Abstract

Increasing the recrystallization temperature to achieve better high-temperature performance is critical in the development of molybdenum alloys for ultrahigh-temperature applications, such as the newest generation of multitype high-temperature nuclear reactors. In this study, an innovative strategy was proposed to improve the performance of molybdenum alloys at high temperature by using the two-dimensional MAX (where M is an early transition metal, A is an A-group element and X is C or N) ceramic material Ti3AlC2. The relationships between flow stress, strain rate and temperature were studied. The microstructure, distribution of misorientation and evolution of dislocations in the Mo–Ti3AlC2 alloy were analyzed. The microscopic mechanism of the Ti3AlC2 phase in the molybdenum alloy at high temperatures was clarified. The experimental results showed that the peak flow stress of Mo–Ti3AlC2 at 1600 °C reached 155 MPa, which was 161.8% greater than that of pure Mo. The activation energy of thermal deformation of Mo–Ti3AlC2 was as large as 537 kJ·mol−1, which was 17.6% more than that of pure Mo. The recrystallization temperature reached 1600 °C or even higher. The topological reaction of the Ti3AlC2 phase consumed a large amount of energy at high temperatures, resulting in increases in the deformation activation energy. Nanolayer structures of AlTi3 and Ti–O Magnéli-phase oxides (TinO2n-1) were formed in-situ, which relied on kink bands and interlayer slip, resulting in many dislocations during deformation. Therefore, the special two-dimensional of the structure Ti3AlC2 ceramic inhibited the recrystallization behavior of the Mo alloy. The results of this study can provide theoretical guidance for the development of a new generation of molybdenum alloys for use in ultrahigh-temperature environments.

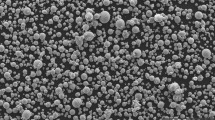

Graphical abstract

摘要

提高再结晶温度以获得更好的高温性能是开发用于超高温环境钼合金的关键,如高温新质核反应堆堆芯材料。在本研究中,我们提出了一种利用二维MAX陶瓷材料Ti3AlC2来提高钼合金高温性能的创新策略。研究了流动应力、应变速率与温度之间的关系。分析了Mo-Ti3AlC2合金的微观结构、位错的分布和演化。阐明了高温下钼合金中Ti3AlC2相的微观机理。实验结果表明,Mo-Ti3AlC2在1600 °C 时的峰值流动应力达到155 MPa,比纯Mo高161.8%。Mo-Ti3AlC2的热变形活化能高达537 kJ∙mol-1,比纯Mo高17.6%。再结晶温度超过1600 °C。Ti3AlC2陶瓷相的在高温下发生拓扑反应,消耗大量的能量,导致变形活化能增加。原位自生纳米层状AlTi3和亚氧化钛(TinO2n-1),大量的扭结带和层间滑移,在变形过程中产生大量位错,抑制晶界迁移,提升再结晶温度。本研究结果可为新一代超高温环境下用钼合金的开发提供理论指导。

Similar content being viewed by others

References

Sobes V, Hiscox B, Popov E, Archibald R, Hauck C, Betzler B, Terrani K. Ai-based design of a nuclear reactor core. Sci Rep. 2021;11(1):19646. https://doi.org/10.1038/s41598-021-98037-1.

Busby JT, Leonard KJ. Space fission reactor structural materials: choices past, present, and future. JOM. 2007;59(4):20. https://doi.org/10.1007/s11837-007-0049-9.

El-Genk MS, Tournier JM. A review of refractory metal alloys and mechanically alloyed-oxide dispersion strengthened steels for space nuclear power systems. J Nucl Mater. 2005;340(1):93. https://doi.org/10.1016/j.jnucmat.2004.10.118.

Xing H, Hu P, He C, Zhang X, Han J, Yang F, Bai R, Zhang W, Wang K, Volinsky AA. Design of high-performance molybdenum alloys via doping metal oxide and carbide strengthening: a review. J Mater Sci Technol. 2023;160:161. https://doi.org/10.1016/j.jmst.2023.03.026.

Que Z, Wei Z, Li X, Zhang L, Dong Y, Qin M, Yang J, Qu X, Li J. Pressureless two-step sintering of ultrafine-grained refractory metals: tungsten-rhenium and molybdenum. J Mater Sci Technol. 2022;126:203. https://doi.org/10.1016/j.jmst.2022.01.033.

Zhou YC, Gao YM, Wei SZ, Hu YJ. Preparation and properties of high-strength molybdenum alloy sheets doped with Al2O3 particles. Rare Met. 2018;37(12):1046. https://doi.org/10.1007/s12598-016-0726-3.

Silva EZ, Kestler H, Sandim HRZ. Particle-stimulated nucleation of recrystallization in the hot-deformed molybdenum alloy MZ-17. Int J Refract Metals Hard Mater. 2018;73:74. https://doi.org/10.1016/j.ijrmhm.2018.01.021.

Hu W, He J, Yang Z, Tan J, Chen S, Liu S, Ma Z, Liu Y. Strengthening the grain boundary of Mo alloy via little TiC addition. Mater Charact. 2023;203:113063. https://doi.org/10.1016/j.matchar.2023.113063.

Xu L, Sun T, Zhou Y, Xiao F, Zhang M, Wei S. Evaluating compressive property and hot deformation behavior of molybdenum alloy reinforced by nanoscale zirconia particles. J Alloys Compd. 2021;860:158289. https://doi.org/10.1016/j.jallcom.2020.158289.

Gan J, Gong Q, Jiang Y, Chen H, Huang Y, Du K, Li Y, Zhao M, Lin F, Zhuang D. Microstructure and high-temperature mechanical properties of second-phase enhanced Mo-La2O3-ZrC alloys post-treated by cross rolling. J Alloys Compd. 2019;796:167. https://doi.org/10.1016/j.jallcom.2019.04.348.

Hu W, Huang Z, Wang Y, Li X, Zhai H, Zhou Y, Chen L. Layered ternary max phases and their MX particulate derivative reinforced metal matrix composite: a review. J Alloys Compd. 2021;856:157313.https://doi.org/10.1016/j.jallcom.2020.157313.

Liu P, Hou B, Wang A, Xie J, Wang Z, Ye F. Superior strength-plasticity synergy in a heterogeneous lamellar Ti2AlC/TiAl composite with unique interfacial microstructure. J Mater Sci Technol. 2023;159:21. https://doi.org/10.1016/j.jmst.2023.03.011.

Chen W, Yu W, Ma C, Ma G, Zhang L, Wang H. A review of novel ternary nano-layered MAX phases reinforced AZ91D magnesium composite. J Magnes Alloys. 2022;10(6):1457. https://doi.org/10.1016/j.jma.2022.05.013.

Zhang Z, Duan X, Jia D, Zhou Y, Van Der Zwaag S. On the formation mechanisms and properties of MAX phases: a review. J Eur Ceram Soc. 2021;41(7):3851. https://doi.org/10.1016/j.jeurceramsoc.2021.02.002.

Chen X, Li R, Li B, Wang J, Wang T, Yan F, Zhang G. Achieving ultra-high ductility and fracture toughness in molybdenum via Mo2TiC2 Mxene addition. Mater Sci Eng: A. 2021;818:141422. https://doi.org/10.1016/j.msea.2021.141422.

Wang W, Zhai H, Chen L, Huang Z, Bei G, Baumgärtner C, Greil P. Preparation and mechanical properties of in situ TiCx–Ni (Si, Ti) alloy composites. Mater Sci Eng: A. 2014;616:214. https://doi.org/10.1016/j.msea.2014.08.020.

Lin X, Zhang G, Zhang W, Li Y, Li B, Wang B. Microstructure and mechanical properties of Mo-12Si-8.5B alloy reinforced by layered Mo2TiAlC2 MAX phase. Int J Refract Metals Hard Mater. 2022;109:105967. https://doi.org/10.1016/j.ijrmhm.2022.105967.

Jiang J, Li S, Li H, Zhou Y. Effect of in situ formed TiCx grains on the microstructural modification of high chromium white iron. J Alloys Compd. 2017;726:430. https://doi.org/10.1016/j.jallcom.2017.07.274.

Li X, Zhang L, Dong Y, Qin M, Wei Z, Que Z, Yang J, Qu X, Li J. Towards pressureless sintering of nanocrystalline tungsten. Acta Mater. 2021;220:117344. https://doi.org/10.1016/j.actamat.2021.117344.

Zhang Q, Li Q, Chen X, Bao J, Chen Z. Effect of Sn addition on the deformation behavior and microstructural evolution of Mg–Gd–Y–Zr alloy during hot compression. Mater Sci Eng: A. 2021;826:142026. https://doi.org/10.1016/j.msea.2021.142026.

Zhao Y, Xu L, Guo M, Li Z, Li X, Wei S. Compressive properties and deformation behaviors of sintered W-m-ZrO2 alloy under different temperature. Mater Sci Eng: A. 2022;859:144238. https://doi.org/10.1016/j.msea.2022.144238.

Yao L, Huang Y, Gao Y, Li Y, Huang X, Wang Y, Liu Q, Zhou C. Hot deformation behavior of nanostructural oxide dispersion-strengthened (ODS) Mo alloy. Int J Refract Metals Hard Mater. 2022;107:105881. https://doi.org/10.1016/j.ijrmhm.2022.105881.

Xu Z, Xu L, Xiong N, Yao Y, Li X, Wei S. Dynamic recrystallization behavior of a Mo-2.0%ZrO2 alloy during hot deformation. Int J Refract Metals Hard Mater. 2022;109:105983. https://doi.org/10.1016/j.ijrmhm.2022.105983.

Liu G, Zhang GJ, Jiang F, Ding XD, Sun YJ, Sun J, Ma E. Nanostructured high-strength molybdenum alloys with unprecedented tensile ductility. Nat Mater. 2013;12(4):344. https://doi.org/10.1038/nmat3544.

Wang B, Yang D, Zhou Y, Xu L, Li Y, Li X, Wei S. Mechanical properties and corrosion behavior in molten zinc of Mo–ZrO2 alloys. J Mater Res Technol. 2023;25:4942. https://doi.org/10.1016/j.jmrt.2023.06.271.

Hu P, Zhou Y, Chang T, Yu Z, Wang K, Yang F, Hu B, Cao W, Yu H. Investigation on compression Behavior of TZM and La2O3 doped TZM alloys at high temperature. Mater Sci Eng: A. 2017;687:276. https://doi.org/10.1016/j.msea.2017.01.059.

Yang HL, Zhu MZ, Wang JY, Ma CX, Zhou XW, Xing HX, Zhang EL, Ji SX. Optimization of mechanical and antibacterial properties of Ti-3wt%Cu alloy through cold rolling and annealing. Rare Met. 2022;41(2):610. https://doi.org/10.1007/s12598-021-01841-x.

Li C, Chen Z, Zhang XQ, Xiao WL, Ma Y. Hot deformation behavior of high Zn-containing 7A65 Al alloy. Rare Met. 2023;42(1):302. https://doi.org/10.1007/s12598-022-02112-z.

Liu XR, He F, Li JJ, Dang YY, Wang ZJ, Wang JC. Tailoring microstructures of CoCrFeNiNb0.25 hypoeutectic high-entropy alloy by hot deformation. Rare Met. 2022;41(6):2028. https://doi.org/10.1007/s12598-021-01932-9.

Bobbili R, Madhu V. Hot deformation behavior and processing maps of Ti–15Al–12Nb alloy. Rare Met. 2022;41(7):2316. https://doi.org/10.1007/s12598-016-0699-2.

Li CM, Huang L, Li CL, Hui SX, Yu Y, Zhao MJ, Guo SQ, Li JJ. Research progress on hot deformation behavior of high-strength β titanium alloy: flow behavior and constitutive model. Rare Met. 2022;41(5):1434. https://doi.org/10.1007/s12598-021-01861-7.

Xue D, Wei W, Shi W, Zhou XR, Wen SP, Wu XL, Gao KY, Rong L, Qi P, Huang H, Nie ZR. Dislocation evolution and induced precipitation on corrosion resistance of a novel Al–Mg–Zn–Er–Zr alloy during hot compression. Rare Met. 2023;42(7):2371. https://doi.org/10.1007/s12598-022-02258-w.

Liu Z, Li P, Xiong L, Liu T, He L. High-temperature tensile deformation behavior and microstructure evolution of Ti55 titanium alloy. Mater Sci Eng: A. 2017;680:259. https://doi.org/10.1016/j.msea.2016.10.095.

Xu L, Song W, Jiao Z, Xu Z, Sun T, Wei S. Evaluating cycle fatigue property of molybdenum alloy by new developed fatigue model. Int J Refract Metals Hard Mater. 2022;107:105907. https://doi.org/10.1016/j.ijrmhm.2022.105907.

Hu W, Sun T, Liu C, Yu L, Ahamad T, Ma Z. Refined microstructure and enhanced mechanical properties in Mo-Y2O3 alloys prepared by freeze-drying method and subsequent low temperature sintering. J Mater Sci Technol. 2021;88:36. https://doi.org/10.1016/j.jmst.2021.01.064.

Hu P, Li H, Zuo YG, Ge SW, Li SL, Xing HR, Han JY, Hua XJ, Wang KS, Li LP. Investigation of microstructure and tensile properties of as-processed TZM alloy at elevated temperature. Mater Charact. 2021;173:110933. https://doi.org/10.1016/j.matchar.2021.110933.

Lu K. The future of metals. Science. 2010;328(5976):319. https://doi.org/10.1126/science.1185866.

Jiang J, Li S, Hu S, Zhang J, Yu W, Zhou Y. Comparison of high Cr white iron composites reinforced with directly added TiC and in situ formed TiCx. J Mater Res Technol. 2020;9(3):3140. https://doi.org/10.1016/j.jmrt.2020.01.059.

Hu W, Huang Z, Cai L, Lei C, Zhai H, Wo S, Li X. In-situ TiC and Γ′-Ni3(Al, Ti) triggered microstructural modification and strengthening of Ni matrix composite by reactive hot-press sintering pure Ni and Ti2AlC precursor. J of Alloys Compd. 2018;747:1043. https://doi.org/10.1016/j.jallcom.2018.03.069.

Akhlaghi M, Tayebifard SA, Salahi E, Shahedi AM. Spark plasma sintering of TiAl–Ti3AlC2 composite. Ceram Int. 2018;44(17):21759. https://doi.org/10.1016/j.ceramint.2018.08.272.

Cao J, Guo Z, Sun T, Zhang F, Liang Y, Ding X, Nan H, Lin J. Refinement of carbide precipitates in high-Nb TiAl by cyclic aging treatments. Scr Mater. 2023;224:115152. https://doi.org/10.1016/j.scriptamat.2022.115152.

Tang Y, Murayama M, Edalati K, Wang Q, Iikubo S, Masuda T, Higo Y, Tange Y, Ohishi Y, Mito M, Horita Z. Phase transformations in Al–Ti–Mg powders consolidated by high-pressure torsion: experiments and first-principles calculations. J Alloys Compd. 2021;889:161815. https://doi.org/10.1016/j.jallcom.2021.161815.

Jing K, Liu R, Xie ZM, Ke JG, Wang XP, Fang QF, Liu CS, Wang H, Li G, Wu XB. Excellent high-temperature strength and ductility of the ZrC nanoparticles dispersed molybdenum. Acta Mater. 2022;227:117725. https://doi.org/10.1016/j.actamat.2022.117725.

Qiu X, Kong H, Li Y, Wang Q, Wang Y. Interface engineering of a Ti4O7 nanofibrous membrane for efficient solar-driven evaporation. ACS Appl Mater Interfaces. 2022;14(49):54855. https://doi.org/10.1021/acsami.2c15997.

Ma ZY, Chen YX, Ren Y, Yu KY, Jiang DQ, Liu YN, Cui LS. In-situ synchrotron high energy X-ray diffraction study of spontaneous reorientation of r phase upon cooling in nanocrystalline Ti50Ni4.55Fe4.5 alloy. Rare Met. 2022;41(6):1948. https://doi.org/10.1007/s12598-022-02001-5.

Wang G, Liu Y, Duan Y, Ye J, Lin Z. Effects of porosity on the electrochemical oxidation performance of Ti4O7 electrode materials. Ceram Int. 2023;49(10):15357. https://doi.org/10.1016/j.ceramint.2023.01.120.

Lu Y, Wang MY, Wang DY, Sun YH, Liu ZH, Gao RK, Yu LD, Zhang DZ. Flexible impedance sensor based on Ti3C2 Mxene and graphitic carbon nitride nanohybrid for humidity-sensing application with ultrahigh response. Rare Met. 2023. https://doi.org/10.1007/s12598-023-02268-2.

Yao L, Gao Y, Li Y, Huang X, Wang Y, Huang Y. Preparation of nanostructural oxide dispersion strengthened (ODS) Mo alloy by mechanical alloying and spark plasma sintering, and its characterization. Int J Refract Metals Hard Mater. 2022;105:105822. https://doi.org/10.1016/j.ijrmhm.2022.105822.

Jiang D, Dong Z, Du Z, Zhao Q, Wang H, Ma Z. Effect mechanism of oxide doping on the microstructure and mechanical properties of Mo–Y2O3 alloys. Mater Sci Eng: A. 2022;831:142344. https://doi.org/10.1016/j.msea.2021.142344.

Zhou Y, Wei S, Wang L, Xu L, Li X, Pan K. Study on thermal fatigue performance of the molybdenum plate doped with Al2O3 particles. J Alloys Compd. 2020;823:153748. https://doi.org/10.1016/j.jallcom.2020.153748.

Wang D, Gao C, Luo H-Y, Yang Y-H, Ma Y. Texture evolution behavior and anisotropy of 2A97 Al–Li alloy during recrystallization at elevated Temperature. Rare Met. 2023;42(9):3139. https://doi.org/10.1007/s12598-018-0997-y.

Acknowledgments

This study was sponsored by National Key R&D Program of China (No. 2020YFB2008400) and Key Technology and Development Program of Henan Province (No. 232102231024).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, L., Zheng, XY., Zhao, Y. et al. Dynamic recrystallization behavior and strengthening mechanism of a novel Mo–Ti3AlC2 alloy at ultrahigh temperature. Rare Met. (2024). https://doi.org/10.1007/s12598-024-02669-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12598-024-02669-x