Abstract

High-alloyed superalloy U720Li is difficult to be processed through the conventional cast and wrought route. Boron is an important strengthening element for superalloys, but the role of boron in the hot ductility of U720Li alloy is not clear. This study is focused on the effect of boron addition, in the range of < 0.0005 wt%–0.0240 wt%, on the microstructure and hot ductility behavior of superalloy U720Li. It is found that boron addition significantly increases the content of eutectic (γ + γ′) and greatly affects the degree of continuity of the grain boundary eutectic (γ + γ′) precipitation. Boron addition dramatically worsens the 1100 °C tensile ductility of conventional cast U720Li alloy and causes a change in tensile fracture mode from transgranular to intergranular. The eutectic (γ + γ′) represents the most effective site for crack initiation. Boron deteriorates the hot ductility mainly by promoting the continuous precipitation of eutectic (γ + γ′) along the grain boundary.

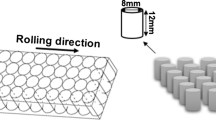

Graphic abstract

Similar content being viewed by others

References

Keefe PW, Mancuso SO, Maurer GE. Effects of heat treatment and chemistry on the long-term phase stability of a high strength nickel-based superalloy. In: Proceedings of Superalloys 1992. Warrendale; 1992. 487.

Helm D, Roder O. Influence of long term exposure in air on microstructure, surface stability and mechanical properties of Udimet 720Li. In: Proceedings of Superalloys 2000. Champion; 2000. 487.

Screrzenie FE, Maurer GE. Development of Udimet720 for high strength disk application. In: Proceedings of Superalloys 1984. Warrendale; 1984. 573.

Zhao GD, Yu LX, Qi F, Liu F, Sun WR, Hu ZQ. The minor precipitation at the final stage of U720Li solidification. Acta Metall Sin (Engl Lett). 2016;29(6):518.

Chang L, Jin H, Sun W. Solidification behavior of Ni-base superalloy Udimet 720Li. J Alloys Compd. 2015;653:266.

Fahrmann M, Suzuki A. Effect of cooling rate on Gleeble hot ductility of UDIMET alloy 720 billet. In: Proceedings of Superalloys 2008. Warrendale; 2008. 311.

Holt RT, Wallace W. Impurities and trace elements in nickel-base superalloys. Int Mater Rev. 1976;21(1):1.

Wang RD, Hu Q, Zhang SM, Zhang FW, Lu CT, Wang ZG. Properties of (Fe–B)-doped Sn–1.0Ag–0.5Cu solders prepared by mechanical alloying. Rare Met. 2019;38(7):665.

Sabol GP, Stickler R. Microstructure of nickel-based superalloys. Phys Status Solidi. 1969;35(1):11.

Garosshen TJ, Tillman TD, McCarthy GP. Effects of B, C, and Zr on the structure and properties of a P/M nickel base superalloy. Metall Trans A. 1987;18(1):69.

Stiller K. Investigations of grain boundary microchemistry in nickel base superalloys. Surf Sci. 1991;246(1–3):225.

Huang X, Chaturvedi MC, Richards NL, Jackman J. The effect of grain boundary segregation of boron in cast alloy 718 on HAZ microfissuring—a SIMS analysis. Acta Mater. 1997;45(8):3095.

Chen W, Chaturvedi MC, Richards NL, McMahon G. Grain boundary segregation of boron in INCONEL 718. Metall Mater Trans A. 1998;29(7):1947.

Cadel E, Lemarchand D, Chambreland S, Blavette D. Atom probe tomography investigation of the microstructure of superalloys N18. Acta Mater. 2002;50(5):957.

Blavette D, Duval P, Letellier L, Guttmann M. Atomic-scale APFIM and TEM investigation of grain boundary microchemistry in Astroloy nickel base superalloys. Acta Mater. 1996;44(12):4995.

Zhou PJ, Yu JJ, Sun XF, Guan HR, Hu ZQ. The role of boron on a conventional nickel-based superalloy. Mater Sci Eng A. 2008;491(1–2):159.

Ladna B, Birnbaum HK. Surface and grain boundary segregation of sulfur and boron in nickel. Acta Met. 1988;36(3):745.

Liu CT, White CL, Horton JA. Effect of boron on grain-boundaries in Ni3Al. Acta Met. 1985;33(2):213.

Cheng XY, Wan XJ, Liu CT, Guo JT. Effect of Zr and B on environmental embrittlement in Ni3Al alloys. Scr Mater. 1998;38(6):959.

Lee CS, Han GW, Smallman RE, Feng D, Lai JKL. The influence of boron-doping on the effectiveness of grain boundary hardening in Ni3Al. Acta Mater. 1999;47(6):1823.

Khadkikar PS, Vedula K, Shabel BS. The role of boron in ductilizing Ni3Al. Metall Trans A. 1987;18(3):425.

Yan BC, Zhang J, Lou LH. Effect of boron additions on the microstructure and transverse properties of a directionally solidified superalloy. Mater Sci Eng A. 2008;474(1–2):39.

Burke MA, Greggi J, Whitlow GA. The effect of boron and carbon on the microstructural chemistries of two wrought nickel base superalloys. Scr Metall. 1984;18(1):91.

Franzoni U, Marchetti F, Sturlese S. Effects of grain boundary segregation and precipitation on the creep behaviour of a 20Cr, Al–Ti, Ni-base superalloy. Scr Metall. 1985;19(4):511.

Zhao G, Yu L, Yang G, Zhang W, Sun W. The role of boron in modifying the solidification and microstructure of nickel-base alloy U720Li. J Alloys Compd. 2016;686:194.

Liu L, Jin T, Zhao N, Sun X, Guan H, Hu Z. Formation of carbides and their effects on stress rupture of a Ni-base single crystal superalloy. Mater Sci Eng A. 2003;361(1–2):191.

Voort GFV. Metallography, Principles and Practice. New York: ASM International; 1984. 45.

Hobbs R, Tin S, Rae C. A castability model based on elemental solid–liquid partitioning in advanced nickel-base single-crystal superalloys. Metall Mater Trans A. 2005;36(10):2761.

Monajati H, Taheri AK, Jahazi M, Yue S. Deformation characteristics of isothermally forged UDIMET 720 nickel-base superalloy. Metall Mater Trans A. 2005;36(4):895.

Wei CN, Bor HY, Chang L. The effects of carbon content on the microstructure and elevated temperature tensile strength of a nickel-base superalloy. Mater Sci Eng A. 2010;527(16–17):3741.

Motejadded H, Soltanieh M, Rastegari S. An investigation about the effect of annealing conditions on microstructure in a Ni3Al base alloy. J Alloys Compd. 2009;486(1–2):881.

Zhang J, Singer RF. Effect of Zr and B on castability of Ni-based superalloy IN792. Metall Mater Trans A. 2004;35(4):1337.

Keene BJ. Review of data for the surface tension of pure metals. Int Mater Rev. 1993;38(4):157.

Busby PE, Warga ME, Wells C. Diffusion and solubility of boron in iron and steel. JOM. 1953;5(11):1463.

Lomaev IL, Novikov DL, Okatov SV, Gornostyrev YN, Burlatsky SF. First-principles study of 4d solute diffusion in nickel. J Mater Sci. 2014;49(11):4038.

Miller MK. Contributions of atom probe tomography to the understanding of nickel-based superalloys. Micron. 2001;32(8):757.

Chuang TH. The mutual effects of boron, zirconium and aluminium on grain boundary segregation in Ni3Al intermetallic compounds. Mater Sci Eng A. 1991;141(2):169.

Momeni A, Abbasi SM, Morakabati M, Badri H, Wang X. Dynamic recrystallization behavior and constitutive analysis of Incoloy 901 under hot working condition. Mater Sci Eng A. 2014;615:51.

Rollett A, Humphreys FJ, Rohrer GS, Hatherly M. Recrystallization and Related Annealing Phenomena. Oxford: Elsevier; 2012. 113.

Gao B, Wang L, Liang T, Liu Y, Song X, Qu J. Plastic deformation behavior of directionally solidified U720Li alloy at elevated temperature. Acta Metall Sin. 2016;52(4):437.

Wang L, Pyczak F, Zhang J, Lou LH, Singer RF. Effect of eutectics on plastic deformation and subsequent recrystallization in the single crystal nickel base superalloy CMSX-4. Mater Sci Eng A. 2012;532:487.

Chen X, Qi YG, Shi XN, Xie BC, Ning YQ. Behaviors and model of dynamic recrystallization of nickel-based superalloy IN718Plus. Chin J Rare Met. 2019;43(12):1260.

Zhu SQ, Yan HG, Chen JH, Wu YZ, Liu JZ, Tian J. Effect of twinning and dynamic recrystallization on the high strain rate rolling process. Scr Mater. 2010;63(10):985.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (No. U1560203).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zhao, GD., Liu, F., Zang, XM. et al. Microstructure and hot ductility behavior of Ni-based superalloy U720Li with boron addition. Rare Met. 40, 1145–1154 (2021). https://doi.org/10.1007/s12598-020-01395-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01395-4