized water to avoid the digestion of bio-compounds in the subsequent Au recovery tests using plant extracts. As presented in Table 2, the diluted leaching solution contains valuable metals (232 mg/L of Au, 26 mg/L of Ag, 11 mg/L of Pd), as well as a high concentration of Pb (15 g/L) and still some contamination with the base metals Cu, Ni, Zn and Fe. Such high concentration of Pb originates from the PbSO4 precipitates that were formed in the initial leaching step and which were scattered among the small fractions of PCBs in the bottom of the container and then were leached with aqua regia. Nevertheless, it is evident that the major part of the base metals leached from PCBs was leached in the initial leaching step with 2 M H2SO4 and 0.2 M H2O2 (~ 98% of Cu, ~ 97% of Ni, ~ 99% of Zn, 99% of Fe, and ~ 50% of Al), which is in agreement with previous reports [45].

Separation of Pb from the Au Bearing PCBs Leachate

Due to the very high Pb concentration in the aqua regia leachate, it was necessary to separate and recover this metal from the solution prior to Au recovery processes. With that aim, the leaching solution was submitted to a precipitation step with 0.15 M Na2SO4 (in 1/1 (v/v) ratio) and ~ 96% of Pb was removed from the solution (Table 2). XRD analysis of particles obtained through this precipitation step revealed that Pb was recovered as PbSO4 and PbCl2 crystals (Figure OR 4), which can be considered a by-product of the Au recovery process here reported.

Au Recovery from the Final PCBs Leachate Using Plant Extracts

In the experiments performed by adding each of the three plant extracts to the final 1/6 diluted Au bearing leachate at 1/1 (v/v) ratios, the target metal Au as well as Pb, Cu and Al as main contaminant metals were analyzed (Table 2; Fig. 2). It was observed that the application of R. idaeus, C. ladanifer and E. andevalensis extracts is highly effective in recovering Au from the leachate with an efficiency of 96, 95 and 90%, respectively. However, there was co-precipitation of Pb ranging between 15 and 60% of its initial concentration in all tested samples and respective controls, and since the concentration of this metal in the diluted (1/6) Au bearing leachate was very high (~ 630 mg/L), this corresponds to a high contamination of the obtained Au particles. The pH measurements of leachate before and after mixing with plant extracts indicated that alkalization was not the cause of metals removal from the solutions, as the pH values in the mixtures were lower than the estimated precipitation threshold for metals according to simulations using the Medusa-Hydra software [64] (Table OR 2). However, in the case of Pb, the estimated precipitation pH (pH 0.37) closely matched the pH of the solution following the mixture with R. idaeus extract (pH −0.55), suggesting the potential of Pb precipitation through alkalization (Table OR 2).

Removal of main metals present in the diluted (1/6 (v/v)) Au bearing leachate, achieved after 1 and 48 h addition of C. ladanifer, E. andevalensis and R. idaeus 70% ethanolic extracts at a 1/1 (v/v) ratio at room temperature (25 ± 3 °C). Results for controls, consisting of the addition of just 70% ethanol (without plant extract), are included. Removals with the same letters do not significantly differ at 0.05 level (ANOVA and Tukey Kramer's tests)

Based on the results obtained from experiments with unimetallic solutions and leachates in 1/1 ratio, R. idaeus was found with the highest Au recovery potential from the leachate. Moreover, R. idaeus leaves are available in large quantities as wastes from agro-industrial production of red raspberry fruits and therefore, further studies were focused on the optimization of using the R. idaeus extract to recover Au from the leachate, on the Au recovery mechanism and on the characterization of the obtained brownish particles.

In this regard, 1/5 and 1/10 (v/v) ratios of R. idaeus extract to Au bearing leachate were tested to analyze Au recovery efficiencies and Pb contamination rates (Fig. 3). Similar removals of Au and Pb from solution were observed in the tests with 1/1 and 1/5 ratios of R. idaeus to Au bearing leachate for both 1 and 48 h of reaction times. In the experiment with the 1/10 ratio of plant extract to Au bearing leachate, a lower removal of Au and Pb was observed after 1 h (~ 11% of Au and 21% Pb), but 48 h after, the removal of Au from the leachate reached 95%. Yet, as it can be seen in Fig. 3, different ratios of plant extract to leachate are not a successful strategy to prevent Pb contamination. With all this, the optimum ratio of plant extract to leachate was selected as 1/10 (v/v).

Pb Washing from the Au Bearing Precipitates from PCBs Leachate

Pb contamination was observed in the synthesized Au nanoparticles. The binding and distribution of Pb on Au nanoparticles could have been occurred by Pb ions adsorption to their surface by interacting with the functional groups of the stabilizing agents (plant compounds) present on Au particles [72], binding to the regions of the particles with crystalline defects [73, 74] or through alloy formation [75]. It worth mentioning that beneficiation of the developed process in Au recovery from Pb-free PCBs [76], can effectively solve the issue of Pb contamination in Au nanoparticles, which could result in Au nanoparticles free of Pb contamination, in alignment with green principles and minimizing environmental risks. However, in this study, precipitates obtained from applying R. idaeus extract to Au bearing leachate at 1/10 ratio were selected for purification. Attempts of PbSO4 separation from the Au particles were performed by washing the precipitates in a ratio of 1/1000 (w/v) with hydrochloric acid, nitric acid, sodium hydroxide and ammonium acetate. Results from these experiments revealed that all the four tested solutions were able to dissolve and separate PbSO4 from the precipitates, but three of them have a higher and similar efficiency (hydrochloric acid, nitric acid and sodium hydroxide), thus suggesting total PbSO4 leaching, while the other (ammonium acetate) results in a lower efficiency (Table 3). The XRD analysis of the brownish precipitates obtained after the washing step with 1 M hydrochloric acid and subsequent washings with water and 96% ethanol revealed the presence of Au as the only crystalline phase (Fig. 4).

The STEM imaging of these precipitates revealed well defined bright white (indicative of heavy elements) flower-shaped porous particles of ~75 to ~360 nm scattered in a less shiny whitish (indicative of lighter elements) mass with no defined shape (Fig. 5). Then, the STEM-EDS mapping of these precipitates (Fig. 5) showed strong Au and S signals along with very weak signals of Cu, Si and Fe, which are coincident with the white bright flower-shaped particles, as well as O, Sn and Cl signals throughout all precipitate mass. The relative abundances of different elements evaluated by STEM-EDS from the whole area of two images of these precipitates (Figure OR 5) are presented in Table 4.

The flower-shaped particles revealed by STEM have the same appearance of Au nanoparticles obtained with different plant extracts and Au solutions by other authors [77], and the EDS signal revealed Au as the most abundant element (27.2 norm. at.%) after O, which are strong evidences that the production of Au particles using the R. idaeus extract was successful. Nevertheless, the high signal obtained for O (40.1 norm. at.%) and the fact that it maps together with Cl in the less shiny whitish mass indicates a high amount of plant material around the particles since these elements are present in plant compounds [78]. Moreover, the relatively high signal of Sn (12.7 norm. at.%) following O and Cl in the mass surrounding the particles indicates the possibility of complex formation of this metal with organic compounds. The other elements with relatively high signals are Cu (7.9 norm. at.%) and S (5.6 norm. at.%), which seem to follow the Au particles. The presence of Cu might be due to incomplete removal of this metal in the leaching step performed to remove base metals, but these analyzes are not enough to theorize about its co-occurrence with Au particles. The presence of S must be viewed with suspicion because this element has a peak very close to peaks of Pb and Au and, thus, the accuracy of its signal can be low.

The HRTEM analysis of these precipitates showed large clusters (~ 100–400 nm) of tiny Au nanoparticles (~ 20 nm) covered with high contents of plant material, and then the FTT analysis confirmed the crystalline nature of the Au particles (Figure OR 6).

Organics Washing from the Au Bearing Precipitates From PCBs Leachate

Based on the STEM-EDS results indicating the contamination of particles with excessive plant material and a few metals putatively complexed with it, another two washing steps with acetone were performed for the elimination of organic compounds. Thereafter, the obtained particles were also analyzed by STEM microscopy and the images revealed two types of particles: flower-shaped particles like those observed prior to acetone washing side by side with compact geometrical particles resembling cubic shapes (Fig. 6), without evidence of other materials surrounding them. These results show that acetone eliminated the organic material around the Au particles and suggest that organic compounds play an important role in the final shape of the Au particles. Synthesis of compact geometrical Au nanoparticles by mixing plant extract with an Au pure solution was reported before for example by Anbu et al. [79], and though these authors described other shapes (such as spherical, triangular and octahedral), the cubic forms are also visible in their TEM images.

STEM image of Pd nanoparticles obtained by adding 70% ethanolic extract of R. idaeus to the Au bearing leachate (washed with pure acetone) and corresponding EDS elemental mapping of Au, Cu, S, O, Pb and Zn. Pink arrows: flower-shaped Au particles. Yellow arrows: compact geometrical particles resembling cubic shapes

Results of the STEM-EDS analysis revealed strong signals correlating with Au and S and relatively weaker signals for O and the contaminant metals Pb, Cu and Zn. On the contrary, the signals of Sn and Cl, which before acetone washing were detected in all the precipitate mass together with O, were much weaker now after organics removal (Fig. 6). In fact, all signals detected now are present on the Au particles, confirming the efficacy of acetone washing.

The relative abundances of elemental composition of the particles determined by STEM-EDS from the whole area of four different images (Figure OR 7) are presented in Table 5. These results showed a much higher abundance for Au (63.5 norm. at.%), comparing to the value observed (27.2 norm. at.%) before acetone washings. This is mainly due to the sharp decrease of elements O and Sn since the reported abundances are relative to the sum of detected elements. Normalized atomic abundance of O was reduced from 40.1 to 3.7%, and of Sn from 12.7 to 0.1%. This almost disappearance of Sn after successful organic residues washing and the simultaneous decrease in O abundances, confirms that Sn was previously complexed with plant material that was removed with acetone. The sharped removal of O and Sn also caused a raise in the relative abundance of other elements that were not washed with acetone. Cu and S, the main contaminants after Sn, were found in almost the same ratio, but in relatively higher abundances (14.8 norm. at.% and 13.5 norm. at.%, respectively). The ratio of these elements is in fact close to 1, the stoichiometric value of CuS, which might indicate the presence of this compound in the free spaces in between smaller Au nanoparticles forming larger structures of Au nanoparticle clusters. Regarding the other minor contaminants, there was a decrease of Al and Si abundances after the acetone washing, and a raise of Pb and Ni. Thus, the first two were probably complexed with phytochemicals while the last two were somehow bound to the Au particles. Probably Pb and Ni were, as PbSO4 and as NiO, also placed in the porous structures of the flower-shaped larger Au nanoparticle clusters when they were formed by aggregation of tiny Au nanoparticles, and then remained trapped in those particles during the washing steps to which they were subjected. Taking into account the good results for lead removal with the washing solutions tested (Table 3) in the particles after precipitation, the following suggestions can be made, for example, to try to obtain purer particles at the end: (1) test those washing solutions but with higher concentrations, (2) repeat a second consecutive wash with those solutions, (3) do a further washing step with those solutions but after the washing step with acetone.

The final Au particles were further analyzed with high-resolution scanning transmission microscopy (HRSTEM) for further characterization on the atomic scale. The HRSTEM images confirmed the presence of tiny cubic Au nanoparticles (~ 20 nm) and large Au particle clusters (~ 0.2–0.8 μm) with flower-shaped and cubic morphologies that seem to be formed by aggregates of the tiny particles (Fig. 7A, B). Moreover, the HRSTEM images showed clear lattice fringes on the tiny particles and the fast Fourier transform (FFT) pattern of the respective area revealed interplanar lattice distance values of two types: ~2 and ~1.2 Å (Figs. 7D, 9E). In addition, the selected area electron diffraction (SAED) pattern confirmed the polycrystalline nature of the Au particles (Fig. 7F).

A, B HRTEM images of the Au nanoparticles aggregates obtained by adding 70% ethanolic extract of R. idaeus to the Au bearing leachate C, D magnified high resolution STEM, E Fast Fourier Transform (FFT) pattern of a single tiny nanoparticle (all area of (D)) and F selected-area electron diffraction (SAED) patterns of the same nanoparticle

Finally, through High-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) imaging on one flower-shaped particle (Figure OR 8), the aggregation of tiny Au nanoparticles forming a porous nanoparticle cluster seems even more evident.

The use of R. idaeus extracts was previously tested with unimetallic solutions for Ag nanoparticles synthesis by leaf extracts [80] and for Au and Ag nanoparticles synthesis by fruit extracts [71, 81, 82]. However, this work confirms for the first time the possibility of using R. idaeus leaf extracts for Au nanoparticles synthesis from Au unimetallic solutions, as well as from complex Au bearing leachates. This is important, not only because according to [34], Au nanoparticle synthesis by plant extracts in general can have advantages aiming the development of environmental friendly processes, but also because the R. idaeus leaves are a by-product of raspberry production available in large amounts, which is suitable for large-scale processes to satisfy the demand for this substance. Utilization of R. idaeus leaf extracts for gold nanoparticles synthesis offers a prime example of resource efficiency and waste valorization. By utilizing the abundant by-product of raspberry production, this approach not only minimizes waste generation but also maximizes the value extraction from the agricultural sector.

Due to their unique physicochemical properties, synthesized gold nanoparticles with slight contamination of Pb have several potential applications such as applications in analytical methods like colorimetric methods for the identification and determination of heavy metal ions in aqueous solutions [83], catalysts in CO oxidation [84], water gas shift reactions [85], development of biosensors [86], coating for improved electrode surface area [87] etc. In addition, they can be used in remediation of contaminated sites or water bodies [88, 89] and the presence of lead in the nanoparticles could enhance their ability to adsorb or capture lead ions from the environment, facilitating the removal of lead contaminants [90]. These findings highlight the opportunity to integrate circular economy principles into nanotechnology research, facilitating the development of environmentally friendly and economically viable processes.

Au Recovery Mechanism with R. idaeus Leaves’ Extract

UV–Visible Spectroscopy

The bio-reduction of Au(III) ions during the reaction with the phytochemicals present in the 70% hydroalcoholic extract of R. idaeus was monitored by molecular UV–visible spectroscopy. Figure 8 presents the UV–visible absorption spectra of the 100 mg/L Au(III) unimetallic solution, R. idaeus extract diluted in 0.02 M HCl (10% plant extract (v/v)) and also different ratios of R. idaeus extract in 100 mg/L Au(III) (4, 6, 8 and 10% plant extract (v/v)) after 1 h reaction time. The change of the solution color from yellow to red and the appearance of an absorption peak at λ = 520 nm in the UV–Vis spectrum are indications of Au(III) ions reduction into Au(0), which is due to the Surface Plasmon Resonance (SPR) of synthesized Au(0) nanoparticles [91]. Thus, the SPR band of Au(0) nanoparticle samples prepared with lower amounts of R. idaeus extract (4 and 6%) illustrated by a broad lower peak is due to the partial reduction of Au(III) ions, while upon the increase of extract the SPR absorbance peak was steadily raised and reached the highest size when 10% (v/v) of extract was used (Fig. 8).

Fourier Transform Infrared Spectroscopy (FT-IR)

FT-IR spectroscopy was performed to monitor the involvement of functional groups of secondary metabolites present in the R. idaeus hydroalcoholic extract and their possible role in the formation and stabilization of Au particles. FT-IR spectra of crude R. idaeus extract as well as the mixture of the R. idaeus extract with 100 mg/L Au(III) solution (1/1 ratio (v/v) and 1 h of reaction time) are shown in Fig. 9. FT-IR spectra of R. idaeus extract reveals several peaks at different wavenumbers due to the used solvent and the presence of a variety of secondary metabolites in the extract: peaks occurring at 1058, 1097 and 2989 cm−1 are related to ethanol [92], the solvent used to prepare the plant extract, while peaks observed at 842, 890, 1463, 1692, 1921, 2139, 2506 and 3579 are therefore correlated to plant phytochemicals. One hour after mixing the plant extract with the Au solution all the peaks related to phytochemicals, except the one at 890 cm−1 corresponding to the C=C bending of alkenes, disappeared or moved to different wavenumbers, suggesting the involvement of different chemical groups of the plant compounds in the bio-reduction and/or stabilization process producing the Au particles.

The peak observed at 842 cm−1, related to the C–Cl stretching in the alkyl halides, after the reaction of extract’s compounds with Au(III) solution shifted to 851 cm−1. The peak at 1463 cm−1, associated to the C-H bending of the methylene group, shifted to 1467 cm−1. The band at 1692 cm−1, which shifted to 1696 cm−1, is related to stretching vibrations of (NH)C=O and/or C=O groups of conjugated aldehydes and carboxylic acids, and has been associated to phenolic acids or organic acids [93], such as ellagic acids [94]. The peak that shifted from 1921 to 1922 cm−1, corresponds to the C-H bending of the aromatic compounds and is probably related to phenolics such as tannins, flavonoids and anthocyanins [95]. The peak first observed at 2139 cm−1 and then totally vanished, is related to N=C=N stretching of the carbodiimide group and probably indicates the presence of amino acids or proteins [96] and/or anthocyanin [71, 82]. The weak peak at 2506 cm−1 that shifted to 2505 cm−1 is related to the S–H stretching in the thiol group, which might be due to the presence of metallothioneins [97] and/or cysteine rich metabolites [98], as both are known for their high metal interaction potential [26], and high concentrations of cysteine have been reported in the leaf extract of R. idaeus by Komisarenko et al. [99]. Finally, the band first occurring at 3579 cm−1 which shifted to 3585 cm−1 is probably related to the –OH vibrations of carboxylic acids, phenols or alcohols and/or –NH vibrations of amines, proteins and peptides.

Studies by Moreno-Medina et al. [100] and Oszmiański et al. [94] show the presence of phenols in high quantities (2.6–6.9% (w/w)), mainly as ellagic acids in the leaves of R. idaeus. Moreover, flavonoids are reported in high contents in the leaves of this plant; for instance, Gudej [101] reports a flavonoid content range between 0.46 and 1.05% of the dried leaves (w/w), while, Durgo et al. [102] reports the flavonoid of the leaves as the main constituent of the phenolic content, comprising about 11% of the leaf extract powder weight. Other types of phenolic compounds present in the leaves of R. idaeus are reported as vanillic acids, ferulic, caffeoyl tartaric, protocatechuic, gentisic, feruloyl tartaric, p-coumaric, p-coumaroyl-glucoside acids, p-hydroxybenzoic [103], caffeic and chlorogenic acid [102], as well as terpenoids including mono- and sesquiterpenes, like terpinolene and triterpenes, squalene and cycloartenol [104, 105].

It is known that plant compounds in the groups of phenols and polyphenols have high interaction capabilities with metals in general, but specifically high with Au [35, 106]. The interaction mechanism of phenols with metals is not totally clear yet; however, it is known that the high capacity of free radical scavenging by the functional groups of phenols and also their high electron/proton donation potential are the main mechanism of interaction of these biomolecules with metals [107]. In addition, another proposed mechanism is suggested by the presence of nucleophilic aromatic rings in conjunction with some functional groups such as carbonyl, carboxyl and hydroxyl groups in the phenolic compounds [108, 109].

In a similar study, Stevanović et al. [80] used aqueous extracts of R. idaeus leaves for the synthesis of Ag nanoparticles and reported the polyphenolics, flavonoids, triterpenoids, proteins and organic acids as the possible reducing and stabilizing agents of Ag nanoparticles [80].

Moreover, another similar study by Demirbas et al. [71], but using extracts of R. idaeus fruits (instead of leaves) for Au(III) reduction and Au nanoparticles synthesis, went further and indicated the specific catecholamine group of anthocyanin as the preferential site of coordination reaction with Au(III) and thus, the formation of anthocyanin-Au(III) complexes. Based on their conclusions, this reaction may initiate Au nucleation for seed formation and then, the oxidation of catecholamine groups results in electrons release, which boosts Au(III) reductin [71]. Taking this into account and the fact that in the R. idaeus leaves there are contents of anthocyanines as high or higher than in the fruits (Veljkovic et al. 2019), it can be suggested that these compounds should also play an important role in the formation of Au particles when leaf extracts are used.

Conclusions

This work shows the high interaction potential of phytochemicals present in the leaves of three different plants (R. idaeus, C. ladanifer and E. andevalensis) with Au(III) ions when in simple unimetallic solutions, resulting in the separation of Au from the liquid phase. The work also shows that extracts from leaves of these three plants can be added to leachates obtained from PCBs, resulting in the separation of Au from the solution along with Pb as a major contaminant.

Moreover, specifically for the R. idaeus leaves extract, it was shown that pure Au nanoparticles can be obtained from Au unimetallic solutions, while Au nanoparticles obtained from PCBs leachates are contaminated with PbSO4, which can be further separated from the Au particles by HCl washing. Plus, it was also shown that acetone efficiently removes the complexed organic-metals contaminants allowing to obtain highly pure Au tiny nanoparticles (~ 18 nm) aggregated in larger Au microparticle clusters (~ 0.8 μm).

Rubus idaeus leaves are the main waste of red raspberry fruit industry, which is widely cultivated in Europe, Asia, and America. Therefore, this study reinforces the idea of beneficiation of those wastes in extract preparation and application for Au separation and recovery from secondary sources. By employing the circular sustainability approach, this research showcases the transformative potential of harnessing plant extracts from R. idaeus leaves as a viable and environmentally friendly solution for Au separation and recovery, contributing to a more sustainable and resource-efficient future.

Data Availability

There are no reservations regarding the disclosure of results. The datasets generated during and/or analysed during the current study are available in the paper and/or in the supplementary materials.

References

Wongsawa, T., Traiwongsa, N., Pancharoen, U., Nootong, K.: A review of the recovery of precious metals using ionic liquid extractants in hydrometallurgical processes. Hydrometallurgy 198, 105488 (2020). https://doi.org/10.1016/j.hydromet.2020.105488

Chen, Y., Qiao, Q., Cao, J., Li, H., Bian, Z.: Precious metal recovery. Joule 5, 3097–3115 (2021). https://doi.org/10.1016/j.joule.2021.11.002

Kim, J.G.: Material flow and industrial demand for palladium in Korea. Resour. Conserv. Recycl. 77, 22–28 (2013). https://doi.org/10.1016/j.resconrec.2013.04.009

Kumar, A., Saini, H.S., Kumar, S.: Bioleaching of gold and silver from waste printed circuit boards by Pseudomonas balearica SAE1 isolated from an e-waste recycling facility. Curr. Microbiol. 75, 194–201 (2018). https://doi.org/10.1007/s00284-017-1365-0

Forti, V., Balde, C., Kuehr, R., Bel, G.: The Global E-waste Monitor 2020: Quantities, flows and the circular economy potential. United Nations University/United Nations Institute for Training and Research, International Telecommunication Union, and International Solid Waste Association, Bonn, Geneva and Rotterdam (2020)

Le, H.-L., Yamasue, E., Okumura, H., Ishihara, K.N.: MEMRECS—a sustainable view for metal recycling from waste printed circuit boards. JEP 04, 803–810 (2013). https://doi.org/10.4236/jep.2013.48094

Luda, M.P.: Recycling of printed circuit boards. In: Integrated Waste Management. Intech, Rijeka (2011)

Mir, S., Dhawan, N.: A comprehensive review on the recycling of discarded printed circuit boards for resource recovery. Resourc. Conserv. Recycl. 178, 106027 (2022). https://doi.org/10.1016/j.resconrec.2021.106027

Sverdrup, H.U., Ragnarsdottir, K.V.: A system dynamics model for platinum group metal supply, market price, depletion of extractable amounts, ore grade, recycling and stocks-in-use. Resour. Conserv. Recycl. 114, 130–152 (2016). https://doi.org/10.1016/j.resconrec.2016.07.011

Bourgeois, D., Lacanau, V., Mastretta, R., Contino-Pépin, C., Meyer, D.: A simple process for the recovery of palladium from wastes of printed circuit boards. Hydrometallurgy 191, 105241 (2020). https://doi.org/10.1016/j.hydromet.2019.105241

Gonzalez Baez, A., Pantoja Muñoz, L., Garelick, H., Purchase, D.: Characterization of industrially pre-treated waste printed circuit boards for the potential recovery of rare earth elements. Environ. Technol. Innov. 27, 102481 (2022). https://doi.org/10.1016/j.eti.2022.102481

Brown, R.M., Mirkouei, A., Reed, D., Thompson, V.: Current nature-based biological practices for rare earth elements extraction and recovery: bioleaching and biosorption. Renew. Sustain. Energy Rev. 173, 113099 (2023). https://doi.org/10.1016/j.rser.2022.113099

Xavier, L.H., Ottoni, M., Abreu, L.P.P.: A comprehensive review of urban mining and the value recovery from e-waste materials. Resour. Conserv. Recycl. 190, 106840 (2023). https://doi.org/10.1016/j.resconrec.2022.106840

Janyasuthiwong, S., Ugas, R., Rene, E.R., Alessandra, C., Esposito, G., Lens, P.N.: Effect of operational parameters on the leaching efficiency and recovery of heavy metals from computer printed circuit boards: recovery of heavy metals from computer printed circuit boards. J. Chem. Technol. Biotechnol. 91, 2038–2046 (2016). https://doi.org/10.1002/jctb.4798

Jeon, S., Tabelin, C.B., Park, I., Nagata, Y., Ito, M., Hiroyoshi, N.: Ammonium thiosulfate extraction of gold from printed circuit boards (PCBs) of end-of-life mobile phones and its recovery from pregnant leach solution by cementation. Hydrometallurgy 191, 105214 (2020). https://doi.org/10.1016/j.hydromet.2019.105214

Magoda, K., Mekuto, L.: Biohydrometallurgical recovery of metals from waste electronic equipment: current status and proposed process. Recycling 7, 67 (2022). https://doi.org/10.3390/recycling7050067

Li, H., Eksteen, J., Oraby, E.: Hydrometallurgical recovery of metals from waste printed circuit boards (WPCBs): Current status and perspectives – A review. Resour. Conserv. Recycl. 139, 122–139 (2018). https://doi.org/10.1016/j.resconrec.2018.08.007

Wu, C., Awasthi, A.K., Qin, W., Liu, W., Yang, C.: Recycling value materials from waste PCBs focus on electronic components: technologies, obstruction and prospects. J. Environ. Chem. Eng. 10, 108516 (2022). https://doi.org/10.1016/j.jece.2022.108516

Dutta, D., Rautela, R., Gujjala, L.K.S., Kundu, D., Sharma, P., Tembhare, M., Kumar, S.: A review on recovery processes of metals from E-waste: a green perspective. Sci. Total Environ. 859, 160391 (2023). https://doi.org/10.1016/j.scitotenv.2022.160391

Huy Do, M., Tien Nguyen, G., Dong Thach, U., Lee, Y., Huu Bui, T.: Advances in hydrometallurgical approaches for gold recovery from E-waste: a comprehensive review and perspectives. Minerals Eng. 191, 107977 (2023). https://doi.org/10.1016/j.mineng.2022.107977

Udayakumar, S., Razak, M.I.B.A., Ismail, S.: Recovering valuable metals from Waste Printed Circuit Boards (WPCB): a short review. Mater. Today: Proc. 66, 3062–3070 (2022). https://doi.org/10.1016/j.matpr.2022.07.364

Islam, A., Ahmed, T., Awual, Md.R., Rahman, A., Sultana, M., Aziz, A.A., Monir, M.U., Teo, S.H., Hasan, M.: Advances in sustainable approaches to recover metals from e-waste-a review. J. Cleaner Prod. 244, 118815 (2020). https://doi.org/10.1016/j.jclepro.2019.118815

Islam, A., Swaraz, A.M., Teo, S.H., Taufiq-Yap, Y.H., Vo, D.-V.N., Ibrahim, M.L., Abdulkreem-Alsultan, G., Rashid, U., Awual, Md.R.: Advances in physiochemical and biotechnological approaches for sustainable metal recovery from e-waste: a critical review. J. Cleaner Prod. 323, 129015 (2021). https://doi.org/10.1016/j.jclepro.2021.129015

Chakraborty, S.C., Zaman, Md.W.U., Hoque, M., Qamruzzaman, Md., Zaman, J.U., Hossain, D., Pramanik, B.K., Nguyen, L.N., Nghiem, L.D., Mofijur, Md., Mondal, Md.I.H., Sithi, J.A., Shahriar, S.M.S., Johir, Md.A.H., Ahmed, M.B.: Metals extraction processes from electronic waste: constraints and opportunities. Environ. Sci. Pollut. Res. 29, 32651–32669 (2022). https://doi.org/10.1007/s11356-022-19322-8

Zulkernain, N.H., Basant, N., Ng, C.C., Kriti, Salari, M., Mallick, S.: Recovery of precious metals from e-wastes through conventional and phytoremediation treatment methods: a review and prediction. J. Mater. Cycles Waste Manag. (2023). https://doi.org/10.1007/s10163-023-01717-5

Nobahar, A., Carlier, J.D., Miguel, M.G., Costa, M.C.: A review of plant metabolites with metal interaction capacity: a green approach for industrial applications. Biometals (2021). https://doi.org/10.1007/s10534-021-00315-y

Clemens, S.: Molecular mechanisms of plant metal tolerance and homeostasis. Planta 212, 475–486 (2001). https://doi.org/10.1007/s004250000458

Ma, Y., Oliveira, R.S., Freitas, H., Zhang, C.: Biochemical and molecular mechanisms of plant-microbe-metal interactions: relevance for phytoremediation. Front. Plant Sci. (2016). https://doi.org/10.3389/fpls.2016.00918

Mejáre, M., Bülow, L.: Metal-binding proteins and peptides in bioremediation and phytoremediation of heavy metals. Trends Biotechnol. 19, 67–73 (2001). https://doi.org/10.1016/S0167-7799(00)01534-1

Ishak, N.A.I., Kamarudin, S.K., Timmiati, S.N.: Green synthesis of metal and metal oxide nanoparticles via plant extracts: an overview. Mater. Res. Express 6, 112004 (2019). https://doi.org/10.1088/2053-1591/ab4458

Sharma, S.S., Schat, H., Vooijs, R.: In vitro alleviation of heavy metal-induced enzyme inhibition by proline. Phytochemistry 49, 1531–1535 (1998). https://doi.org/10.1016/S0031-9422(98)00282-9

Pietrobelli, J.M.T.A., Módenes, A.N., Fagundes-Klen, M.R., Espinoza-Quiñones, F.R.: Cadmium, copper and zinc biosorption study by non-living Egeria densa biomass. Water Air Soil Pollut. 202, 385–392 (2009). https://doi.org/10.1007/s11270-009-9987-x

Khan, T., Ullah, N., Khan, M.A., Mashwani, Z.-R., Nadhman, A.: Plant-based gold nanoparticles; a comprehensive review of the decade-long research on synthesis, mechanistic aspects and diverse applications. Adv. Colloid Interface Sci. 272, 102017 (2019). https://doi.org/10.1016/j.cis.2019.102017

Kumar, V., Yadav, S.K.: Plant-mediated synthesis of silver and gold nanoparticles and their applications. J. Chem. Technol. Biotechnol. 84, 151–157 (2009). https://doi.org/10.1002/jctb.2023

Sengani, M., Grumezescu, A.M., Rajeswari, V.D.: Recent trends and methodologies in gold nanoparticle synthesis – a prospective review on drug delivery aspect. OpenNano 2, 37–46 (2017). https://doi.org/10.1016/j.onano.2017.07.001

Kaya, M.: Recovery of metals and nonmetals from electronic waste by physical and chemical recycling processes. Waste Manag. 57, 64–90 (2016). https://doi.org/10.1016/j.wasman.2016.08.004

Ilankoon, I.M.S.K., Ghorbani, Y., Chong, M.N., Herath, G., Moyo, T., Petersen, J.: E-waste in the international context – A review of trade flows, regulations, hazards, waste management strategies and technologies for value recovery. Waste Manag. 82, 258–275 (2018). https://doi.org/10.1016/j.wasman.2018.10.018

Aswathi, V.P., Meera, S., Maria, C.G.A., Nidhin, M.: Green synthesis of nanoparticles from biodegradable waste extracts and their applications: a critical review. Nanotechnol. Environ. Eng. 8, 377–397 (2023). https://doi.org/10.1007/s41204-022-00276-8

Fraga-Corral, M., García-Oliveira, P., Pereira, A.G., Lourenço-Lopes, C., Jimenez-Lopez, C., Prieto, M.A., Simal-Gandara, J.: Technological application of tannin-based extracts. Molecules 25, 614 (2020). https://doi.org/10.3390/molecules25030614

Wang, J., Faraji, F., Ramsay, J., Ghahreman, A.: A review of biocyanidation as a sustainable route for gold recovery from primary and secondary low-grade resources. J. Cleaner Prod. 296, 126457 (2021). https://doi.org/10.1016/j.jclepro.2021.126457

Nobahar, A., Carlier, J.D., Costa, M.C.: Recovery of catalytic metals from leaching solutions of spent automotive catalytic converters using plant extracts. Clean Technol. Environ. Policy (2023). https://doi.org/10.1007/s10098-023-02523-1

Serga, V., Zarkov, A., Blumbergs, E., Shishkin, A., Baronins, J., Elsts, E., Pankratov, V.: Leaching of gold and copper from printed circuit boards under the alternating current action in hydrochloric acid electrolytes. Metals 12, 1953 (2022). https://doi.org/10.3390/met12111953

Arshadi, M., Mousavi, S.M.: Multi-objective optimization of heavy metals bioleaching from discarded mobile phone PCBs: simultaneous Cu and Ni recovery using Acidithiobacillus ferrooxidans. Sep. Purif. Technol. 147, 210–219 (2015). https://doi.org/10.1016/j.seppur.2015.04.020

Li, H., Oraby, E.A., Eksteen, J.J.: Development of an integrated glycine-based process for base and precious metals recovery from waste printed circuit boards. Resour. Conserv. Recycl. 187, 106631 (2022). https://doi.org/10.1016/j.resconrec.2022.106631

Birloaga, I., Coman, V., Kopacek, B., Vegliò, F.: An advanced study on the hydrometallurgical processing of waste computer printed circuit boards to extract their valuable content of metals. Waste Manag. 34, 2581–2586 (2014). https://doi.org/10.1016/j.wasman.2014.08.028

Park, Y.J., Fray, D.J.: Recovery of high purity precious metals from printed circuit boards. J. Hazard. Mater. 164, 1152–1158 (2009). https://doi.org/10.1016/j.jhazmat.2008.09.043

Cui, J., Zhang, L.: Metallurgical recovery of metals from electronic waste: a review. J. Hazard. Mater. 158, 228–256 (2008). https://doi.org/10.1016/j.jhazmat.2008.02.001

Skoog, D.A., West, D.M., Holler, F.J., Crouch, S.R.: Analytical Chemistry - An Introduction. Saunders College Publishing, Philadelphia (2000)

Neto, I.F.F.: A Simple and Sustainable Approach to Recover Metals from Spent Printed Circuit Boards (2018)

Abreu, M.M., Santos, E., Fernandes, E., Batista, M.J., Ferreira, M.: Accumulation and translocation of trace elements in Cistus ladanifer L. from IPB Portuguese mining areas. Rev. Ciênc. Agrár. 34, 45–56 (2011)

Santos, E.S., Abreu, M.M., Nabais, C., Magalhães, M.C.F.: Trace element distribution in soils developed on gossan mine wastes and Cistus ladanifer L. tolerance and bioaccumulation. J. Geochem. Explor. 123, 45–51 (2012). https://doi.org/10.1016/j.gexplo.2012.05.006

Santos, E.S., Abreu, M.M., Batista, M.J., Magalhães, M.C.F., Fernandes, E.: Inter-population variation on the accumulation and translocation of potentially harmful chemical elements in Cistus ladanifer L. from Brancanes, Caveira, Chança, Lousal, Neves Corvo and São Domingos mines in the Portuguese Iberian Pyrite Belt. J. Soils Sediments 14, 758–772 (2014). https://doi.org/10.1007/s11368-014-0852-1

Santos, E.S., Abreu, M.M., Magalhães, M.C.F.: Cistus ladanifer phytostabilizing soils contaminated with non-essential chemical elements. Ecol. Eng. 94, 107–116 (2016). https://doi.org/10.1016/j.ecoleng.2016.05.072

Durães, N., Bobos, I., Ferreira da Silva, E., Dekayir, A.: Copper, zinc and lead biogeochemistry in aquatic and land plants from the Iberian Pyrite Belt (Portugal) and north of Morocco mining areas. Environ. Sci. Pollut. Res. 22, 2087–2105 (2015). https://doi.org/10.1007/s11356-014-3394-6

Cabezudo, B., Rivera, J.: Notas taxonómicas y corológicas sobre la Flora de Andalucía occidental. 2: Erica andevalensis Cabezudo y Rivera sp. nov. Lagascalia 9, 223–226 (1980)

Rossini-Oliva, S., Abreu, M.M., Leidi, E.O.: A review of hazardous elements tolerance in a metallophyte model species: Erica andevalensis. Geoderma 319, 43–51 (2018). https://doi.org/10.1016/j.geoderma.2017.12.035

Quental, L., Bourguignon, A., Sousa, A.J., Batista, M.J., Cottard, F.: MINEO Southern Europe environment test site. Contamination impact mapping and modelling-Final Report. Assessing and Monitoring the Environmental Impact of Mining Activities in Europe Using Advanced Earth Observation Techniques 5yth FP-IST. (MINEO). 1999–10337 (2002)

Abreu, M.M., Tavares, M.T., Batista, M.J.: Potential use of Erica andevalensis and Erica australis in phytoremediation of sulphide mine environments: São Domingos, Portugal. J. Geochem. Explor. 96, 210–222 (2008). https://doi.org/10.1016/j.gexplo.2007.04.007

Monaci, F., Leidi, E.O., Mingorance, M.D., Valdés, B., Oliva, S.R., Bargagli, R.: Selective uptake of major and trace elements in Erica andevalensis, an endemic species to extreme habitats in the Iberian Pyrite Belt. J. Environ. Sci. 23, 444–452 (2011). https://doi.org/10.1016/S1001-0742(10)60429-9

Pantelidis, G., Vasilakakis, M., Manganaris, G., Diamantidis, G.: Antioxidant capacity, phenol, anthocyanin and ascorbic acid contents in raspberries, blackberries, red currants, gooseberries and Cornelian cherries. Food Chem. 102, 777–783 (2007). https://doi.org/10.1016/j.foodchem.2006.06.021

Wang, L., Lin, X., Zhang, J., Zhang, W., Hu, X., Li, W., Li, C., Liu, S.: Extraction methods for the releasing of bound phenolics from Rubus idaeus L. leaves and seeds. Ind. Crops Prod. 135, 1–9 (2019). https://doi.org/10.1016/j.indcrop.2019.04.003

Fisher, S.R.A.: Statistical Tables for Biological, Agricultural, and Medical Research. Hafner Pub. Co., New York (1973)

Tukey, J.W.: Comparing individual means in the analysis of variance. Biometrics 5, 99 (1949). https://doi.org/10.2307/3001913

Puigdomenech, I.: Hydra/medusa chemical equilibrium database and plotting software (database update: 01–01–2015; Hydra: 32 bit version 18 Aug. 2009; Medusa: 32 bit version 16 Dec. 2010). KTH Royal Institute of Technology, Stockolm (2015)

Bard, A.J., Parsons, R., Jordan, J.: International Union of Pure And Applied Chemistry. Standard potentials in aqueous solution (1985)

Milazzo, G., Caroli, S., Sharma, V.K.: Tables of Standard Electrode Potentials. Wiley, London (1978)

Shah, S., Shah, S.A., Faisal, S., Khan, A., Ullah, R., Ali, N., Bilal, M.: Engineering novel gold nanoparticles using Sageretia thea leaf extract and evaluation of their biological activities. J. Nanostruct. Chem. 12, 129–140 (2022). https://doi.org/10.1007/s40097-021-00407-8

Zhu, B., Xie, N., Yue, L., Wang, K., Bani-Fwaz, M.Z., Hussein Osman, H.-E., El-kott, A.F., Bai, X.: Formulation and characterization of a novel anti-human endometrial cancer supplement by gold nanoparticles green-synthesized using Spinacia oleracea L. Leaf aqueous extract. Arab. J. Chem. 15, 103576 (2022). https://doi.org/10.1016/j.arabjc.2021.103576

Botha, T.L., Elemike, E.E., Horn, S., Onwudiwe, D.C., Giesy, J.P., Wepener, V.: Cytotoxicity of Ag, Au and Ag-Au bimetallic nanoparticles prepared using golden rod (Solidago canadensis) plant extract. Sci. Rep. 9, 4169 (2019). https://doi.org/10.1038/s41598-019-40816-y

Yang, D., Fan, R., Luo, F., Chen, Z., Gerson, A.R.: Facile and green fabrication of efficient Au nanoparticles catalysts using plant extract via a mesoporous silica-assisted strategy. Colloids Surf. A Physicochem. Eng. Asp. 621, 126580 (2021). https://doi.org/10.1016/j.colsurfa.2021.126580

Demirbas, A., Büyükbezirci, K., Celik, C., Kislakci, E., Karaagac, Z., Gokturk, E., Kati, A., Cimen, B., Yilmaz, V., Ocsoy, I.: Synthesis of long-term stable gold nanoparticles benefiting from red raspberry (Rubus idaeus), strawberry (Fragaria ananassa), and blackberry (Rubus fruticosus) extracts-gold ion complexation and investigation of reaction conditions. ACS Omega 4, 18637–18644 (2019). https://doi.org/10.1021/acsomega.9b02469

Sidhu, A.K., Verma, N., Kaushal, P.: Role of biogenic capping agents in the synthesis of metallic nanoparticles and evaluation of their therapeutic potential. Front. Nanotechnol. 3, 801620 (2022). https://doi.org/10.3389/fnano.2021.801620

Mourdikoudis, S., Pallares, R.M., Thanh, N.T.K.: Characterization techniques for nanoparticles: comparison and complementarity upon studying nanoparticle properties. Nanoscale 10, 12871–12934 (2018). https://doi.org/10.1039/C8NR02278J

Baig, N., Kammakakam, I., Falath, W.: Nanomaterials: a review of synthesis methods, properties, recent progress, and challenges. Mater. Adv. 2, 1821–1871 (2021). https://doi.org/10.1039/D0MA00807A

Chen, Y.-Y., Chang, H.-T., Shiang, Y.-C., Hung, Y.-L., Chiang, C.-K., Huang, C.-C.: Colorimetric assay for lead ions based on the leaching of gold nanoparticles. Anal. Chem. 81, 9433–9439 (2009). https://doi.org/10.1021/ac9018268

Herat, S.: Green electronics through legislation and lead free soldering. Clean Soil Air Water 36, 145–151 (2008). https://doi.org/10.1002/clen.200700164

Firdhouse, M.J., Lalitha, P.: Flower-shaped gold nanoparticles synthesized using Kedrostis foetidissima and their antiproliferative activity against bone cancer cell lines. Int. J. Ind. Chem. 7, 347–358 (2016). https://doi.org/10.1007/s40090-016-0098-4

Engvild, K.C.: Chlorine-containing natural compounds in higher plants. Phytochemistry 25, 781–791 (1986). https://doi.org/10.1016/0031-9422(86)80002-4

Anbu, P., Gopinath, S.C., Jayanthi, S.: Synthesis of gold nanoparticles using Platycodon grandiflorum extract and its antipathogenic activity under optimal conditions. Nanomater. Nanotechnol. 10, 184798042096169 (2020). https://doi.org/10.1177/1847980420961697

Stevanović, M., Zvezdanović, J., Stanojević, L., Stanojević, J., Petrović, S., Cakić, M., Cvetković, D.: Synthesis, characterization and antioxidant activity of silver nanoparticles stabilized by aqueous extracts of wild blackberry (Rubus spp.) and raspberry (Rubus idaeus L.) leaves. Adv. Technol. 8, 47–58 (2019). https://doi.org/10.5937/SavTeh1901047S

Demirbas, A., Yilmaz, V., Ildiz, N., Baldemir, A., Ocsoy, I.: Anthocyanins-rich berry extracts directed formation of Ag NPs with the investigation of their antioxidant and antimicrobial activities. J. Mol. Liq. 248, 1044–1049 (2017). https://doi.org/10.1016/j.molliq.2017.10.130

Ekrikaya, S., Yilmaz, E., Celik, C., Demirbuga, S., Ildiz, N., Demirbas, A., Ocsoy, I.: Investigation of ellagic acid rich-berry extracts directed silver nanoparticles synthesis and their antimicrobial properties with potential mechanisms towards Enterococcus faecalis and Candida albicans. J. Biotechnol. 341, 155–162 (2021). https://doi.org/10.1016/j.jbiotec.2021.09.020

Hyder, A., Buledi, J.A., Nawaz, M., Rajpar, D.B., Shah, Z.-H., Orooji, Y., Yola, M.L., Karimi-Maleh, H., Lin, H., Solangi, A.R.: Identification of heavy metal ions from aqueous environment through gold, silver and copper nanoparticles: an excellent colorimetric approach. Environ. Res. 205, 112475 (2022). https://doi.org/10.1016/j.envres.2021.112475

Al Soubaihi, R., Saoud, K., Dutta, J.: Critical review of low-temperature CO oxidation and hysteresis phenomenon on heterogeneous catalysts. Catalysts 8, 660 (2018). https://doi.org/10.3390/catal8120660

Pal, D.B., Chand, R., Upadhyay, S.N., Mishra, P.K.: Performance of water gas shift reaction catalysts: a review. Renew. Sustain. Energy Rev. 93, 549–565 (2018). https://doi.org/10.1016/j.rser.2018.05.003

Dimcheva, N.: Nanostructures of noble metals as functional materials in biosensors. Curr. Opin. Electrochem. 19, 35–41 (2020). https://doi.org/10.1016/j.coelec.2019.09.008

Li, Z., Ravaine, V., Ravaine, S., Garrigue, P., Kuhn, A.: Raspberry-like gold microspheres: preparation and electrochemical characterization. Adv. Funct. Mater. 17, 618–622 (2007). https://doi.org/10.1002/adfm.200600667

Barakat, T., Rooke, J.C., Genty, E., Cousin, R., Siffert, S., Su, B.-L.: Gold catalysts in environmental remediation and water-gas shift technologies. Energy Environ. Sci. 6, 371–391 (2013). https://doi.org/10.1039/C2EE22859A

Thangavelu, L., Veeraragavan, G.R., Mallineni, S.K., Devaraj, E., Parameswari, R.P., Syed, N.H., Dua, K., Chellappan, D.K., Balusamy, S.R., Bhawal, U.K.: Role of nanoparticles in environmental remediation: an insight into heavy metal pollution from dentistry. Bioinorg. Chem. Appl. 2022, 1–13 (2022). https://doi.org/10.1155/2022/1946724

Lin, Y.-W., Huang, C.-C., Chang, H.-T.: Gold nanoparticle probes for the detection of mercury, lead and copper ions. Analyst. 136, 863–871 (2011). https://doi.org/10.1039/C0AN00652A

Lee, K.X., Shameli, K., Yew, Y.P., Teow, S.-Y., Jahangirian, H., Rafiee-Moghaddam, R., Webster, T.: Recent developments in the facile bio-synthesis of gold nanoparticles (AuNPs) and their biomedical applications. IJN 15, 275–300 (2020). https://doi.org/10.2147/IJN.S233789

Silverstein, R.M., Webster, F.X.: Spectrometric Identification of Organic Compounds. Wiley, New York (1997)

Lu, P., Hsieh, Y.-L.: Cellulose isolation and core–shell nanostructures of cellulose nanocrystals from chardonnay grape skins. Carbohyd. Polym. 87, 2546–2553 (2012). https://doi.org/10.1016/j.carbpol.2011.11.023

Oszmiański, J., Wojdyl̷o, A., Gorzelany, J., Kapusta, I.: Identification and characterization of low molecular weight polyphenols in berry leaf extracts by HPLC-DAD and LC-ESI/MS. J. Agric. Food Chem. 59, 12830–12835 (2011). https://doi.org/10.1021/jf203052j

Veljkovic, B., Djordjevic, N., Dolicanin, Z., Licina, B., Topuzovic, M., Stankovic, M., Zlatic, N., Dajic-Stevanovic, Z.: Antioxidant and anticancer properties of leaf and fruit extracts of the wild raspberry (Rubus idaeus L.). Not. Bot. Horti Agrobo. 47, 359–367 (2018). https://doi.org/10.15835/nbha47111274

Fiehn, O., Kopka, J., Trethewey, R.N., Willmitzer, L.: Identification of uncommon plant metabolites based on calculation of elemental compositions using gas chromatography and quadrupole mass spectrometry. Anal. Chem. 72, 3573–3580 (2000). https://doi.org/10.1021/ac991142i

Leszczyszyn, O.I., Imam, H.T., Blindauer, C.A.: Diversity and distribution of plant metallothioneins: a review of structure, properties and functions. Metallomics 5, 1146 (2013). https://doi.org/10.1039/c3mt00072a

Harada, E., Yamaguchi, Y., Koizumi, N., Hiroshi, S.: Cadmium stress induces production of thiol compounds and transcripts for enzymes involved in sulfur assimilation pathways in Arabidopsis. J. Plant Physiol. 159, 445–448 (2002). https://doi.org/10.1078/0176-1617-00733

Komisarenko, M.A., Polischuk, I.M., Upyr, T.V., Saidov, N.B.: Study of Amino acid composition and immunomodulatory activity of Rubus idaeus alcoholic extract. Res. J. Pharm. Technol. 14, 1329–1332 (2021). https://doi.org/10.5958/0974-360X.2021.00236.5

Moreno-Medina, B.L., Casierra-Posada, F., Cutler, J.: Phytochemical composition and potential use of Rubus species. Gesunde Pflanzen. 70, 65–74 (2018). https://doi.org/10.1007/s10343-018-0416-1

Gudej, J.: Kaempferol and quercetin glycosides from Rubus idaeus L. leaves. Acta Poloniae Pharma. 60, 313–316 (2003)

Durgo, K., Belščak-Cvitanović, A., Stančić, A., Franekić, J., Komes, D.: The bioactive potential of red raspberry (Rubus idaeus L.) leaves in exhibiting cytotoxic and cytoprotective activity on human laryngeal carcinoma and colon adenocarcinoma. J. Med. Food 15, 258–268 (2012). https://doi.org/10.1089/jmf.2011.0087

Brandely, P.: Raspberry leaf. In: A Handbook of Scientific Information on Widely Used Plant Drugs. British Herbal Medicine Association, Bournemouth (2006)

Committee on Herbal Medicinal Products (HMPC): Assessment Report on Rubus idaeus L., Folium (2012)

Kylli, P.: Berry phenolics : isolation, analysis, identification, and antioxidant properties. Dissertation, University of Helsinki (2010)

Santhoshkumar, J., Rajeshkumar, S., Venkat Kumar, S.: Phyto-assisted synthesis, characterization and applications of gold nanoparticles – a review. Biochem. Biophys. Reports 11, 46–57 (2017). https://doi.org/10.1016/j.bbrep.2017.06.004

Kaurinovic, B., Vastag, D.: Flavonoids and phenolic acids as potential natural antioxidants. In: Shalaby, E. (ed.) Antioxidants. IntechOpen, Rijeka (2019)

Kulbat, K.: The role of phenolic compounds in plant resistance. Biotechnol. Food Sci. 80, 97–108 (2016)

Liu, Y.-S., Chang, Y.-C., Chen, H.-H.: Silver nanoparticle biosynthesis by using phenolic acids in rice husk extract as reducing agents and dispersants. J. Food Drug Anal. 26, 649–656 (2018). https://doi.org/10.1016/j.jfda.2017.07.005

Acknowledgements

This study received Portuguese national funds from FCT—Foundation for Science and Technology through projects UIDB/04326/2020, UIDP/04326/2020 and LA/P/0101/2020, and also by national funds from FCT co-financed by the Algarve´s Regional Operational Program (CRESC Algarve 2020) through Portugal 2020 and European Regional Development Fund (FEDER), under the project METALCHEMBIO (no. 29251). Moreover, this work was carried out in part using the Structural and Analytical Chemistry Platform of CCMAR (for metal analysis), for which we especially thank Vera Almeida Gomes for helping with metal analysis, and Isabel Marín-Beltrán for helping with FTIR analysis.

Funding