Abstract

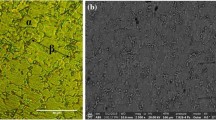

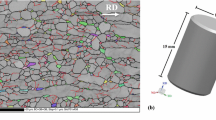

High-strength metastable β alloys, for example, Ti-5Al-5Mo-5V-3Cr, have replaced steel as the material of choice for large components, such as the main truck beam on the latest generation of airframes. The production of these components is carried out by hot near-net-shape forging, during which process variable control is essential to achieve the desired microstructural condition and subsequent mechanical properties. The flow behavior and microstructural evolution during subtransus isothermal forging of Ti-5Al-5Mo-5V-3Cr has been investigated for two different starting microstructures and analysis has incorporated previously published results. The flow behavior, irrespective of initial microstructural condition, is found to be very similar at strains ≥0.35. It is thought that this is due to a common microstructural state being reached, where dynamic recovery of the β phase is the dominating deformation mechanism. At strains <0.35, the flow behavior is believed to be dominated by the morphology and volume fraction of the α phase. Small globular α particles are thought to have little effect on the flow behavior, while the observed flow softening is directly linked to the fragmentation of acicular α precipitates.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

ImageJ (version 1.37), W. Rasband, National Institutes of Health, Bethesda, MD.

References

R.R. Boyer and R.D. Briggs: J. Mater. Eng. Perform., 2005, vol. 14, pp. 681–85.

J.C. Fanning and R.R. Boyer: Titanium 2003: Science and Technology, G. Luetjering and J. Albrecht, eds., Wiley-VCH, Hamburg, Germany, 2003, vol. IV, pp. 2635–42.

R.R. Boyer: J. Met., 1994, vol. 46, pp. 20–23.

A. Hasegawa, S. Ishigai, and T. Matsushita: 6th World Conf. on Titanium, P. Lacombe, R. Tricot, and G. Beranger, eds., Les Editions de Physique, Les Ulis, Cannes, France, 1988, pp. 1263–68.

S.L. Semiatin, V. Seetharaman, and A.K. Ghosh: Phil. Trans. R. Soc. London, Ser. A, 1999, vol. 357, pp. 1487–1512.

S.L. Semiatin, V. Seetharaman, and I. Weiss: Mater. Sci. Eng. A, 1999, vol. 263, pp. 257–71.

S.L. Semiatin: Acta Mater., 2001, vol. 49, pp. 3565–73.

S.L. Semiatin and T.R. Bieler: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 1871–71.

S.L. Semiatin and T.R. Bieler: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 1787–99.

E.B. Shell and S.L. Semiatin: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 3219–29.

M. Jackson, R. Dashwood, L. Christodoulou, and H.M. Flower: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 1317–27.

M. Jackson, R.J. Dashwood, L. Christodoulou, and H.M. Flower: Mater. Sci. Technol., 2000, vol. 16, pp. 1437–44.

N.G. Jones, R.J. Dashwood, D. Dye, and M. Jackson: Mater. Sci. Eng. A, 2008, vol. 490, pp. 369–77.

M. Jackson, N.G. Jones, D. Dye, and R.J. Dashwood: Mater. Sci. Eng. A, 2009, vol. 501, pp. 248–54.

R.R. Boyer: J. Met., 1992, vol. 44, pp. 23–25.

C.C. Chen, J.A. Hall, and R.R. Boyer: Titanium ‘80: Science and Technology, H. Kimura and O. Izumi, eds., TMS-AIME, Kyoto, Japan, 1983, pp. 457–66.

S.R. Seagle, K.O. Yu, and S. Giangiordano: Mater. Sci. Eng. A, 1999, vol. 263, pp. 237–42.

J.D. Cotton, R.R. Boyer, R.D. Briggs, R.G. Baggerly, C.A. Meyer, M.D. Carter, W. Wood, G. Tewksbury, V. Li, and X. Yao: Ti-2007: Science and Technology, M. Ninomi, S. Akiyama, M. Ikeda, M. Hagiwara, and K. Maruyama, eds., The Japan Institute of Metals, Kyoto, 2007, pp. 471–74.

J. Fanning: J. Mater. Eng. Perform., 2005, vol. 14, pp. 788–91.

C.C. Chen and R.R. Boyer: J. Met., 1979, vol. 31, pp. 33–39.

R.R. Boyer: J. Met., 1980, vol. 32, pp. 61–65.

C.C. Chen: in Titanium Science and Technology, G. Luetjering, U. Zwicker, and W. Bunk, eds., Deuteche Gesellschaft fur Metallkunde e.V., Munich, 1984, vol. 1, pp. 461–68.

M. Harper, R. Williams, G.B. Viswanathan, J. Tiley, R. Banerjee, D.J. Evans, and H.L. Fraser: Titanium 2003: Science and Technology, G. Lutjering and J. Albrecht, eds., Wiley-VCH, Hamburg, 2003, vol. 3, pp. 1559–66.

N. Clement, A. Lenain, and P.J. Jacques: J. Met., 2007, vol. 59, pp. 50–53.

V. Venkatesh, M. Kamal, and J. Fanning: Ti-2007: Science and Technology, M. Niinomi, S. Akiyama, M. Ikeda, M. Hagiwara, and K. Maruyama, eds., The Japan Institute of Metals, Kyoto, 2007, pp. 503–06.

C.M. Sellars and W.J.M. Tegart: Acta Metall., 1966, vol. 14, pp. 1136–38.

I. Weiss and S.L. Semiatin: Mater. Sci. Eng. A, 1998, vol. 243, pp. 46–65.

M. Jackson: Ph.D. Thesis, University of London, London, 2002, pp. 65–84.

Acknowledgments

The authors thank Messier–Dowty for the supply of material and Professor X. Wu, from the University of Birmingham, for facilitating forging at 950 °C. The work was carried out while NGJ was funded by an EPSRC DTA studentship under platform Grant No. ET/T26344/01.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 18, 2008.

Rights and permissions

About this article

Cite this article

Jones, N., Dashwood, R., Dye, D. et al. The Flow Behavior and Microstructural Evolution of Ti-5Al-5Mo-5V-3Cr during Subtransus Isothermal Forging. Metall Mater Trans A 40, 1944–1954 (2009). https://doi.org/10.1007/s11661-009-9866-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-9866-5