Abstract

The frequent leakage of petroleum and organic solvents has catastrophic and far-reaching implications for the ecological environment, resulting in severe threats to aquatic organisms. Absorbing oil from water with porous material has emerged as an eco-friendly and efficient option. Among these explored sorbents, biomass-based/derived materials are abundant in pores and their multiscale porosity serving as a storage space for the absorption, making them excellent sorbents especially after surface modification. In this review, we summarized several biomass-based/derived porous materials for oil/water separation including biochars (BC), cellulose-based/derived materials, chitosan-based/derived materials, lignin-based/derived materials, biomass waste-based/derived materials and some other common biomass-based/derived materials. The detailed synthesis methodologies and activation/modification mechanism together with their effective participation in the field of oil/water adsorption/absorption were discussed. Moreover, perspectives for future application of the biomass-based/derived porous materials in the area are also provided.

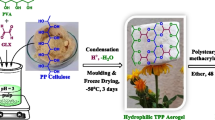

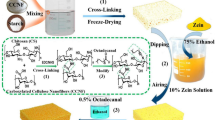

Graphical Abstract

(Copyright 2018 Springer)

(Copyright 2021 Elsevier)

(Copyright 2021 Elsevier)

Similar content being viewed by others

Data Availability

Research data available on reasonable request from the corresponding authors.

References

Unur, E.: Functional nanoporous carbons from hydrothermally treated biomass for environmental purification. Micropor. Mesopor. Mater. 168, 92–101 (2013). https://doi.org/10.1016/j.micromeso.2012.09.027

Inyang, M., Dickenson, E.: The potential role of biochar in the removal of organic and microbial contaminants from potable and reuse water: a review. Chemosphere 134, 232–240 (2015). https://doi.org/10.1016/j.chemosphere.2015.03.072

Gui, X., Zeng, Z., Lin, Z., Gan, Q., Xiang, R., Zhu, Y., Cao, A., Tang, Z.: Magnetic and highly recyclable macroporous carbon nanotubes for spilled oil sorption and separation. ACS Appl. Mater. Interfaces 5, 5845–5850 (2013). https://doi.org/10.1021/am4015007

Zhang, X., Li, Z., Liu, K., Jiang, L.: Bioinspired multifunctional foam with self-cleaning and oil/water separation. Adv. Funct. Mater. 23, 2881–2886 (2013). https://doi.org/10.1002/adfm.201202662

Bi, H., Yin, Z., Cao, X., Xie, X., Tan, C., Huang, X., Chen, B., Chen, F., Yang, Q., Bu, X., Lu, X., Sun, L., Zhang, H.: Carbon fiber aerogel made from raw cotton: a novel, efficient and recyclable sorbent for oils and organic solvents. Adv. Mater. 25, 5916–5921 (2013). https://doi.org/10.1002/adma.201302435

Sam, E.K., Sam, D.K., Lv, X., Liu, B., Xiao, X., Gong, S., Yu, W., Chen, J., Liu, J.: Recent development in the fabrication of self-healing superhydrophobic surfaces. Chem. Eng. J. 373, 531–546 (2019). https://doi.org/10.1016/j.cej.2019.05.077

Bhatnagar, A., Sillanpää, M.: Removal of natural organic matter (NOM) and its constituents from water by adsorption—a review. Chemosphere 166, 497–510 (2017). https://doi.org/10.1016/j.chemosphere.2016.09.098

Sabir, S.: Approach of cost-effective adsorbents for oil removal from oily water. Crit. Rev. Environ. Sci. Technol. 45, 1916–1945 (2015). https://doi.org/10.1080/10643389.2014.1001143

Bi, H., Xie, X., Yin, K., Zhou, Y., Wan, S., He, L., Xu, F., Banhart, F., Sun, L., Ruoff, R.S.: Spongy graphene as a highly efficient and recyclable sorbent for oils and organic Solvents. Adv. Funct. Mater. 22, 4421–4425 (2012). https://doi.org/10.1002/adfm.201200888

Sakthivel, T., Reid, D.L., Goldstein, I., Hench, L., Seal, S.: Hydrophobic high surface area zeolites derived from fly ash for oil spill remediation. Environ. Sci. Technol. 47, 5843–5850 (2013). https://doi.org/10.1021/es3048174

Wang, C.F., Tzeng, F.S., Chen, H.G., Chang, C.J.: Ultraviolet durable superhydrophobic Zinc oxide-coated mesh films for surface and underwater-oil capture and transportation. Langmuir 28, 10015–10019 (2012). https://doi.org/10.1021/la301839a

Carmody, O., Frost, R., Xi, Y., Kokot, S.: Adsorption of hydrocarbons on organo-clays implications for oil spill remediation. J. Colloid Interface Sci. 305, 17–24 (2007). https://doi.org/10.1016/j.jcis.2006.09.032

Lin, J., Shang, Y., Ding, B., Yang, J., Yu, J., Al-Deyab, S.S.: Nanoporous polystyrene fibers for oil spill cleanup. Mar. Pollut. Bull. 64, 347–352 (2012). https://doi.org/10.1016/j.marpolbul.2011.11.002

Doshi, B., Sillanpää, M., Kalliola, S.: A review of bio-based materials for oil spill treatment. Water Res. 135, 262–277 (2018). https://doi.org/10.1016/j.watres.2018.02.034

Chai, W., Liu, X., Zou, J., Zhang, X., Li, B., Yin, T.: Pomelo peel modified with acetic anhydride and styrene as new sorbents for removal of oil pollution. Carbohydr. Polym. 132, 245–251 (2015). https://doi.org/10.1016/j.carbpol.2015.06.060

Wu, C., Huang, X.Y., Wu, X.F., Qian, R., Jiang, P.K.: Mechanically flexible and multifunctional polymer-based graphene foams for elastic conductors and oil/water separators. Adv. Mater. 25, 5658–5662 (2013). https://doi.org/10.1002/adma.201302406

Sun, H.Y., Xu, Z., Gao, C.: Multifunctional, ultra-flyweight, synergistically assembled carbon aerogels. Adv. Mater. 25, 2554–2560 (2013). https://doi.org/10.1002/adma.201204576

Kang, W.W., Cui, Y., Qin, L., Yang, Y.Z., Zhao, Z.B., Wang, X.Z., Liu, X.G.: A novel robust adsorbent for efficient oil/water separation: magnetic carbon nanospheres/graphene composite aerogel. J. Hazard. Mater. 392, 122499 (2020). https://doi.org/10.1016/j.jhazmat.2020.122499

Zhu, Q., Chu, Y., Wang, Z.K., Chen, N., Lin, L., Liu, F.T., Pan, Q.M.: Robust superhydrophobic polyurethane sponge as a highly reusable oil-absorption material. J. Mater. Chem. A 1, 5386–5393 (2013). https://doi.org/10.1039/C3TA00125C

Ge, D.D., Zhang, Y., Cui, Z.S., Wang, G.L., Liu, J., Lv, X.M.: Constructing robust and magnetic PU sponges modified with Fe3O4/GO nanohybrids for efficient oil/water separation. J. Coat. Technol. Res. (2022). https://doi.org/10.1007/s11998-022-00699-7

Zhang, L., Wu, J.J., Wang, Y.X., Long, Y.H., Zhao, N., Xu, J.: Combination of bioinspiration: a general route to superhydrophobic particles. J. Am. Chem. Soc. 134, 9879–9881 (2012). https://doi.org/10.1021/ja303037j

Zhou, X.Y., Zhang, Z.Z., Xu, X.H., Guo, F., Zhu, X.T., Men, X.H., Ge, B.: Robust and durable superhydrophobic cotton fabrics for oil/water separation. ACS Appl. Mater. Interfaces 5, 7208–7214 (2013). https://doi.org/10.1021/am4015346

Tang, X.M., Si, Y., Ge, J.L., Ding, B., Liu, L.F., Zheng, G., Luo, W.J., Yu, J.Y.: In-situ polymerized superhydrophobic and superoleophilic nanofibrous membranes for gravity driven oil/water separation. Nanoscale 5, 11657–11664 (2013). https://doi.org/10.1039/C3NR03937D

Zhang, J.P., Seeger, S.: Polyester materials with superwetting silicone nanofilaments for oil/water separation and selective oil absorption. Adv. Funct. Mater. 21, 4699–4704 (2011). https://doi.org/10.1002/adfm.201101090

Wang, Z.J., Wang, Y., Liu, G.J.: Rapid and efficient separation of oil from oil-in-water emulsions using a janus cotton fabric. Angew. Chem. Int. Ed. 55, 1291–1294 (2016). https://doi.org/10.1002/ange.201507451

Wang, Y.F., Lai, C.L., Wang, X.W., Liu, Y., Hu, H.W., Guo, Y.J., Ma, K.K., Fei, B., Xin, J.H.: Beads-on-string structured nanofibers for smart and reversible oil/water separation with outstanding antifouling property. ACS Appl. Mater. Interfaces 8, 25612–25620 (2016). https://doi.org/10.1021/acsami.6b08747

Niu, Z.Q., Liu, L., Zhang, L., Chen, X.: Porous graphene materials for water remediation. Small 10, 3434–3441 (2014). https://doi.org/10.1002/smll.201400128

Sankaranarayanan, S., Lakshmi, D.S., Vivekanandhan, S., Ngamcharussrivichai, C.: Biocarbons as emerging and sustainable hydrophobic/oleophilic sorbent materials for oil/water separation, Sustainable. Mater. Technol. 28, 2214–9937 (2021). https://doi.org/10.1016/j.susmat.2021.e00268

Yang, W.J., Yuen, A.C.Y., Li, A., Lin, B., Chen, T.B.Y., Yang, W., Lu, H.D., Yeoh, G.H.: Recent progress in bio-based aerogel absorbents for oil/water separation. Cellulose 26, 6449–6476 (2019). https://doi.org/10.1007/s10570-019-02559-x

Spiridon, I., Darie-Nit, R.N., Hitruc, G.E., Ludwiczak, J., Spiridon, I.A.C., Niculaua, M.: New opportunities to valorize biomass wastes into green materials. J. Cleaner Prod. 133, 235–242 (2016). https://doi.org/10.1016/j.jclepro.2016.05.143

Tao, Y.S., Kanoh, H., Abrams, L., Kaneko, K.: Mesopore modified zeolites: preparation, characterization, and applications. Chem. Rev. 106, 896–910 (2006). https://doi.org/10.1021/cr040204o

Tan, I.A.W., Hameed, B.H., Ahmad, A.L.: Equilibrium, kinetic studies on basic dye adsorption by oil palm fibre activated carbon. Chem. Eng. J. 127, 111–119 (2007). https://doi.org/10.1021/cr040204o

Mahari, W.A.W., Waiho, K., Azwar, E., Fazhan, H., Peng, W.X.: A state-of-the-art review on producing engineered biochar from shellfish waste and its application in aquaculture wastewater treatment. Chemosphere 288, 132559 (2021). https://doi.org/10.1016/j.chemosphere.2021.132559

Guleria, A., Kumari, G., Lima, E.C., Ashish, D.K., Thakur, V., Singh, K.: Removal of inorganic toxic contaminants from wastewater using sustainable biomass: a review. Sci. Total Environ. 823, 153689 (2022). https://doi.org/10.1016/j.scitotenv.2022.153689

Sam, E.K., Liu, J., Lv, X.M.: Surface Engineering materials of superhydrophobic sponges for oil/water separation: a review. Ind. Eng. Chem. Res. 60, 2353–2364 (2021). https://doi.org/10.1021/acs.iecr.0c05906

Yang, J., Xu, P., Xia, Y.F., Chen, B.B.: Multifunctional carbon aerogels from typha orientalis for oil/water separation and simultaneous removal of oil-soluble pollutants. Cellulose 25, 5863–5875 (2018). https://doi.org/10.1007/s10570-018-1994-x

Foong, S.Y., Chan, Y.H., Chin, B.L.F., Lock, S.S.M., Yee, C.Y.: Production of biochar from rice straw and its application for wastewater remediation—an overview. Bioresour. Technol. 360, 127588 (2022). https://doi.org/10.1016/j.biortech.2022.127588

Xiang, W., Zhang, X., Chen, J., Zou, W., He, F., Hu, X., Tsang, D.C.W., Ok, Y.S., Gao, B.: Biochar technology in wastewater treatment: a critical review. Chemosphere 252, 126539 (2020). https://doi.org/10.1016/j.chemosphere.2020.126539

Foong, S.Y., Chan, Y.H., Lock, S.S.M., Chin, B.L.F.: Microwave processing of oil palm wastes for bioenergy production and circular economy: recent advancements, challenges, and future prospects. Bioresour. Technol. 369, 128478 (2023). https://doi.org/10.1016/j.biortech.2022.128478

Nguyen, H.N., Pignatello, J.J.: Laboratory tests of biochars as absorbents for use in recovery or containment of marine crude oil spills. Environ. Eng. Sci. 30, 374–380 (2013). https://doi.org/10.1089/ees.2012.0411

Sohaimi, K.S.A., Ngadi, N., Mat, H., Inuwa, I.M., Wong, S.: Synthesis, characterization and application of textile sludge biochars for oil removal. J. Environ. Chem. Eng. 5, 1415–1422 (2017). https://doi.org/10.1016/j.jece.2017.02.002

Alameri, K., Giwa, A., Yousef, L., Alraeesi, A., Taher, H.: Sorption and removal of crude oil spills from seawater using peat-derived biochar: an optimization study. J. Environ. Manag. 250, 109465 (2019). https://doi.org/10.1016/j.jenvman.2019.109465

Gheriany, I.A.E., El Saqa, F.A., Amer, A.A., El, R., Hussein, M.: Oil spill sorption capacity of raw and thermally modified orange peel waste. Alexandr. Eng. J. 59, 925–932 (2020). https://doi.org/10.1016/j.aej.2020.03.024

Devi, N.S., Hariram, M., Vivekanandhan, S.: Modification techniques to improve the capacitive performance of biocarbon materials. J. Energy Storage 33, 101870 (2021). https://doi.org/10.1016/j.est.2020.101870

Guo, S., Peng, J., Li, W., Yang, K., Zhang, L., Zhang, S., Xia, H.: Effects of CO2 activation on porous structures of coconut shell-based activated carbons. Appl. Surf. Sci. 255, 8443–8449 (2009). https://doi.org/10.1016/j.apsusc.2009.05.150

Rajapaksha, A.U., Vithanage, M., Ahmad, M., Seo, D.C., Cho, J.S., Lee, S.E., Lee, S.S., Ok, Y.S.: Enhanced sulfamethazine removal by steam-activated invasive plant-derived biochar. J. Hazard. Mater. 290, 43–50 (2015). https://doi.org/10.1016/j.jhazmat.2015.02.046

Rajak, V.K., Kumar, S., Thombre, N.V., Mandal, A.: Synthesis of activated charcoal from saw-dust and characterization for adsorptive separation of oil from oil-in-water emulsion. Chem. Eng. Commun. 205, 897–913 (2018). https://doi.org/10.1080/00986445.2017.1423288

Gao, S., Li, X., Li, L., Wei, X.: A versatile biomass derived carbon material for oxygen reduction reaction, supercapacitors and oil/water separation. Nano Energy 33, 334–342 (2017). https://doi.org/10.1016/j.nanoen.2017.01.045

Yang, I., Jung, M., Kim, M.S., Choi, D., Jung, J.C.: Physical and chemical activation mechanisms of carbon materials based on the microdomain model. J. Mater. Chem. A 9, 9815–9825 (2021). https://doi.org/10.1039/d1ta00765c

Canales-Flores, R.A., Prieto-García, F.: Activation methods of carbonaceous materials obtained from agricultural waste. Chem. Biodivers. 13, 261–268 (2016). https://doi.org/10.1002/cbdv.201500039

MohamadNor, N., Lau, L.C., Lee, K.T., Mohamed, A.R.: Synthesis of activated carbon from lignocellulosic biomass and its applications in air pollution control—a review. J. Environ. Chem. Eng. 1, 658 (2013). https://doi.org/10.1016/j.jece.2013.09.017

Gwenzi, W., Chaukura, N., Noubactep, C., Mukome, F.N.D.: Biochar-based water treatment systems as a potential low-cost and sustainable technology for clean water provision. J. Environ. Manag. 197, 732–749 (2017). https://doi.org/10.1016/j.jenvman.2017.03.087

Sam, D.K., Sam, E.K., Durairaj, A., Lv, X.M., Zhou, Z.J., Liu, J.: Synthesis of biomass-based carbon aerogels in energy and sustainability. Carbohydr. Res. 491, 107986 (2020). https://doi.org/10.1016/j.carres.2020.107986

A. C. Pierre, A. Rigacci, Adv. Sol–Gel Deriv. Materials Technol, in: Aerogels Handbook, 2011, pp. 21–46, https://doi.org/10.1007/978-1-4419-7589-8_2

Joshi, P., Sharma, O.P., Ganguly, S.K., Srivastava, M., Khatri, O.P.: Fruit waste-derived cellulose and graphene-based aerogels: plausible adsorption pathways for fast and efficient removal of organic dyes. J. Colloid Interface Sci. 608, 2870–2883 (2022). https://doi.org/10.1016/j.jcis.2021.11.016

Wang, S., Peng, X., Zhong, L., Tan, J., Jing, S., Cao, X., Chen, W., Liu, C., Sun, R.: An ultralight, elastic, cost-effective, and highly recyclable superabsorbent from microfibrillated cellulose fibers for oil spillage cleanup. J. Mater. Chem. A 3, 8772–8781 (2015). https://doi.org/10.1039/C4TA07057G

Li, Y.Q., Samad, Y.A., Polychronopoulou, K., Alhassan, S.M., Liao, K.: Carbon aerogel from winter melon for highly efficient and recyclable oils and organic solvents absorption. ACS Sustain. Chem. Eng. 2, 1492–1497 (2014). https://doi.org/10.1021/sc500161b

Wang, Y., Zhu, L., Zhu, F., You, L., Shen, X., Li, S.: Removal of organic solvents/oils using carbon aerogels derived from waste durian shell. J. Taiwan Inst. Chem. Eng. 78, 351–358 (2017). https://doi.org/10.1016/j.jtice.2017.06.037

Yuan, W., Zhang, X., Zhao, J., Li, Q., Ao, C., Xia, T., Zhang, W., Lu, C.: Ultra-lightweight and highly porous carbon aerogels from bamboo pulp fibers as an effective sorbent for water treatment. Results Phys. 7, 2919–2924 (2017). https://doi.org/10.1016/j.rinp.2017.08.011

Liu, Y., Zhang, K., Yao, W.G., Zhang, C.C., Han, Z.W., Ren, L.Q.: A facile electrodeposition process for the fabrication of superhydrophobic and superoleophilic copper mesh for efficient oil/water separation. Ind. Eng. Chem. Res. 55, 2704–2712 (2016). https://doi.org/10.1021/acs.iecr.5b03503

Sun, F., Liu, W., Dong, Z., Deng, Y.: Underwater superoleophobicity cellulose nanofibril aerogel through regioselective sulfonation for oil/water separation. Chem. Eng. J. 15, 774–782 (2017). https://doi.org/10.1016/j.cej.2017.07.142

Zhang, H., Li, Y.Q., Shi, R.H., Chen, L.H., Fan, M.Z.: A robust salt-tolerant superoleophobic chitosan/nanofibrillated cellulose aerogel for highly efficient oil/water separation. Carbohydr. Polym. 200, 611–615 (2018). https://doi.org/10.1016/j.carbpol.2018.07.071

Meng, G., Peng, H., Wu, J., Wang, Y., Wang, H.: Fabrication of superhydrophobic cellulose/chitosan composite aerogel for oil/water separation. Fibers Polym. 18, 706–712 (2017). https://doi.org/10.1007/s12221-017-1099-4

Li, Y.Z., Zhu, L.Q., Grishkewich, N., Tam, K.C., Yuan, J.Y., Mao, Z.P., Sui, X.F.: CO2-responsive cellulose nanofibers aerogels for switchable oil−water separation. ACS Appl. Mater. Interfaces 11, 9367–9373 (2019). https://doi.org/10.1021/acsami.8b22159

Zhao, L., Li, L., Wang, Y., Wu, J., Meng, G., Liu, Z., Guo, X.: Preparation and characterization of thermo- and pH dual-responsive 3D cellulose-based aerogel for oil/water separation. Appl. Phys. A Mater. Sci. Process. 124, 1–9 (2018). https://doi.org/10.1007/s00339-017-1358-7

Li, Z.X., Lei, S.J., Xi, J.C., Ye, D.L., Hu, W.Z., Song, L., Hu, Y., Cai, W., Gui, Z.: Bio-based multifunctional carbon aerogels from sugarcane residue for organic solvents adsorption and solar-thermal-driven oil removal. Chem. Eng. J. 426, 129580 (2021). https://doi.org/10.1016/j.cej.2021.129580

Wang, G., He, Y., Wang, H., Zhang, L., Yu, Q.Y., Peng, S.S., Wu, X.D., Ren, T.H., Zeng, Z.X., Xue, Q.J.: Robust superhydrophilicity and under-water superoleophobicity cellulose sponge for highly effective oil/water separation. Green Chem. 17, 3093–3099 (2015). https://doi.org/10.1039/C5GC00025D

Chen, J., Zhang, Y., Chen, C., Xu, M., Wang, G., Zeng, Z., Wang, L., Xue, Q.: Cellulose sponge with superhydrophilicity and high oleophobicity both in air and under water for efficient oil/water emulsion separation. Macromol. Mater. Eng. 302, 1700086 (2017). https://doi.org/10.1002/mame.201700086

Meng, X., Dong, Y.Y., Zhao, Y.J., Liang, L.P.: Preparation and modification of cellulose sponge and application of oil/water separation. RSC Adv. 10, 41713 (2020). https://doi.org/10.1039/D0RA07910C

Qin, Y., Li, S., Li, Y., Pan, F., Han, L., Chen, Z., Yin, X., Wang, L., Wang, H.: Mechanically robust polybenzoxazine/reduced graphene oxide wrapped-cellulose sponge towards highly efficient oil/water separation, and solar-driven for cleaning up crude oil. Compos. Sci. Technol. 197, 54 (2020). https://doi.org/10.1016/j.compscitech.2020.108254

Wei, M., Gao, Y., Li, X., Serpe, M.J.: Stimuli-responsive polymers and their applications. Polym. Chem. 8, 127–143 (2017). https://doi.org/10.1039/C6PY01585A

Li, L., Rong, L., Xu, Z., Wang, B., Feng, X., Mao, Z., Xu, H., Yuan, J., Liu, S., Sui, X.: Cellulosic sponges with pH responsive wettability for efficient oil/water separation. Carbohydr. Polym. 237, 116133 (2020). https://doi.org/10.1016/j.carbpol.2020.116133

Periyasamy, T., Asrafali, S.P., Haldhar, R., Madhappan, S., Vanaraj, R., Raorane, C.J., Kim, S.C.: Modified cotton sponge with bio-based polybenzoxazine for plasticizer absorption and oil–water separation. ACS Appl. Polym. Mater. 4, 950–959 (2022). https://doi.org/10.1021/acsapm.1c01408

Yi, L.F., Yang, J.Y., Fang, X., Xia, Y., Zhao, L.J., Wu, H., Guo, S.Y.: Facile fabrication of wood-inspired aerogel from chitosan for efficient removal of oil from water. J. Hazard. Mater. 385, 121507 (2020). https://doi.org/10.1016/j.jhazmat.2019.121507

Yin, Z.C., Sun, X.J., Bao, M.M., Li, Y.: Construction of a hydrophobic magnetic aerogel based on chitosan for oil/water separation applications. Int. J. Biol. Macromol. 165, 1869–1880 (2020). https://doi.org/10.1016/j.ijbiomac.2020.10.068

Su, C., Yang, H., Zhao, H., Liu, Y., Chen, R.: Recyclable and biodegradable superhydrophobic and superoleophilic chitosan sponge for the effective removal of oily pollutants from water. Chem. Eng. J. 330, 423–432 (2017). https://doi.org/10.1016/j.cej.2017.07.157

Li, Z.Y., Shao, L., Hu, W.B., Zheng, T.T., Lu, L.B., Cao, Y., Chen, Y.J.: Excellent reusable chitosan/cellulose aerogel as an oil and organic solvent absorbent. Carbohydr. Polym. 191, 183–190 (2018). https://doi.org/10.1016/j.carbpol.2018.03.027

Wang, C., He, G., Cao, J., Fan, L., Cai, W., Yin, Y.: Underwater superoleophobic and salt tolerant sodium alginate/N-Succinyl chitosan composite aerogel for highly efficient oil–water separation. ACS Appl. Polym. Mater. 2, 1124–1133 (2020). https://doi.org/10.1021/acsapm.9b00908

Liang, F.Y., Hou, T.T., Li, S.D., Liao, L.S., Li, P.W., Li, C.P.: Elastic, super-hydrophobic and biodegradable chitosan sponges fabricated for oil/water separation. J. Environ. Chem. Eng. 9, 106027 (2021). https://doi.org/10.1016/j.jece.2021.106027

Yu, M.D., Mishra, D., Cui, Z.Y., Wang, X., Lu, Q.Y.: Recycling papermill waste lignin into recyclable and flowerlike composites for effective oil/water separation. Compos. Part B 216, 108884 (2021). https://doi.org/10.1016/j.compositesb.2021.108884

Oribayo, O., Feng, X.S., Rempel, G.L., Pan, Q.M.: Synthesis of lignin-based polyurethane/graphene oxide foam and its application as an absorbent for oil spill clean-ups and recovery. Chem. Eng. J. 323, 191–202 (2017). https://doi.org/10.1016/j.cej.2017.04.054

Bertella, S., Luterbacher, J.S.: Lignin functionalization for the production of novel materials. Trends Chem. 5, 440–453 (2020). https://doi.org/10.1016/j.trechm.2020.03.001

Zhang, N., Li, Z., Xiao, Y., Pan, Z., Jia, P., Feng, G., Bao, C., Zhou, Y., Hua, L.: Lignin-based phenolic resin modified with whisker silicon and its application. J. Bioresour. Bioprod. 5, 67–77 (2020). https://doi.org/10.1016/j.jobab.2020.03.008

Xia, Z., Li, J., Zhang, J., Zhang, X., Zhang, J.: Processing and valorization of cellulose, lignin and lignocellulose using ionic liquids. J. Bioresour. Bioprod. 5, 79–95 (2020). https://doi.org/10.1016/j.jobab.2020.04.001

Zhou, W., Chen, F., Zhang, H., Wang, J.: Preparation of a polyhydric aminated lignin and its use in the preparation of polyurethane film. J. Wood Chem. Technol. 37, 323–333 (2017). https://doi.org/10.1080/02773813.2017.1299185

Chen, S., Shen, S., Yan, X., Mi, J., Wang, G., Zhang, J., Zhou, Y.: Synthesis of surfactants from alkali lignin for enhanced oil recovery. J. Dispersion Sci. Technol. 37, 1574–1580 (2015). https://doi.org/10.1080/01932691.2015.1118703

Chio, C.L., Sain, M., Qin, W.S.: Lignin utilization: a review of lignin depolymerization from various aspects. Renew. Sustain. Energy Rev. 107, 232–249 (2019). https://doi.org/10.1016/j.rser.2019.03.008

Kazzaz, A.E., Feizia, Z.H., Fatehi, P.: Grafting strategies for hydroxy groups of lignin for producing materials. Green Chem. 21, 5714–5752 (2019). https://doi.org/10.1039/C9GC02598G

Huang, D., Li, R., Xu, P., Li, T., Deng, R., Chen, S., Zhang, Q.: The cornerstone of realizing lignin value-addition: Exploiting the native structure and properties of lignin by extraction methods. Chem. Eng. J. 402, 126237 (2020). https://doi.org/10.1016/j.cej.2020.126237

Chen, C.Z., Li, F.F., Zhang, Y.R., Wang, B.X., Fan, Y.M., Wang, X.L., Sun, R.K.: Compressive, ultralight and fire-resistant lignin-modified graphene aerogels as recyclable absorbents for oil and organic solvents. Chem. Eng. J. 350, 173–180 (2018). https://doi.org/10.1016/j.cej.2018.05.189

Meng, Y., Liu, T., Yu, S., Cheng, Y., Lu, J., Wang, H.: A lignin-based carbon aerogel enhanced by graphene oxide and application in oil/water separation. Fuel 15, 118376 (2020). https://doi.org/10.1016/j.fuel.2020.118376

Sun, H.D., Liu, Z.M., Liu, K.Y., Gibril, M.E., Kong, F.G., Wang, S.J.: Lignin-based superhydrophobic melamine resin sponges and their application in oil/water separation. Ind. Crops Prod. 170, 113798 (2021). https://doi.org/10.1016/j.indcrop.2021.113798

Yue, Y.Y., Wang, Y., Li, J.Y., Cheng, W.L., Han, G.P., Lu, T., Huang, C.B., Wu, Q.L., Jiang, J.C.: High strength and ultralight lignin-mediated fire-resistant aerogel for repeated oil/water separation. Carbon 193, 285–297 (2022). https://doi.org/10.1016/j.carbon.2022.03.015

Vannarath, A., Thalla, A.K.: Synthesis and characterisation of an ultra-light, hydrophobic and flame-retardant robust lignin-carbon foam for oil/water separation. J. Cleaner Prod. 325, 129263 (2021). https://doi.org/10.1016/j.jclepro.2021.129263

Zhang, S.G., Yang, M.C., Meng, S.Y., Yang, Y.C., Li, Y.C., Tong, Z.H.: Biowaste-derived, nanohybrid-reinforced double-function slow-release fertilizer with metal-adsorptive function. Chem. Eng. J. 450, 138084 (2022). https://doi.org/10.1016/j.cej.2022.138084

Matveeva, V.G., Bronstein, L.M.: From renewable biomass to nanomaterials: does biomass origin matter? Prog. Mater. Sci. 130, 100999 (2022). https://doi.org/10.1016/j.pmatsci.2022.100999

Li, L., Li, B., Zhang, J.: Dopamine-mediated fabrication of ultralight graphene aerogels with low volume shrinkage. J. Mater. Chem. A 4, 512–518 (2016). https://doi.org/10.1039/C5TA08829A

Liu, Y., Peng, Y., Zhang, T., Qiu, F., Yuan, D.: Superhydrophobic, ultralight and flexible biomass carbon aerogels derived from sisal fibers for highly efficient oil/water separation. Cellulose 25, 3067–3078 (2018). https://doi.org/10.1007/s10570-018-1774-7

Lv, Y., Gan, L., Liu, M., Xiong, W., Xu, Z., Zhu, D.: A self-template synthesis of hierarchical porous carbon foams based on banana peel for supercapacitor electrodes. J. Power Sources 209, 152–157 (2012). https://doi.org/10.1016/j.jpowsour.2012.02.089

Ma, Q., Yu, Y., Sindoro, M., Fane, A.G., Wang, R., Zhang, H.: Carbon-based functional materials derived from waste for water remediation and energy storage. Adv. Mater. 29, 1605361 (2017). https://doi.org/10.1002/adma.201605361

Nguyen, S.T., Feng, J., Le, N.T., Le, A.T.T., Hoang, N., Tan, V.B.C., Duong, H.M.: Cellulose aerogel from paper waste for crude oil spill cleaning. Ind. Eng. Chem. Res. 52, 18386–18391 (2013). https://doi.org/10.1021/ie4032567

Akhlamadi, G., Goharshadi, E.K.: Sustainable and superhydrophobic cellulose nanocrystal-based aerogel derived from waste tissue paper as a sorbent for efficient oil/water separation. Process Saf. Environ. Prot. 154, 155–167 (2021). https://doi.org/10.1016/j.psep.2021.08.009

Li, L., Li, B., Sun, H., Zhang, J.: Compressible and conductive carbon aerogels from waste paper with exceptional performance for oil/water separation. J. Mater. Chem. A 5, 14858–14864 (2017). https://doi.org/10.1039/C7TA03511J

Bi, H.C., Huang, X., Wu, X., Cao, X.H., Tan, C.L., Yin, Z.Y., Lu, X.H., Sun, L.T., Zhang, H.: Carbon microbelt aerogel prepared by waste paper: an efficient and recyclable sorbent for oils and organic solvents. Small 10, 3544–3550 (2014). https://doi.org/10.1002/smll.201303413

Han, S.J., Sun, Q.F., Zheng, H.H., Li, J.P., Jin, C.D.: Green and facile fabrication of carbon aerogels from cellulose-based waste newspaper for solving organic pollution. Carbohydr. Polym. 136, 95–100 (2016). https://doi.org/10.1016/j.carbpol.2015.09.02

Li, N., Yue, Q.Y., Gao, B.Y., Xu, X., Su, R.D., Yu, B.J.: One-step synthesis of peanut hull/graphene aerogel for highly efficient oil/water separation. J. Cleaner Prod. 207, 764–771 (2019). https://doi.org/10.1016/j.jclepro.2018.10.038

Jing, F., Ding, J.C., Zhang, T., Yang, D.Y., Qiu, F.X., Chen, Q.Y., Xu, J.C.: Flexible, versatility and superhydrophobic biomass carbon aerogels derived from corn bracts for efficient oil/water separation. Food Bioprod. Process. 115, 134–142 (2019). https://doi.org/10.1016/j.fbp.2019.03.010

Huang, J.W., Li, D.D., Huang, L.H., Tan, S.A., Liu, T.: Bio-based aerogel based on bamboo, waste paper, and reduced graphene oxide for oil/water separation. Langmuir 38, 3064–3075 (2022). https://doi.org/10.1021/acs.langmuir.1c02821

Baig, N., Alghunaimi, F.I., Saleh, T.A.: Hydrophobic and oleophilic carbon nanofiber impregnated styrofoam for oil and water separation: a green technology. Chem. Eng. J. 360, 1613–1622 (2019). https://doi.org/10.1016/j.cej.2018.10.042

Zhang, Z.T., Dai, G.C., Liu, Y., Fan, W.W., Yang, K.F., Li, Z.J.: A reusable, biomass-derived, and pH-responsive collagen fiber-based oil absorbent material for effective separation of oil-in-water emulsions. Colloids Surf. A 633, 127906 (2022). https://doi.org/10.1016/j.colsurfa.2021.127906

Zhai, Z.Z., Zheng, Y.X., Du, T.M., Tian, Z.S., Ren, B., Xu, Y.L., Wang, S.S., Zhang, L.H., Liu, Z.F.: Green and sustainable carbon aerogels from starch for supercapacitors and oil/water separation. Ceram. Int. 47, 22080–22087 (2021). https://doi.org/10.1016/j.ceramint.2021.04.229

Kuang, Y.D., Chen, C.J., Chen, G., Pei, Y., Pastel, G., Jia, C., Song, J.W., Mi, R.Y., Yang, B., Das, S., Hu, L.B.: Bioinspired solar-heated carbon absorbent for efficient cleanup of highly viscous crude oil. Adv. Funct. Mater. 29, 1900162 (2019). https://doi.org/10.1002/adfm.201900162

Mahari, W.A.W., Waiho, K., Fazhan, H., Necibi, M.C.: Progress in valorisation of agriculture, aquaculture and shellfish biomass into biochemicals and biomaterials towards sustainable bioeconomy. Chemosphere 291, 133036 (2022). https://doi.org/10.1016/j.chemosphere.2021.133036

Yong, J.L., Huo, J.L., Chen, F., Yang, Q.: Oil/water separation based on the natural materials with super-wettability: recent advances. Phys. Chem. Chem. Phys. 20, 25140–25163 (2018). https://doi.org/10.1039/c8cp04009e

Wang, N., Deng, Z.W.: Synthesis of magnetic, durable and superhydrophobic carbon sponges for oil/water separation. Mater. Res. Bull. 115, 19–26 (2019). https://doi.org/10.1016/j.materresbull.2019.03.007

Nematian, M., Keske, C., Ng’ombe, J.N.: A techno-economic analysis of biochar production and the bioeconomy for orchard biomass. Waste Manag. 135, 467–477 (2021). https://doi.org/10.1016/j.wasman.2021.09.014

Harsono, S.S., Grundman, P., Lau, L.H., Hansen, A., Salleh, M.A.M.: Energy balances, greenhouse gas emissions and economics of biochar production from palm oil empty fruit bunches. Resour. Conserv. Recycl. 77, 108–115 (2013). https://doi.org/10.1016/j.resconrec.2013.04.005

Osman, A.I.: Mass spectrometry study of lignocellulosic biomass combustion and pyrolysis with NOx removal. Renew. Energy 146, 484–496 (2020). https://doi.org/10.1016/j.renene.2019.06.155

Zhang, H., Zhao, T., Chen, Y., Hu, X., Xu, Y.: A sustainable nanocellulose-based superabsorbent from kapok fiber with advanced oil absorption and recyclability. Carbohydr. Polym. 278, 118948 (2022). https://doi.org/10.1016/j.carbpol.2021.118948

Thinkohkaew, K., Rodthongkum, N., Ummartyotin, S.: Coconut husk (Cocos nucifera) cellulose reinforced poly vinyl alcohol-based hydrogel composite with control-release behavior of methylene blue. J. Mater. Res. Technol. 9, 6602–6611 (2020). https://doi.org/10.1016/j.jmrt.2020.04.051

Tian, F., Yang, Y., Wang, X.L., An, W.L., Zhao, X., Xu, S.M., Wang, Y.Z.: From waste epoxy resins to efficient oil/water separation materials via a microwave assisted pore-forming strategy. Mater. Horiz. 6, 1733–1739 (2019). https://doi.org/10.1039/C9MH00541B

Kazaka, O., Eker, Y.R., Bingol, H., Tora, A.: Novel preparation of activated carbon by cold oxygen plasma treatment combined with pyrolysis. Chem. Eng. J. 325, 564–575 (2017). https://doi.org/10.1016/j.cej.2017.05.107

Roy, P., Dias, G.: Prospects for pyrolysis technologies in the bioenergy sector: a review. Renewable Sustainable Energy Rev. 77, 59–69 (2017). https://doi.org/10.1016/j.rser.2017.03.136

Wang, T.T., Li, G.L., Yang, K.Q., Zhang, X.Y., Wang, K., Cai, J.J., Zheng, J.Y.: Enhanced ammonium removal on biochar from a new forestry waste by ultrasonic activation: characteristics, mechanisms and evaluation. Sci. Total Environ. 778, 146295 (2021). https://doi.org/10.1016/j.scitotenv.2021.146295

Xu, Y.H., Zhang, Z.D., Geng, X.F., Jin, J., Iqbal, M., Han, A., Ding, B., Liu, J.F.: Smart carbon foams with switchable wettability for fast oil recovery. Carbon 149, 242–247 (2019). https://doi.org/10.1016/j.carbon.2019.04.039

Acknowledgements

The research work is funded by the Zhenjiang Key Research and Development Program (GY2021004), the Opening Project of Henan Province Key Laboratory of Water Pollution Control and Rehabilitation Technology (CJSP202205), Innovation and Practice fund of Jiangsu University Industrial Center (ZXJG202208), Jiangsu Collaborative Innovation Center for Water Treatment Technology and Materials.

Funding

Zhenjiang Key Research and Development Program, GY2021004, Xiaomeng Lv, Opening Project of Henan Province Key Laboratory of Water Pollution Control and Rehabilitation Technology, CJSP202205, Jun Liu, Jiangsu Collaborative Innovation Center for Water Treatment Technology and Materials, Innovation and Practice fund of Jiangsu University Industrial Center, ZXJG202208, Yun Zhang.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

Authors have no competing interests to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Y., Sam, E.K., Liu, J. et al. Biomass-Based/Derived Value-Added Porous Absorbents for Oil/Water Separation. Waste Biomass Valor 14, 3147–3168 (2023). https://doi.org/10.1007/s12649-023-02112-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02112-9