Abstract

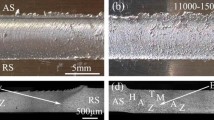

Stop-action technique was employed in order to study grain structure and texture evolution of thin 6082-T6 aluminum alloy sheets during friction stir welding (FSW). The evolutions of microstructure and texture were studied in different regions (ahead, behind, far behind the tool and base material as well) of the deformed samples. Materials ahead the tool experienced shear deformation were induced by rotation of the tool as well as the shoulder, which can pronounce copper and Goss texture. Grains behind the tool experienced dynamic recovery and recrystallization, exhibiting a characteristic of {110}<001> recrystallization Goss texture. Materials far behind the tool probably experienced more thermal cycling. Recrystallization grains will grow and present {100}<012> texture. In addition, the shoulder gave rise to a large shear stress that led to {111}<110> shear texture.

Similar content being viewed by others

References

Barbosa C, Dille J, Delplancke JL, et al. A Microstructural Study of Flash Welded and Aged 6061 and 6013 Aluminum Alloys[J]. Materials Characterization, 2006, 57: 187–192

Lucas G. Aluminum Structural Applications[J]. Advanced Materials & Processes, 1996, 149: 29–30

Demir H, Süleyman Gündüz. The Effects of Aging on Machinability of 6061 Aluminium Alloy[J]. Materials & Design, 2009, 30: 1 480–1 483

Suhuddin UFHR, Mironov S, Sato Y S, et al. Grain Structure and Texture Evolution during Friction Stir Welding of Thin 6016 Aluminum Alloy Sheets[J]. Materials Science & Engineering: A, 2010, 527: 1 962–1 969

Jata KV, Semiatin SL. Continuous Dynamic Recrystallization during Friction Stir Welding of High Strength Aluminum Alloys[J]. Scripta Materialia, 2000, 43: 743–749

Fonda RW, Bingert JF, Colligan KJ. Development of Grain Structure during Friction Stir Welding[J]. Scripta Materialia, 2004, 51: 243–248

Mironov S, Inagaki K, Sato YS, et al. Effect of Welding Temperature on Microstructure of Friction–stir Welded Aluminum Alloy[J]. Metallurgical & Materials Transactions A, 2015, 46: 783–790

Prangnell PB, Heason CP. Grain Structure Formation during Friction Stir Welding Observed by the ‘Stop Action Technique’[J]. Acta Materialia, 2005, 53: 3 179–3 192

Colligan K. Material Flow Behavior during Friction Stir Welding of Aluminum[J]. Welding Journal, Research Supplement., 1999, 78: 229s–237s

Suhuddin UFHR, Mironov S, Sato YS, et al. Grain Structure Evolution during Friction–stir Welding of AZ31 Magnesium Alloy[J]. Acta Materialia, 2009, 57: 5 406–5 418

Lebensohn RA, Tomé CN. A Self–consistent Viscoplastic Model: Prediction of Rolling Textures of Anisotropic Polycrystals[J]. Materials Science & Engineering A, 1994, 175: 71–82

Cho JH, Kim WJ, Lee CG. Texture and Microstructure Evolution and Mechanical Properties during Friction Stir Welding of Extruded Aluminum Billets[J]. Materials Science & Engineering A, 2014, 597: 314–323

Pantleon W. On the Statistical Origin of Disorientations in Dislocation Structures[J]. Acta Materialia, 1998, 46: 451–456

Gourdet S, Montheillet F. A Model of Continuous Dynamic Recrystallization[ J]. Acta Materialia,2003, 51: 2 685–2 699

Lee DN. The Evolution of Recrystallization Textures from Deformation Textures[J]. Scripta Metallurgica et Materialia, 1995, 32: 1 689–1 694

Sato YS, Kokawa H, Ikeda K, et al. Microtexture in the Friction–stir Weld of an Aluminum Alloy[J]. Metallurgical & Materials Transactions A, 2001, 32: 941–948

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Major National Science and Technology Projects( No.2012ZX04008011) and the Fundamental Research Funds of Gansu Province for Higher Education Institutions

Rights and permissions

About this article

Cite this article

Zhang, L., Wang, X. & Wei, X. Evolution of Grain Structure and Texture for 6082-T6 Aluminum Alloy during Friction Stir Welding. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 34, 397–403 (2019). https://doi.org/10.1007/s11595-019-2065-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-019-2065-3