Abstract

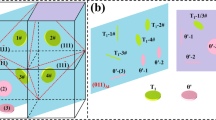

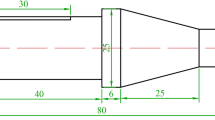

Cold-rolled 2024–T3 sheet alloy was subjected to bobbin-tool friction stir welding (BTFSW). The microstructural characteristics and mechanical properties of the nugget zone in the as-welded state were investigated. The results show that the equiaxed grain size of BTFSW 2024–T3 alloy decreases from 7.6 to 2.8 μm as the welding speed is increased from 80 to 120 mm/min; in addition, fine grains are generated in the nugget zone and the size distribution is non-uniform. All Al2CuMg (S′) precipitates dissolve into the Al matrix, whereas Mn-rich phases confirmed as T phases (Al20Cu2Mn3, Al6Mn, or Al3Mn) remain unchanged. The optimized parameters for BTFSW are verified as the rotation speed of 350 r/min and the travel speed of 100 mm/min. The variations in precipitation and dislocation play more important roles than grain size in the nugget zone with respect to influencing the mechanical properties during the BTFSW process. After the BTFSW process, the fracture mode of base material 2024–T3 alloy transforms from ductile rupture to ductile-brittle mixed fracture.

Similar content being viewed by others

References

R. Nandan, T. Debroy, and H.K.D.H. Bhadeshia, Recent advances in friction-stir welding process, weldment structure and properties, Prog. Mater. Sci., 53(2008), No. 6, p. 980.

W.J. Arbegast, A flow-partitioned deformation zone model for defect formation during friction stir welding, Scripta Mater., 58(2008), No. 5, p. 372.

H.L. Qin, H. Zhang, D.T. Sun, and Q.Y. Zhuang, Corrosion behavior of the friction-stir-welded joints of 2A14–T6 aluminum alloy, Int. J. Miner. Metall. Mater., 22(2015), No. 6, p. 627.

G.R. Cui, Z.Y. Ma, and S.X. Li, The origin of non-uniform microstructure and its effects on the mechanical properties of a friction stir processed Al–Mg alloy, Acta Mater., 57(2009), No. 19, p. 5718.

A.A. Nia and A. Shirazi, Effects of different friction stir welding conditions on the microstructure and mechanical properties of copper plates, Int. J. Miner. Metall. Mater., 23(2016), No. 7, p. 799.

J. Hilgert, J.F. dos Santos, and N. Huber, Shear layer modelling for bobbin tool friction stir welding, Sci. Technol. Weld. Joining, 17(2012), No. 6, p. 454.

H. Zhang, M. Wang, X. Zhang, and G. Yang, Microstructural characteristics and mechanical properties of bobbin tool friction stir welded 2A14–T6 aluminum alloy, Mater. Des., 65(2015), p. 559.

M.A. Sutton, B. Yang, A.P. Reynolds, and R. Taylor, Microstructural studies of friction stir welds in 2024–T3 aluminum, Mater. Sci. Eng. A, 323(2002), No. 1-2, p. 160.

B. Rahimi, H. Khosravi, and M. Haddad-Sabzevar, Microstructural characteristics and mechanical properties of Al–2024 alloy processed via a rheocasting route, Int. J. Miner. Metall. Mater., 22(2015), No. 1, p. 59.

Y.H. Yau, A. Hussain, R.K. Lalwani, H.K. Chan, and N. Hakimi, Temperature distribution study during the friction stir welding process of Al2024–T3 aluminum alloy, Int. J. Miner. Metall. Mater., 20(2013), No. 8, p. 779.

A.A. Csontos and E.A. Starke, The effect of inhomogeneous plastic deformation on the ductility and fracture behavior of age hardenable aluminum alloys, Int. J. Plast., 21(2005), No. 6, p. 1097.

C. Gao, Z. Zhu, J. Han, and H. Li, Correlation of microstructure and mechanical properties in friction stir welded 2198–T8 Al–Li alloy, Mater. Sci. Eng. A, 639(2015), p. 489.

J. Hilgert, H.N.B. Schmidt, J.F. dos Santos, and N. Huber, Thermal models for bobbin tool friction stir welding, J. Mater. Process. Technol., 211(2011), No. 2, p. 197.

Y.C. Chen, J.C. Feng, and H.J. Liu, Precipitate evolution in friction stir welding of 2219–T6 aluminum alloys, Mater. Charact., 60(2009), No. 6, p. 476.

J.M. Rosalie and L. Bourgeois, Silver segregation to θ′(Al2Cu)–Al interfaces in Al–Cu–Ag alloys, Acta Mater., 60(2012), No. 17, p. 6033.

F.F. Wang, W.Y. Li, J. Shen, S.Y. Hu, and J.F. dos Santos, Effect of tool rotational speed on the microstructure and mechanical properties of bobbin tool friction stir welding of Al–Li alloy, Mater. Des., 86(2015), p. 933.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dong, Jh., Gao, C., Lu, Y. et al. Microstructural characteristics and mechanical properties of bobbin-tool friction stir welded 2024–T3 aluminum alloy. Int J Miner Metall Mater 24, 171–178 (2017). https://doi.org/10.1007/s12613-017-1392-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-017-1392-7