Abstract

The production of metabolites in microalgae is influenced by extreme cultivation conditions. Bicarbonate is an inorganic carbon source for phototrophic microalgae culturing. In this study, the effect of dissolved inorganic carbon (DIC) (0.4–13 g L−1) on the accumulation of metabolites in Dunaliella tertiolecta biomass is presented. The highest levels of primary metabolites [lipid (239.6 ± 24.3 mg g−1), protein (336.2 ± 47.5 mg g−1)], secondary metabolites [total phenolic (12.8 ± 2.0 mg g−1), total flavonoid (14.4 ± 2.3 mg g−1), total ascorbate (4.7 ± 1.1 mg g−1)], and pigments [chlorophyll (27.2 ± 3.1 mg g−1), carotenoid (2.0 ± 0.1 mg g−1)] were observed when cells were grown with 5.7 g L−1 of DIC (NaHCO3). The highest biomass concentrations (1.5 ± 0.1 g L−1) were obtained for cells grown in a mixture of DIC (4.3 + 1.1 g L−1, NaHCO3 + Na2CO3). This study recommends the optimal levels of bicarbonate carbon of 5.7 g L−1 for maximising the generation of metabolites in the biomass. It also demonstrates that exogenous excessive DIC in the growth medium would be an effective stressor to produce high-value metabolites in Dunaliella or alkali-halophilic strains.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

Overall production of metabolites in Dunaliella tertiolecta CCAP 19/30 under high levels of NaHCO3 (alkalihalophilic medium) has not yet been reported. This study examines the effect of excess dissolved inorganic carbon on the growth of D. tertiolecta in order to maximize biomass yield and yields of the following metabolites: (a) primary metabolites (lipid and protein); (b) secondary metabolites (total phenolic content, ascorbate, and flavonoid); and (c) pigment (chlorophyll and carotenoid). Based on the range of input conditions, the recommended optimal conditions for maximum yield of biomass and metabolites have been provided.

Introduction

Microalgal biomass has become an attractive renewable and sustainable source to produce biofuels and high-value products due to its ability to grow in a wide range of water sources: fresh, brackish, saline, and wastewater (industrial, municipal, and agricultural effluents). By using solar energy (or artificial light), it provides faster volumetric biomass growth (several folds greater than that of our most productive crops) with a steady biomass supply the whole year under controlled conditions, while not competing for cultivable land with terrestrial agriculture [1]. Microalgae are living ‘micro-bio-factories’, producing a wide variety of metabolites: primary (lipid, carbohydrate, and protein); secondary (phenolic, flavonoids, ascorbate); and pigments (chlorophyll, carotenoids) [2]. Microalgae can accumulate 10–60% protein, 10–55% carbohydrate, 5–40% lipid, 0.5–4% phenolic, 0.1–0.5% flavonoids, 0.1–2% carotenoids, up to 1% vitamin C and vitamin E, and 5% minerals and oligo-elements [3,4,5]. Primary metabolites are mainly associated with biofuel production, food supplements and animal feed, whilst secondary metabolites are used as bioactive compounds in food, pharmaceutical, nutraceutical, and cosmeceutical industries [6, 7]. However, the productivity of biomass and intercellular metabolites of microalgae depends on the strain varieties, and the environmental and nutritional parameters in the culture medium or culturing systems.

In photoautotrophic microalgal growth, inorganic carbon (IC) (in addition to light energy and water) is one of the most fundamental culturing parameters, which is directly associated with the synthesis of cellular metabolites in microalgae [8]. IC can be supplied to the culture as CO2, either by pumping air, air with concentrated CO2, or as dissolved inorganic carbon (DIC), mainly in the form of bicarbonate (HCO3−) salts. DIC as a carbon source in the culturing of microalgae is more advantageous relative to CO2 due to its high solubility in water (NaHCO3 solubility = 100.3 g L−1 at 25 °C) [9], enhanced utilisation efficiency, lack of energy-intensive compression, and lower transportation costs enabling spatial separation between CO2 production and algae cultivation [10]. In addition, NaHCO3 can be used to separate carbon capture from algae growth—this enables better control of both processes while avoiding oxygen contamination (e.g. during biogas purification) [11].

Alkali halophilic microalgae strains have a high tolerance to DIC and can grow under high concentrations of bicarbonate in the culture medium. High concentrations of sodium bicarbonate not only enhanced metabolite content but have also been shown to have a bactericidal and bacteriostatic effect that may minimise or control microbial contamination in the algal culture [12, 13]. Recently, there is significant interest in integrated bicarbonate-based carbon capture and algae biomass production systems to both store carbon and produce metabolites [14] using halotolerant microalgae. These applications favour elevated bicarbonate concentrations (20 g L−1 and above) to increase the efficiency of the CO2 absorption step [11]. High concentration of sodium bicarbonate or supplemented bicarbonate in the culture medium alleviates oxygen stress by enhancing the ratio of dCO2 to dO2 (to balance photosynthesis and photorespiration) [15, 16]. In addition, excessive DIC can reduce stress by mitigating the production of reactive oxygen species (ROS) by improving the activities of antioxidant enzymes (SOD, CAT, and APX), helping to increase cell densities and the accumulation of metabolites. However, the solubility of bicarbonate and its up-taking ability by microalgae is highly influenced by the increase of culture pH during algae growth [17]. The pH of the culture medium can drift by > 1.5 when growing microalgae with sodium bicarbonate, whereas pH drifts only by ~ 0.5 when growing algae with the supply of CO2 [18]. The drifting of pH can be minimised using a higher concentration of sodium bicarbonate in the growth medium, as reported by Zhu et al. [19].

Generally, organic buffers such as Tris (Tris-(hydroxymethyl)-amino methane) are used in the culture medium to stabilise the pH as well as to increase the microalgal growth [20, 21]. It has been reported that microalgal growth mediums with low levels of bicarbonate use Tris-buffer to adjust and stabilise pH for growing Dunaliella tertiolecta below 0.84 g L−1 NaHCO3 [22] or Dunaliella salina below 2.1 g L−1 NaHCO3 [23]. However, the drifting of pH in D. salina cultures grown with 2.1 and 42 g L−1 of NaHCO3 (from 8.0 to 10.3 and 8.0 to 9.8, respectively), demonstrates the limitation of Tris-buffer to stabilise pH over time and higher NaHCO3 itself may have a strong buffer effect on pH [21]. Some studies have reported that Tris can inhibit photosynthesis in some species of phytoplankton and freshwater algae, while simultaneously stimulating bacterial growth [24]. Therefore, further work is required to assess the value of adding Tris-buffer to cultures grown in excess bicarbonate or in the presence of carbonate-buffer on microalgal growth and the accumulation of intercellular compounds. Eliminating Tris-base (£85 per kg, Fisher Scientific, UK) from microalgal growth medium could also help reduce cultivation costs.

The effect of DIC (sodium bicarbonate) on the accumulation of metabolites in several microalgae has been studied earlier, however, these studies were limited to either relatively low HCO3− concentrations or focusing on a specific metabolite content [8, 25]. For example, Xi et al. [21] studied the effect of NaHCO3 on D. salina growth and reported the production of biomass (0.89 g L−1) and β carotene (41 mg L−1) in cells when grown with 17 g L−1 of NaHCO3 [21]. The biomass content was found to be ~ 6 g L−1 in Synechococcus when cells were grown with 44 and 88 g L−1 of NaHCO3 [8]. A study by Peng et al. [12] reported the production of biomass content (1.04 g L−1) and lipid content (15%) in Neochloris oleoabundans, where cells were grown with 17 g L−1 of NaHCO3 [12]. Dunaliella tertiolecta CCAP 19/30 has been identified in the earlier study as alkali halotolerant microalgae which can be grown at concentrations up to 90 g L−1 of NaHCO3 with maximum cell growth at 40 g L−1 of NaHCO3 [11]. However, the overall production of metabolites in D. tertiolecta CCAP 19/30 under high levels of NaHCO3 (alkalihalophilic medium) has not yet been reported. In order to use D. tertiolecta biomass as a source of high-value compounds, it is necessary to study and understand the effect of DIC concentration (using either NaHCO3 alone or a carbonate mixture of NaHCO3 + Na2CO3 as a carbon source) on enhanced production of metabolites in the culture medium.

Therefore, the aim of this research is to evaluate the effect of excess DIC content on the accumulation of pigments, primary and secondary metabolites content, and to identify the optimal DIC content in growth medium for the maximum levels of metabolites in D. tertiolecta in batch cultures. This has been achieved by measuring chlorophyll, carotenoid, phenolic, ascorbate, flavonoid, protein, carbohydrate, and lipids contents in the produced biomass. Furthermore, the effect of DIC (40 g L−1) using different ratios of NaHCO3 and Na2CO3 in the culture medium (with or without) Tris-buffer was evaluated to justify the suitability of carbonate buffer as a carbon source on growth and production of metabolites content in biomass.

Materials and Methods

Materials and Algae Species

Dunaliella tertiolecta (CCAP 19/30) was purchased from the culture collection of Algae and Protozoa (CCAP, Scotland, UK). All reagents and compounds for the preparation of the culture medium were purchased from Fisher Scientific (UK).

Culturing Microalgae Strain

Dunaliella tertiolecta (CCAP 19/30) was cultured in Modified Johnson medium (J/I) containing NaCl (11.68 g L−1) as described in the earlier study of Roy et al. [11]. The total working volume of the cultures was 200 mL. To assess the DIC on the accumulation of metabolites, D. tertiolecta (CCAP 19/30) (1 × 105 cells mL−1) was inoculated with different concentrations of NaHCO3 solutions (2.5, 20, 40, 60, 80, and 90 g L−1) with the addition of Tris-buffer in orbital shaker incubator with continuous shaking (100 rpm) at (20 °C ± 2) under LED (light-emitting diode) light. The light was a mixture of cool and warm white, with irradiation of 12 Klux, and a light: dark cycle of 16:8 h. Different concentrations of NaHCO3 (2.5, 20, 40, 60, 80, and 90 g L−1) are denoted as TC2.5, TC20, TC40, TC60, TC80, TC90 respectively, where TC represents NaHCO3 with the addition of Tris-buffer. The effect of DIC (carbonate buffer) on growth and the accumulation of metabolites was assessed by culturing D. tertiolecta (CCAP 19/30) (1 × 105 cells mL−1) in mixtures of NaHCO3 and Na2CO3, both without Tris, 40 + 0 g L−1 (BC40C0) and 30 + 10 g L−1 (BC30C10), and 20 + 20 g L−1 (BC20C20), and with Tris, 30 + 10 g L−1 (TC30C10) and 20 + 20 g L−1 (TC20C20)), where TC and BC represent the NaHCO3 concentration, with, or without the addition of Tris, respectively, whereas C represents the concentration of Na2CO3. All experiments were carried out in biological triplicate (n = 3).

Growth Rate, Doubling Time, and Cell Density

Cultures (1 mL) were sampled every two days and used for counting the number of cells and measuring the optical density. Optical density was measured at 680 nm against the blank and cells number in the culture were counted using a haemocytometer. After transferring the cells to the Eppendorf tube, formalin solution (2%, 8 µL) was added. After placing the coverslip on the haemocytometer, cell suspension (0.01 mL) was added slowly so that it spread into each chamber and the total number of cells was calculated using Eq. 1. Specific growth rate (µ) and doubling time (Td) of all cultures were calculated according to the formulas previously described in the study of Roy et al. [11].

Carbonate and Bicarbonate Content in a Culture

Carbonate and bicarbonate content was determined in a mixture using the method previously described by Roy et al. [11]. Briefly, carbonate content was precipitated with 10% BaCl2 solution and the remaining NaOH solution in the mixture was titrated with HCl for phenolphthalein endpoint. Then, total carbonate and bicarbonate in a mixture were converted into carbonic acid by treatment with HCl. Therefore, the volume of HCl required for methyl orange indicator (pH 3.0–4.3) indicated the endpoint of a complete conversion of carbonate and bicarbonate to carbonic acid (pH about 4.5).

Total Chlorophyll and Carotenoid Content

Total chlorophyll and carotenoid content were measured using the method described in the earlier study [26]. In brief, fresh cells (1 mL culture) pellet was homogenised in acetone solution (85%v/v, 1 mL) using a vortex mixer. The absorbance of the extract was taken at 480, 647, and 663 nm against a blank of 85% acetone solution using a spectrophotometer (Jenway 6305, UK). Total chlorophyll and carotenoid content in the extract (µg mL−1) were calculated using the following formulas (Eqs. 2–5).

where Abs480 nm, Abs647 nm Abs664 nm are the absorbance of the acetone extract measured at 480, 647, 664 nm, respectively.

Total Phenolic Content

Fresh cells (10 mL culture) were harvested by centrifugation (1400×g, 4 °C, 15 min) and the extract was prepared using the method of Dey and Kuhad [27]. Briefly, the pellet was homogenised in an aqueous methanol solution (80% v/v) using a shaker (250 rpm, 40 °C, 60 min) with continuous shaking. After centrifugation (14,400×g, 4 °C, 20 min), the residue was re-extracted with the fresh solvent. The two extracts were pooled and used for the estimation of total phenolic content by Folin–Ciocalteau colorimetric method using gallic acid as standard [26]. Extract (0.2 mL) was mixed with Folin–Ciocalteau reagent (10% v/v, 0.4 mL) and incubated (3 min, room temperature). After adding Na2CO3 (10% w/v, 0.8 mL), the reaction mixture was incubated (1 h, room temperature in the dark). The absorbance was taken using a spectrophotometer (750 nm) against a blank containing aqueous methanol solution (70% w/w, 0.2 mL). The total phenolic compound in the crude extract was expressed as gallic acid equivalent (GAE).

Total flavonoid content

Fresh cells (10 mL culture) were harvested by centrifugation (1400×g, 4 °C, 15 min) and the extract was prepared using the method of Haoujar et al. [3]. Briefly, the pellet was homogenised in methanol solution (1.5 mL) using a vortex (30 s) with continuous stirring. The sample mixture was placed in a sonication bath (45 min). After centrifugation (7500×g, 4 °C, 10 min), the residue was re-extracted twice with the fresh solvent (methanol). The three extracts were pooled and used for the estimation of total flavonoid content. 0.1 mL of the sample was mixed with the methanol (0.3 mL). Potassium acetate (1 M, 0.02 mL), aluminum chloride (10%, 0.02 mL), and DI water (0.56 mL) were added to the sample solution mixture. After incubation (30 min) in the dark, the optical density of the solution was recorded against the blank (prepared by mixing all reagents without the sample) using a spectrophotometer (at 415 nm). The calibration curve was prepared using the quercetin standard in methanol, and the total flavonoid in the crude extract was expressed as quercetin equivalent.

Total Ascorbate Content

Fresh cells (10 mL culture) were harvested by centrifugation (1400×g, 4 °C, 15 min). The preparation of cell extract and assay was conducted as previously described in the study of Roy et al. [26]. In brief, the pellet was homogenised in TCA (0.5 mL, 10% w/v) using vortex (5 min) and the solution was incubated (10 min) on ice. The supernatant was separated by centrifugation (4000×g, 4 °C, 10 min) from the residue. Cell extract (0.1 mL) was transferred to a clean plastic cuvette (l = 1 cm) containing 0.9 mL dH2O. After adding Follin–Ciocalteu (FC) reagent (0.2 mL, 10% v/v), the reaction mixture was shaken vigorously (5 min, vortex, room temperature) and the absorbance was measured (760 nm) against a blank sample containing TCA (0.1 mL, 10%) instead of cells extract. A calibration curve of a standard solution of ascorbic acid (in dH2O) (5–50 µg) was used for quantifying ascorbate content.

Total Protein Content

Fresh cells (10 mL culture) were harvested by centrifugation (3000×g, 4 °C, 15 min) and the pellet was homogenised in NaOH (5 mL, 0.1 mM) using the method previously described by Roy et al. [26]. After incubation (continuous agitation, 250 rpm, 45 min, 40 °C) the supernatant was separated by centrifugation (14,400×g, 4 °C, 30 min) and collected as the first extract. A second extraction was carried out for the residue, and the second supernatant was mixed with the first extract and used for protein assay. The total protein content in the crude extract was determined by the method of Lowry assay using bovine serum albumin (BSA) as the protein standard.

Total Lipid Content

Fresh cells (10 mL culture) were harvested by centrifugation (1400×g, 4 °C, 15 min) and the pellet was homogenised in methanol (2.5 mL, 99%) by vortexing (5 min) using the method previously described by Matyash et al. [28]. After adding Methyl Tert Butyl Ether (MTBE) (7.5 mL), the mixture was sonicated (30 min) and incubated (60 min, room temperature). After adding dH2O (2 mL), the sample was kept at room temperature for phase separation (10 min). After centrifugation (1000×g, 10 min), the upper organic layer was collected into a glass vial, and the lower phase was re-extracted with the mixture of Methanol (1 mL) and MTBE (2.5 mL). The extraction procedure was repeated for the residue. Two extracts were combined and dried in a rotary evaporator and then the sample was kept in an oven overnight (50 °C). The weight of the dried lipid was determined by subtracting the weight of the empty glass vial from the total weight of the sample with a glass vial.

Total Carbohydrate Content

Fresh cells (10 mL culture) were harvested by centrifugation (1400×g, 4 °C, 15 min). Extracting crude extract and total carbohydrate content in the extract was determined using the method described in the earlier study by Jain et al. [29]. In brief, the pellet was homogenised in HCl (2.5 N, 10 mL) and boiled in a water bath (3 h). After cooling to room temperature, solid sodium carbonate was added to the extract until the ceasing the effervescence. After filtering, 0.5 mL of extract was added to 1 mL of phenol solution (5%) and 5 mL of sulfuric acid (96%). The solution was mixed by shaking and was incubated in a water bath (25–30 °C, 20 min). The optical density was measured at 490 nm against a blank (prepared by mixing all reagents without a sample). Calibration graphs were prepared using the glucose standard (0.05–0.25 mg).

Results and Discussion

Effect of DIC on Cellular Growth

Growth Curve

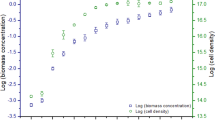

Dunaliella tertiolecta CCAP 19/30 cells were grown at 40 g L−1 of bicarbonate/carbonate (different ratio of NaHCO3 and Na2CO3) in modified Johnson medium (J/I) with the addition of Tris-buffer or without Tris-buffer. The growth curves demonstrate that cell densities of the cultures gradually increased over time, where the exponential growth phase of up to 6 days, is followed by a stationary growth phase (Fig. 1a). In addition, the results also demonstrate that high concentrations of DIC do not inhibit the growth of D. tertiolecta. This could be due to the high adaptability of Dunaliella species to elevated Na+ concentrations in high salinity, as observed in the study of Chi et al. [14]. Cell densities at the stationary phase were not significantly different except for cells grown under 20 + 20 g L−1 of NaHCO3 and Na2CO3 with Tris-buffer (TC20C20), where the lowest specific growth rate (0.7 ± 0.0 day−1), the highest doubling time (0.9 ± 0.0 days) at exponential phase, and the lowest cell density (1.1 × 107 cells mL−1) at stationary phase (11th day culture) were observed (Fig. 1a, c). The highest cell density (1.6 × 107 cells mL−1) was found in the final culture (11th day) for cells grown in a mixture of NaHCO3 and Na2CO3 (30 + 10 g L−1) (BC30C10), which was significantly higher relative to cells grown with 40 g L−1 of NaHCO3 without Na2CO3 and Tris-buffer (BC40C0) (Fig. 1a). The available DIC in BC40C0 is higher compared to that in BC30C10, which demonstrates that excess carbon above a certain level does not contribute to increased cell numbers, and that the higher cell density obtained in BC30C10 may be attributed to the activity of pH buffering (HCO31−/CO32−) at the beginning of culture [14]. The cell density of the presented study was comparable to the reported findings with D. tertiolecta (1.5 × 107 cells mL−1) [30]. However, cell density was lower compared to that observed in D. tertiolecta (6.5 × 107 cells mL−1) by the study of Liang et al. [31], which may be due to the difference in cultivation conditions and method.

Growth properties of D. tertiolecta cells cultured with a different ratios of NaHCO3 and Na2CO3 (carbonate buffer) with or without the addition of Tris-buffer; b different concentration of NaHCO3 (the data have been previously published in Roy et al. [11]); Growth rate, doubling time, and biomass content; c at different ratios of NaHCO3 and Na2CO3; d at different ratios of NaHCO3 (some of these data have been previously reported in the study Roy et al. [11])

The effect of NaHCO3 on D. tertiolecta was studied in the earlier study of Roy et al. [11] and no significant difference in cell density was observed between cultures grown in 20 to 80 g L−1 of NaHCO3 with Tris buffer (Fig. 1b). Although cell densities grown in BC40C0 (Fig. 1a) were higher compared to those grown in TC40 (1.0 × 107) (Fig. 1b), biomass content obtained in TC40 (Fig. 1d) was higher than in BC40C0 (1.3 g L−1), which could be attributed to the uses of higher concentration of NaCl (87 g L−1) in the culture medium (TC40). Relatively higher cell density in the final cultures grown without Tris (BC40C0) revealed that the addition of Tris-buffer at high DIC does not effectively improve the cell density or production of biomass.

Specific growth rate and doubling time were not significantly different between cells grown in BC40C0, BC30C10, BC20C20, and TC30C10, and the highest specific growth (1.0 ± 0.1 day−1) and lowest doubling time (0.7 days) were found in cells cultured in BC40C0 and TC30C10 (Fig. 1 ). Specific growth of cells grown in 20–80 g L−1 of NaHCO3 with Tris-buffer ranged from 1.1 to 1.3 day−1 (Fig. 1d), which was higher relative to that observed in mixtures of NaHCO3 and Na2CO3. Growth curves also indicate that Tris-buffer may help to accelerate the adaptability of cells during the lag phase to a higher concentration of NaHCO3. The specific growth rate of the presented report was consistent with previous studies with N. oleoabundans grown at 42 g L−1 NaHCO3 (1.2 ± 0.0 day−1) [19] and Synechococcus PCC 7002 grown at 44 g L−1 NaHCO3 (1.2 day−1) [8]. A study by Lakaniemi et al. [32] reported a growth rate of 1.4 day−1 for D. tertiolecta, which was not consistent with the presented study, and the discrepancies in growth rate could be due to the difference in cultivation technique (Flat-plate bioreactor).

Even though the specific growth rate was higher for BC40C0, biomass content in the final culture was higher in cells grown with the mixtures of carbonates (Fig. 1c). The higher biomass (1.5 g L−1) was obtained in cells cultured with a mixture of NaHCO3 and Na2CO3 (BC30C10 or BC20C20), which might be due to the increase in carbon utilising efficiency with the decrease in bicarbonate concentration as well as lower drifting of pH in the growth medium [19]. Compared to biomass content obtained in BC30C10, biomass was not significantly higher in TC20 (1.7 g L−1) (Fig. 1d). Moreover, higher NaCl (87 g L−1) was used in the growth medium, which may increase the biomass ash content during growth with TC20. The production of biomass in the present study was comparable to earlier studies with D. tertiolecta (1.2–1.3 g L−1) [31, 33] and N. oleoabundans (1.5 g L−1) [19, 34]. However, the biomass content of the presented study was lower compared to the study of Lakaniemi et al. [32], who reported 2.9 g L−1 of biomass in D. tertiolecta, which may be attributed to the use of a different bioreactor (flat-plate), and cultivation medium (dominated by Gammaproteobacteria, Flavobacteria, and Alphaproteobacteria). In addition, the presented findings also revealed that uses of a mixture of carbonate as DIC could enhance the cell numbers and production of biomass, which also demonstrates the suitability of using only partially converted carbonate from CO2 carbon capture, or the possibility to recycle partially converted bicarbonate solution for algae cultivation to increase process efficiency and minimise cultivation costs.

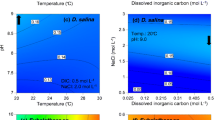

The Status of DIC in Growth Medium

Bicarbonate (DIC) content in the growth medium gradually decreased over time, with the simultaneous increase in carbonate (DIC) content during the cultivation of cells at different concentrations of NaHCO3 or carbonate buffer (mixtures of NaHCO3 and Na2CO3), as shown for a bicarbonate concentration of 40 g L− 1 (carbon content of 5.7 g L−1) in Fig. 2a. During cell growth, bicarbonate content decreased by 58% (bicarbonate carbon content 2.4 g L−1) at 6th day and 82% (bicarbonate carbon content 1.1 g L−1) at 11th day simultaneous with the generation of carbonate and an increase in total organic carbon content (TOC) in the culture medium (Fig. 3a), indicating the conversion of bicarbonate into carbonate (DIC) (2.21 g L−1 at 11th day) and TOC content (0.6 g L−1 at 11th day). Similarly, the reduction of bicarbonate (6th day) was 44% during growth in BC30C10, 36% in BC20C20, 56% in TC30C10, and 40% in TC20C20 (Table 1).

Relatively higher conversion of bicarbonate at the growth of C40 may be attributed to raising the pH of the growth medium to the equilibrium value for bicarbonate/carbonate (HCO3− ↔ CO32− equilibrium pH 8.3) as well as higher algae growth, resulting in higher bicarbonate consumption, supported by a higher cell density (the lowest doubling time) at exponential phase. An increase in pH from 8.0 to 9.0 at the growth of BC40C0 (4th day of culture) also suggests the faster conversion of bicarbonate (Fig. 2b), which is due to the production of carbonate simultaneous with algal growth (Fig. 2a).

The consumption of bicarbonate continued until the 11th day, and the conversion of bicarbonate into carbonate was relatively higher in cultures grown with the addition of Tris-buffer (Table 1). According to the Fig. 2b, an increase in the pH of the culture medium indicates the conversion of NaHCO3 into Na2CO3, as observed previously [11]. The changes in pH from 8.0 (day of cultivation) to 9.6 (11th day) in the culture at BC40C0, demonstrate the formation of carbonate from bicarbonate along with algal growth. Moreover, the increase in pH during growth in BC20C20 (0.8) or BC30C10 (1.0) was lower compared to the growth of BC40C0 (drifting of pH by 1.6), which suggests that carbonate buffer is better at stabilising the pH of the culture than Tris-buffer (Fig. 2b).

Total carbon content (TC) in the growth medium (shown for 40 g L−1 of bicarbonate) decreased from 5.7 g L−1 (the day of starting cultivation) to 5.1 (4.4 + 0.6) g L−1 (11th day) with cultivation time (Fig. 2a). The same trend was observed in case of TC in the culture medium when grown under the mixture of NaHCO3 and Na2CO3 (Table 1), which indicates the consumption of carbon either by the algae or release of carbon (as CO2) into the environment (Table 1). Losses of carbon (subtraction of TC (final culture) and carbon consumed by algae from the TC of initial culture) during growth in BC40C0, BC30C10, and BC20C20 were found to be 0.7, 0.6, and 0.2 g L−1, respectively, suggesting that more biomass production and lower carbon loss can be achieved when using a mixture of bicarbonate and carbonate, rather than pure bicarbonate, in the growth medium.

Chlorophyll and Carotenoid Content

Total chlorophyll and carotenoid content in the cells gradually increased with time when cultured with different concentrations of NaHCO3 (with Tris-buffer) or mixtures of NaHCO3 and Na2CO3 (BC40C0, BC30C10, BC20C20, TC30C10, TC20C20) (Fig. 3). The accumulation of total chlorophyll and carotenoid content in the exponential phase was relatively higher in cells grown with 20–60 g L−1 of NaHCO3 (with Tris-buffer), with maximum chlorophyll content (31.7 ± 1.8 µg mL−1) found in cells grown with 60 g L−1 of NaHCO3 with Tris-buffer (Fig. 3). An increase in pigments over time may be attributed to the increase in the cell number with the increase in available DIC in the culture medium that can enhance photosynthetic efficiency of cells, which supported synthesising photosynthetic pigments along with an increase in division of cells [13]. In addition, the production of higher chlorophyll content also represents the good physiological state of microalgae since carbon content and chlorophyll have a linear relationship at fixed light and temperature [35], consistent with the higher growth at an exponential phase in cells grown with 20–60 g L−1 of NaHCO3 reported in our earlier study [11]. However, chlorophyll content levelled off after the 6th day of culture with 2.5 g L−1 of NaHCO3 and after the 7th day of culture with 20 g L−1 of NaHCO3 (Fig. 3a), which indicates that the concentration of bicarbonate significantly impacts the production of chlorophyll content. According to the Fig. 1b, the growth curve demonstrated the starting of the stationary phase after the 6th day and 7th day in cells grown with 2.5 and 20 g L−1 of NaHCO3 (with Tris-buffer) respectively, which indicated carbon-limited-growth and caused the chlorophyll content in the cells to remain constant. Moreover, the accumulation of chlorophyll in cells in the stationary phase was increased when grown with 40–60 g L−1 of NaHCO3 (with Tris-buffer) (Fig. 3a).

Like chlorophyll, no significant difference in total carotenoid content at the end of culture was found in cells grown within the range of 20–90 g L−1 NaHCO3 and the lowest carotenoid content was produced in cells grown with 2.5 g L−1 of NaHCO3 (Fig. 3c). The results demonstrate that a minimum amount of DIC (> 2.5 g L−1 of NaHCO3) is needed in the growth medium to accumulate higher levels of photosynthetic components (chlorophyll and carotenoids). Despite displaying lower values after 6 days of cultivation, the generation of total carotenoid and chlorophyll in cells grown with 80–90 g L−1 in the final culture was not significantly lower relative to the cells grown with 20–60 g L−1 of NaHCO3. This could be due to the initial conversion of chlorophyll carbon to other compounds in response to oxidative stress, resulting in slower initial growth rates, or due to the overproduction of pigments to protect cells by mitigating the excess NaHCO3 introduced osmotic stress in the stationary growth phase. It is also expected that the ratio of carotenoid to chlorophyll (Car/Chl) would be increased with time since the ratio of Car/Chl ratio was previously demonstrated as the marker of cellular physiological stress and carotenogenesis in the microalgae [33]. In the presented study, the ratio of Car/Chl was gradually increased in cells over time, however, the ratio did not vary significantly between cells cultured under different concentrations of NaHCO3 (2.5–90 g L−1).

The production trend of total carotenoid content with time in cells grown at a mixture of NaHCO3 and Na2CO3 (BC40C0, BC30C10, BC20C20, TC30C10, TC20C20) was the same as observed in the cells grown at NaHCO3 (20–90 g L−1) in the exponential growth region (Fig. 3d). However, total carotenoid content reached a maximum at the late-exponential phase of growth (8th day of culture) and then decreased in cells grown with a mixture of NaHCO3 and Na2CO3 (Fig. 3d). The lowering of carotenoid in the final culture may be attributed to the depletion of nutrients over time, since the accumulation of total carotenoid in cells is associated with the cultivation factors (mainly nutrients such as nitrogen and phosphate) [36]. Rahman et al. [37] investigated the effect of the growth phase on the carotenoid production in several chlorophytes strains and observed a lower level of total carotenoid in the stationary phase relative to the exponential phase, which is consistent with the present study.

Characterisation of Biomass

Biomass was characterised by assessing the content of pigments (total chlorophyll and carotenoids), accumulation of primary metabolites (total phenolic, flavonoid, and ascorbate), and the production of secondary metabolites (total lipid, protein, and carbohydrate) in harvested stationary phase cells.

Pigments Content

The production of total chlorophyll and total carotenoid contents in the biomass gradually increased with the increase in the concentration of NaHCO3 from 2.5 to 40 g L−1 (Fig. 4a). Beyond this point accumulation of both pigments was not significantly increased with further increase in NaHCO3 (with Tris-buffer) in the growth medium (Fig. 4a), which indicates the optimal concentration of NaHCO3 would be 40 g L−1 or greater to obtain higher levels of pigments. Though the accumulation rate of pigments (chlorophyll and carotenoids) in cells grown in TC90 was not higher compared to cells grown at other concentrations of NaHCO3 (Fig. 3a), the content of the pigment was the maximum in this biomass. The highest total chlorophyll (25.4 ± 1.8 mg g−1) and carotenoid contents (3.1 ± 0.2 mg g−1) were found in the biomass grown in TC90 (Fig. 4a). However, the overall pigment production rate was low due to the low production of biomass at this concentration. Nevertheless, higher concentrations of NaHCO3 excessively increase the concentration of Na+ which may lead to the overproduction of reactive oxygen species (ROS) [34], which stimulated cells to accumulate higher pigment content to protect cells by reducing the Na+-induced osmotic stress at stationary phase resulting enhanced chlorophyll and carotenoids (mg per g biomass) in the cells grown at 90 g L−1 of NaHCO3 with Tris-buffer.

Accumulation of pigments (chlorophyll and carotenoid) in D. tertiolecta grown under different alkali halophilic conditions. a different concentration of NaHCO3, g L−1 with Tris-buffer; b mixture ofNaHCO3 + Na2CO3 (g L−1) with or without Tris-buffer. Data presented as mean ± standard deviation (n = 3). The same small letter denotes no significant difference at p > 0.05. The different letters indicate a statistically significant difference at p < 0.05

The cells grown with 40 g L−1 NaHCO3 (without Tris-buffer) or a mixture of NaHCO3 and Na2CO3 demonstrate that total chlorophyll and total carotenoid contents in biomass were not significantly different except the chlorophyll content in cells grown at C30C10 (Fig. 4b). The highest chlorophyll content (27.2 ± 1.3 mg g−1) in the biomass was observed for cells grown under NaHCO3 (without Tris-buffer) (Fig. 4b), which was significantly higher than for cells grown at TC40 (21.8 ± 2.4 mg g−1). A study by Liang et al. [32] showed chlorophyll (6.9 mg g−1) and carotenoid (3.7 mg g−1) in D. tertiolecta [31], where chlorophyll content was lower, and carotenoid content was comparable to the presented study. However, both chlorophyll (65–108 mg g−1) and carotenoid (18–33 mg g−1) content in D. tertiolecta reported earlier in the study of Alessandra et al. [33] were higher relative to the presented finding, which may be due to uses of different growth medium for the cultivation of algae.

Primary Metabolites

Production of primary metabolites in microalgae was stimulated by exposing cells to osmic or oxidative stress, which was induced by manipulating cultivation conditions mainly nutrients concentration (excess or deprivation) and environmental factors (variation of light intensities and wavelength, fluctuation of temperatures and pH) [26]. Concentrations of carbon (inorganic) in the culture are mainly associated with algal growth and cellular compounds since carbon is the key nutrient to perform photosynthesis and photorespiration and can increase the level of carbohydrate, lipid, protein and other components under starvation of other nutrients in the culture [15].

Total Lipid

Total lipid content in the biomass was increased with the increase in NaHCO3 from 2.5 to 40 g L−1, and beyond this, the production of lipid content was not significantly enhanced in the biomass when cells grown under the higher concentration of NaHCO3 (60–90 g L−1) with Tris-buffer (Fig. 5a). An increase in lipid content with increase in NaHCO3 may be attributed to an increase in the concentration of CO32− with pH of the culture medium, since stimulating effect of DIC (CO32−) on enhanced lipid production (245 mg g−1) were observed in Chlorella vulgaris grown with 13 g L−1 NaHCO3 at pH 9.5 [25]. The highest level of total lipid content (262.2 ± 53.2 mg g−1) was determined in the biomass when cells grown under 80 g L−1 of NaHCO3 with Tris-buffer, which was fivefold higher compared to lipid produced in cells grown under 2.5 g L−1 of NaHCO3, which could be due to the ability of NaHCO3 to alleviate the oxidative stress by activating antioxidant enzymes together with accumulating lipid as an electron sink [16]. A higher concentration of DIC (HCO3−) can increase the efficiency of the CO2 absorption process by enhancing the carbon concentrating mechanism (CCM) through elevating the activity of carbonic anhydrase. Furthermore, stabilising pH [34] can supply sufficient carbon at the beginning of the culture for growth, and remaining available carbon may rapidly accumulate via the synthesis de novo cellular organic compound (such as lipid) [15], resulting in higher lipid content in cells. The production of total lipid content in the biomass was not significantly different among cells grown under BC40C0, BC30C10, BC20C20, TC30C10, and TC20C20 (Fig. 5b). The lipid content was not significantly changed between cells grown in TC40 and BC40C0, which suggests that addition of Tris-buffer in the growth medium has no impact on the production of lipid in biomass.

Production of primary metabolites in Dunaliella tertiolecta grown under different alkali halophilic conditions. a different concentration of NaHCO3, g L−1 with Tris-buffer; b mixture of NaHCO3 and Na2CO3 (g L−1) with or without Tris-buffer. Data presented as mean ± standard deviation (n = 3). The same small letter denotes no significant difference at p > 0.05. The different letters indicate a statistically significant difference at p < 0.05

Total lipid content in the presented study was comparable to previous studies with Neochloris oleoabundans (234 mg g−1 at 25 g L−1 of NaHCO3) [34] and was higher than the earlier studies with N. oleoabundans (151 mg g−1 at 13 g L−1 of NaHCO3) [16]. Liang et al. [31] treated D. tertiolecta with triethylamine and obtained a lipid content of 377 mg g−1, Schulze et al. [38] reported 484 mg g−1 of lipid production in Tetraselmis chuii by exposing cells to light-induced stress, which were higher relative to the presented finding. These data demonstrate that the accumulation of lipids in the culture is strains-specific and is dependent on the cultivation conditions.

Total Protein

Like the accumulation of total lipid, the generation of total protein in the biomass increased gradually as the concentration of NaHCO3 in the culture medium was increased from 2.5 to 40 g L−1 with Tris-buffer. The highest total protein content in cells grown under 40 g L−1 of NaHCO3 with Tris-buffer (TC40) was found to be 331.1 ± 26.4 mg g−1 (Fig. 5a). The total protein content in the biomass was reduced with the increase in the level of NaHCO3 (> 60 g L−1 or higher) in the growth medium. An increase in total protein content under sufficient nitrogen and excess carbon may be attributed to the direct association of nitrogen to the formation of structural and functional peptides, proteins, and enzymes [26] and NO3− assimilation of the cells was increased with the concentration of DIC [39] resulting in incremented accumulation of total protein in the culture. In addition, the availability of carbon in the growth medium may be directed the cell to synthesise protein, which causes higher protein content than was observed in the study of Picardo et al. [40], where the higher protein was measured in Isochrysis galbana when grown with enriched CO2. However, the allocation of carbon to cellular organic components production is affected by the ratio of carbon to nitrogen (C:N), the utilisation efficiency of carbon and nitrogen, the storage capacity of cells, physiological and genetic characteristic of cells, etc. [40].

Total protein content was not significantly different in the biomass obtained from the cells grown with the mixture of NaHCO3 and Na2CO3 (BC40C0, BC30C10, BC20C20, TC30C10, and TC20C20) (Fig. 5b). The highest values (336.2 ± 17.5 mg g−1) have been observed in cells grown with 40 g L−1 of NaHCO3, but this was not significantly higher relative to the cells cultured under the same concentration of NaHCO3 with Tris buffer. Protein content in the presented study was comparable to the reported studies with D. tertiolecta (386 mg g−1) [41] but higher than that reported for D. salina (241 mg g−1) [15]. However, the total protein content of 430 mg g−1 in D. salina was reported by Gomes [42], which was higher compared to the presented finding.

Total Carbohydrate

The production of total carbohydrate was not consistently increasing with the increase in the concentration of NaHCO3 in presence of Tris-buffer (Fig. 5a). Total carbohydrate content decreased as the NaHCO3 increased from 2.5 to 20 g L−1 in the growth medium (Fig. 5a),but increased to 324.1 ± 5.5 mg g−1 at 40 g L−1 NaHCO3, demonstrating the enhanced carbohydrate content with the concentration of NaHCO3 from 20 to 40 g L−1 in the growth medium (Fig. 5a). The production of total carbohydrate in the biomass was not significantly different, as the concentration of NaHCO3 increased up to 80 g L−1 during cell growth but was lower compared to growth at 2.5 g L−1 of NaHCO3. The highest total carbohydrate content was found to be 373.3 ± 17.6 mg g−1 in cells grown under 90 g L−1, although not significantly higher compared to cells grown at 2.5 g L−1 of NaHCO3 (Fig. 5a). According to this result, it is also suggested that total carbohydrate content may not proportionally increase with the concentration of DIC, which may be due to contributing carbon to other components such as lipid and protein. After assimilating carbon through the Calvin cycle, the primarily produced metabolite is carbohydrate as carbon and energy storage in the stationary phase [40], therefore, it is expected a relatively higher carbohydrate in cells rather than lipid under sufficient levels of carbon in the growth medium. This agrees with the higher carbohydrate production at the growth of 2.5 g L−1 of NaHCO3 in the presented work. Under excessive DIC, carbohydrate and lipid are the primary carbon sinks as glycerol-3-phosphate is the precursor for both [43], which causes enhanced total carbohydrate and lipid content in cells grown at 90 g L−1 of NaHCO3 in the presented work. Silva et al. [8] investigated the effect of NaHCO3 and a maximum of 250 mg g−1 carbohydrate in Synechococcus PCC 7002 at 88 g L−1 was reported, which was lower compared to the presented data at 90 g L−1 of NaHCO3.

Since the change of pH in the culture medium between 8.0 and 10 either at pure NaHCO3 or a mixture of NaHCO3 and Na2CO3 (with or without Tris-buffer) in the presented study and the availability of IC (HCO3−) in the culture medium enables cells to absorb it by activating carbonic anhydrase enzyme [40], therefore it could be assumed that pH may not impact the accumulation of carbohydrate in cells. Moreover, total carbohydrate content was significantly lower in cells grown in mixtures of NaHCO3 and Na2CO3 (BC40C0, BC30C10, BC20C20, TC30C10) relative to cells grown in NaHCO3 with Tris buffer, which suggests that Tris-buffer could be beneficial to enrich the cells with carbohydrate (Fig. 5). Lower carbohydrate and higher lipid and protein at the growth of TC20 compared to the growth of BC20C20 (Fig. 5) indicated that carbon pool is directed from carbohydrate to the production lipid and protein in cells. Total carbohydrate content in the presented study is in agreement with that previously reported for Chlorella sp. (405 mg g−1) [44] and is higher relative to the earlier studies with D. salina (271 mg g−1) [15]. A study by Rizwan et al. [45] reported the total carbohydrate content in D. tertiolecta (545 mg g−1), which was higher compared to the presented study, which may be attributed to the uses of heavy metal, inducing stress under different growth medium and cultivation system (bubble column).

Secondary Metabolites

The accumulation of secondary metabolites (total phenolic, total flavonoid, total ascorbate) in the biomass gradually increased as the concentration of NaHCO3 was increased from 2.5 to 40 g L−1 with the addition of Tris-buffer in the growth medium (Fig. 6a). An increase in the concentration of NaHCO3 (60 g L−1 or higher) in the culture medium did not improve the flavonoid and ascorbate content. However, total phenolic content was drastically reduced in cells grown with 60 g L−1 or higher NaHCO3. An increase in the concentration of NaHCO3 increases the photosynthetic activity resulting in an incremental increase in total ascorbate content in cells, which could be attributed to involvement of ascorbate in cellular metabolism by increasing photosynthetic efficiencies, and contributing to the alternative electron donor of l-galactono-1,4-lactone dehydrogenase in photorespiration [46]. Moreover, a higher concentration of NaHCO3 can produce over oxidative stress. It can directly react with ROS or act as a cofactor of violaxanthin de-epoxidase, thus sustaining the dissipation of excess energy to protect against cell damage [26], and it also may stimulate an increase in the level of ascorbate.

Accumulation of secondary metabolites in Dunaliella tertiolecta grown under different alkali halophilic conditions. a different concentration of NaHCO3, g L−1 with Tris-buffer; b mixture of NaHCO3 + Na2CO3 (g L−1) with Tris-buffer or without Tris-buffer. Data presented as mean ± standard deviation (n = 3). The same small letter denotes no significant difference at p > 0.05. The different letters indicate a statistically significant difference at p < 0.05

A twofold (11.8 ± 0.6 mg g−1) and three-fold (17.3 ± 0.6 mg g−1) increased phenolic and flavonoid content respectively was found at growth in TC40 relative to D. tertiolecta cells grown in 2.5 g L−1 of NaHCO3 with Tris-buffer (5.9 mg g−1 of phenolic, and 5.8 mg g−1 of flavonoid) (Fig. 6a). An increase in total phenolic and flavonoid contents with the concentration of DIC may be attributed to increasing in the ratio of carbon to nitrogen, promoting the synthesis of secondary metabolites by directing carbon to the secondary metabolism likely to the reported study with Arthrospira platensis [47], where enhanced total polyphenolic content was observed under CO2 enriched growth medium. In addition, higher total phenolic content at the growth of TC40 could be due to the optimal conditions of growth, where carbon flow is allocated in the phenolic biosynthesis through the phenylpropanoid pathway during optimal growth conditions [26].

Both total phenolic and flavonoid content in cells grown with 40 g L−1 of NaHCO3 were not significantly lower compared to those produced in cells grown with BC30C10, BC20C20, TC30C10, TC20C20 (Fig. 6b), which demonstrates that carbonate buffer or carbonate buffer with the addition of Tris-buffer has no effect on the accumulation of phenolic and flavonoid content in cells. In addition, the highest phenolic (12.8 ± 2.0 mg g−1) and flavonoid (14.4 ± 2.3 mg g−1) content in the biomass grown in BC40C0 were not significantly higher or lower relative to those produced in growing cells at TC40 (Fig. 6a, 6b), which indicate not requiring the addition of Tris-buffer in the growth medium (40 g L−1 NaHCO3) to enrich cells with phenolic flavonoid content.

Total phenolic and flavonoid content in D. tertiolecta in the present study was higher compared to those previously reported with D. salina (5.9 mg g−1 GAE (phenolic), 2.3 ± 0.2 mg QE g−1 (flavonoid)) [48], C. vulgaris (8.5 ± 0.1 mg g−1 GAE, phenolic) [4], which suggest that cells exposed to DIC-induced stress may be one of the efficient strategies to improve the accumulation of total phenolic and flavonoid content in Dunaliella. However, the total phenolic content in the presented study here was lower compared to the earlier study with four microalgae strains (Phaeodactylum tricornutum, N. gaditana, Nannochloris sp, Tetraselmis suecica) (22.9—39.3 mg g−1 GAE, phenolic) [3], with C. vulgaris (547.0 ± 34.7 mg g−1 rutin, flavonoid) in [4], which could be attributed to the varieties of strains and cultivation factors, uses of different extracting solvents to solubilise phenolic and flavonoids content, and use of a different standard (rutin). As there are limited studies available on the accumulation of phenolic compounds by Dunaliella under stress induced by excessive DIC in the culture medium, further research is still required to explore the reduction of phenolic content in D. tertiolecta when cells were grown under excess NaHCO3 (> 60 g L−1).

Cells grown in BC40C0, BC30C10, BC20C20, TC30C10, and TC20C20 (Fig. 6b) demonstrated a decreased trend of total ascorbate content with a decrease in the concentration of NaHCO3 with or without the addition of Tris-buffer. However, total ascorbate content did not significantly change in growing cells under the mixture of NaHCO3 and Na2CO3 with or without the addition of Tris-buffer. The total ascorbate content in the study presented here was comparable to the earlier study with three strains (P. tricornutum, T. suecica, and C. vulgaris) (2–5 mg g−1) [49], and was higher relative to previously studied with D. salina, C. marina, and Navicula clavate (0.6–1.1 mg g−1) [50]. Total ascorbate content (4.7 ± 1.1 mg g−1) at the growth of 40 g L−1 NaHCO3 was not significantly higher relative to that found in cells grown in TC40, which suggests that carbonate buffer or Tris-buffer is not needed, high concentration of NaHCO3 (not more than 40 g L−1) in the culture medium can produce the higher levels of ascorbate content in the biomass.

Conclusions

This research evaluated the effect of DIC (with or without Tris-buffer) on the production of biomass and the accumulation of metabolite content.. The highest biomass content (1.5 ± 0.1 g L−1) was observed in cells grown in a mixture of NaHCO3 and Na2CO3 (30 + 10 g L−1). Overall, higher metabolites, chlorophyll (27.2 ± 3.1 mg g−1), carotenoid (2.0 ± 0.1 mg g−1), protein (336.2 ± 47.5 mg g−1), carbohydrate (207.5 ± 26.3 mg g−1), lipid (239.6 ± 24.3 mg g−1), total phenolic (12.8 ± 2.0 mg g−1), total flavonoid (14.4 ± 2.3 mg g−1), total ascorbate (4.7 ± 1.1 mg g−1) were measured in the biomass obtained from the growing cells with 40 g L−1 of NaHCO3. This study recommends an optimal NaHCO3 concentration of 40 g L−1 to produce maximum levels of pigments, primary and secondary metabolites, and a mixture of NaHCO3 and Na2CO3 (30 + 10 g L−1) for the maximum production of biomass. These results suggest that industrial application of algae-based carbon capture and utilisation do not require full carbonate-to-bicarbonate conversions prior to algae culture, improving system operability and flexibility. D. tertiolecta would be a suitable strain to grow under high levels of dissolved inorganic carbon not only for large-scale biomass production but also can be processed to produce value-added products.

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author upon reasonable request.

References

Shariati, M., Hadi, M.R.: Microalgal biotechnology and bioenergy in Dunaliella. Prog. Mol. Environ. Bioeng. - From Anal. Model. to Technol. Appl. 447–506 (2011)

Sathasivam, R., Radhakrishnan, R., Hashem, A., Abd Allah, E.F.: Microalgae metabolites: a rich source for food and medicine. Saudi J. Biol. Sci. 26, 709–722 (2019). https://doi.org/10.1016/j.sjbs.2017.11.003

Haoujar, I., Cacciola, F., Abrini, J., Mangraviti, D., Giu, D., Oulad, Y., Majdoub, E., Kounnoun, A., Miceli, N., Taviano, M.F., Mondello, L., Rigano, F., Senhaji, N.S.: The contribution of carotenoids, phenolic compounds, and flavonoids to the antioxidative properties of marine microalgae isolated from mediterranean Morocco. Molecules 24, 4037 (2019). https://doi.org/10.3390/molecules24224037

Mtaki, K., Kyewalyanga, M.S., Mtolera, M.S.P.: Assessment of antioxidant contents and free radical-scavenging capacity of chlorella vulgaris cultivated in low cost media. Appl. Sci. 10, 1–11 (2020). https://doi.org/10.3390/app10238611

Mutanda, T., Naidoo, D., Bwapwa, J.K., Anandraj, A.: Biotechnological applications of microalgal oleaginous compounds: current trends on microalgal bioprocessing of products. Front. Energy Res. 8, 1–21 (2020). https://doi.org/10.3389/fenrg.2020.598803

Sajjadi, B., Chen, W.Y., Raman, A.A.A., Ibrahim, S.: Microalgae lipid and biomass for biofuel production: a comprehensive review on lipid enhancement strategies and their effects on fatty acid composition. Renew. Sustain. Energy Rev. 97, 200–232 (2018). https://doi.org/10.1016/j.rser.2018.07.050

Roy, U.K., Nielsen, B.V., Milledge, J.J.: Antioxidant production in Dunaliella. Appl. Sci. 11, 1–24 (2021). https://doi.org/10.3390/app11093959

De Farias Silva, C.E., Grisa, B., Sforza, E., Rocca, N.L., Bertucco, A.: Effects of sodium bicarbonate on biomass and carbohydrate production in synechococcus PCC 7002. Chem. Eng. Trans. 49, 241–246 (2016). https://doi.org/10.3303/CET1649041

Haynes, W.M.: CRC Handbook of Chemistry and Physics. CRC Press, Boca Raton (2014)

Leng, L., Li, J., Wen, Z., Zhou, W.: Use of microalgae to recycle nutrients in aqueous phase derived from hydrothermal liquefaction process. Bioresour. Technol. 256, 529–542 (2018). https://doi.org/10.1016/j.biortech.2018.01.121

Roy, U.K., Radu, T., Wagner, J.L.: Carbon-negative biomethane fuel production: Integrating anaerobic digestion with algae-assisted biogas purification and hydrothermal carbonisation of digestate. Biomass Bioenergy 148, 106029 (2021). https://doi.org/10.1016/j.biombioe.2021.106029

Peng, L., Lan, C.Q., Zhang, Z., Sarch, C., Laporte, M.: Control of protozoa contamination and lipid accumulation in Neochloris oleoabundans culture: effects of pH and dissolved inorganic carbon. Bioresour. Technol. 197, 143–151 (2015)

Salbitani, G., Bolinesi, F., Affuso, M., Carraturo, F., Mangoni, O., Carfagna, S.: Rapid and positive effect of bicarbonate addition on growth and photosynthetic efficiency of the green microalgae Chlorella Sorokiniana (Chlorophyta, Trebouxiophyceae). Appl. Sci. 10, 4515 (2020). https://doi.org/10.3390/app10134515

Chi, Z., Elloy, F., Xie, Y., Hu, Y., Chen, S.: Selection of microalgae and cyanobacteria strains for bicarbonate-based integrated carbon capture and algae production system. Appl. Biochem. Biotechnol. 172, 447–457 (2014). https://doi.org/10.1007/s12010-013-0515-5

Srinivasan, R., Mageswari, A., Subramanian, P., Suganthi, C., Chaitanyakumar, A., Aswini, V., Gothandam, K.M.: Bicarbonate supplementation enhances growth and biochemical composition of Dunaliella salina V-101 by reducing oxidative stress induced during macronutrient deficit conditions. Sci. Rep. 8, 1–14 (2018). https://doi.org/10.1038/s41598-018-25417-5

Peng, L., Zhang, Z., Lan, C.Q., Basak, A., Bond, N., Ding, X., Du, J.: Alleviation of oxygen stress on Neochloris oleoabundans: effects of bicarbonate and pH. J. Appl. Phycol. 29, 143–152 (2017)

Chen, Y., Zhang, L., Xu, C., Vaidyanathan, S.: Dissolved inorganic carbon speciation in aquatic environments and its application to monitor algal carbon uptake. Sci. Total Environ. 541, 1282–1295 (2016)

Umetani, I., Janka, E., Sposób, M., Hulatt, C.J., Kleiven, S., Bakke, R.: Bicarbonate for microalgae cultivation: a case study in a chlorophyte, Tetradesmus wisconsinensis isolated from a Norwegian lake. J. Appl. Phycol. 33, 1341–1352 (2021). https://doi.org/10.1007/s10811-021-02420-4

Zhu, C., Zhang, R., Cheng, L., Chi, Z.: A recycling culture of Neochloris oleoabundans in a bicarbonate-based integrated carbon capture and algae production system with harvesting by auto-flocculation. Biotechnol. Biofuels 11, 1–11 (2018). https://doi.org/10.1186/s13068-018-1197-6

Rocha, J.M.S., Garcia, J.E.C., Henriques, M.H.F.: Growth aspects of the marine microalga Nannochloropsis gaditana. Biomol. Eng. 20, 237–242 (2003). https://doi.org/10.1016/S1389-0344(03)00061-3

Xi, Y., Wang, J., Xue, S., Chi, Z.: β-Carotene production from dunaliella salina cultivated with bicarbonate as carbon source. J. Microbiol. Biotechnol. 30, 868–877 (2020). https://doi.org/10.4014/jmb.1910.10035

Xu, Y., Ibrahim, I.M., Harvey, P.J.: The influence of photoperiod and light intensity on the growth and photosynthesis of Dunaliella salina (chlorophyta) CCAP 19/30. Plant Physiol. Biochem. 106, 305–315 (2016). https://doi.org/10.1016/j.plaphy.2016.05.021

Gim, G.H., Ryu, J., Kim, M.J., Kim, P.I., Kim, S.W.: Effects of carbon source and light intensity on the growth and total lipid production of three microalgae under different culture conditions. J. Ind. Microbiol. Biotechnol. 43, 605–616 (2016). https://doi.org/10.1007/s10295-016-1741-y

Nguyen, T.T., Bui, X.T., Pham, M.D., Guo, W., Ngo, H.H.: Effect of Tris-(hydroxymethyl)-amino methane on microalgae biomass growth in a photobioreactor. Bioresour. Technol. 208, 1–6 (2016). https://doi.org/10.1016/j.biortech.2016.02.043

Li, J., Li, C., Lan, C.Q., Liao, D.: Effects of sodium bicarbonate on cell growth, lipid accumulation, and morphology of Chlorella vulgaris. Microb. Cell Fact. 17, 1–10 (2018). https://doi.org/10.1186/s12934-018-0953-4

Roy, U.K., Nielsen, B.V., Milledge, J.J.: Tuning Dunaliella tertiolecta for enhanced antioxidant production by modification of culture conditions. Mar. Biotechnol. (2021). https://doi.org/10.1007/s10126-021-10041-8

Dey, T.B., Kuhad, R.C.: Enhanced production and extraction of phenolic compounds from wheat by solid-state fermentation with Rhizopus oryzae RCK2012. Biotechnol. Rep. 4, 120–127 (2014). https://doi.org/10.1016/j.btre.2014.09.006

Matyash, V., Liebisch, G., Kurzchalia, T.V., Shevchenko, A., Schwudke, D.: Lipid extraction by methyl-terf-butyl ether for high-throughput lipidomics. J. Lipid Res. 49, 1137–1146 (2008). https://doi.org/10.1194/jlr.D700041-JLR200

Vardhaman MulchandJain, G.N.K., Arun Suresh Dodamani, G.V.M.: Estimating the carbohydrate content of various forms of tobacco by phenol-sulfuric acid method. J. Educ. Health Promot. 6, 1–6 (2017). https://doi.org/10.4103/jehp.jehp

Binte Safie, S.R., Ng, Y.K., Yao, L., Lee, Y.K.: Growth bottlenecks of microalga Dunaliella tertiolecta in response to an up-shift in light intensity. Eur. J. Phycol. 53, 509–519 (2018). https://doi.org/10.1080/09670262.2018.1478131

Liang, M.H., Xue, L.L., Jiang, J.G.: Two-stage cultivation of Dunaliella tertiolecta with glycerol and triethylamine for lipid accumulation: a viable way to alleviate the inhibitory effect of triethylamine on biomass. Appl. Environ. Microbiol. 85, 1–10 (2019). https://doi.org/10.1128/AEM.02614-18

Lakaniemi, A.M., Intihar, V.M., Tuovinen, O.H., Puhakka, J.A.: Growth of Dunaliella tertiolecta and associated bacteria in photobioreactors. J. Ind. Microbiol. Biotechnol. 39, 1357–1365 (2012). https://doi.org/10.1007/s10295-012-1133-x

Alessandra, Y., Moura, S., Ara, D.D., Ana, L., Bezerra, R.P., Converti, A.: Pigments production, growth kinetics, and bioenergetic patterns in Dunaliella tertiolecta (Chlorophyta) in response to different culture media. Energies 13, 1–19 (2020)

Zhang, R.L., Wang, J.H., Cheng, L.Y., Tang, Y.J., Chi, Z.Y.: Selection of microalgae strains for bicarbonate-based integrated carbon capture and algal production system to produce lipid. Int. J. Green Energy. 16, 825–833 (2019). https://doi.org/10.1080/15435075.2019.1641103

Jayasankar, R., Valsala, K.: Influence of different concentrations of sodium bicarbonate on growth rate and chlorophyll content of Chlorella salina. J. Mar. Biol. Assoc. India 50, 74–78 (2008)

McClure, D.D., Luiz, A., Gerber, B., Barton, G.W., Kavanagh, J.M.: An investigation into the effect of culture conditions on fucoxanthin production using the marine microalgae Phaeodactylum tricornutum. Algal Res. 29, 41–48 (2018)

Rahman, N.A., Katayama, T., Wahid, M.E.A., Kasan, N.A., Khatoon, H., Yamada, Y., Takahashi, K.: Taxon- and growth phase-specific antioxidant production by chlorophyte, bacillariophyte, and haptophyte strains isolated from tropical waters. Front. Bioeng. Biotechnol. 8, 1–16 (2020). https://doi.org/10.3389/fbioe.2020.581628

Schulze, P.S.C., Pereira, H.G.C., Santos, T.F.C., Schueler, L., Guerra, R., Barreira, L.A., Perales, J.A., Varela, J.C.S.: Effect of light quality supplied by light emitting diodes ( LEDs ) on growth and biochemical pro files of Nannochloropsis oculata and Tetraselmis chuii. Algal Res 16, 387–398 (2016)

Millán-Oropeza, A., Torres-Bustillos, L.G., Fernández-Linares, L.: Simultaneous effect of nitrate (NO3-) concentration, carbon dioxide (CO2) supply and nitrogen limitation on biomass, lipids, carbohydrates and proteins accumulation in Nannochloropsis oculata. Biofuel Res. J. 2, 215–221 (2015). https://doi.org/10.18331/BRJ2015.2.1.8

Picardo, M.C., De Medeiros, J.L., de Araújo, O.Q.F., Chaloub, R.M.: Effects of CO2 enrichment and nutrients supply intermittency on batch cultures of Isochrysis galbana. Bioresour. Technol. 143, 242–250 (2013). https://doi.org/10.1016/j.biortech.2013.05.113

Da SilvaGorgônio, C.M., Aranda, D.A.G., Couri, S.: Morphological and chemical aspects of Chlorella pyrenoidosa, Dunaliella tertiolecta, Isochrysis galbana and Tetraselmis gracilis microalgae. Nat. Sci. 05, 783–791 (2013). https://doi.org/10.4236/ns.2013.57094

Gomes, D.I.C.: Extraction and Characterization of Microalgae Proteins from the Extremophile Dunaliella. Técn, Lisboa, p 1 (2017)

Wang, H., Yao, C., Ai, J., Cao, X., Xue, S., Wang, W.: Identification of carbohydrates as the major carbon sink of the marine microalga Isochrysis zhangjiangensis (Haptophyta) and optimization of its productivity by nitrogen manipulation. Bioresour. Technol. 171, 298–304 (2014). https://doi.org/10.1016/j.biortech.2014.08.090

Paes, C.R.P.S., Faria, G.R., Tinoco, N.A.B., Castro, D.J.F.A., Barbarino, E., Lourenço, S.O.: Growth, nutrient uptake and chemical composition of Chlorella sp. and Nannochloropsis oculata under nitrogen starvation. Lat. Am. J. Aquat. Res. 44, 275–292 (2016). https://doi.org/10.3856/vol44-issue2-fulltext-9

Rizwan, M., Mujtaba, G., Lee, K.: Effects of iron sources on the growth and lipid/carbohydrate production of marine microalga Dunaliella tertiolecta. Biotechnol. Bioprocess. Eng. 22, 68–75 (2017). https://doi.org/10.1007/s12257-016-0628-0

Sun, H., Zhao, W., Mao, X., Li, Y., Wu, T., Chen, F.: High-value biomass from microalgae production platforms: strategies and progress based on carbon metabolism and energy conversion. Biotechnol. Biofuels 11, 1–23 (2018). https://doi.org/10.1186/s13068-018-1225-6

sassi Aydi, S., Aydi, S., Ben Abdallah Kolsi, R., Haddeji, N., Rahmani, R., Ktari, N., Bouajila, J.: CO2 enrichment: enhancing antioxidant, antibacterial and anticancer activities in Arthrospira platensis. Food Biosci. 35, 100575 (2020). https://doi.org/10.1016/j.fbio.2020.100575

Al-Rashed, S.A., Ibrahim, M.M., El-Gaaly, G.A., Al-Shehri, S., Mostafa, A.: Evaluation of radical scavenging system in two microalgae in response to interactive stresses of UV-B radiation and nitrogen starvation. Saudi J. Biol. Sci. 23(6), 706–712 (2016). https://doi.org/10.1016/j.sjbs.2016.06.010

Goiris, K., Van Colen, W., Wilches, I., León-Tamariz, F., De Cooman, L., Muylaert, K.: Impact of nutrient stress on antioxidant production in three species of microalgae. Algal Res. 7, 51–57 (2015). https://doi.org/10.1016/j.algal.2014.12.002

Hemalatha, A., Girija, K., Parthiban, C., Saranya, C., Anantharaman, P.: Antioxidant properties and total phenolic content of a marine diatom, Navicula clavata and green microalgae, Chlorella marina and Dunaliella salina. Pelagia Res. Libr. 4, 151–157 (2013)

Acknowledgements

This work was funded jointly by the Engineering and Physical Sciences Research Council (EPSRC) and the Department of Transport through a flexible funding Grant from the Supergen Bioenergy Hub (SGBH FF Feb2019 2).

Funding

This work was funded jointly by the Engineering and Physical Sciences Research Council (EPSRC) and the Department of Transport through a flexible funding Grant from the Supergen Bioenergy Hub (SGBH FF Feb2019 2).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Roy, U.K., Wagner, J. & Radu, T. Production of Metabolites in Microalgae Under Alkali Halophilic Growth Medium Using a Dissolved Inorganic Carbon Source. Waste Biomass Valor 14, 3339–3354 (2023). https://doi.org/10.1007/s12649-023-02053-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02053-3