Abstract

Problem of decreasing resources of phosphate rock for phosphorus fertilizers production, can be mitigated by biological degradation of low quality substrates, performed by bacterial species able to produce mineral and low molecular organic acids. It was found that Bacillus megaterium was able to solubilize phosphorus incorporated with organic matter—biogenic apatite—bones. Using the microbial treatment (by acids produced by microorganisms) it was possible to produce liquid phosphorus fertilizers. At the same time the problem with utilization of noxious wastes can be solved. Two materials were used: bones and phosphorite. Two times higher solubilization factor for bones were achieved when compare to phosphorite. It was possible to obtain the organic liquid fertilizer with the content of P2O5 0.09 % (m/m). It is necessary to evaluate the utilitarian properties of obtained fertilizer in the germination test.

Similar content being viewed by others

Introduction

It is surprising that so much global attention has been paid to “peak oil” that we have missed noticing the threat of “peak phosphorus”, since the last few years decrease in fertilizer production all over the world is observed [1–3].

The reason of such wide exploitation of phosphorus are its irreplaceable properties. Phosphorus is essential and unsubstitutable nutrient for plants and animals [4, 5]. Animals can gain P with food, while plant from soil. Because soil has been intensively exploited during the last 50 years it is necessary to supplement the deficiency caused by intense agriculture, what can be done by application of phosphorus fertilizers. Fertile soils are the key to sustainable commercial-scale production of crops for food, feed and fibre [4].

There are two main raw materials used for phosphorus fertilizers production: phosphorite (sedimentary rock) and apatite rock (volcanic sediment) [6]. Processes responsible for the formation of phosphorus ore—phosphogenesis are based on integral physical phenomena and chemical reactions, that last for thousands of years [4].

Typical sedimentary rocks have an average P concentration of about 0.1 wt %, whereas phosphate rocks have P concentrations more than 100 of that amount [1, 7]. An element is taken from a high-concentration source and distributed broadly—although the elemental P mass is conserved, it is now scattered across the globe and effectively diluted. As with all resources, millions of years was needed to form sedimentary deposits with high P concentrations, but humans have extracted these resources at rates so high that the current phosphate rock reserves might be largely depleted in this century [1].

Given the resource limitation, steps should be taken to increase the efficiency of P use in agriculture, reduce the loss of P from agricultural soils, consider crops that more effectively take up P that has been over-applied (e.g., perennial crops), and effectively recycle P from our waste streams.

By application of biotechnological methods it is possible to activate/mobilize reserves present in the soil, that occur in not available form to plants (bound with Fe, Al and Mg)—retrogradation form. By this way it is possible to increase intake of phosphate as a nutrient using agriculture.

Bones

The use of bones as fertilizers represents a valuable recycling strategy [8]. Soil application of animal residues has become a valuable strategy for animal disposal. The problem of Bovine Spongiform Encephalopathy and the consequent EU prohibition on the use of meat waste for feeding animals destined for human consumption created the problem with the utilization of bones [9]. The most concentrated form of organic phosphorus are bones [5, 10]. The total production of MBM in the European Union (EU) exceeds 3,500,000 tons/year. The progressive restriction of the use of MBM in applications, such as animal feed [11] (except pet food [12]) has led to a significant increase in the amount of MBM to be eliminated [13].

Considering that MBM has a heating value ranging between 13 and 30 MJ/kg, incineration in a thermal plant could be one of the most appropriate methods to eliminate this residue [13]. However, incineration always produces ashes that must then be managed. It has been shown that between 100 and 310 kg of ash is produced for each ton of MBM that is incinerated. Thermal treatment of the entire production of MBM in Europe would then produce a large amount of ash (350,000–1000,000 tons/year). Therefore, the fate of such a stock of ashes is a major environmental concern [13].

Bone meal or degelatinized bone meal are among the fertilizers allowed by the European legislation in organic farming [14]. Cayuela [9] reported the soil amendment with meat bone meal resulted with an immediate and remarkable increase of C mineralization and N availability (carbon and nitrogen mineralization are the main process regulating the availability of nutrients for plant) and microbial biomass size and activity in the soil, that fatherly control decomposition dynamics. They are the main source of enzymes in the soil [15].

Another alternative for utilization of bones is to use high content of phosphorus. The calcium and phosphorus contents in MBM ashes (25–29 % Ca and 15–19 % P) were of the same order of magnitude with the average contents found in natural phosphate rocks (35 ± 2 % Ca and 15 ± 1 % P) [13].

Bones, or other by-products obtained from its rendering industry may serve as an additional P resource. Bone can be divided into main parts inorganic and organic. The former consisted mainly of calcium phosphate. The latter is made up of gelatin [16]. Utilization of bones as a source of phosphorus has already a long history. After 1770, when phosphorus was discovered in bones and many other parts of various animals, many attempts were made to obtain phosphorus from them. Until the middle of nineteenth century, bone and guano were used as the raw material to produce phosphorus and phosphoric acids [16]. In 1842 John B. Lawes had the first British patent in this field on the manufacture of superphosphate by reacting bone with sulphuric acids [16].

Depending on the age of rocks, phosphates have a different chemical activity, lower- older (hard) or higher–younger (soft) [1]. If we will compare the two forms of phosphorus that can be found in bones with that found in sediments we will arrive to a conclusion, that it is easier to work with bone as more reactive form of phosphorus.

At the same time, phosphate minerals efficiently capture cations, they may naturally contain high concentrations of metals and other impurities (contaminants) that could be of concern when they are used [17, 18]. Biogenic apatite (bone) has the lowest total concentrations of all elements. Low concentrations of impurity in biogenic apatite are the result of a short accumulation time (few weeks are needed for bone formation) [19]. However, after this material becomes deposited in sediments, it incorporates trace elements over geological timeframes at concentration levels that are enriched by many orders of magnitude over initial levels [18]. Another advantage of application of bones is the lack of fluorine in bones, that plays a major role in the formation of sedimentary apatite and contributes to its preservation in sediments [20].

Additionally, it was found that biogenic apatite (bone) had the largest apparent solubility after 12 days with a log(Ksp) of 45.2, compared with 57.0 for the mined rock phosphate and 48.0 for beneficiated phosphate rock [13].

Also, biogenic apatite had the highest P concentrations in the water soluble fraction (505 mg/kg compared with 307 mg/kg for processed phosphate and 22 mg/kg for mined phosphate). Biogenic apatite has lower concentrations of impurities than mined and beneficiated phosphate, especially mined and processed phosphates from older deposits [17].

Bones and Microbes

It is known that phosphate deposit contains the teeth, bones and waste excrements from marine life and also the bones of terrestrial pre-historic animals. Biological and chemical changes transformed the phosphate that existed in the sea into the phosphate sediment that is mined today [17]. Microbes are considered to play an important role in phosphate enrichment and phosphogenesis [21].

Most heterotrophic bacteria and fungi have the capability to hydrolytically break down organically bound phosphate using specific enzymes as catalysts (e.g., phosphatase, phytase, nucleotidase, etc.). Microbial solubilization can be achieved through: (1) the production of inorganic and organic acids that attack the solid phosphates; (2) the production of chelators, such as 2-ketogluconate, citrate, oxalate, and lactate, that complex the cationic part of solid phosphates and thus force their dissolution; and (3) the production of H2S, which may induce the formation of iron sulfide and liberate phosphate [2].

On the Fig. 1 the simplified cycle of phosphorus was presented. It is possible to replace the long term process of formation of phosphorus ore—phosphogenesis, that leads to obtain main raw material for fertilizers production, by solubilization performed by microbes of animal wastes that plays the role of main phosphorus sink [22]. Nature gives a hint to utilize properties of microorganisms that are considered to play an important role in the phosphogenesis to solve problems with deficiency of phosphorus.

Mechanism

Many microorganisms present in the soil have been identified to produce low-molecular-weight organic acids and sulfuric acid that are reported to solubilize phosphorus [23]. Solubilization of phosphate-bearing inorganic materials by microorganisms excreting organic acids seems to be an attractive approach that has been actively studied during the last decade [24–26]. Figure 2 presents examples of microbes and acid produced by them. But in the literature there is a lack of information related to microbial solubilization of bones as a sources of phosphorus.

Nowadays, phosphorus fertilizers are mainly produced from phosphorite treated with sulfuric acid that decomposed phosphate rock into a waste phosphogypsum (CaSO4·2H2O (dihydrate) and CaSO4·0.5 H2O (semi-hydrate)) and wet process phosphoric acid [3, 27]. Similar to a certain extent, process can be performed by Thiobacillus ferroxidans or Acidithiobacillus thiooxidans that are able to produce sulfuric acid [28, 29]. The possible chemical reactions of microbial solubilization are presented in the Fig. 3.

It is also possible to use the ability of microbes to solubilize, other than bones, sources of phosphorus (Fig. 4). Phosphorite treated with organic acids/H2SO4 produced by microorganism is an interesting alternative to conventional process of production phosphate fertilizers. When bones or sludge from enhanced biological phosphorus removal (both have high level of phosphorus [3]) serves as a source of P in the cultivation of mircobes solubilizing P, additionally, organic form of carbon and other nutrients are supplied to the growth medium [30], making solubilizing process easier and more efficient. Biochar [31] or bones ash are other alternative sources of phosphorus, possible to use as raw material for fertilizers production in the case when microbes are utilized. Both of them are free of organic matter that can be used as a source of carbon for solubilizing phosphorus bacteria, but the content of P (P2O5) is higher than in bone and sludge from EBFR [32].

Materials and Methods

Phosphate Source

In solubilization experiment, as sources of phosphorus, poultry boiled bone that contains about 18.6 % P2O5 and Morocco phosphate rock with 22.7 % P2O5 were used. Both phosphate substrates were grinded by blender. The results of sieve analysis of used material was presented in the Table 1. While the structural characterization of phosphate source were presented on the Fig. 5.

Bacteria and Culture Medium

Phosphate sources were treated with Bacillus megaterium as a phosphate–solubilizing microorganism. Bacteria was obtained from Polish Collection of Microorganisms located at the Institute of Immunology and Experimental Therapy in Wroclaw. For cultivation of bacteria growth medium, containing: 10 g glucose; 0.5 g (NH4)2SO4; 0.2 g NaCl; 0.1 g MgSO4·7H2O; 0.2 g KCl; 0.002 g MnSO4 H2O; 0.002 g FeSO4·7H2O; 0.5 g yeast extract [22] was used.

Experimental and Analytical Methods

The solubilization experiment was conducted in Erlenmeyer’s flasks (capacity 500 mL) with 250 mL medium and 1.00 g phosphate source at 34°C under sterile conditions. The medium solution with the phosphate source was inoculated with bacteria from agar slant by inoculating loops and incubated as batch cultures. For 14 days, pH was recorded by pH-meter Mettler Toledo SevenMulti. After shaking the flasks for predetermined time intervals (one time per day), the reaction mixture was filtered through filter paper, the filtrate was used to analyze P2O5 concentration. The soluble–P2O5 concentration in culture medium was measured by colorimetric vanadomolybdophosphoric acid colorimetric method with a Varian Cary 50 Cone UV–Visible Spectrophotometr at 420 nm. The method is based on the formation of yellow vanadomolybdo- phosphoric acid upon the addition of ammonium molybdate and vanadium to ortho-phosphate solution. Ammonium molybdate reacts under acid conditions to form a heteropolyacid. In the presence of vanadium, yellow vanadomolybdophosphoric acid is formed, the intensity of which indicates the amount of orthophosphate present. The equation of calibration curve y = −0.0542 + 0.0233 × (R2 = 0.988) was obtained.

In order to investigate efficiency and consequently bioavailability of phosphorus, P2O5 ammonium citrate and water soluble fractions were determined. The experiment was carried out in two stages, by 1 h at 65 °C for ammonium citrate and 30 min at 25 °C for water, according to Regulation (EC) No 2003/2003 of the European Parliament and of the Council relating to fertilizers (method 3.1.4 Extraction of phosphorus which is soluble in neutral ammonium citrate, and 3.1.6 Extraction of water soluble phosphorus). The contribution of soluble and available of phosphorus was evaluated by colorimetric phosphomolybdate method.

In the structural characterization of phosphate source by FT-IR, about 1 mg of samples with 100 mg of KBr were ground. The mixture was compressed into a transparent disc. Prepared sample was analyzed by using spectrometer Perkin-Elmer System 2000 FT-IR in the mid–IR range between 4,000–400 cm−1.

Results

The results of sieve analysis of used material is presented in Table 1. While the structural characterization of phosphate source are presented in Fig. 5. The mineral fraction (PO4 3−, CO3 2−) of phosphate substrates was detected as peaks between 750 and 1,195 cm−1 spectral region.

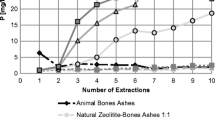

Results are presented on the Fig. 6 for bone solubilization and for Morocco phosphate rock on Fig. 7.

Phosphorus content of bones (Fig. 6) and phosphate rock (Fig. 7) can be divided into two types of fractions based on the availability to plants (extraction with water and citrate) [22, 33]. In the case first, the higher pool of phosphorus 94 %–not available to plant, and 6 %–available (2.8 % that dissolved in the water, and the remaining 3.2 dissolved in the citrate). Similar results were obtained for phosphorite.

All phosphorus not available to plants present in the bones was transformed into the form available to plants.

An increase of amount of available P to plant after microbial solubilization was also observed in the case of phosphorite (Fig. 7) and was satisfactory. From the Eq. (1), the solubilization factor (SF), % (Fig. 6) for bones and phosphorite were determined.

During the solubilization experiment the solubilization factor (SF) increased (Fig. 8) while pH decreased (Fig. 9). On the Fig. 8 the results of solubilization of phosphorite and poultry bone in bacteria medium without bacteria, are presented. The bone as well as phosphorite are slightly soluble in the microbiological media. SF calculated for bones was 9.21 % in the 14th day of incubation, while for phosphorite 2.31 %. At the same time the pH slightly increased from 6.2 to 6.6 for bones and from 7.1 to 8.0 in the case of phosphorite. These findings confirm the crucial role of microorganism in efficient solubilization. The production of organic acids by Bacillus megaterium significantly modifies the phosphorous sources from not available to plants to increased availability.

Two times higher solubilization factor for bones were achieved when compare to phosphorite. The differences in solubilization of phosphorus efficiency by solubilizing bacteria from bones and phosphorite was related with the different chemical activity of used materials (lower time of formation and lower degree of mineralization—bones—higher solubilization efficiency; higher time of formation and higher degree of mineralization—phosporite—lower solubilization efficiency). Microorganisms (bacteria and fungi) present in the soil are able to mobilize phosphorus present in the soil, for example by lowering the pH which makes the phosphorus more available. But it is rather time-consuming process, that in natural environment is not efficient enough to cover needs of intense agriculture. Application of bacteria able to solubilize the unavailable phosphorus make the process more efficient, and may be alternative to traditional phosphorus fertilizer production methods [34]. Application of bones as a raw material for phosphorus fertilizer production has another valuable attribute; lower concentration of inpurities, which is the result of short accumulation time for metals into bones.

Conclusions

There is a need to develop a more effective, eco-friendly and sustainable system where the supply of P to plants can be ensured [35]. In the present work the possibility of utilization of the intermediates from agriculture and industry such as bone or other (bone ash, biochar, sludge EBFR) as a raw material for phosphorus fertilizers production was presented. Meat and bone meal are not authorized for cattle but they can be used for others animals such as pets, or other animals not intended for consumption like fur animals, but they can not be used for any other others animals such as poultry or pigs according to the Regulation (EC) No 999/2001 of the European Parliament and of the council of 22 May 2001, laying down rules for the prevention, control and eradication of certain transmissible spongiform encephalopathies. The problem of BSE and prohibition on the use of meat-bone wastes in animal feeding make the use of bones as fertilizer, a valuable recycling strategy. By utilization of raw material that did not undergo the phosphogenesis, it possible to obtain liquid fertilizer in mild conditions and by a weak acids produced by microorganism in solubilization process.

References

Filippelli, G.M.: Phosphate rock formation and marine phosphorus geochemistry: the deep time perspective. Chemosphere 84, 759–766 (2011)

Föllmi, K.B.: The phosphorus cycle, phosphogenesis and marine phosphate-rich deposits. Earth Sci. Rev. 40, 55–124 (1996)

Schipper, W.J., Klapwijk, A., Potjer, B., Rulkens, W.H., Temmink, B.G., Kiestra, F.D.G., Lijmbach, A.C.M.: Phosphate recycling in the phosphorus industry. Environ. Technol. 22, 1337–1345 (2001)

Dawson, C.J., Hilton, J.: Fertilizer availability in a resource-limited world: production and recycling of nitrogen and phosphorus. Food Policy 36, S14–S22 (2011)

Schröder, H.C., Kurz, L., Mller, W.E.G., Lorens, B.: Polyphosphate in Bone. Biochemistry 65, 353–361 (2000)

Mohammadkhani, M., Noaparast, M., Shafaei, S.Z., Amini, A., Amini, E., Abdollahi, H.: Double reverse flotation of a very low grade sedimentary phosphate rock, rich in carbonate and silicate. Int. J. Min. Process. 100, 157–165 (2011)

Aydin, I., Imamoglu, S., Aydin, F., Saydut, A., Hamamci, C.: Determination of mineral phosphate species in sedimentary phosphate rock in Mardin, SE Anatolia, Turkey by sequential extraction. Microchem. J. 91, 63–69 (2009)

Mondini, C., Cayuela, M.L., Sinicco, T., Sanchez-Monedro, M.A., Bertolone, E., Bardi, L.: Soil application of meat and bone meal. Short-term effects on mineralization dynamics and soil biochemical and microbiological properties. Soil Biol. Biochem. 40, 462–474 (2008)

Cayuela, M.L., Sinicco, T., Mondini, C.: Mineralization dynamica and biochemical properties during initial decomposition of plant and animal residues in soil. Appl. Soil Ecol. 41, 118–127 (2009)

Su, X., Sun, K., Cui, F.Z., Landis, W.J.: Organization of apatite crystals in human woven bone. Bone 32(2), 150–162 (2003)

Abrial, D., Calavas, D., Jarrige, N., Ducrot, C.: Spatial heterogeneity of the risk of BSE in France following the ban of meat and bone meal in cattle feed. Prev. Vet. Med. 67, 69–82 (2005)

Cascarosa, E., Gloria, G., Arauzo, J.: Thermochemical processing of meat and bone meal: a review. Renew Sustain. Energ. Rev. 16, 942–957 (2012)

Coutand, M., Cyr, M., Deydier, E., Guilet, R., Clastres, P.: Characteristics of industrial and laboratory meat and bone meal ashes and their potential applications. J. Hazard. Mat. 150, 522–532 (2008)

European Commission, 1991. Council Regulation (EEC) No 2092/91 of 24 June 1991 on organic production of agricultural products and indications referring thereto on agricultural products and foodstuffs

Enowashu, E., Poll, C., Lamersdorf, N., Kandeler, E.: Microbial biomass and enzyme activities under reduced nitrogen deposition in a spruce forest soil. Appl. Soil Ecol. 43, 11–21 (2009)

Demirbaş, A., Abalı, Y., Mert, E.: Recovery of phosphate from calcinated bone by dissolution in hydrochloric acid solutions. Res. Conserv. Rec. 26, 251–258 (1999)

Knox, A.S., Kaplan, D.I., Paller, M.H.: Phosphate sources and their suitability for remediation of contaminated soils. Sci. Tota Environ. 357, 271–279 (2006)

Sneddon, I.R., Orueetxebarria, M., Hodson, M.E., Schofield, P.F., Valsami-Jones, E.: Use of bone meal amendments to immobilise Pb, Zn and Cd in soil: a leaching column study. Environ. Poll. 144, 816–825 (2006)

Tütken, T., Vennemann, T.W., Pfretzschner, H.-U.: Early diagenesis of bone and tooth apatite in fluvial and marine settings: constraints from combined oxygen isotope, nitrogen and REE analysis. Palaeogeogr. Palaeoclimatol. Palaeoecol. 266, 254–268 (2008)

Soudry, D., Nathan, Y.: Microbial infestation: a pathway of fluorine enrichment in bone apatite fragments (Negev phosphorites, Israel). Sedimen. Geol. 132, 171–176 (2000)

Arning, E.T., Birgel, D., Schulz-Vogt, H.N., Holmkvist, L., Jørgensen, B.B., Larsson A., Peckmann, J.: Phosphogenesis in recent upwelling areas: the importance of microbial communities indicated by lipid biomarkers. http://www.fromage.ethz.ch/news.html, (abstract) Goldschmidt Conference Abstracts 2007

Labuda, M., Saeid, A., Chojnacka, K.: Zastosowanie Bacillus megaterium w solubilizacji fosforu. Przemysł Chemiczny, under review (2012)

Vassilev, N., Vassileva, M., Fenice, M., Federici, F.: Immobilized cell technology applied in solubilization of insoluble inorganic (rock) phosphates and P plant acquisition. Bioresour. Technol. 79, 263–271 (2001)

Vassileva, M., Azcon, R., Barea, J.-M., Vassilev, N.: Rock phosphate solubilization by free and encapsulated cells of Yarowia lipolytica. Process Biochem. 35, 693–697 (2000)

Chun-Qiao, X., Ru-An, C., Xiao-Hui, H., Zhang, W.-X., Guan-Zhou, Q., Dian-Zuo, W.: Optimization for rock phosphate solubilization by phosphate-solubilizing fungi isolated from phosphate. Ecol. Eng. 33, 187–193 (2008)

Xuan, Y., Xu, L., Tian-Hui, Z., Liu, G-H., Cui, M.: Co-inoculation with phosphate-solubilzing and nitrogen-fixing bacteria on solubilization of rock phosphate and their effect on growth promotion and nutrient uptake by walnut. Eur. J. Soil. Biol. (2012). doi:10.1016/j.ejsobi.2012.01.004

Phosphate Fertilizer Plants, Pollution Prevention and Abatement Handbook WORLD BANK GROUP Effective July pp. 387–390 (1998)

Bhatti, T.M., Yawar, W.: Bacterial solubilization of phosphorus from phosphate rock containing sulfur-mud. Hydrometallurgy 103, 54–59 (2010)

Semenza, M., Viera, M., Curutchet, G., Donati, E.: The role of Acidithiobacillus caldus in the bioleaching of metal sulfides. Lat. Am. Appl. Res. 32, 303–306 (2002)

Melligan, F., Dussan, K., Auccaise, R., Novotny, E.H., Leahy, J.J., Hayes, M.H.B., Kwapinski W.: Characterisation of the products from pyrolysis of residues after acid hydrolysis of Miscanthus. Biores. Technol. (2011). doi: 10.1016/j.biortech.2011.12.110

Vassilev, N., Vassileva, M.: Biotechnological solubilization of rock phosphate on media containing agro-industrial wastes. Appl. Microbiol. Biotechnol. 61, 435–440 (2003)

de-Bashan, L.E., Bashan, Y.: Recent advances in removing phosphorus from wastewater and its future use as fertilizer (1997–2003). Water Res. 38, 4222–4246 (2004)

Regulation (EC) No 2003/2003 of the European Council of 13 October 2003 relating to fertilizers, (Dz.U. L 304 21.11.2003)

Fernández-Jalvo, Y., Andrews, P., Pesquero, D., Smith, C., Marín-Monfort, D., Sánchez, B., Geigl, E.-M., Alonso, A.: Early bone diagenesis in temperate environments: Part I: surface features and histology. Palaeogeogr. Palaeoclimatol. Palaeoecol. 288, 62–81 (2010)

Kijkowska, R., Pawlowska-Kozinska, D., Kowalski, Z., Jodko, M., Wzorek, Z.: Wet-process phosphoric acid obtained from Kola apatite. Purification from sulphates, fluorine, and metals. Sep. Purif. Technol. 28, 197–205 (2002)

Acknowledgments

Work financed by the Ministry No. N N209 117237, “An alternative method of manufacture of phosphate fertilizers by biological digestion of low quality raw materials” and by the European Union under the European Social Fund.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Saeid, A., Labuda, M., Chojnacka, K. et al. Valorization of Bones to Liquid Phosphorus Fertilizer by Microbial Solubilization. Waste Biomass Valor 5, 265–272 (2014). https://doi.org/10.1007/s12649-013-9238-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-013-9238-7