Abstract

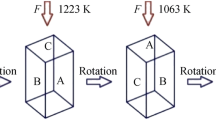

Microstructures and tensile properties of a new β high-strength titanium alloy Ti-5321 (Ti–5Al–3Mo–3V–2Zr–2Cr–1Nb–1Fe) were investigated in this study. Four microstructures, including equiaxed microstructure (EM), bimodal microstructure (BM), basket-weave microstructure (WM) and lamellar microstructure (LM), were tailored by changing the forging process, and the influences of different microstructures on tensile properties were also analyzed. The results indicated that Ti-5321 exhibits a better combination of strength and ductility, compared to Ti-5553, Ti-1023, BT22 and Ti15-3. The ultimate tensile strength, total elongation and reduction in area could be achieved in a range of 1200–1300 MPa, 10%–15% and 40%–60%, respectively. The influences of variant selection on the tensile properties in Ti-5321 alloy were also analyzed. After β forging and solution treatment, α phase maintained strictly Burgers orientation relation with adjacent β phase. Morphological features of the fractography in BM and LM were also explored to further explain the tensile properties and the fracture mode of Ti-5321 alloy.

Graphic abstract

Similar content being viewed by others

References

Banerjee D, Williams J. Perspective on titanium science and technology. Acta Mater. 2013;61(3):844.

Huang C, Zhao Y, Xin S, Wei Z, Qian L, Zeng W. Effect of microstructure on tensile properties of Ti–5Al–5Mo–5V–3Cr–1Zr alloy. J Alloys Compd. 2017;693:582.

Qin D, Lu Y, Guo D, Zheng L, Liu Q, Zhou L. Tensile deformation and fracture of Ti–5Al–5V–5Mo–3Cr–1.5Zr–0.5Fe alloy at room temperature. Mater Sci Eng A. 2013;587(1):100.

Santhosh R, Geetha M, Saxena VK, Nageswararao M. Studies on single and duplex aging of metastable beta titanium alloy Ti–15V–3Cr–3Al–3Sn. J Alloys Compd. 2014;605(9):222.

Chen Y, Du Z, Xiao S, Xu L, Tian J. Effect of aging heat treatment on microstructure and tensile properties of a new β high strength titanium alloy. J Alloys Compd. 2014;586:588.

Zhuo L, Changmeng L, Dong L, Huaming W. Effect of heat treatment on microstructure and tensile properties of laser deposited titanium alloy TC21. Mater Res Innov. 2015;18(4):929.

Li D, Wang K, Yan Z, Cao Y, Misra RDK, Xin R. Evolution of microstructure and tensile properties during the three-stage heat treatment of TA19 titanium alloy. Mater Sci Eng A. 2018;716:157.

Li C, Chen J, Li W, He JJ, Qiu W, Ren YJ. Study on the relationship between microstructure and mechanical property in a metastable β titanium alloy. J Alloys Compd. 2015;627(10):222.

Li CL, Zou LN, Fu YY, Ye WJ, Hui SX. Effect of heat treatments on microstructure and property of a high strength/toughness Ti–8V–1.5Mo–2Fe–3Al alloy. Mater Sci Eng A. 2014;616:207.

Lu J, Zhao Y, Peng G, Zhang Y, Niu H, Wei Z. Precipitation behavior and tensile properties of new high strength beta titanium alloy Ti-1300. J Alloys Compd. 2015;637:1.

Shekhar S, Sarkar R, Kar SK, Bhattacharjee A. Effect of solution treatment and aging on microstructure and tensile properties of high strength β titanium alloy, Ti–5Al–5V–5Mo–3Cr. Mater Des. 2015;66:596.

Shi Y, Zhang G, Ming L, Guo D, Zhang Z, Wei B. Effect of heat treatment on the microstructure and tensile properties of deformed α/β Ti–47Zr–5Al–3V alloy. J Alloys Compd. 2016;665(14):1.

Jones NG, Dashwood RJ, Dye D, Jackson M. Thermomechanical processing of Ti–5Al–5Mo–5V–3Cr. Mater Sci Eng A. 2008;490(1):369.

Kar SK, Suman S, Shivaprasad S, Chaudhuri A, Bhattacharjee A. Processing-microstructure-yield strength correlation in a near β Ti alloy, Ti–5Al–5Mo–5V–3Cr. Mater Sci Eng A. 2014;610(5):171.

Shi ZF, Guo HZ, Han JY, Yao ZK. Microstructure and mechanical properties of TC21 titanium alloy after heat treatment. Trans Nonferr Met Soc. 2013;23(10):2882.

Quan GZ, Wen HR, Pu SA, Zou ZY, Wu DS. Optimization of β/near-β forging process parameters of Ti–6.5Al–3.5Mo–1.5Zr–0.3Si by using processing maps. Mater Charact. 2015;60(7):492.

Cui C, Hu B, Zhao L, Liu S. Titanium alloy production technology, market prospects and industry development. Mater Des. 2011;32(3):1684.

Zhao YQ, Ma CL, Chang H, Xin SW, Zhou L. New high strength and high toughness titanium alloy with 1200 MPa. Mater China. 2016;35(12):914.

Lü ZD, Zhang CJ, Du ZX. Relationship between microstructure and tensile properties on a near-β titanium alloy after multidirectional forging and heat treatment. Rare Met. 2019;38(3):336.

Fan J, Li J, Kou H, Hua K, Tang B, Zhang Y. Influence of solution treatment on microstructure and mechanical properties of a near β titanium alloy Ti-7333. Mater Des. 2015;83(4):499.

Zhao YH, Ge P, Zhao YQ. Hot deformation behavior of Ti-1300 alloy. Rare Met Mater Eng. 2009;38(1):46.

Cai X, Lei M, Wan MP. Continuous cooling transformation diagram of TC17 titanium alloy. Chin J Rare Met. 2019;43(12):1291.

Furuhara T, Takagi S, Watanabe H, Maki T. Crystallography of grain boundary α precipitates in a β titanium alloy. Metall Mater Trans A. 1996;27(6):1635.

Foltz JW, Welk B, Collins PC, Fraser HL, Williams JC. Formation of grain boundary α in β Ti alloys: its role in deformation and fracture behavior of these alloys. Metall Mater Trans A. 2011;42(3):645.

Williams JC, Hickman BS, Leslie DH. The effect of ternary additions on the decomposition of metastable beta-phase titanium alloys. Metall Trans. 1971;2(2):477.

Jones NG, Dashwood RJ, Dye D, Jackson M. The flow behavior and microstructural evolution of Ti–5Al–5Mo–5V–3Cr during subtransus isothermal forging. Metall Mater Trans A. 2009;40(8):1944.

Srinivasu G, Natraj Y, Bhattacharjee A, Nandy TK, Nageswara Rao GVS. Tensile and fracture toughness of high strength β titanium alloy, Ti–10V–2Fe–3Al, as a function of rolling and solution treatment temperatures. Mater Des. 2013;47:323.

Yang Y, Wang W, Ma B, Wen Z, Wang Y, Ma H. Effect of microstructure on mechanical properties of BT22 titanium alloy bar. Rare Met Lett. 2007;26:3.

Huang X, Bao RQ, Huang LJ, Lin HZ, Guo L. Effect of hot-die forging process on the microstructure and properties of Ti1023 alloy. Rare Met Mater Eng. 2004;33(5):539.

Zhao YQ, Qu HL, Feng L, Yang HY, Li H. Research on high strength, high toughness and high damage-tolerant titanium alloy. Titan Ind Prog. 2004;21(1):22.

Boyer RR, Rack HJ, Venkatesh V. The influence of thermomechanical processing on the smooth fatigue properties of Ti–15V–3Cr–3Al–3Sn. Mater Sci Eng A. 1998;243(1–2):97.

Sadeghpour S, Abbasi SM, Morakabati M, Bruschi S. Correlation between alpha phase morphology and tensile properties of a new beta titanium alloy. Mater Des. 2017;121:24.

Acknowledgements

This study was financially supported by the International Science and Technology Cooperation Program of China (No. 2015DFA51430) and the National Natural Science Foundation of China (No. 51471136).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, H., Xin, SW., Zhao, YQ. et al. Forging–microstructure–tensile properties correlation in a new near β high-strength titanium alloy. Rare Met. 40, 2109–2117 (2021). https://doi.org/10.1007/s12598-020-01533-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01533-y